Rotary ash eliminator of circular pipe electro-precipitator

A technology of electrostatic precipitator and ash cleaning device, which is applied in electrode cleaning, electrostatic separation and other directions, can solve the problems of affecting the service life of electrostatic precipitator, high mechanical vibration and noise, and short service life of rapping device. Anti-corona phenomenon, avoid secondary flying, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

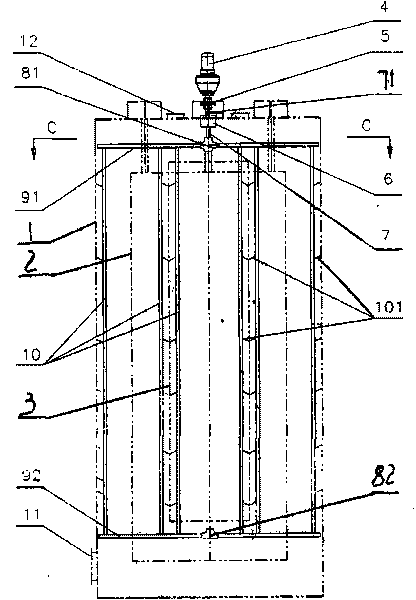

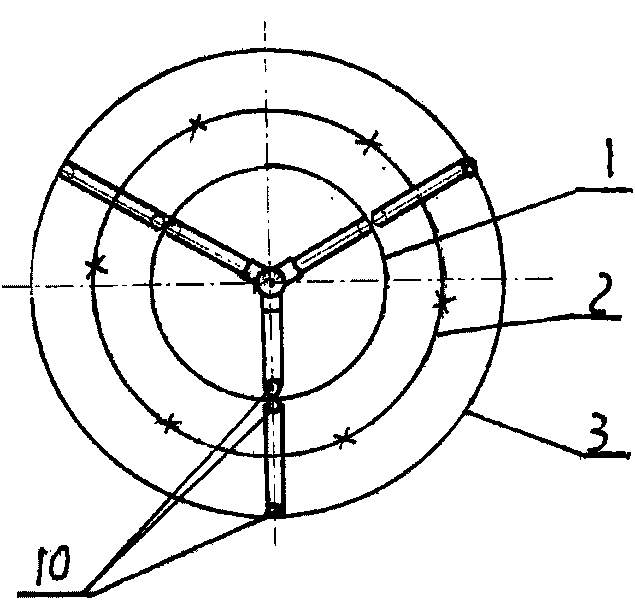

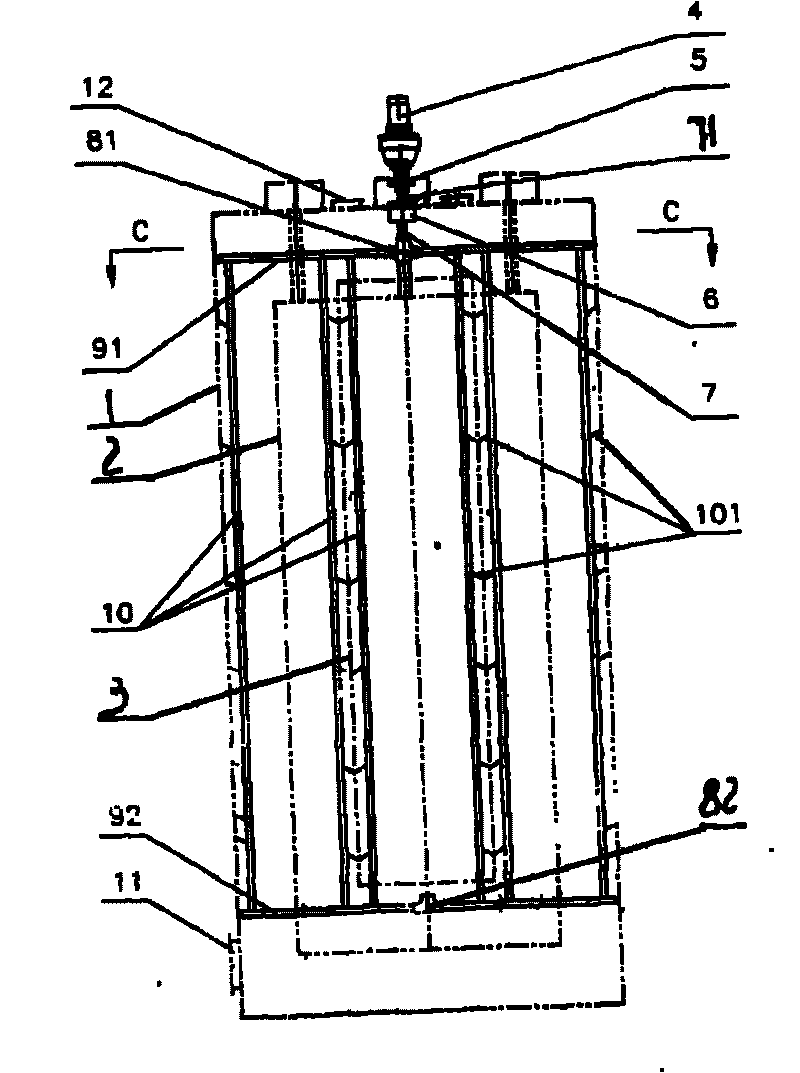

[0008] like figure 1 , 2 As shown, the rotary dust cleaning device of the circular tube electrostatic precipitator includes an outer anode cylinder 1 with an air inlet 11 at the bottom and an air outlet 12 at the top and a cylindrical cathode wire frame 2 suspended in the outer anode cylinder And the inner anode cylinder 3, the top of the outer anode cylinder is centered with a vertical motor 4, the output shaft of the vertical motor is connected to the main shaft 7 through the coupling 5, and the main shaft is vertically suspended outside the anode cylinder through the bearing 6 fixed in the middle of the top plate of the outer anode cylinder In the anode cylinder, the main shaft suspended in the outer anode cylinder is connected with a rotary mechanism composed of an upper triple sleeve and a lower triple sleeve, an upper rotary arm, a lower rotary arm and a row of cleaning rods. The upper and lower triple sleeves 81, 82 are respectively provided with three sleeves at 120 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com