Vibration box of block making machine

A block forming machine and vibration box technology, applied in ceramic forming machines, auxiliary forming equipment, manufacturing tools, etc., can solve the problems of not being able to be used as mold vibration, breakage, insufficient vibration, etc., and achieve good vibration effect, simple maintenance, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

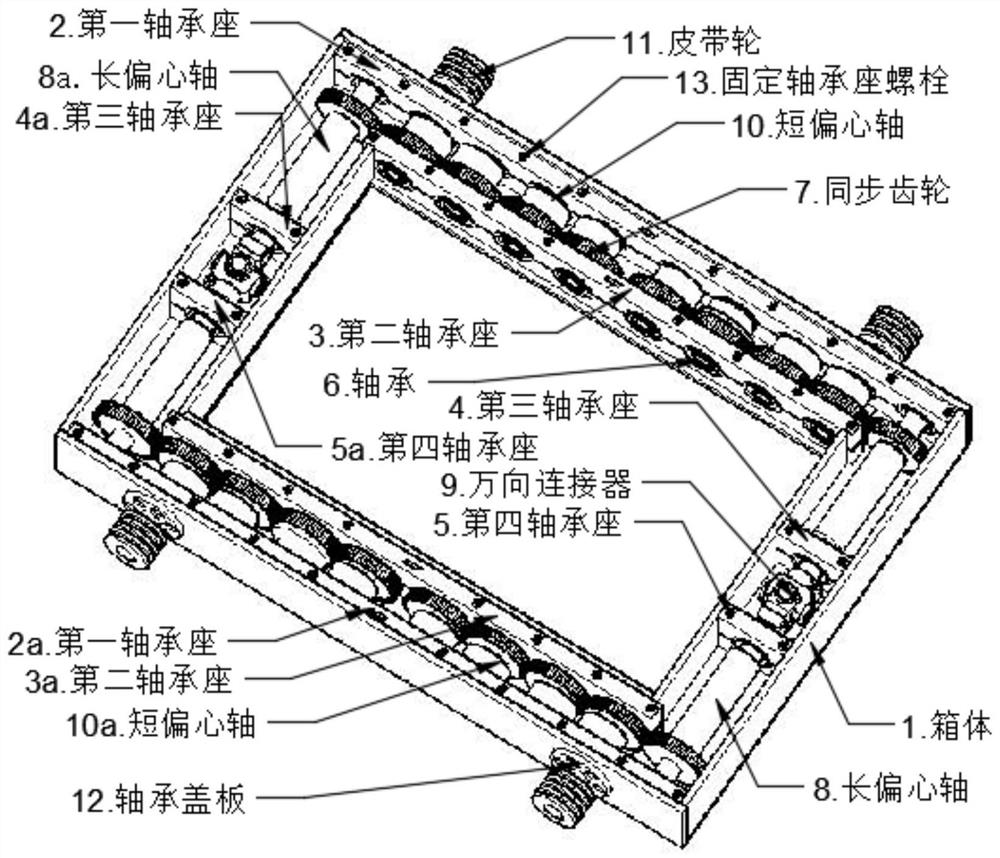

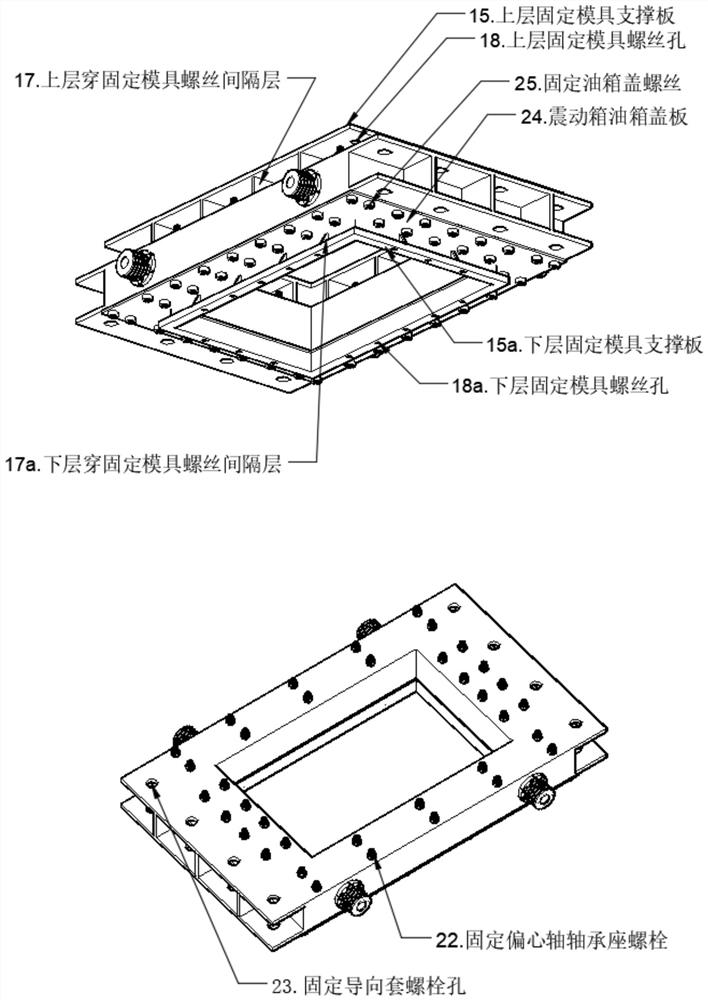

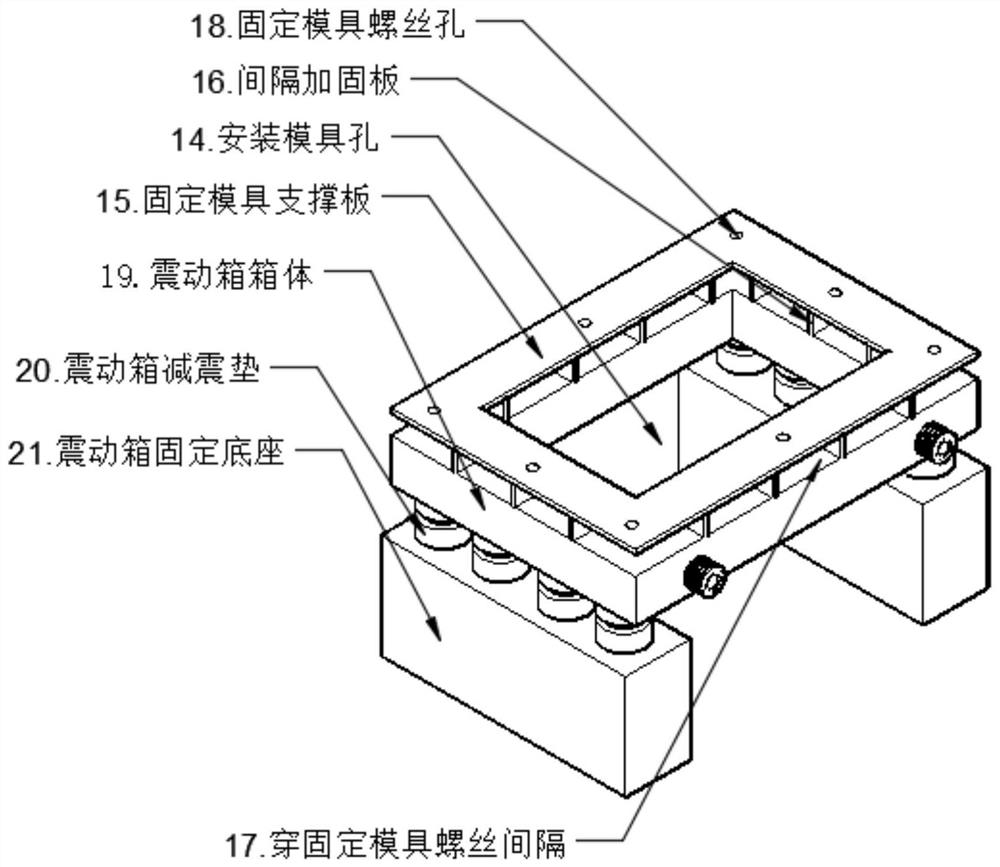

[0021] Such as figure 1 As shown, according to one embodiment of the present invention, the vibrating box of the block forming machine of the present invention is divided into front, rear, left, and right sides including a box body 1, and the middle part of the box body 1 is provided with an installation through hole 14 for installing block mold. Such as image 3 As shown, according to one embodiment of the invention, the installation through hole 14 can be set in a rectangular or square hole shape.

[0022] In the present invention, along the figure 1 The shown box body 1 is symmetrically provided with the first bearing seat (2, 2a), the second bearing seat (3, 3a), the first bearing seat (2, 2a), the second bearing seat (3, 3a) A plurality of short eccentric shafts (10, 10a) are connected to the top, and synchronous gears 7 and bearings 6 are arranged on the short eccentric shafts. A third bearing seat (4, 4a) and a fourth bearing seat (5, 5a) are symmetrically arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com