Patents

Literature

31results about How to "Avoid secondary flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

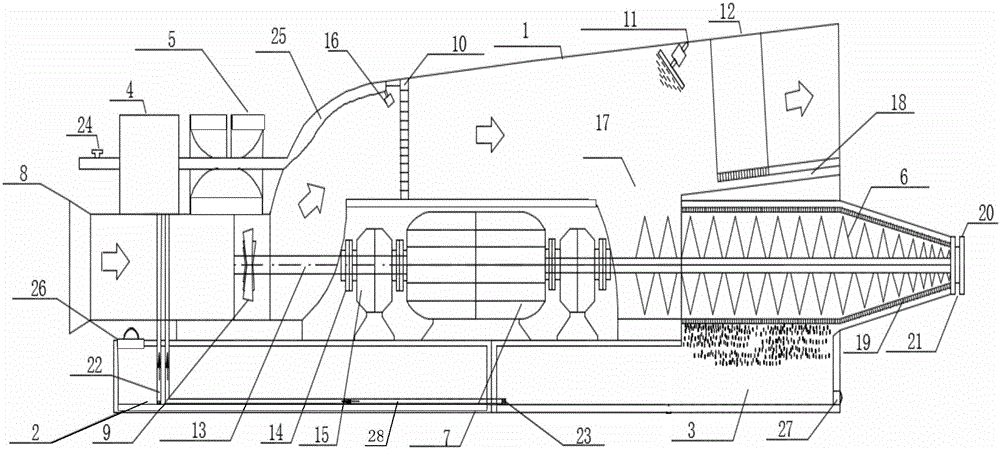

Carbon fiber smashing equipment

InactiveCN103567046AReduce the temperatureReduce the number of replacementsGrain treatmentsElectricityCarbon fibers

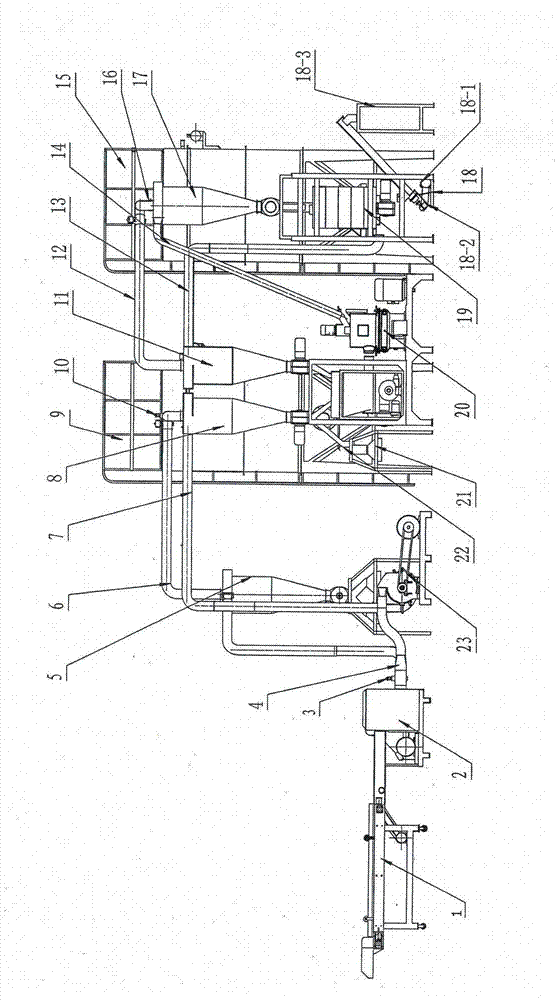

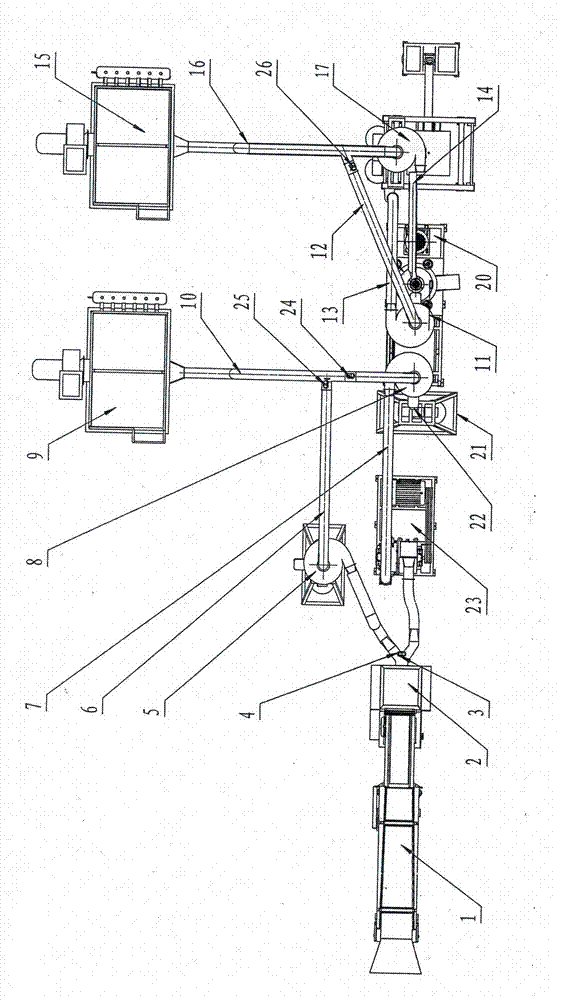

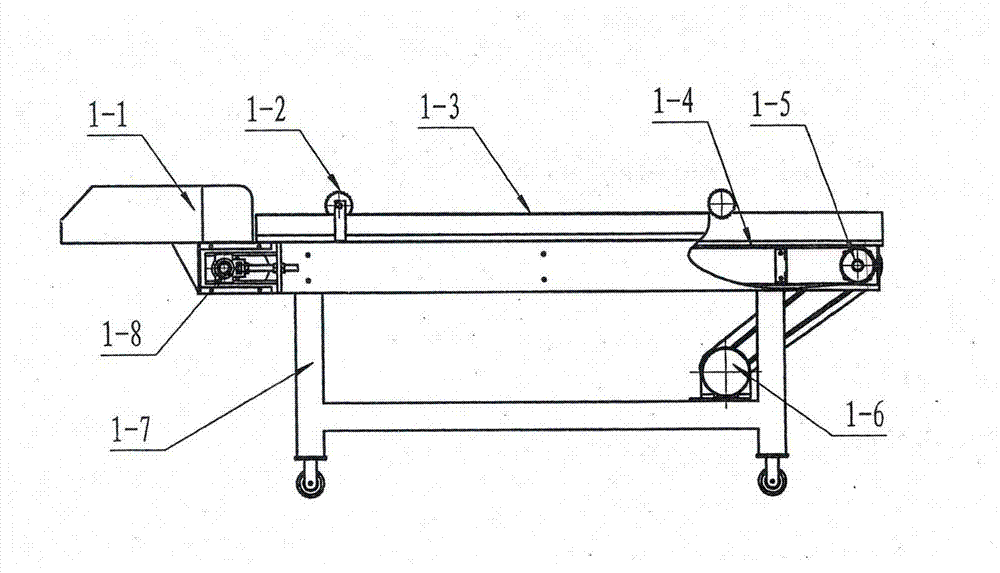

The invention discloses carbon fiber smashing equipment. The carbon fiber smashing equipment is mainly composed of a supplied material conveyor, a cut-off machine, a coarse pulverizer, an atomizer mill, a screening machine and a finished product conveyor as well as a cyclone separator and a pulse dust collector which are connected through a corresponding air conveying pipeline. The equipment can produce carbon fiber products with multiple lengths and finenesses, the highest fineness can achieve 300 meshes, the annual output can achieve 1000 tons, and the requirements of carbon fiber sections and thin powders of different specifications required by a carbon fiber production processing industry are fully achieved. The carbon fiber smashing equipment disclosed by the invention has the characteristics that the property is good, the efficiency is high, the structure is compact, the floor space is small, the yield is high, the operation is convenient, the smashing fineness is adjusted, the carbon fiber smashing equipment is wear-resisting and is easy to maintain, the labor is saved, the electricity is saved, and the environment can achieve the standard; the carbon fiber smashing equipment is ideal carbon fiber smashing equipment instead of imported equipment.

Owner:HENAN JIXING MACHINERY

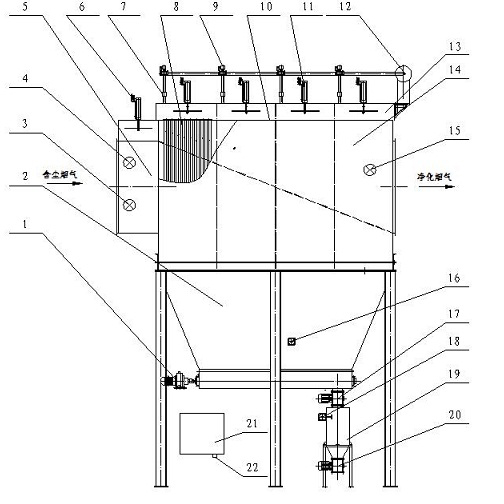

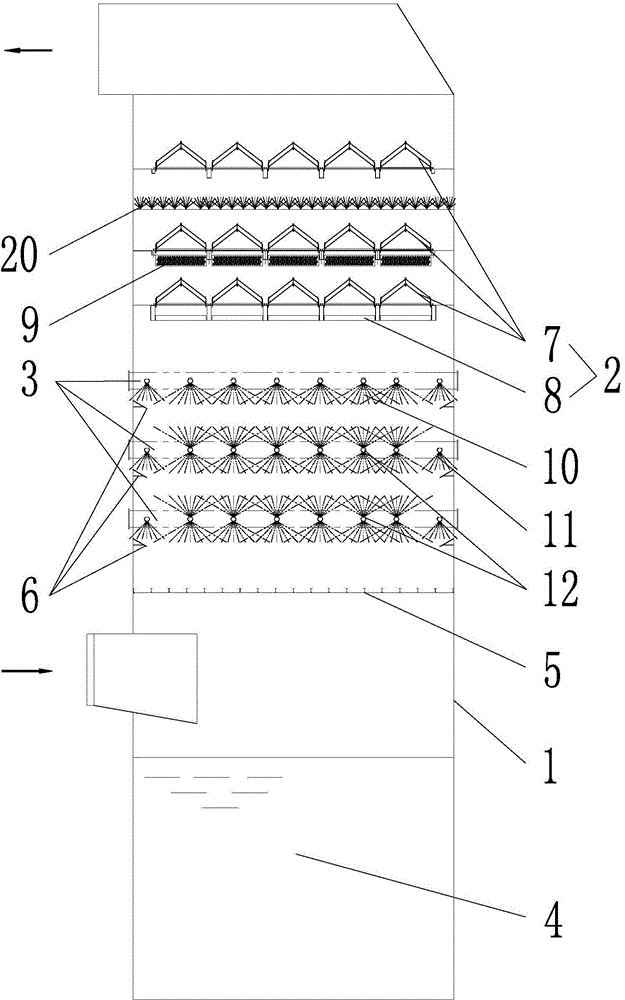

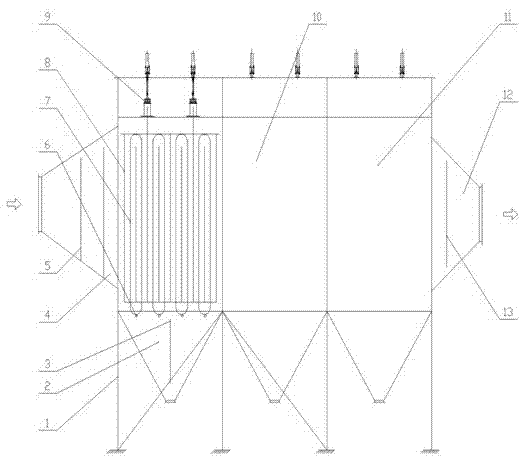

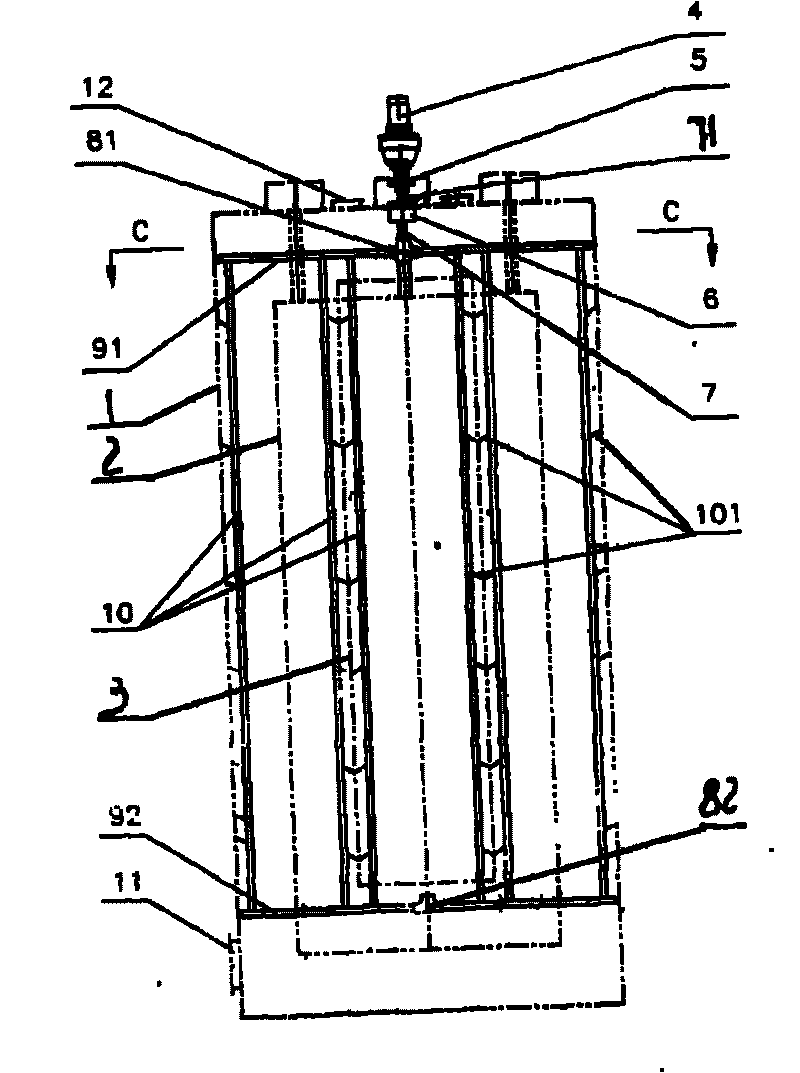

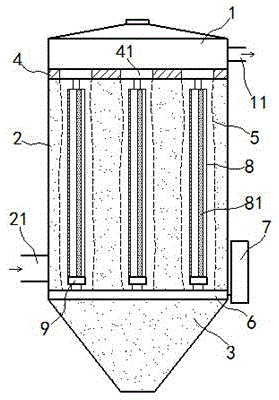

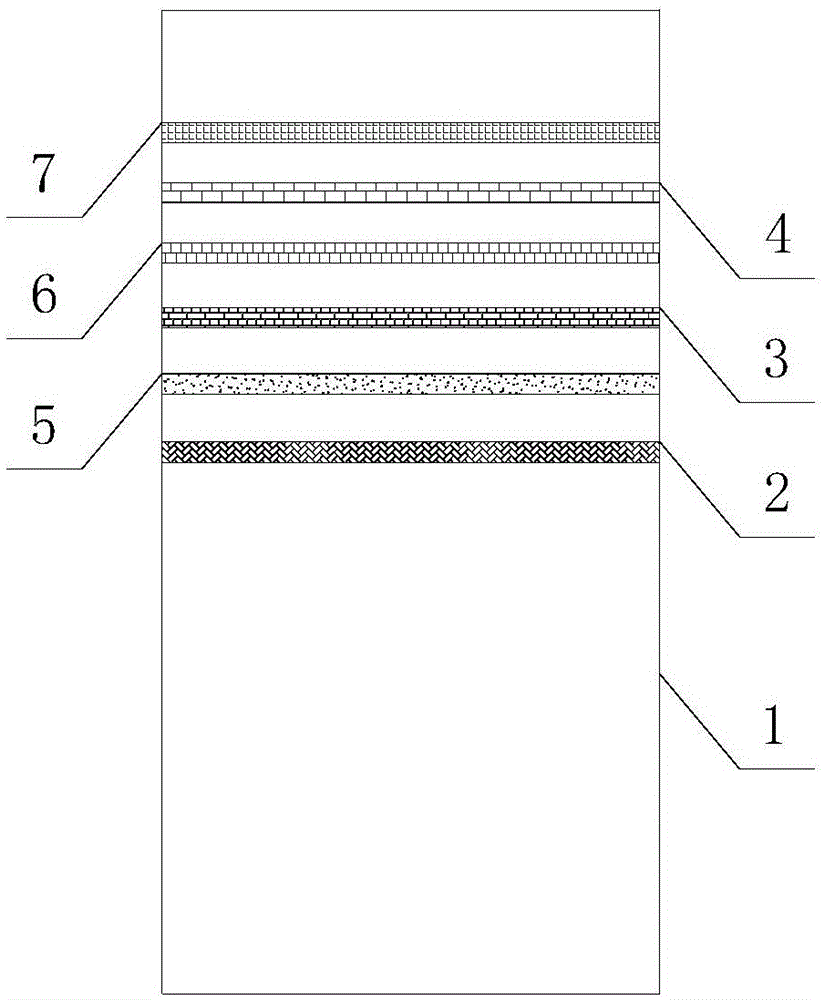

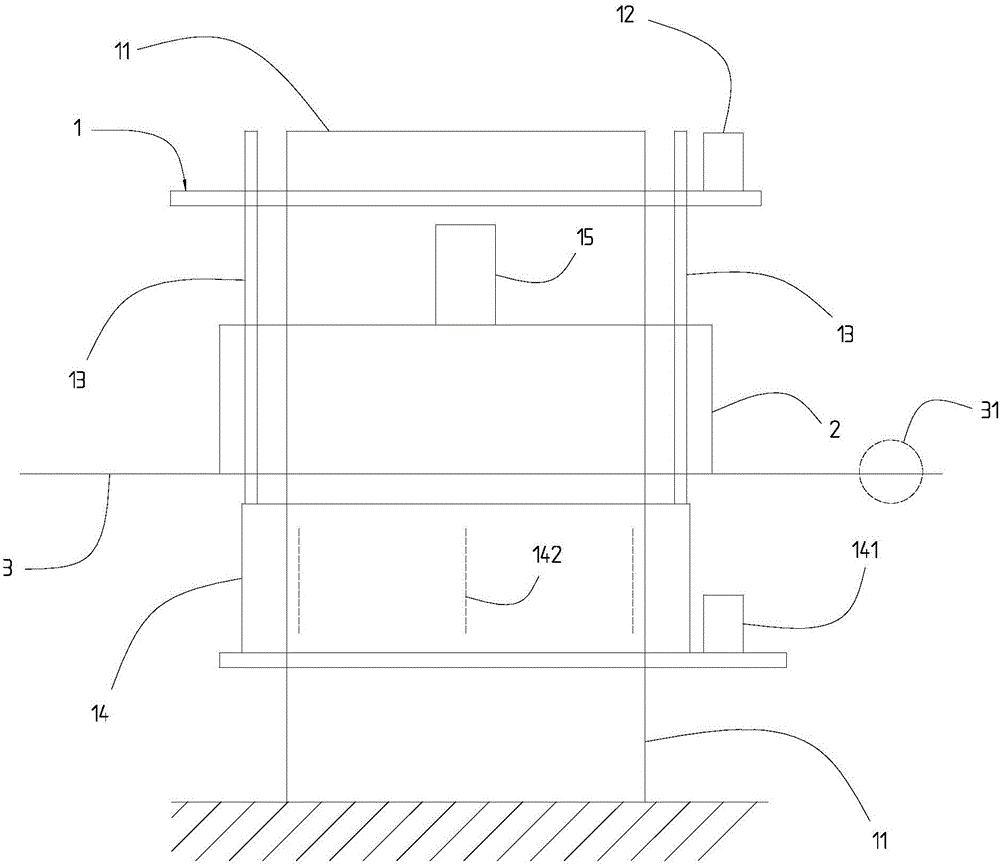

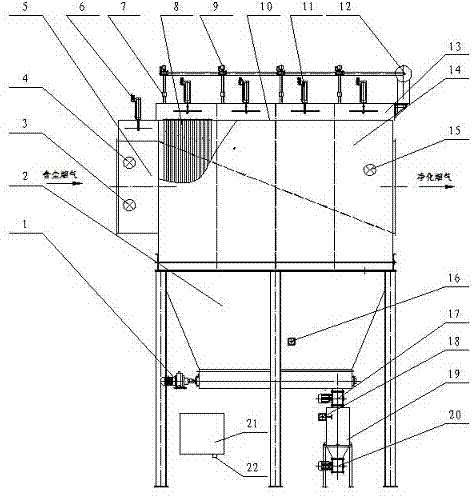

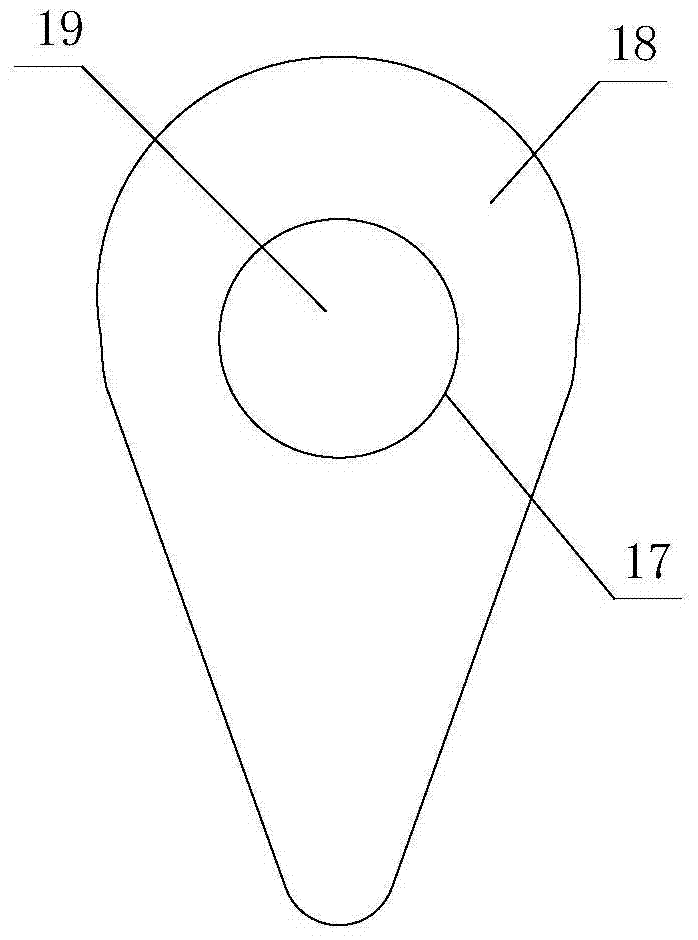

Split-type pulse dust collector for drying and burning sludge

InactiveCN102107107AAvoid secondary flyingExtended service lifeDispersed particle filtrationBypass valveControl system

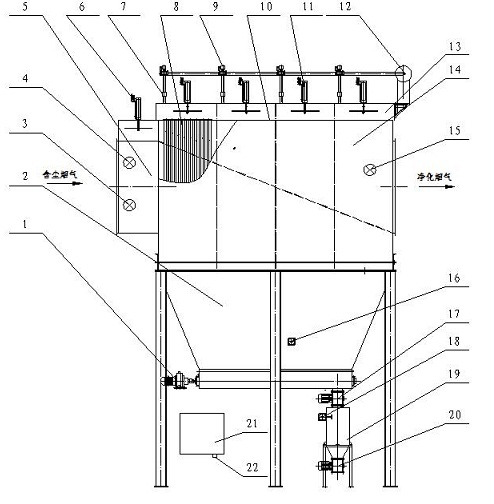

The invention relates to a split-type pulse dust collector for drying and burning sludge, which comprises an upper box body, a lower box body and a control system, wherein the upper box body comprises at least one filtering unit; the filtering unit comprises a purified gas chamber arranged in the upper layer, a filtering chamber arranged in the lower layer and a porous plate spacer arranged at the middle; a bypass channel is arranged inside the upper box body; the bypass channel extends out of the upper box body and is communicated with the external air through a by-pass valve; the by-pass valve plays the role of protecting against high temperature; the lower box body comprises an ash bu0063ket and a material bin; a vibrating and beating device is arranged inside the ash bucket; and the control system comprises a power control box and a power supply inlet. With the structure, the invention has the characteristics that: the split-type pulse dust collector for drying and burning sludge is convenient for installation, removes the ash completely, improves the seal performance, reduces the oxygen content, prolongs the service life of the filter bags, achieves the reasonable distribution of the filter bags, avoids the problem of bridging deposition of ashes inside the ash bucket during the use, and allows the by-pass valve and the lifting valve to be closed tightly. Besides, the split-type pulse dust collector for drying and burning sludge has the high temperature protection function.

Owner:JIANGSU WEITONG ELECTRICAL EQUIP

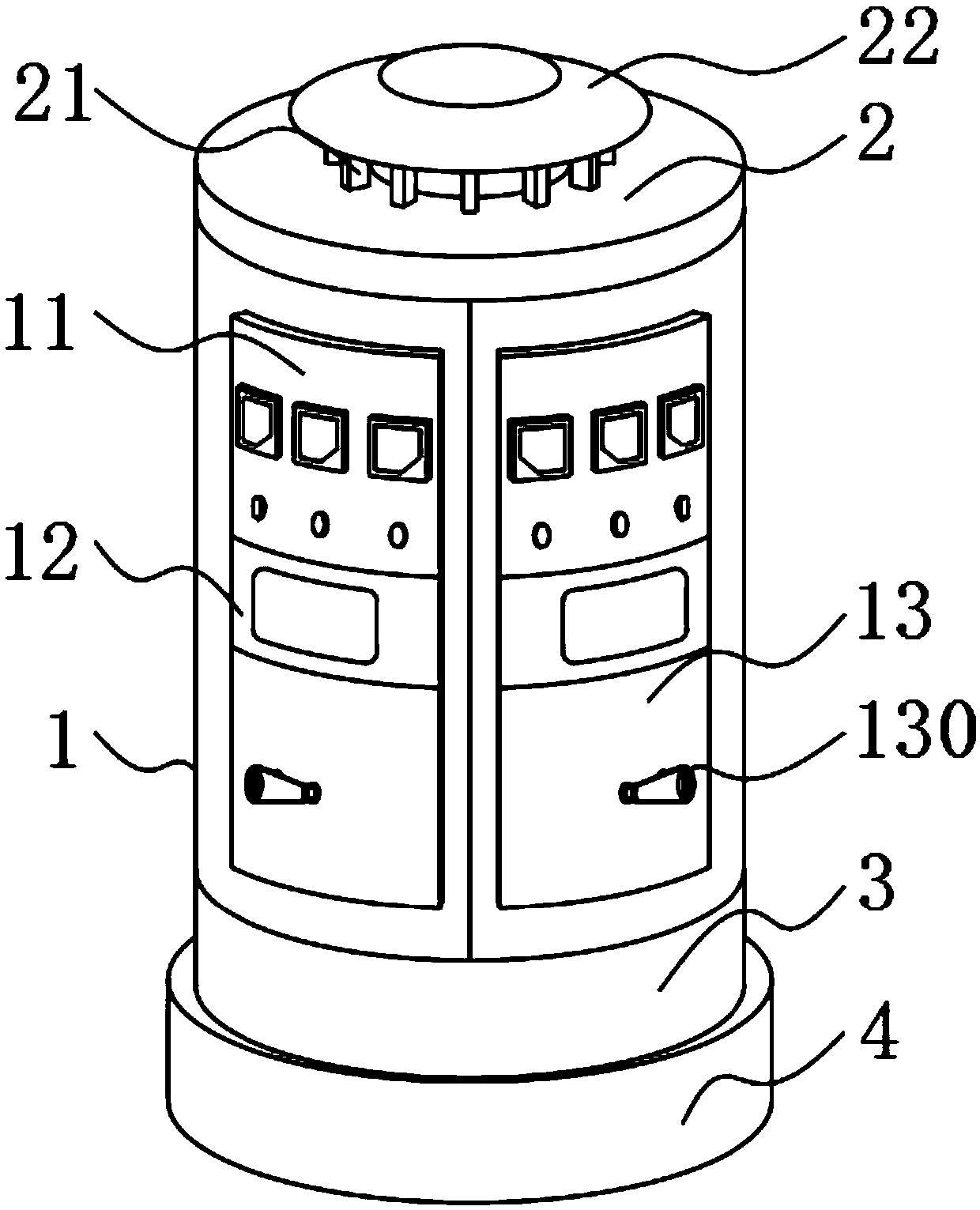

Power electrical distribution cabinet for factory production and processing

InactiveCN109524905AImprove working environmentAvoid normal workSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringPower equipment

The invention discloses a power electrical distribution cabinet for factory production and processing, which relates to the technical field of power equipment. The power electrical distribution cabinet includes cabinets, a top cover fixedly installed on the top of the cabinets, an installation chassis fixedly installed at the bottom of the cabinets, a fixed chassis rotationally connected to the bottom of the installation chassis, fixed seats fixedly connected to the inside walls of the cabinets, and spacer rings fixedly installed on the inside walls of the cabinets. There are four cabinets which form a hollow cylindrical shape. Through the setting of the cabinets forming a hollow cylindrical shape as well as heat dissipation holes in the inside walls of the cabinets, heat dissipation fan blades and a dust shield, heat dissipation can be carried out in the inner ring of the hollow cylinder formed by the cabinets. There is no need to reserve a channel between the distribution cabinet andthe wall for the placement of the distribution cabinet in a factory, and the operation of the heat dissipation equipment in the distribution cabinet is avoided. The air in the cabinet equipment exchanges with the outside air at the ventilation opening at the back of the cabinets. The factory space occupied by the distribution cabinet is reduced.

Owner:陈炜健

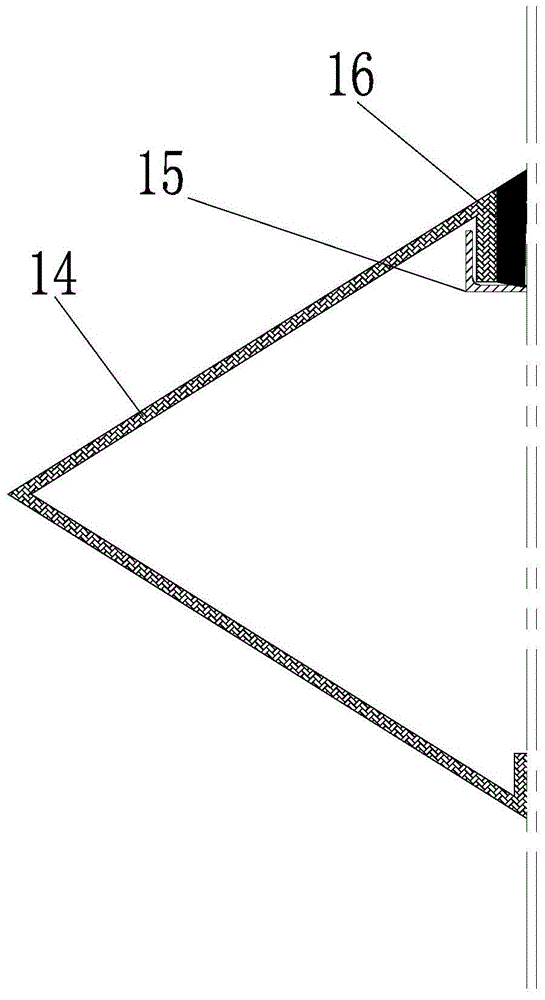

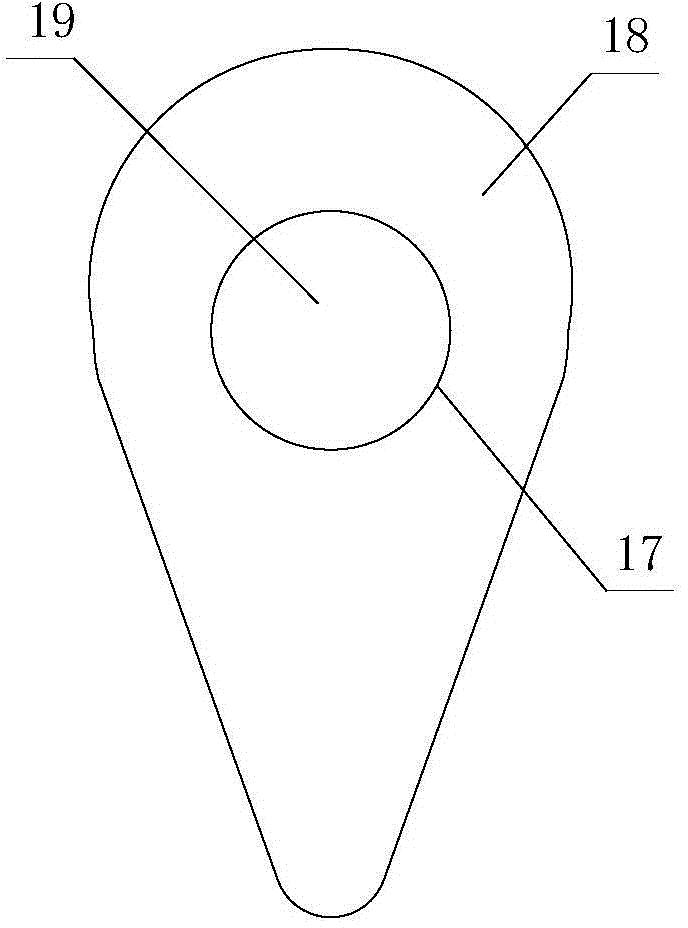

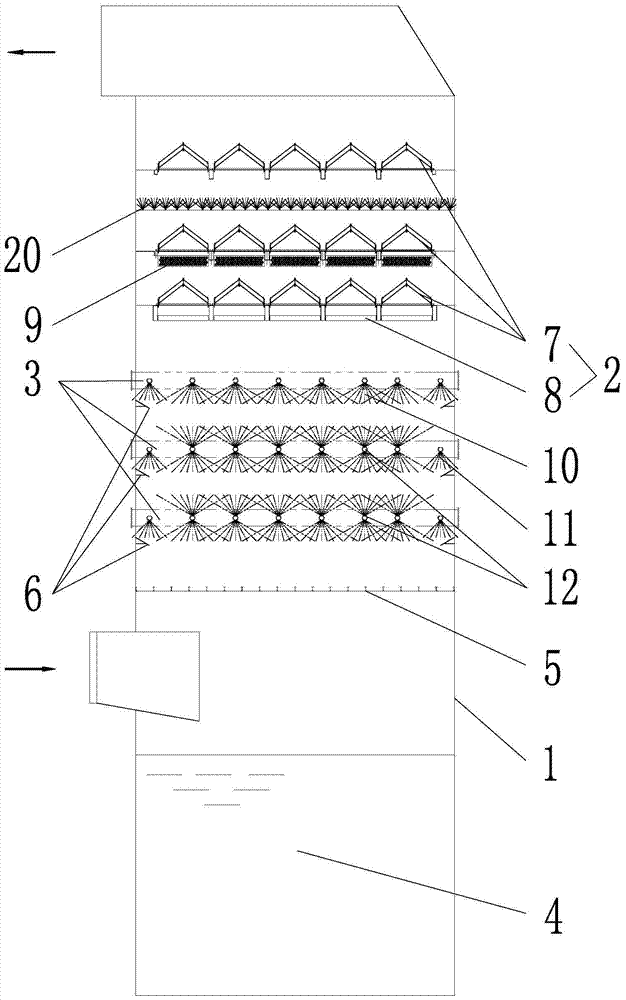

Ultra-low emission absorption tower

ActiveCN104958999AIncrease spray coverageIncrease spray densityUsing liquid separation agentEngineeringSlurry flow

The invention discloses an ultra-low emission absorption tower, which comprises an absorption tower body, a demister, spraying layers and a slurry trough, wherein the slurry trough is arranged at the bottom in the absorption tower body; the demister is arranged at the upper part in the absorption tower body; the spraying layers are arranged below the demister; a slurry distribution plate is arranged below the lowermost spraying layer; a slurry flow guide ring is arranged below each spraying layer; the demister consists of three groups of ridge-type demisters and a group of tubular demisters; the tubular type demisters are arranged below the lowermost layer of the ridge-type demisters; a condensation and coagulation system is arranged between the lowermost layer of the ridge-type demisters and the middle layer of the ridge-type demisters. The ultra-low emission absorption tower can be used for removing tiny dust with a small particle size from smoke of a power plant, so that the spraying coverage rate is effectively increased, the efficiency of removing SO2 and dust from the smoke is improved, and the inner wall of the absorption tower body can be effectively prevented from being abraded; in addition, smoke can be guided, so that smoke can flow to a spraying dense region to relieve pressure loss of the edge wall.

Owner:CHINA HUADIAN ENG +1

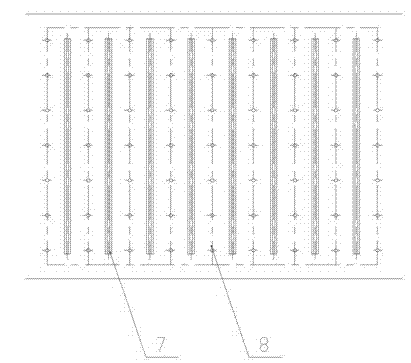

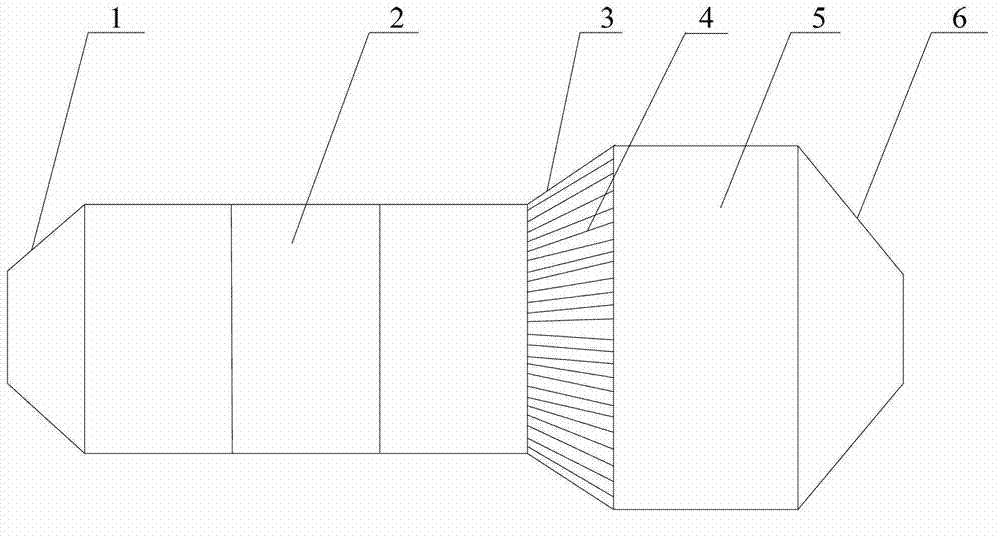

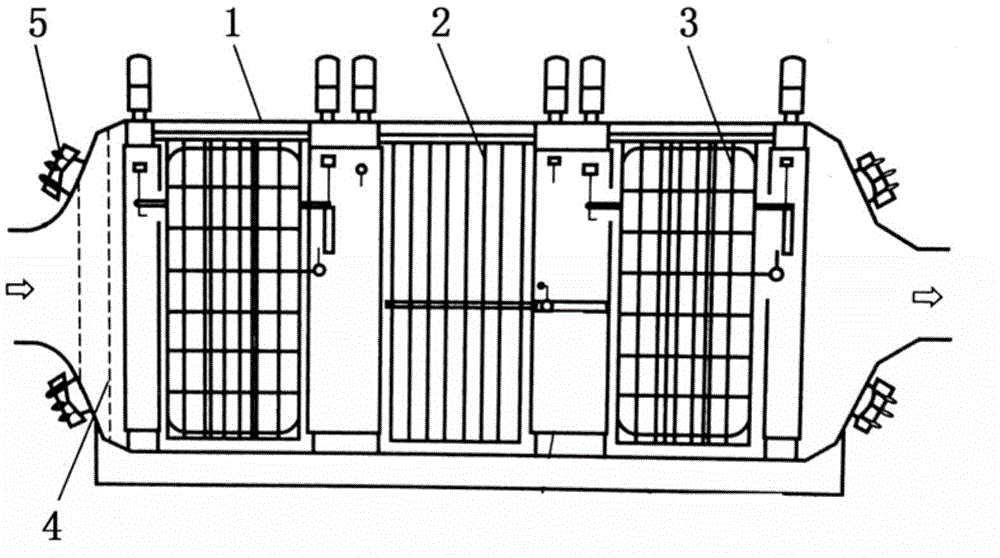

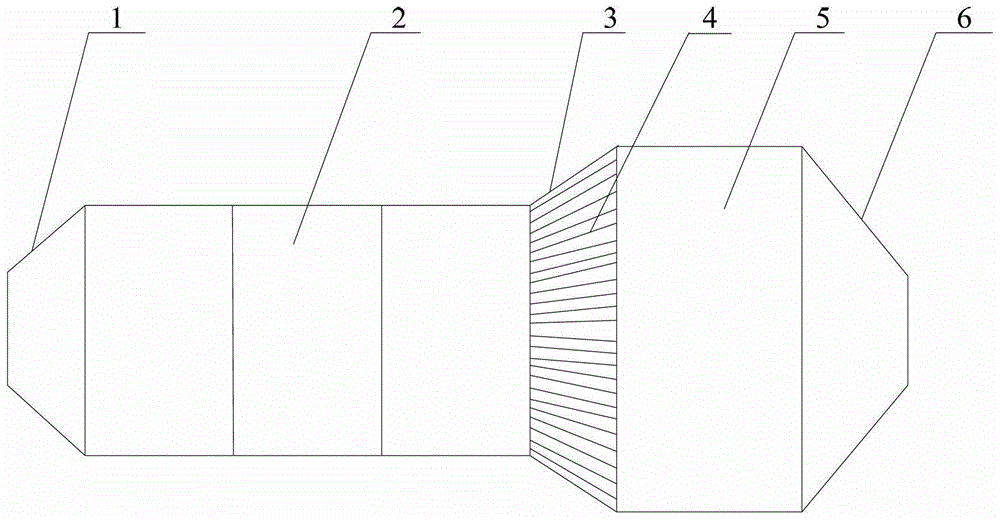

Differential movable type transverse electrode electrostatic precipitator

InactiveCN102728467AGood vibration effectPrevent secondary flyingExternal electric electrostatic seperatorElectrode constructionsPhysicsElectric field

The invention relates to a differential movable type transverse electrode electrostatic precipitator which comprises a housing. Two ends of the housing are provided with an inlet seal head and an outlet seal head, the lower part of the housing is provided with an ash bucket, and an anode system and a corresponding cathode system are provided in the housing; the anode system is composed of a plurality of vertically arranged annular anode rows at equal intervals, each anode row annularly moves under the driving of a transmission device, the bottom of each anode row is provided with an anode plate striking gear used for rapping and ash removal, and the cathode system and the anode system form a plurality of evenly-spaced, parallel and alternatively arranged sets of movable type differential electric field perpendicular to the direction of air flow. According to the invention, through cooperation between the movable annular anode rows and the anode plate striking gears at the bottom of the anode rows, the problem of secondary stirring of dust generated by rapping and ash removal of the anode of an electrostatic precipitator is overcome; gaps among anode plates are decreased, migration distance of charged dust is reduced, and an effective dust collecting area of a single electric field is increased.

Owner:江保祥

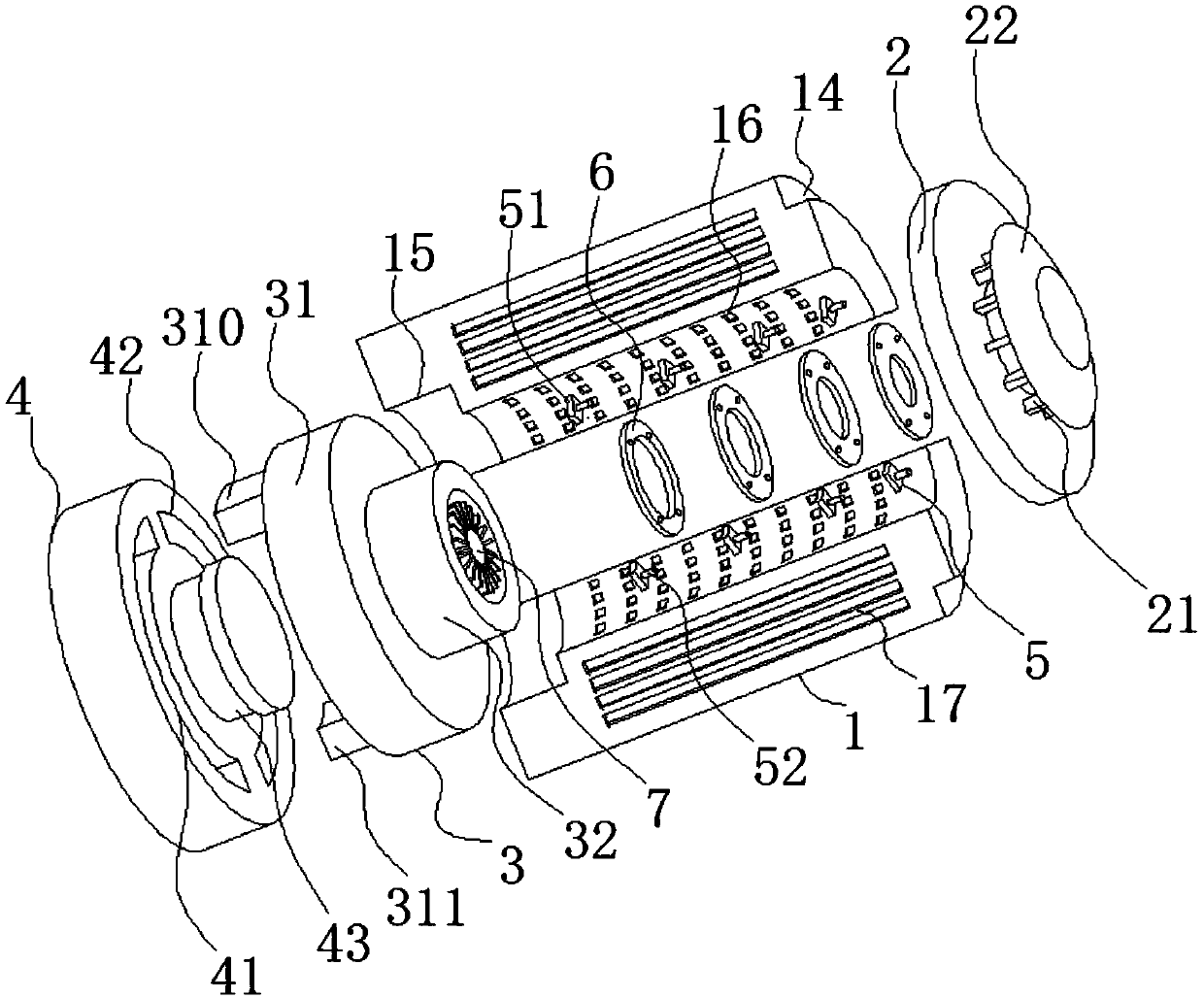

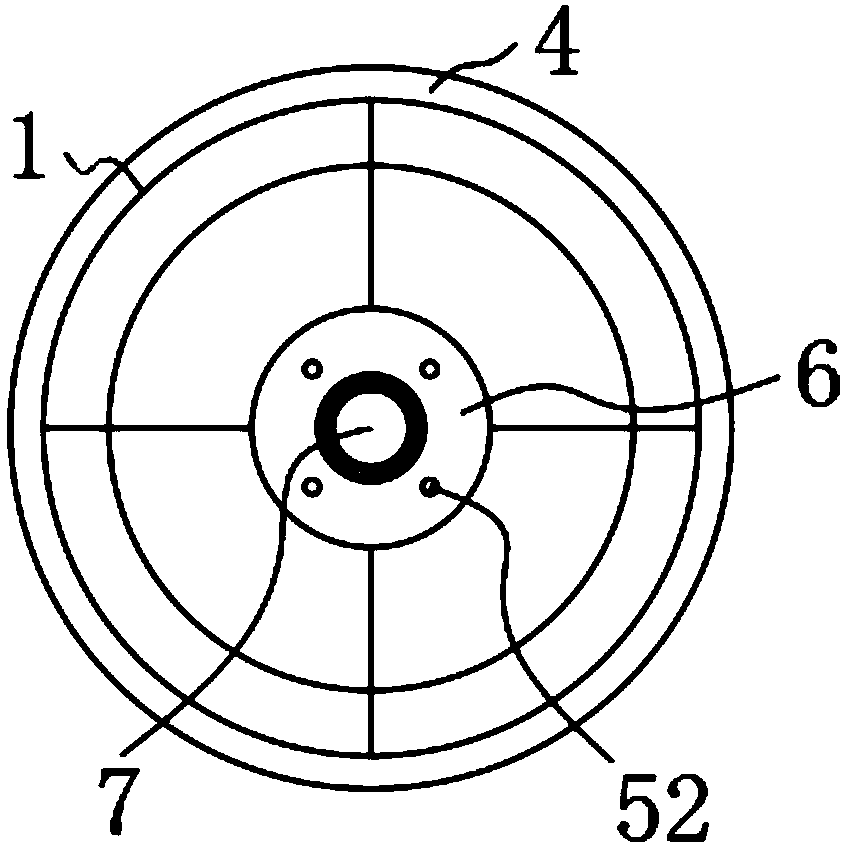

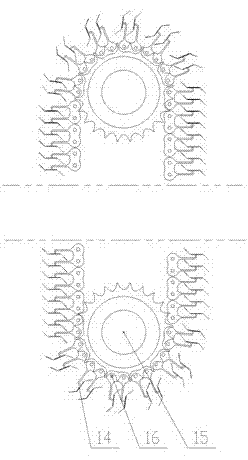

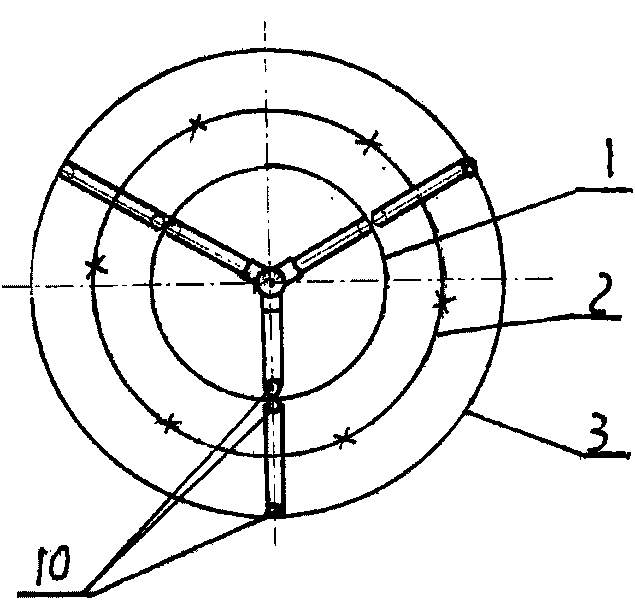

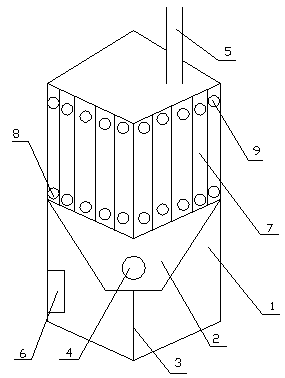

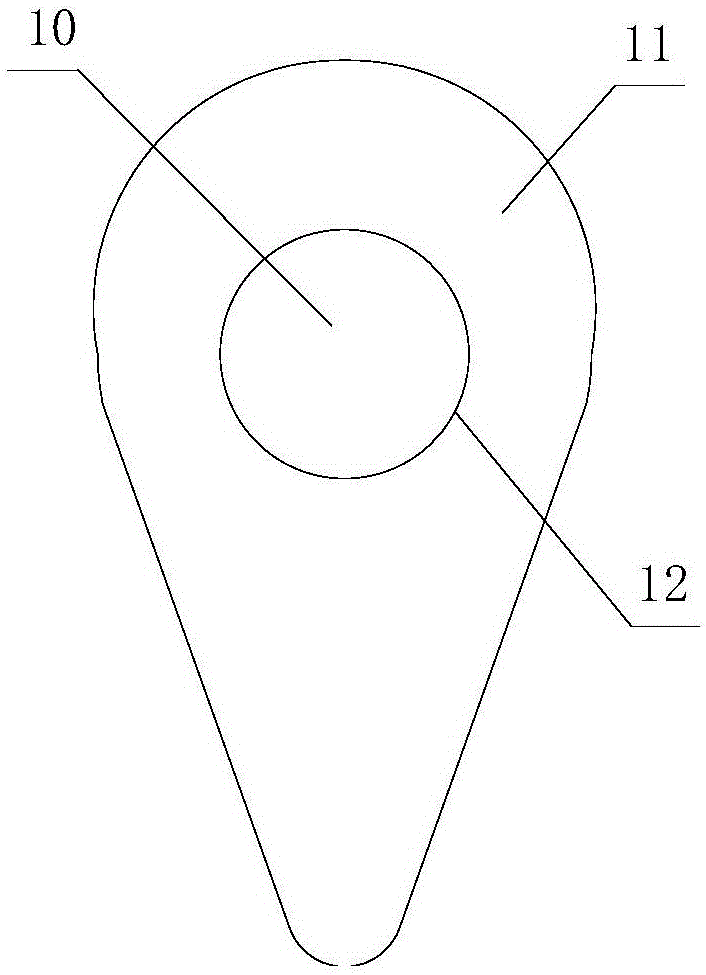

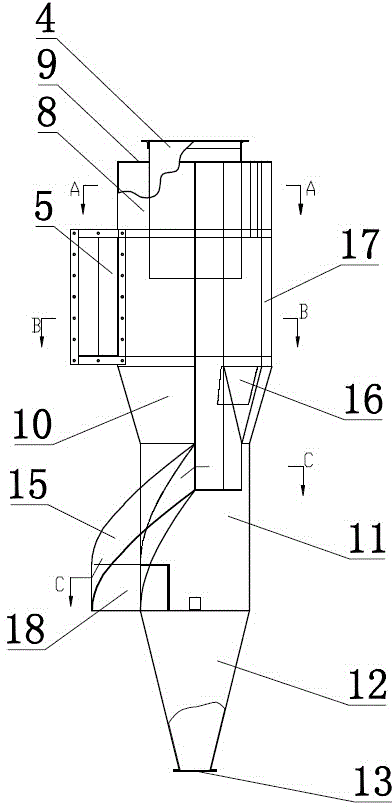

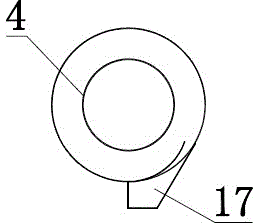

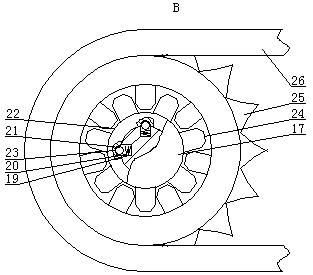

Rotary ash eliminator of circular pipe electro-precipitator

InactiveCN101745466AAvoid secondary flyingAvoid back corona phenomenonElectrodes cleaningEngineeringCathode

The invention discloses a rotary ash eliminator of circular pipe electro-precipitator, which belongs to the technical field of electro-precipitator, and aims at providing a rotary ash eliminator of circular pipe electro-precipitator with good ash eliminating effect and long service life. The rotary ash eliminator of circular pipe electro-precipitator is technically characterized by including an external anode cylinder (1) the bottom of which is provided with an air inlet and the top end of which is provided with an air outlet, at least one cylindrical cathode wire framework (2) hung in the external anode cylinder and at least one inner internal anode cylinder (3); a vertical motor (4) is arranged in the center above the top end of the external anode cylinder; the output shaft of the vertical motor is connected with a main shaft (7) through a coupling (5); the main shaft is vertically hung in the external anode cylinder through a bearing (6) fixed in the middle of the top plate of the external anode cylinder; the main shaft hung in the external anode cylinder is connected with a swing mechanism consisting of an upper triple sleeve and a lower triple sleeve; an upper swinging arm and a lower swimming arm, as well as a sweeping rod; and one surface of the sweeping rod (10) closed to the inner anode cylinder and the external anode cylinder is embedded with a high-temperature resistant flexible brush (101).

Owner:HEFEI CEMENT RES DESIGN INST

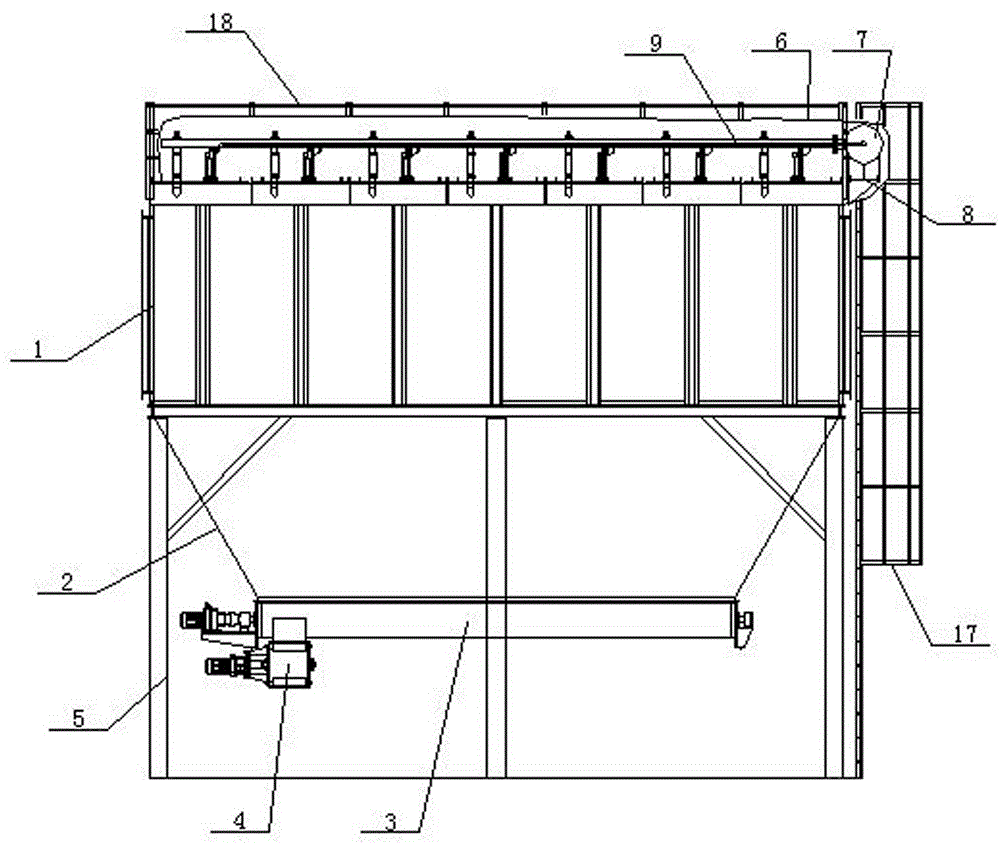

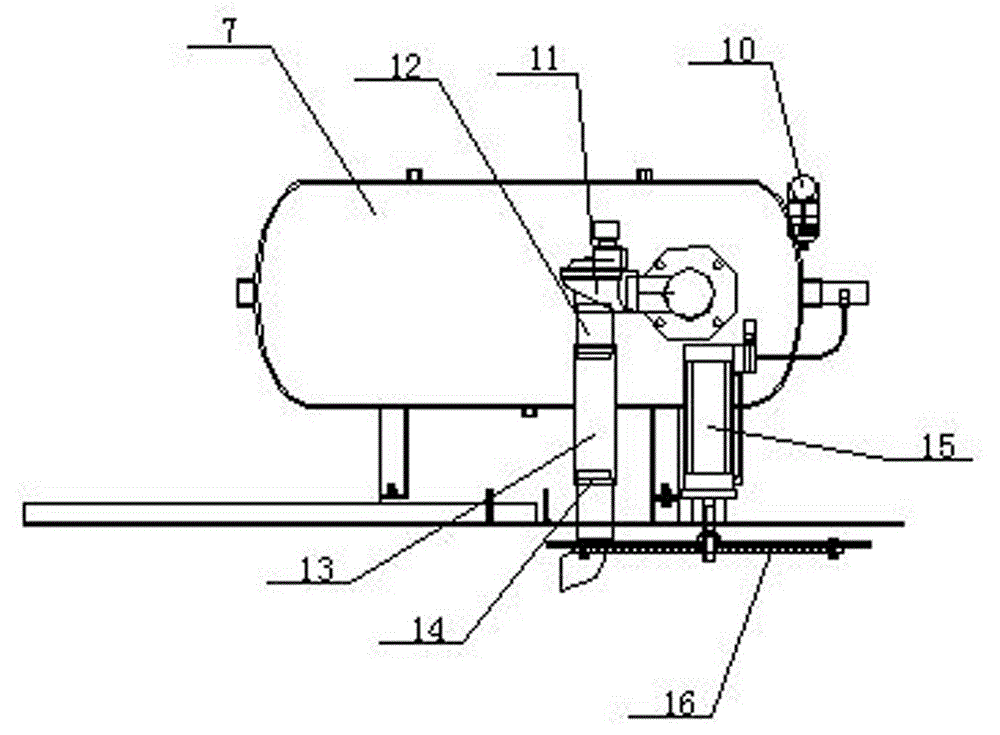

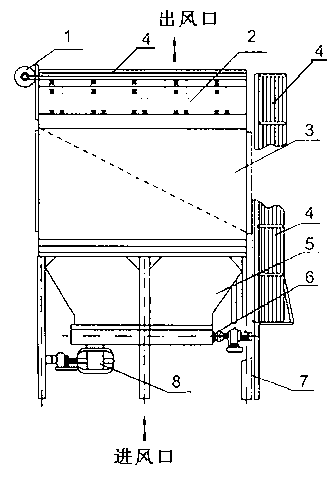

Air box type pulse bag dust collector

InactiveCN102716625AAvoid secondary flyingExtended service lifeDispersed particle filtrationFiltrationElectromagnetic pulse

The invention provides an air box type pulse bag dust collector, and relates to the technical field of dust collector devices. A pulse jet device comprises an air storage tank, an air storage tank support, a jet pipe, an air source piece, an electromagnetic pulse valve, a non-standard joint, a rubber pipe, a hoop and an air cylinder, wherein the air storage tank is fixedly mounted on the air storage tank support; the air source piece is arranged on the air storage tank; the air storage tank is sequentially connected with the jet pipe through the electromagnetic pulse valve, the non-standard joint, the rubber pipe and the hoop; the air cylinder is connected with the air storage tank; and a lifting valve plate is connected to the bottom of the air cylinder. The air box type pulse bag dust collector integrates the advantages of compartment reverse blow bag dust collectors and jet pulse ash removing bag dust collectors, and corrects the deficiencies that the strength of compartment reverse blow ash removal is not enough and jet pulse ash removal is conducted along with filtration, thereby extending the application range of bag dust collection, improving the dust collection efficiency and prolonging the service life of filter bags.

Owner:JIANGSU HONGMINGDA MACHINERY

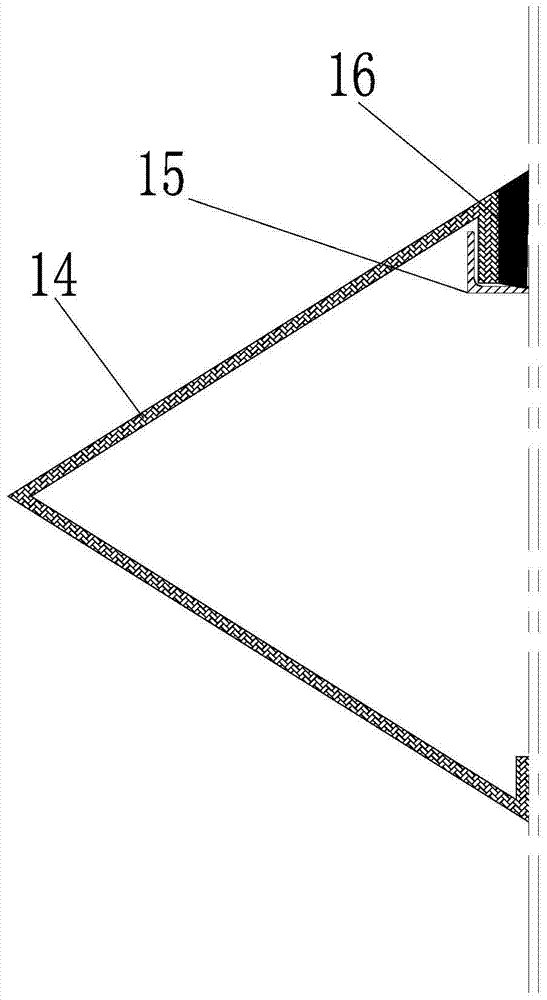

Double-cartridge filter

InactiveCN105582769AImprove dust removal efficiencyAvoid secondary flyingCombination devicesEngineeringElectrostatic generator

Owner:TAIZHOU AODE FURNITURE ACCESSORIES

Electrical precipitator

ActiveCN102728471AReduce process downtimeReduce economic lossElectrostatic separation detailsLoudspeakerElectric field

Owner:FUJIAN LONGKING

Gas box type pulse dust remover

InactiveCN102989239AAvoid secondary flyingDispersed particle filtrationAirflowElectrical and Electronics engineering

The present invention relates to a gas box type pulse dust remover, which comprises a dust remover housing, an ash hopper, an ash discharging device, a dust remover bracket, an air inlet, an air outlet pipe and an ash cleaning control box, wherein the air inlet is arranged outside the ash hopper, and the upper portion of the ash hopper is connected with the ash discharging device and the air outlet pipe. According to the present invention, separation plates are adopted to separate into a plurality of independent dust collection chambers, ash cleaning is performed on every dust collection chamber according to a given time interval, and when the one dust collection chamber is subjected to injection ash cleaning, filtration air flow is cut off so as to avoid secondary dust flying due to injection ash cleaning, such that gas containing dust with a concentration of up to 1000 g / m<3> can be caught.

Owner:从乃祥

Magnetic foam washer capable of recycling foam concentrate and using method thereof

InactiveCN106014470AAvoid secondary flyingImprove utilization efficiencyUsing liquid separation agentDust removalFoaming agentPipette

The invention provides a magnetic foam dust remover capable of recycling foam concentrate and a using method thereof. The magnetic foam washer comprises a ventilating duct. The ventilating duct is provided with a foamer storage tank on the outer side; the foamer storage tank is connected to a two-stage proportional mixer through a first pipette; the two-stage proportional mixer is connected to self-aspirating magnetic foam making equipment; the self-aspirating magnetic foam making equipment is connected to a nozzle or / and a drainage mesh through a magnetic foam conveying pipe; an ultrasonic foam breaker is arranged behind the drainage mesh; a spiral extrusion device is arranged below the ultrasonic foam breaker; a recovered solution storage tank is arranged below the spiral extrusion device; the recovered solution storage tank is connected to the two-stage proportional mixer. According to the invention, magnetic foam generated by the magnetic foam dust remover is capable of capturing dust in dust-contained airflow, dust and foam separation of dust-contained foam concentrate is realized, dust can be stored in a concentrated way after being gathered, the foam concentrate can be further recycled, re-entrain dust is avoided, the utilization efficiency of the foamer is improved, the operating cost of the device is effectively reduced, and the adverse influence on the working environment caused by discharging foam freely is avoided.

Owner:LIAONING TECHNICAL UNIVERSITY

Spray coagulation and tiny dust removal system

InactiveCN105056675AAvoid secondary flyingMeet emission standardsCombination devicesVapor condensationFlue gasSpray tower

The invention discloses a spray coagulation and tiny dust removal system. The system comprises a first stage reciprocating demisting device, the first stage reciprocating demisting device is arranged in a spraying tower, a top spraying layer is arranged in the spraying tower, and the first stage reciprocating demisting device is positioned above the top spraying layer. Power plant flue gas undergoes grading treatment in order to remove tiny dusts with large, medium and small particle sizes in the flue gas; and multi-stage reciprocating spraying devices are arranged in the system, so secondary flying of the tiny dusts is prevented, liquid droplets with the dimension being greater than 15[mu]m in the flue gas are removed, and discharge standards required by national environmental protection are reached.

Owner:CHINA HUADIAN ENG +2

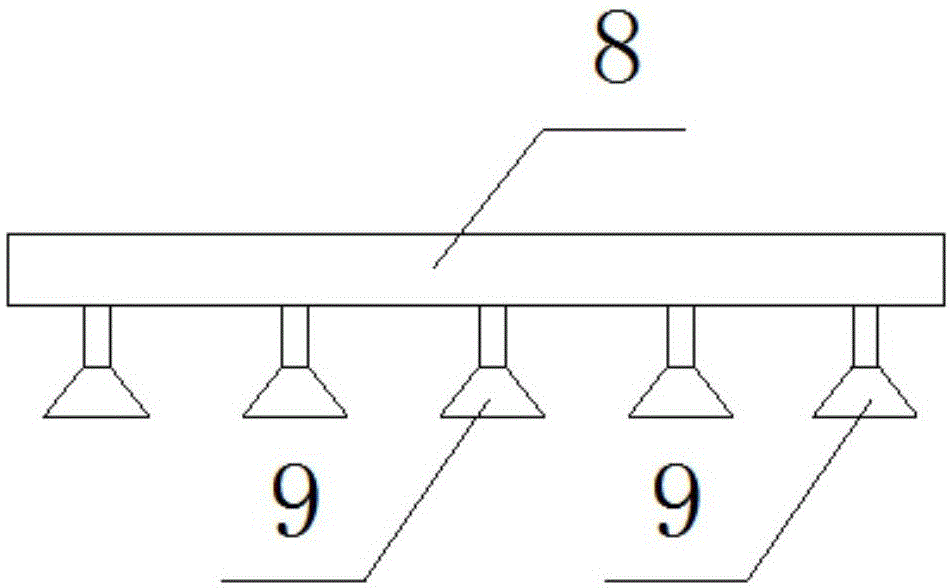

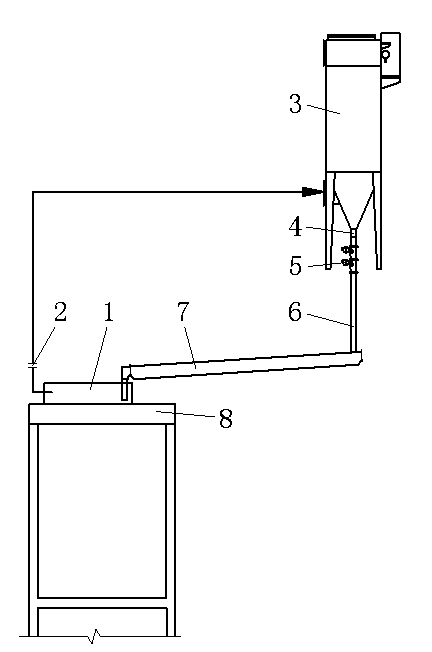

Dust extraction and treatment system for discharging platform of aluminum oxide warehouse

InactiveCN103658145AAvoid secondary flyingReduce secondary flyoverDirt cleaningDust controlWorking environment

The invention discloses a dust extraction and treatment system for a discharging platform of an aluminum oxide warehouse. The dust extraction and treatment system comprises a dust-collecting cover (1) arranged on a technical discharging platform (8) of the aluminum oxide warehouse, the dust-collecting cover is connected with a dust extractor (3) through a pipeline, a chute (4) at the bottom of the dust extractor (3) is connected with the discharging platform (8) through a double-layer rectangular lock air hammer turn-plate cinder valve (5), a dust discharging pipe (6) and a pneumatic chute (7). Dust collected by the dust extractor can return to the processing procedure. The integral process is completed in the closed system, and secondary splashing of dust to cause local pollution to the working environment of operators is avoided. With no need of manual and forklift clearing, workload is alleviated, and work efficiency is improved. Dust clearing of the dust extractor is greatly reduced, aluminum powder is effectively utilized, the working environment is improved, working property is changed, secondary splashing of the dust is avoided, and energy resources are saved.

Owner:GUIYANG AL-MG DESIGN & RES INST

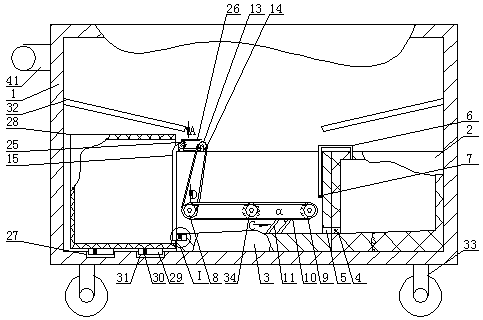

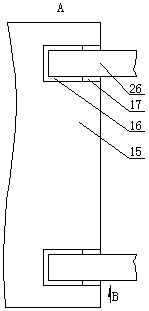

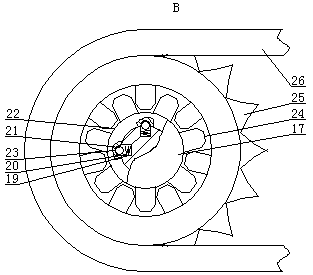

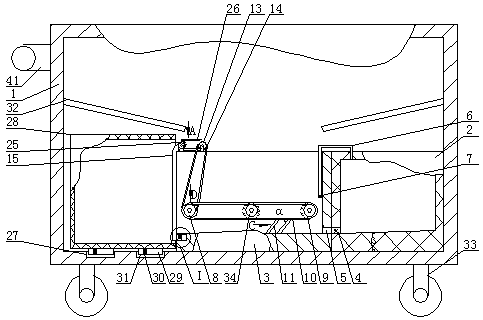

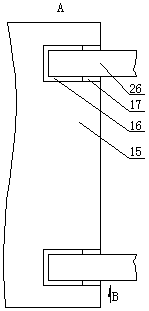

Environment-friendly mobile collecting box for decoration cutting dust

ActiveCN108636005AThe dragging process is smoothAvoid secondary flyingUsing liquid separation agentWorking accessoriesEngineeringWater tanks

Provided is an environment-friendly mobile collecting box for decoration cutting dust. The mobile collecting box comprises a box body, wherein a water tank is fixedly mounted on one side of the bottomsurface of the inner wall of the box body, the bottom surface and the outer side of the water tank are fixedly connected to the inner wall of the box body separately, the inner side of the water tankis fixedly connected to one side of the box body, and openings are formed in the top surface and the other side of the box body; a first through hole is formed in the bottom of the inner side of theinner wall of the water tank, a switching valve is disposed in the first through hole, and a second through hole is formed in one side of the box body; the interior of the first through hole communicates with the interior of the second through hole, and the second through hole communicates with the interior of the box body; the top surface of the water tank is fixedly connected to one end of a hose, and the other end of the hose is arranged in the box body, and a floating plate is fixedly mounted on the periphery of the other end of the hose. Sediment in the box body can be pushed directly into the garbage bag through cooperative use of a mud box and a garbage bag, and the mud box can be taken and placed freely; after the mud box is taken out, a sealing cap of the garbage bag containing the sediment is removed, and after the garbage bag is replaced by a new garbage bag, the mud box is put back, and the sediment is not in contact with the mud box, and cleaning of the mud box by a user is not needed, so that time and labor are saved.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

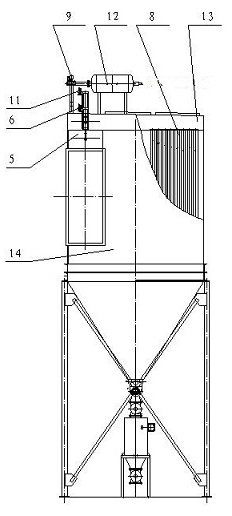

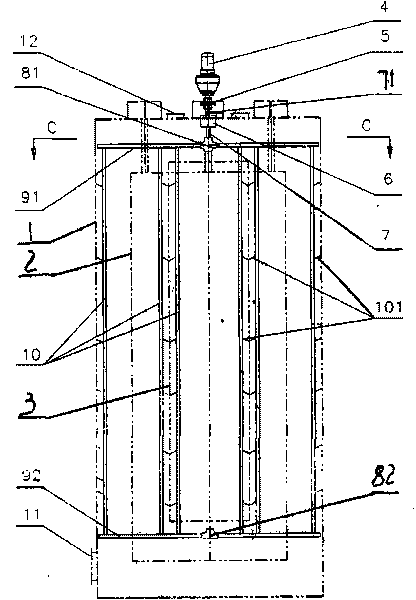

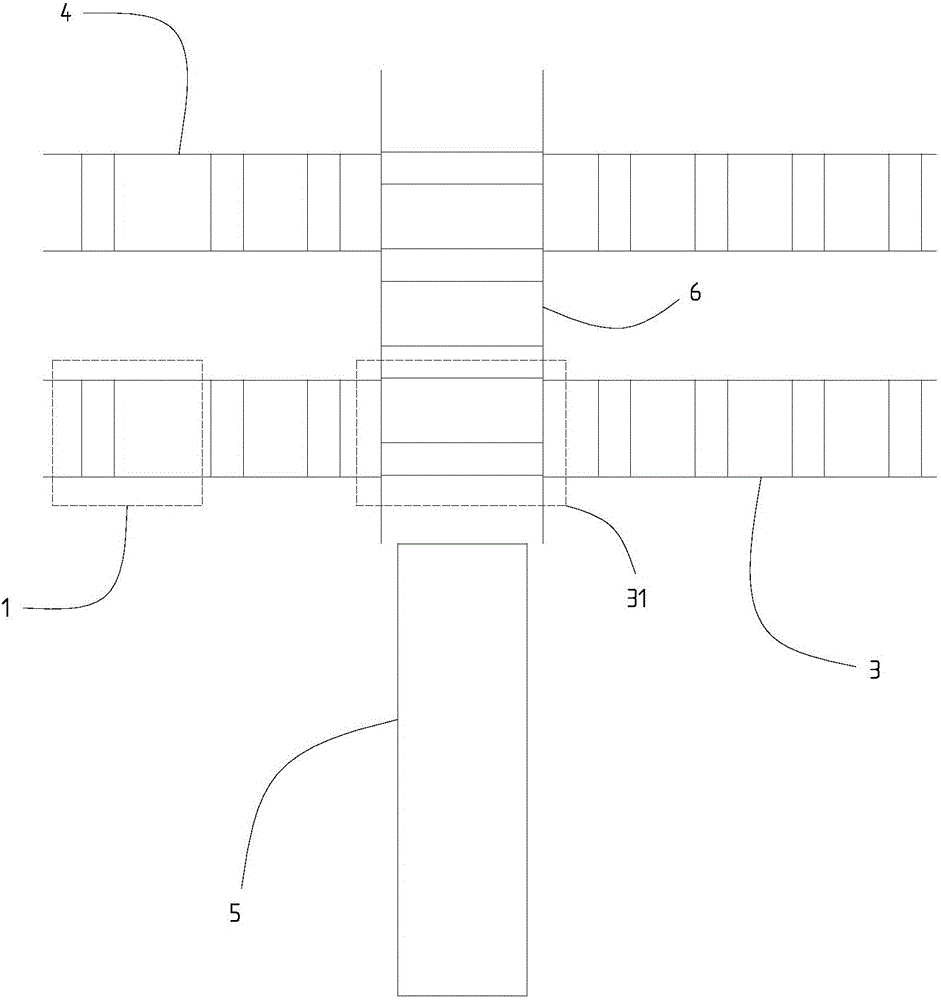

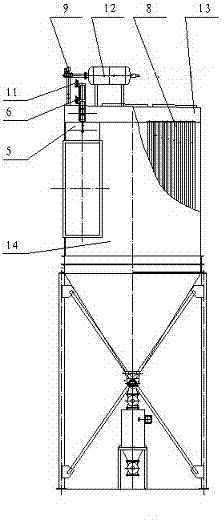

Air box pulse bag dust collector

InactiveCN103285676AAvoid secondary flyingService life of directorHuman health protectionDispersed particle filtrationImpellerEngineering

The invention provides an air box pulse bag dust collector. The air box pulse bag dust collector comprises a stand column (7), a box body (3) fixed at the upper part of the stand column (7), an ash bucket (5) fixed at the lower part of the stand column (7), an air storage tank (1) connected with the box body (3), a plurality of filter bags in the box body (3), lifting valves (2) connected with the filter bags, and a turbine (8) and a screw conveyer (6) which are connected with the ash bucket (5), wherein two guardrails (4) are arranged at the outer side of the stand column (7) and the top of the box body respectively, and the filter bags are connected with the lifting valves (2) in one-to-one correspondence. The air box pulse bag dust collector has the technical effects that back-blowing injection dust removal is adopted, so that secondary flying of dust can be avoided. The dust collector is simple and convenient to maintain, improves the use adaptation and the dust collection efficiency and prolongs the service lives of the filter bags. The air box pulse bag dust collector can be used for treating dust-containing gas with common concentration and dust-containing gas with the concentration of 1000g / Nm.

Owner:NANTONG AORUN BUILDING MATERIAL TECH

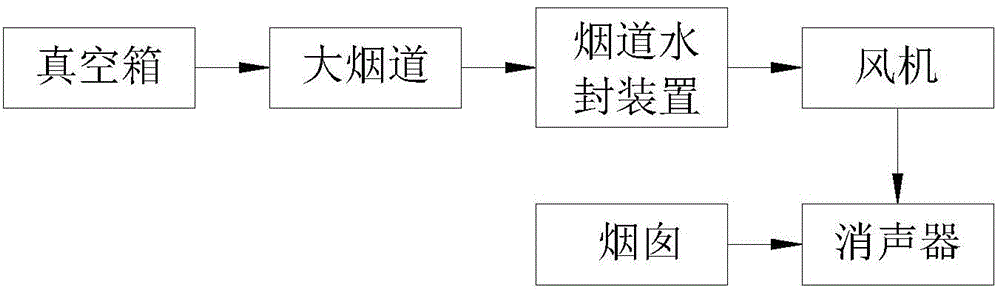

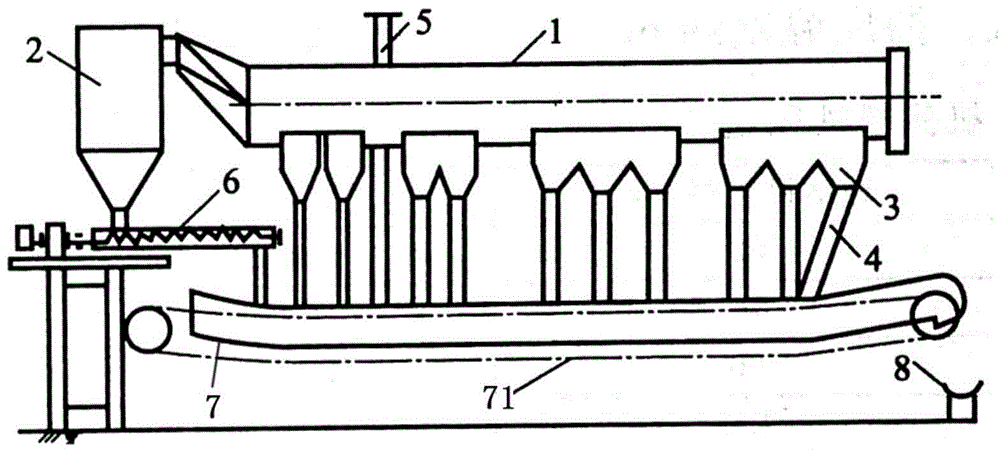

Sintering smoke dust treating device

InactiveCN104399335AImprove sealingAvoid secondary flyingCombination devicesUsing liquid separation agentPulp and paper industryBelt conveyor

The invention discloses a sintering smoke dust treating device. The sintering smoke dust treating device comprises a vacuum box, a large flue, a fan, a silencer, a flue water sealing device, a water-sealed chain-driving machine and a belt conveyor, wherein the output end of the vacuum box is connected with the input end of the large flue; the output end of the large flue is connected with the input end of the fan; the output end of the fan is connected with the input end of the silencer; the flue water sealing device is connected between the large flue and the fan and comprises a flue body; an ash collecting hopper is arranged on the circumferential wall surface of the flue body and communicated with the flue; the other end of the ash collecting hopper is connected with one end of an ash discharging pipe; the output end of the water-sealed chain-driving machine is positioned above the belt conveyor; the water-sealed chain-driving machine consists of a water tank and a zipper; the zipper is mounted at the bottom of the water tank; the other end of the ash discharging pipe is inserted into the water tank of the water-sealed chain-driving machine. According to the device, the treatment efficiency of the smoke dust of fume passing through the flue is improved, and the phenomenon of valve sticking is avoided.

Owner:CHANGZHOU CHANGLONG INFORMATION TECH

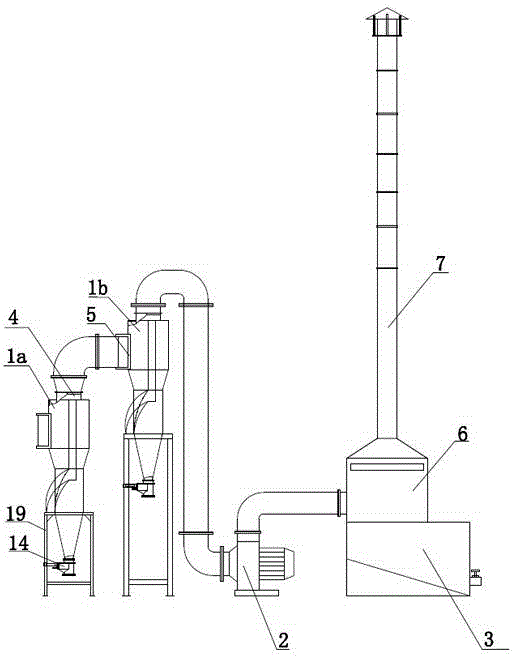

Reclaimed sand dedusting system

InactiveCN104587776AAvoid secondary flyingGuaranteed dust removal performanceCombination devicesCycloneEngineering

The invention provides a reclaimed sand dedusting system which can effectively purify dust-containing gas, has good dedusting effect and carries out further treatment on purified gas so as to prevent dust-containing gas from secondary diffusion, which is beneficial for environmental protection. The reclaimed sand dedusting system is characterized in that the reclaimed sand dedusting system comprises cyclone dusters, an exhaust fan and a pool which are sequentially connected through pipelines; at least two cyclone dusters are arranged and are connected with each other in series, and a discharge pipe of the front cyclone duster is connected with an air inlet pipe of the rear cyclone duster; an outer cover is arranged above the pool; and the top of the outer cover is connected with a chimney.

Owner:WUXI KANGHUI MACHINE BUILDING

Anode slotting method

ActiveCN104760068BReduce adverse effectsEliminate congestionMetal working apparatusWorking environmentPulp and paper industry

The invention provides an anode slotting method. The anode slotting method comprises the following steps of 1 using an input roller way to convey a calcinated anode carbon block to a slotting position of a slotting machine, 2 using an amplitude-limiting filtering method to eliminate an interference signal, 3 pressing down and fixing the calcinated anode carbon block by means of a pressing device of the slotting machine, 4 using a frequency converter to adjust the rotation speed of a cutter motor from 1200-1300 turns / minute to 900-1000 turns / minutes, 5 using a lifting motor to lift a cutter rest and slotting the bottom of the calcinated anode carbon block, 6 using the input roller way to convey the slotted calcinated anode carbon block to a carbon block shunting position of the input roller way after slotting, 7 adding a connecting roller way connected with the input roller way and an output roller way at the carbon block shunting position and arranging an air cylinder on the connecting roller way. Compared with the relevant arts, the anode slotting method has the advantages that the slotted anode carbon block is better in quality, higher in slotting efficiency and better in working environment.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

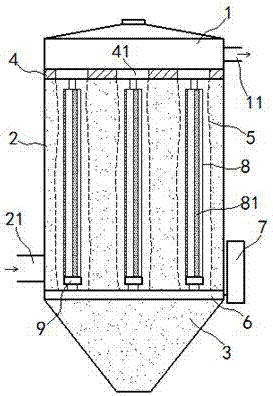

Double barrel dust collector

InactiveCN105582769BAvoid secondary flyingReduce wind speedCombination devicesEngineeringElectrostatic generator

The invention relates to a double-cartridge filter. The double-cartridge filter comprises a top cover, a purification chamber, a dust removal chamber and an ash hopper, wherein an air inlet pipe is mounted on the side wall of the dust removal chamber, and an air outlet pipe is mounted on the side wall of the purification chamber; the purification chamber and the dust removal chamber are isolated by a porous plate; cartridges are mounted at pores of the porous plate, upper ends of the cartridges are sealed and fixed with the pores of the porous plate, and the lower ends are fixed on a support reticular plate; the support reticular plate is fixed between the dust removal chamber and the ash hopper; an electrostatic generator is further mounted outside the dust removal chamber and comprises a reversing switch; electrostatic tubes are coaxially arranged in the cartridges, and lower ends of the electrostatic tubes are mounted on the support reticular plate; the electrostatic tubes are electrically connected with the electrostatic generator. The double-cartridge filter can promote dust to be attached to the cartridges rapidly, realizes efficient dust removal and can clean ash simply and rapidly.

Owner:TAIZHOU AODE FURNITURE ACCESSORIES

Split-type pulse dust collector for drying and burning sludge

InactiveCN102107107BExtended service lifeGuaranteed flatnessDispersed particle filtrationControl systemSludge

The invention relates to a split-type pulse dust collector for drying and burning sludge, which comprises an upper box body, a lower box body and a control system, wherein the upper box body comprises at least one filtering unit; the filtering unit comprises a purified gas chamber arranged in the upper layer, a filtering chamber arranged in the lower layer and a porous plate spacer arranged at the middle; a bypass channel is arranged inside the upper box body; the bypass channel extends out of the upper box body and is communicated with the external air through a by-pass valve; the by-pass valve plays the role of protecting against high temperature; the lower box body comprises an ash bu0063ket and a material bin; a vibrating and beating device is arranged inside the ash bucket; and the control system comprises a power control box and a power supply inlet. With the structure, the invention has the characteristics that: the split-type pulse dust collector for drying and burning sludge is convenient for installation, removes the ash completely, improves the seal performance, reduces the oxygen content, prolongs the service life of the filter bags, achieves the reasonable distribution of the filter bags, avoids the problem of bridging deposition of ashes inside the ash bucket during the use, and allows the by-pass valve and the lifting valve to be closed tightly. Besides, the split-type pulse dust collector for drying and burning sludge has the high temperature protection function.

Owner:JIANGSU WEITONG ELECTRICAL EQUIP

An ultra-low emission absorption tower

ActiveCN104958999BReduce escapeReduce the amount of slurry carriedUsing liquid separation agentFlue gasSlurry

The invention discloses an ultra-low emission absorption tower, which comprises an absorption tower body, a mist eliminator, a spray layer and a slurry pool, the slurry pool is arranged at the bottom of the absorption tower body, and the mist eliminator is arranged at the upper part of the absorption tower body , the spray layer is set under the demister, the bottom of the lowest spray layer is provided with a slurry distribution plate; the bottom of each spray layer is equipped with a slurry guide ring; the demister is composed of three sets of roof-type defogging It consists of a demister and a set of tube type demisters. The tube type demisters are located below the ridge type demisters on the lowest level, and there is a condensation and system. The invention can remove fine dust with small particle size in the flue gas of the power plant, effectively increase the spray coverage, and increase the SO in the flue gas. 2 It can effectively prevent the wear of the inner wall of the absorption tower body, and at the same time guide the flue gas to make the flue gas flow to the spray intensive area and reduce the pressure loss at the side wall.

Owner:CHINA HUADIAN ENG +1

Magnetized foam dust collector with recyclable foam liquid and method of using the same

InactiveCN106014470BAvoid secondary flyingImprove utilization efficiencyUsing liquid separation agentDust removalPipetteWorking environment

A magnetized foam dust remover with recyclable foam liquid and its use method. The magnetized foam dust remover includes an air guide tube, and a foaming agent storage tank is arranged on the outside of the air guide tube. The foaming agent storage tank passes through a first liquid suction pipe and The two-stage proportional mixer is connected, the two-stage proportional mixer is connected to the self-priming magnetic foamer, and the self-priming magnetic foamer is connected to the nozzle or / and the drainage screen through the magnetic foam transfer pipe, and the drainage screen There is an ultrasonic defoamer behind the ultrasonic defoamer, a screw extruder under the ultrasonic defoamer, and a recovery liquid storage tank under the screw extruder, which is connected to a two-stage proportional mixer. The magnetized foam produced by the invention can capture the dust in the dust-laden airflow, and can realize the separation of the dust-liquid of the dust-laden foam liquid. After the dust is enriched, it can be stored in a centralized manner, and the foam liquid can be further recycled, avoiding the secondary flying of the dust. It can improve the utilization efficiency of the blowing agent, effectively reduce the operation cost of the device, and avoid the adverse effect of random discharge of foam on the working environment.

Owner:LIAONING TECHNICAL UNIVERSITY

an electric dust collector

ActiveCN102728471BReduce depositionEmission reductionElectrostatic separation detailsElectricityEngineering

Owner:FUJIAN LONGKING

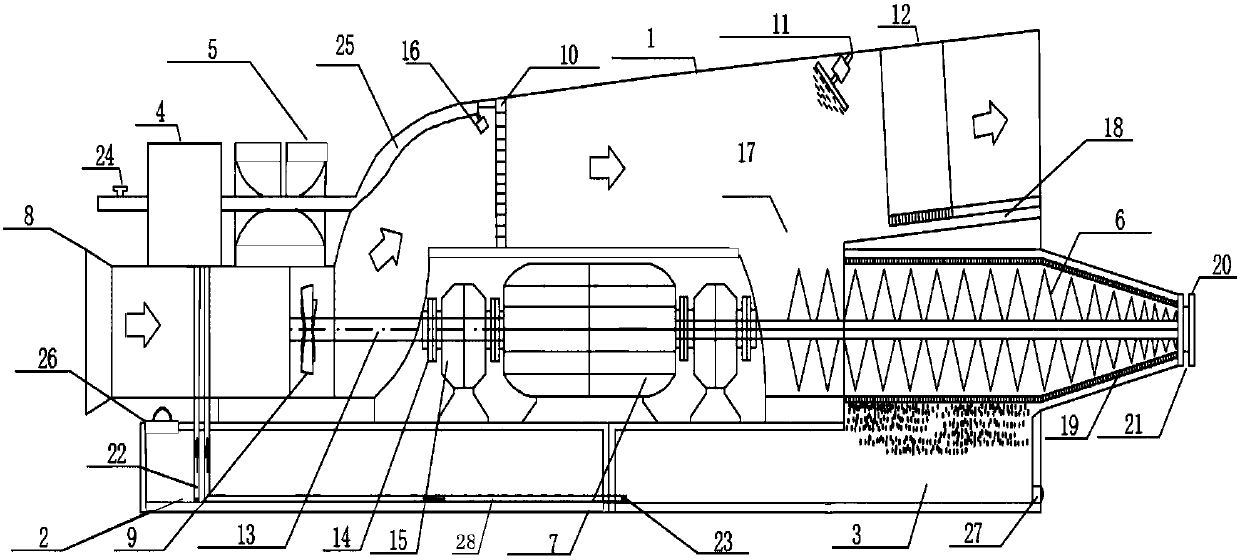

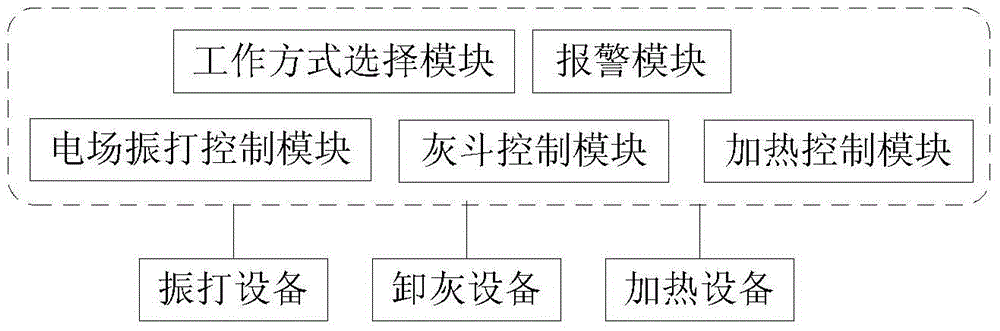

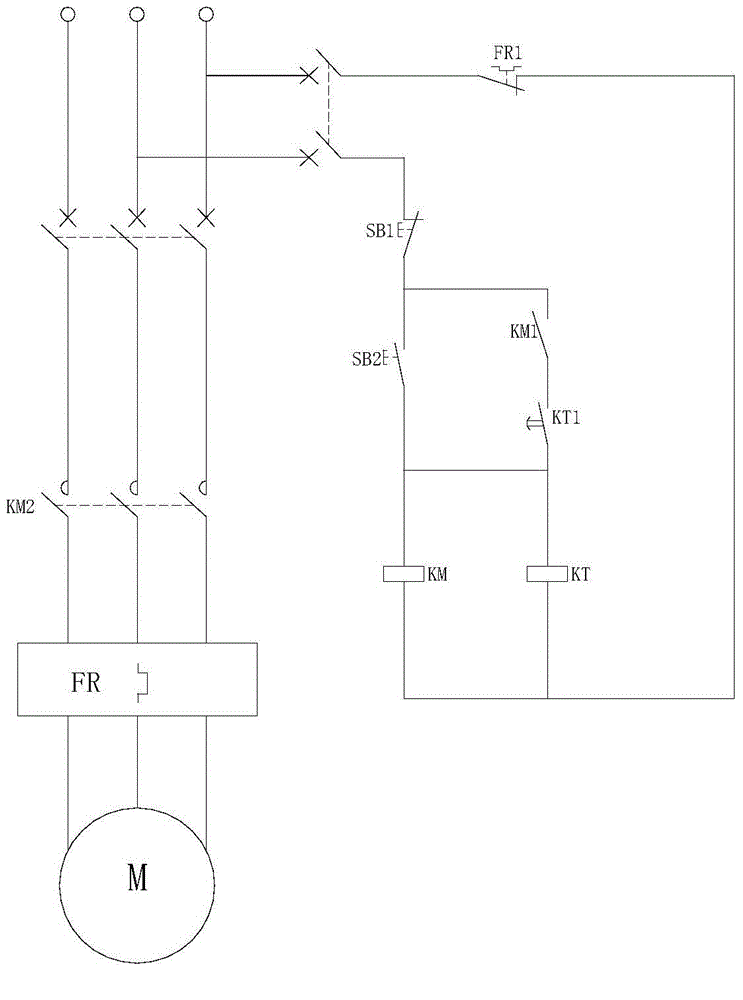

ILC single-field low-voltage control system

InactiveCN104549756ARational programmingAvoid secondary flyingElectric supply techniquesStopped workVibration control

The invention discloses an ILC single-field low-voltage control system. The ILC single-field low-voltage control system comprises an electric field vibration control module, an ash hopper control module, a heating control module, a working mode selection module and a warning module, wherein the electric field vibration control module is connected with vibration equipment and is used for controlling the vibration time sequence of an electric field; the ash hopper control module is connected with ash unloading equipment and is used for controlling the working process of an ash hopper; the heating control module is connected with heating equipment and is used for controlling the heating temperature and the heating process; the working mode selection module is connected with the vibration equipment, the ash unloading equipment and the heating equipment and is used for selecting the automatic, manual and stop working modes of the vibration equipment, the ash unloading equipment and the heating equipment; the warning module is connected with the vibration equipment, the ash unloading equipment and the heating equipment, and is used for warning when the vibration equipment, the ash unloading equipment and the heating equipment break down. The ILC single-field low-voltage control system can conveniently realize reasonable programming of the vibration time sequence of the electric field, so that secondary fly-up is avoided, and the dust collection efficiency is improved.

Owner:大连德维电子科技有限公司

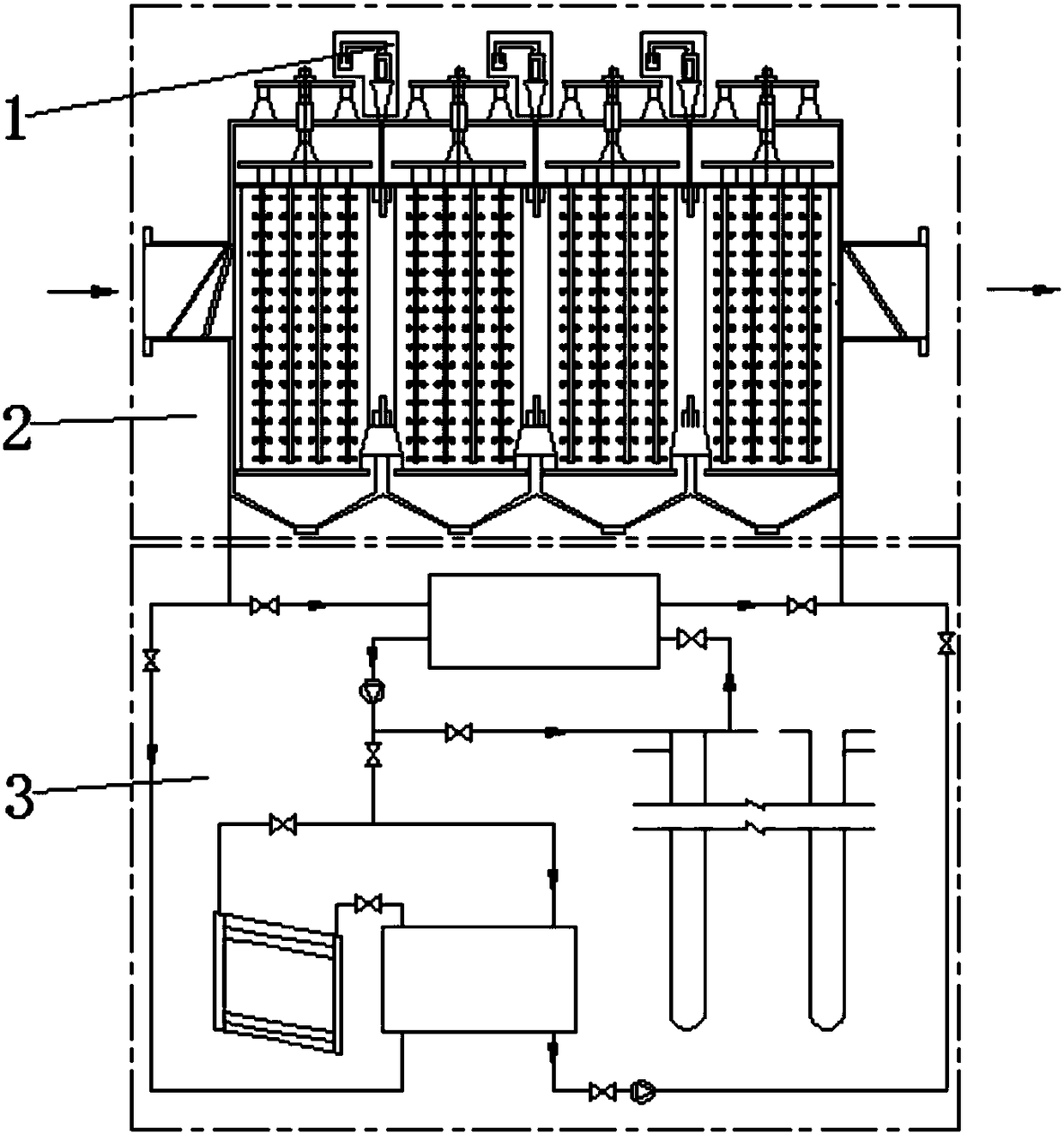

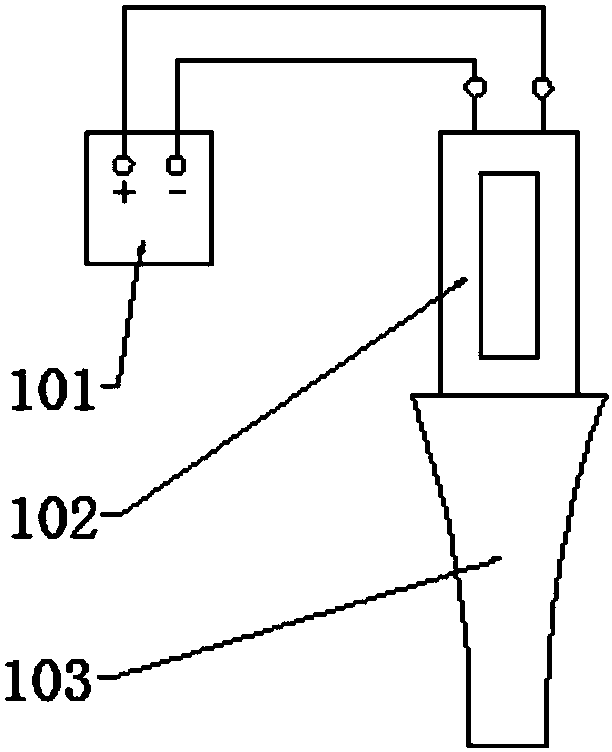

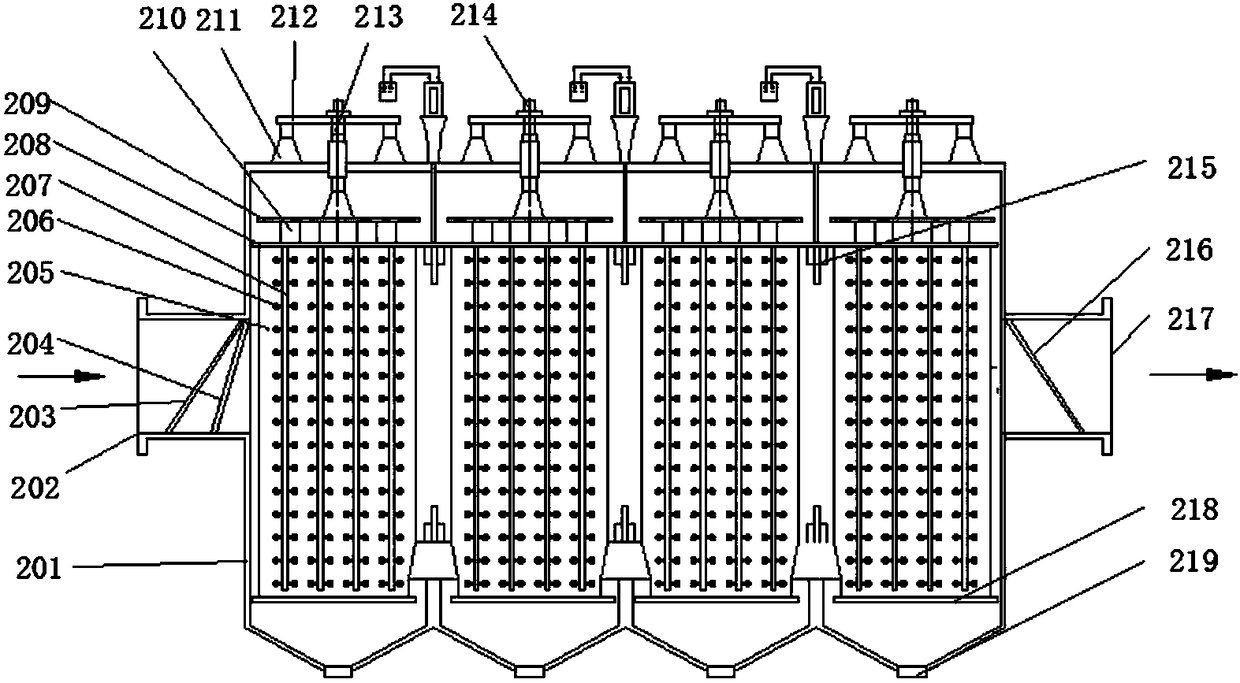

Ultrasonic nano-biology self-cleaning-type joint heat-insulation film static dust removal device

InactiveCN108160327ALow costLight in massElectrode constructionsElectrodes cleaningJoint heatUltrasonic vibration

An ultrasonic nano-biology self-cleaning-type joint heat-insulation film static dust removal device is characterized in that the ultrasonic nano-biology self-cleaning-type joint heat-insulation film static dust removal device comprises an ultrasonic vibration system (1), a dust removal system (2) and a heat insulation system (3); the dust removal system (2) comprises an inlet (202), an outlet (217), a dust discharging opening (219) and a shell (201); the ultrasonic vibration system (1) is used for enabling dust collected by a circular dust collecting pole (205) to fall into the dust discharging opening (219) in a vibrated mode, the ultrasonic vibration system (1) is mounted on the upper portion of the dust removal system (2) and connected with a dust collecting pole upper portion support (208) through a magnitude-variable rod (103), and the magnitude-variable rod transmits ultrasonic vibration to the circular dust collecting pole (205) through the dust collecting pole upper portion support (208); and heat insulation system (3) is used for enabling the dust removal system (2) to be in a constant-temperature work state so as to ensure the stability of the dust removal efficiency. Theultrasonic nano-biology self-cleaning-type joint heat-insulation film static dust removal device is simple in structure, good in dust removal effect and convenient to clean.

Owner:JIANGSU DONGZE ENVIRONMENTAL PROTECTION TECH

Flue water sealing device

The invention discloses a flue water sealing device which comprises a flue body. A dust collecting bucket is arranged on the circumferential wall face of the flue body. The dust collecting bucket is communicated with a flue, and the other end of the dust collecting bucket is connected with one end of a dust discharging pipe. The flue water sealing device further comprises a water sealing zipper machine and a belt conveyor. The output end of the water sealing zipper machine is located above the belt conveyor, and the water sealing zipper machine is composed of a water groove and a zipper. The zipper is installed at the bottom of the water groove, and the other end of the dust discharging pipe is inserted in the water groove of water sealing zipper machine. The processing efficiency of dust of smoke in the flue is improved, and therefore the phenomenon of clamping of a valve is avoided.

Owner:常州市苏三零工具有限公司

Method for utilizing bauxite dust

The invention relates to a method for utilizing bauxite dust produced during the aluminum oxide producing process by an ore dressing Bayer method, comprising the following steps of mixing the bauxite dust with the overflow water of a concentrate thickener to obtain the slurry with a certain concentration; after the slurry is mixed with the overflow of a second-grade grader in grinding process according to a certain rate, adding regulator, dispersant and collecting agent to the obtained slurry according to the requirements; and then obtaining the concentrate and tailings after the operations of coarsely scavenging for one time, finely scavenging for two times and scavenging (coarsely scavenging and finely scavenging). The method of the invention prevents the raw ore dust from secondarily flying, overcomes the argillization phenomenon of dramatically grinding the raw ore dust, optimizes the flotation work environment of the bauxite, and improves the selection index.

Owner:中铝中州铝业有限公司

Decoration cutting dust environmental protection mobile collection box

ActiveCN108636005BThe dragging process is smoothAvoid secondary flyingUsing liquid separation agentWorking accessoriesStructural engineeringBin bag

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

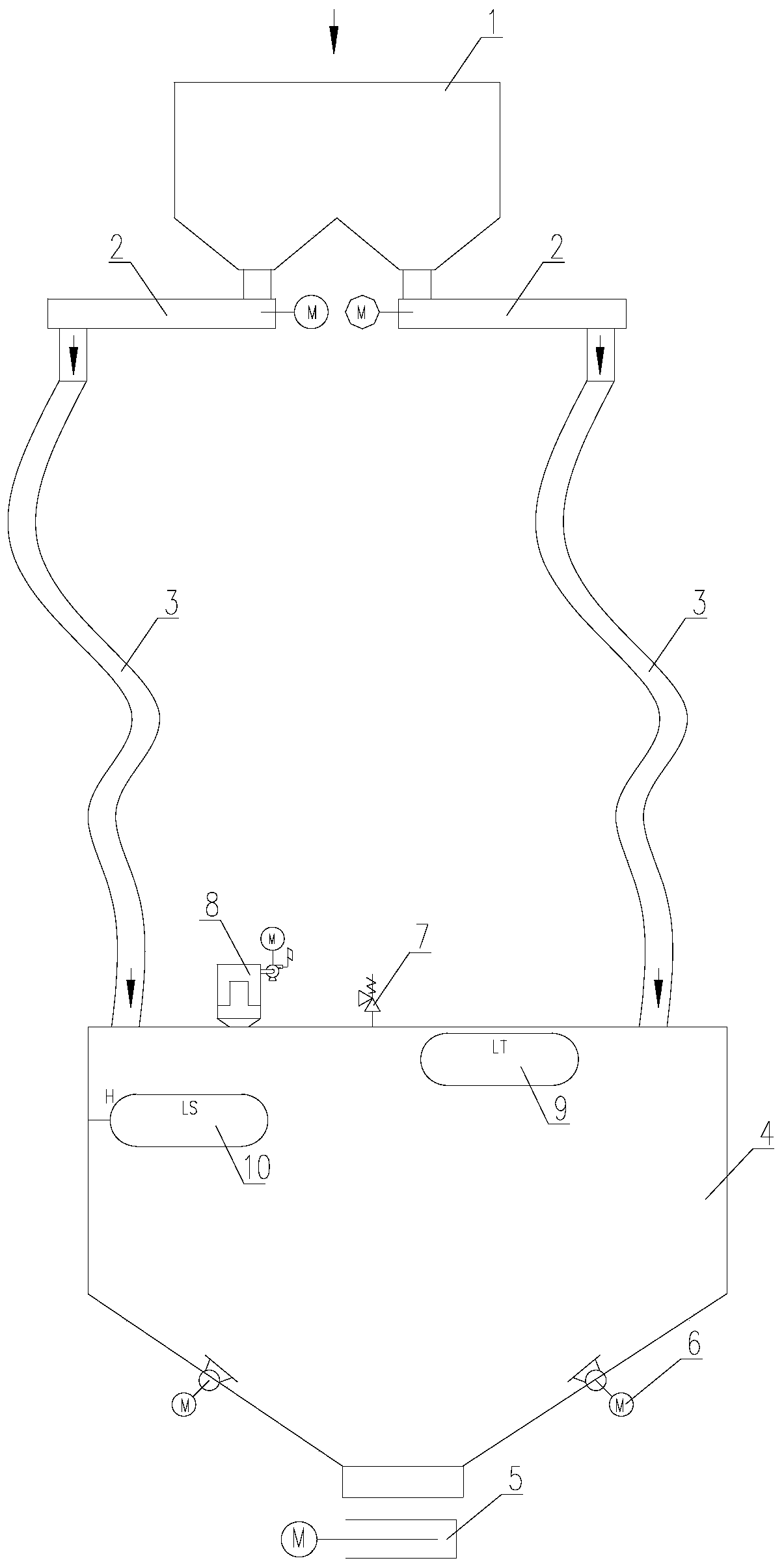

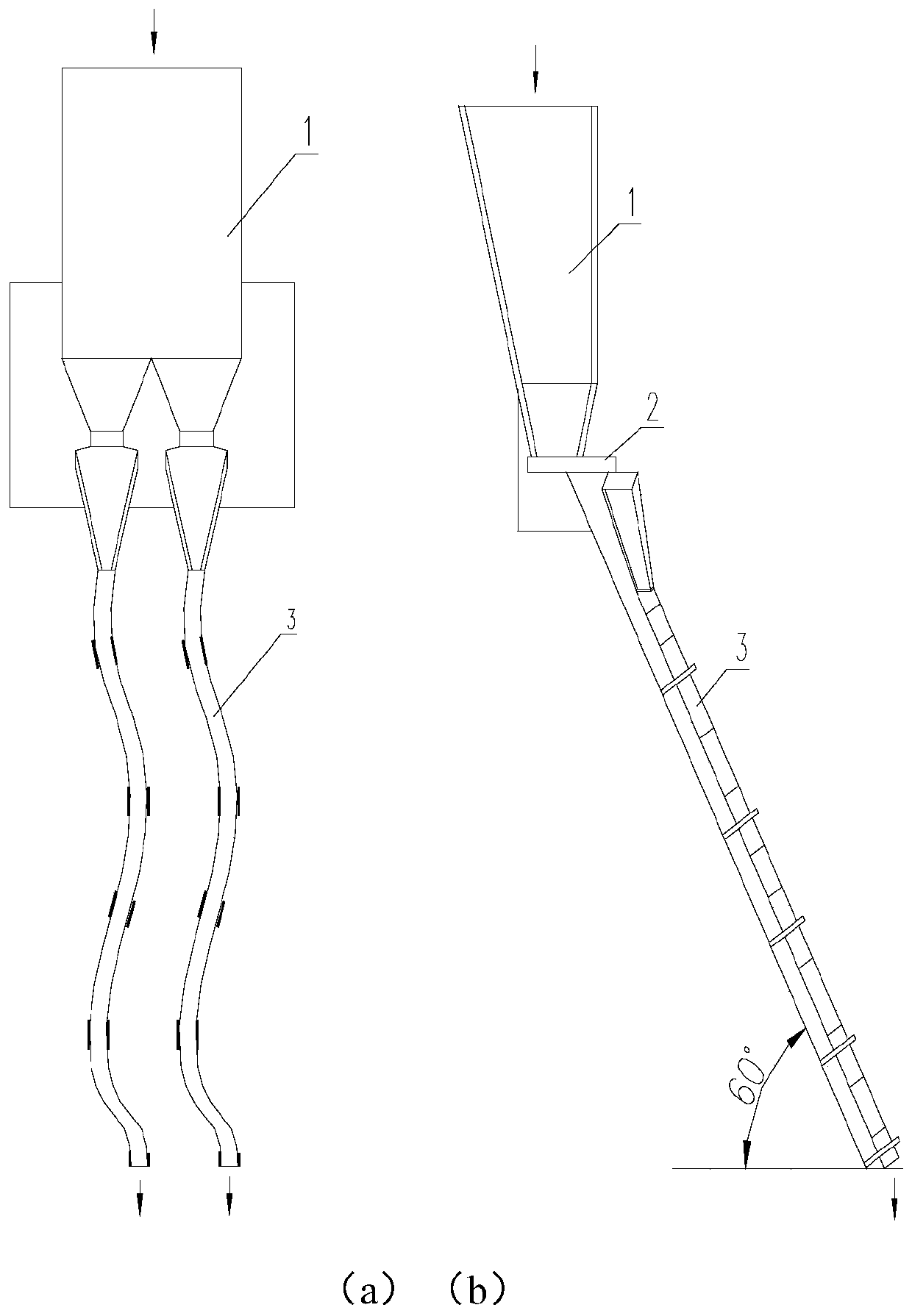

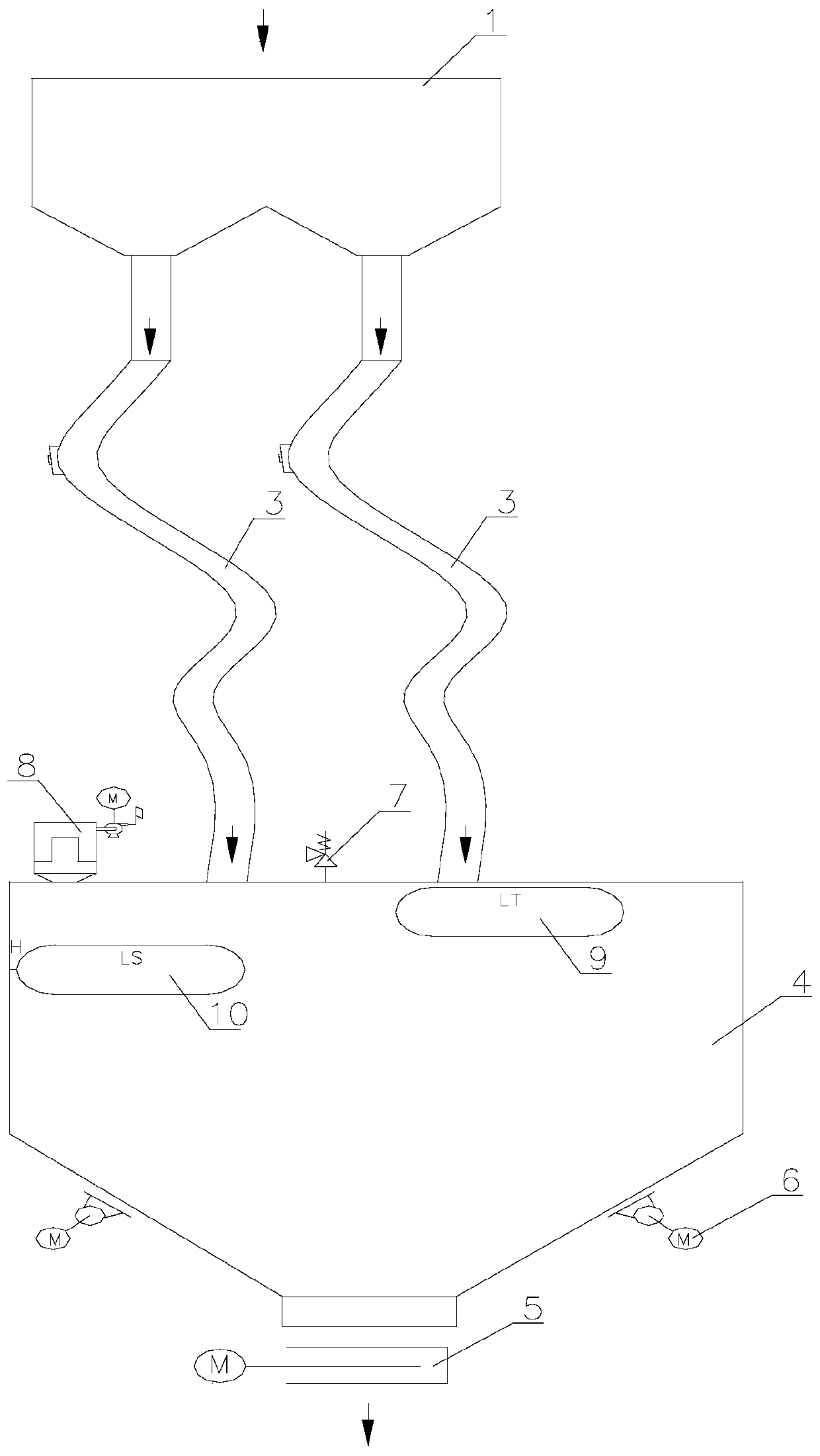

Ash unloading device for large drop ash field

PendingCN110562771AAvoid stickingSolution to short lifeLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses an ash unloading device for a large drop ash field, and belongs to the field of ash conveying. The ash unloading device for the large drop ash field comprises a material receiving hopper, wherein the discharging opening of the material receiving hopper is provided with a curved ash conveying pipe, the discharging opening of the curved ash conveying pipe is provided with a closed material bin, the closed material bin comprises a cylindrical upper end and an inverted circular truncated cone-shaped contractable end, and an ash unloading valve is arranged at the bottom of the contractable end. When ash material in the material receiving hopper falls into the curved ash conveying pipe, the ash material falls under the action of gravity and is continuously accelerated, the fallen ash material continuously impacts the inner wall of the curved ash conveying pipe due to the existence of the curved ash conveying pipe, the deceleration effect is achieved, and the ash material falling speed is controlled; the device is of a fully closed structure, and thus the occurrence of the flying ash condition generated in the ash unloading process is avoided; and on the other hand, due to the existence of the curved ash conveying pipe, the fallen ash material continuously impacts the inner wall of the curved ash conveying pipe, the deceleration effect is achieved, the fallingspeed of the ash material is controlled, so that the source for generating flying ash is further reduced, and secondary flying, caused by too fast speed during ash unloading and conveying, of the ashis prevented.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

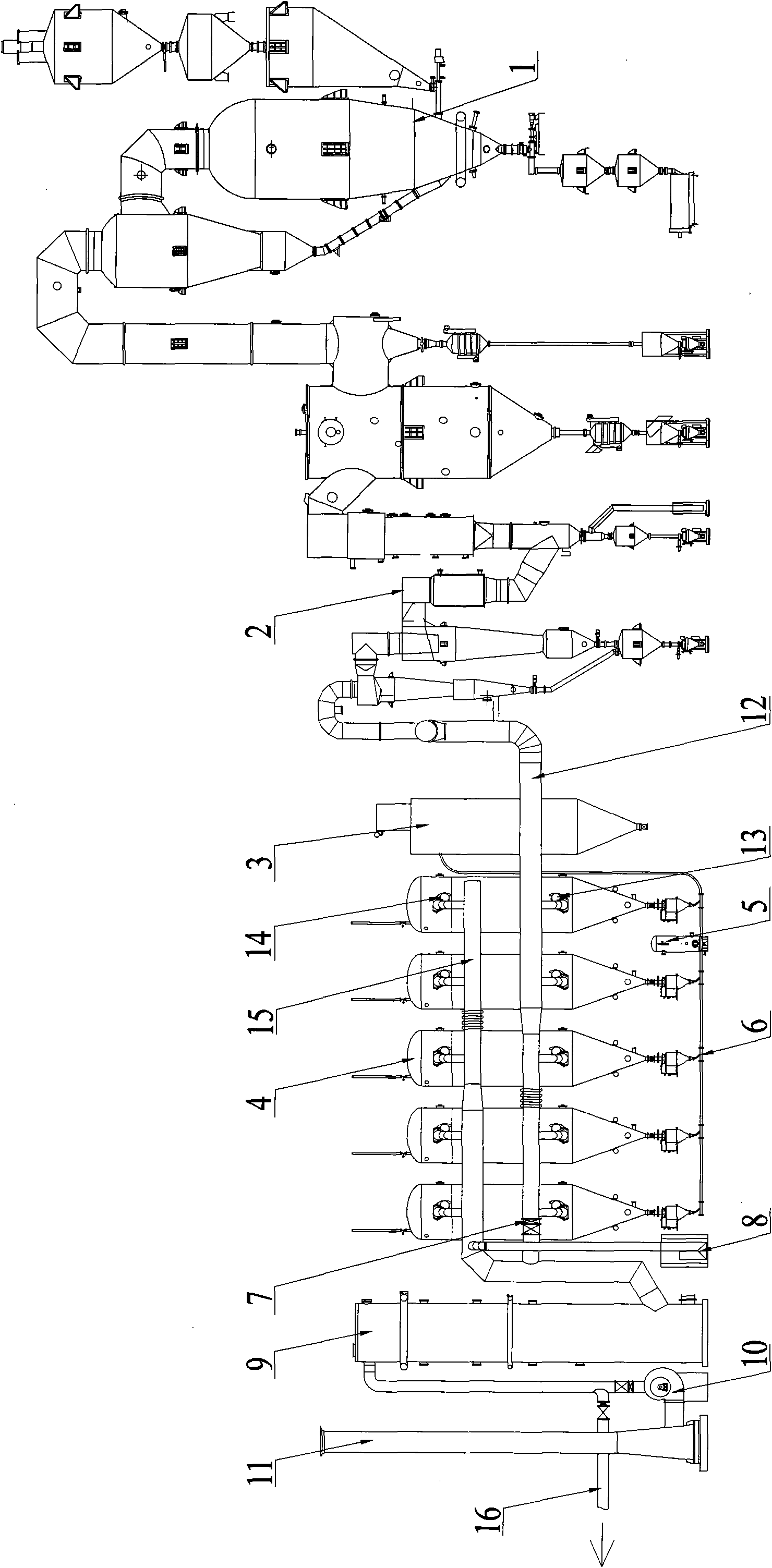

Dry-method bag-type gas purification device for coal gas of coal gasifier

ActiveCN101831324BEliminate consumptionEliminate generationEnergy inputGas purification by liquid washingNitrogenProcess engineering

The invention relates to a dry-method bag-type gas purification device for coal gas of a coal gasifier. The adopted technical scheme is as follows: the coal gasifier is connected with a waste heat recoverer, the waste heat recoverer is connected with a raw gas pipeline, the raw gas pipeline is communicated with a low-pressure pulse bag-type dust collector, the other end of the raw gas pipeline iscommunicated with a clean gas pipeline through a by-pass valve assembly, the low-pressure pulse bag-type dust collector is communicated with the clean gas pipeline, the clean gas pipeline is providedwith a gas water sealer, the clean gas pipeline is connected with a spraying and washing tower, the spraying and washing tower is connected with a furnace starting and stopping diffusing tower through a furnace starting and stopping fan, a pipeline between the spraying and washing tower and the furnace starting and stopping fan is connected with a system pipe network, the low-pressure pulse bag-type dust collector is connected with a pneumatic ash conveying device, the pneumatic ash conveying device is connected with a master ash bin, and a nitrogen preheating device is respectively connectedwith the low-pressure pulse bag-type dust collector and the pneumatic ash conveying device. The device protects the environment, has good gas purification effect, saves energy, has low cost and is safe.

Owner:HUANYU PURIFYING ENG EQUIP MFG DASHIQIAO CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com