An ultra-low emission absorption tower

An absorption tower and ultra-low technology, applied in the field of absorption towers, can solve the problems of not meeting ultra-low emission requirements, low dust removal efficiency of absorption towers, and excessive dust emission concentration, etc., to increase spray coverage, facilitate installation, reduce Effects of Repair and Replacement Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

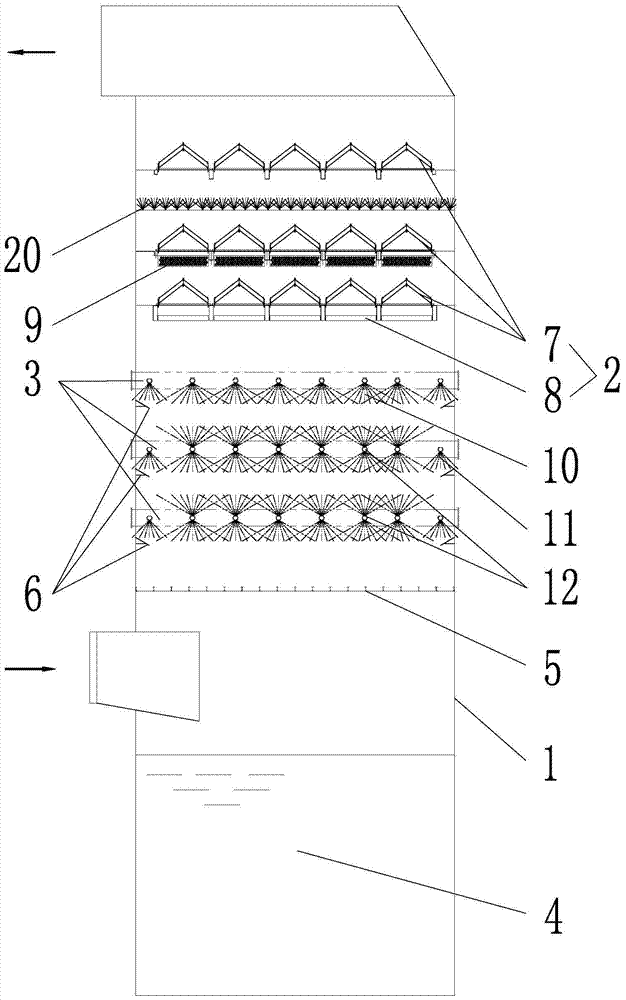

[0035] Embodiment 1 of the present invention: such as figure 1 As shown, an ultra-low emission absorption tower includes an absorption tower body 1, a mist eliminator 2, a spray layer 3, and a slurry tank 4. The slurry tank 4 is located at the bottom of the absorption tower body 1, and the mist eliminator 2 is located In the upper part of the absorption tower body 1, the spray layer 3 is arranged below the mist eliminator 2, and the lowermost spray layer 3 is provided with a slurry distribution plate 5; each spray layer 3 is provided with a slurry diversion Ring 6; Demister 2 is composed of three sets of roof-type mist eliminators 7 and a set of tube-type mist eliminators 8. The tube-type mist eliminators 8 are located under the lowest roof-type mist eliminators 7, and the lowest roof-type mist eliminators A condensation system 9 is provided between the mist eliminator 7 and the roof-type mist eliminator 7 in the middle layer. The spraying layer 3 has more than two layers, and ...

Embodiment 2

[0040] Embodiment 2 of the present invention: such as figure 1 As shown, an ultra-low emission absorption tower includes an absorption tower body 1, a mist eliminator 2, a spray layer 3, and a slurry tank 4. The slurry tank 4 is located at the bottom of the absorption tower body 1, and the mist eliminator 2 is located In the upper part of the absorption tower body 1, the spray layer 3 is arranged below the mist eliminator 2, and the lowermost spray layer 3 is provided with a slurry distribution plate 5; each spray layer 3 is provided with a slurry diversion Ring 6; Demister 2 is composed of three sets of roof-type mist eliminators 7 and a set of tube-type mist eliminators 8. The tube-type mist eliminators 8 are located under the lowest roof-type mist eliminators 7, and the lowest roof-type mist eliminators A condensation system 9 is provided between the mist eliminator 7 and the roof-type mist eliminator 7 in the middle layer. The spraying layer 3 has more than two layers, and ...

Embodiment 3

[0045] Embodiment 3 of the present invention: figure 1 As shown, an ultra-low emission absorption tower includes an absorption tower body 1, a mist eliminator 2, a spray layer 3, and a slurry tank 4. The slurry tank 4 is located at the bottom of the absorption tower body 1, and the mist eliminator 2 is located In the upper part of the absorption tower body 1, the spray layer 3 is arranged below the mist eliminator 2, and the lowermost spray layer 3 is provided with a slurry distribution plate 5; each spray layer 3 is provided with a slurry diversion Ring 6; Demister 2 is composed of three sets of roof-type mist eliminators 7 and a set of tube-type mist eliminators 8. The tube-type mist eliminators 8 are located under the lowest roof-type mist eliminators 7, and the lowest roof-type mist eliminators A condensation system 9 is provided between the mist eliminator 7 and the roof-type mist eliminator 7 in the middle layer. The spraying layer 3 has more than two layers, and the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com