Anode slotting method

A slotting method and anode technology, applied in the field of anodes, can solve problems such as affecting slotting efficiency, too fast cutter motor speed, and poor working environment, so as to shorten the time of entering the output roller table, have obvious shunt effects, and eliminate adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

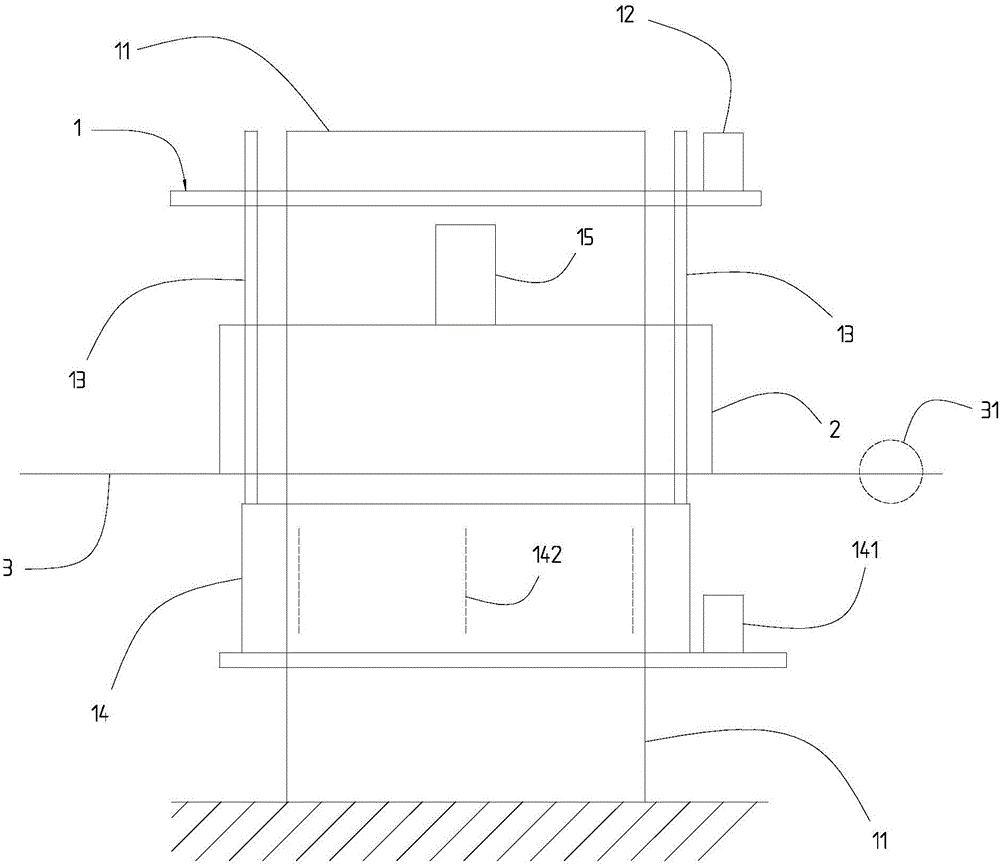

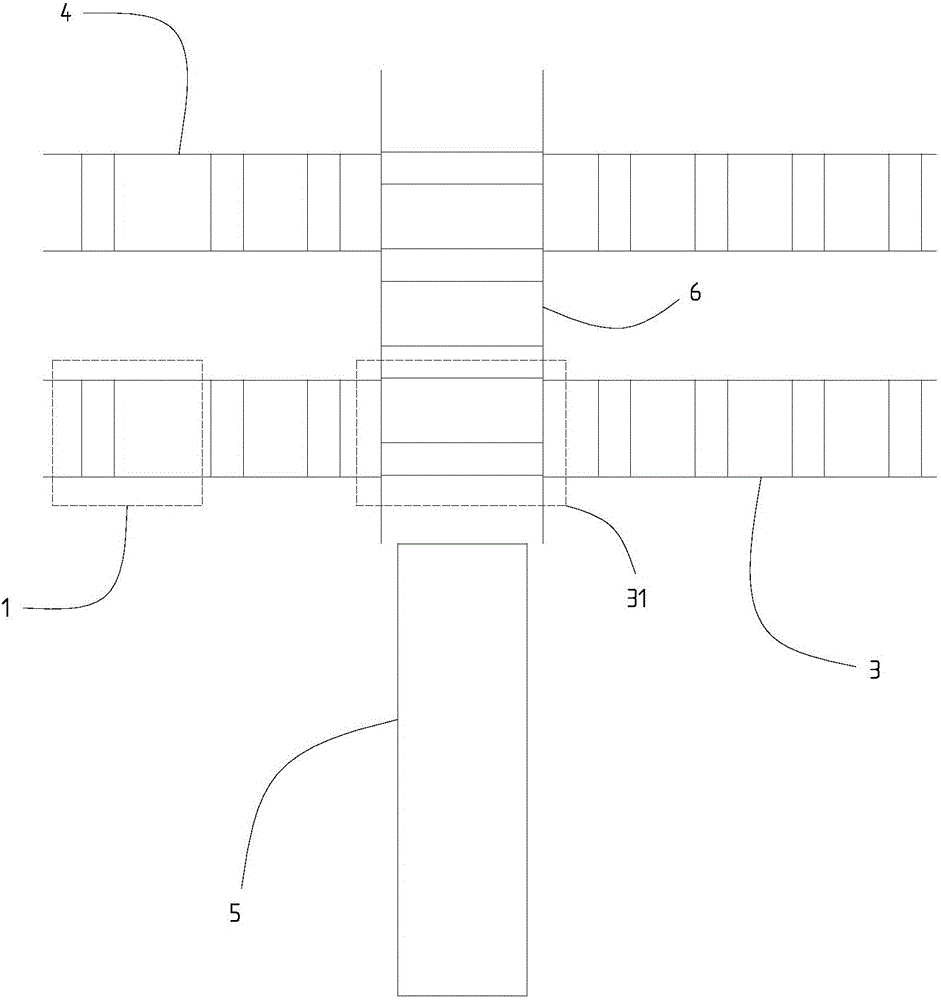

[0019] Such as figure 1 Shown, a kind of anode slotting method of the present invention comprises the following steps:

[0020] Step 1, providing the anode carbon block 2 after roasting, slotting machine 1, input roller table 3 and output roller table 4 connected in parallel with input roller table 3, slotting machine 1 includes frame 11, and is fixed on frame 11 Elevate motor 12 and hold-down device 15, tool rest 14 and the connecting rod 13 that is respectively fixed on the top two ends of tool rest 14, lift motor 12 controls the rise and fall of tool rest 14 by two connecting rods 13, is fixed on the cutter rest 14 A plurality of blades 142 and a cutter motor 141 that controls the rotation of the blades, the rotating speed of the cutter motor 141 is 1200 to 1300 rpm;

[0021] Step 1, using the input roller table 3 to transport the roasted anode car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com