Double barrel dust collector

A dust collector and dual-cylinder technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of secondary large-scale dust raising, low dust removal efficiency, large air consumption, etc., and achieve high dust removal efficiency. , Easy to operate, to prevent the effect of secondary flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

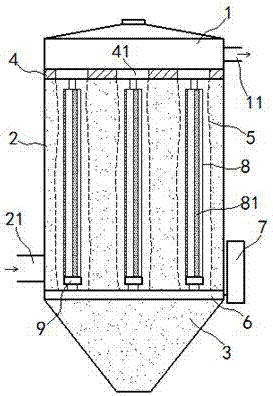

[0012] exist figure 1 In the shown embodiment, the double cylinder dust collector includes a roof, a clean room 1, a dust removal room 2 and an ash hopper 3; an air inlet pipe 21 is installed on the side wall of the dust removal room 2, and An outlet pipe 11 is installed on the side wall of 1; the dust removal chamber 2 and the clean room 1 are separated by a flower plate 4; a filter cartridge 5 is installed at each flower plate hole 41 of the flower plate 4; the filter cartridge The upper end of 5 is sealed and fixed with the flower plate hole 41, and the lower end is fixed on the support screen 6; the support screen 6 is fixed between the dust removal chamber 2 and the ash hopper 3; 7, the electrostatic generator 7 includes a reverse switch; the coaxial device in each of the filter cartridges 5 has an electrostatic cylinder 8, and the lower end of each of the electrostatic cylinders 8 is installed on the support grid 6, and each A rotary motor 9 is also installed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com