Air box pulse bag dust collector

A dust collector and pulse technology, which is applied in the field of air box pulse bag dust collectors, can solve the problems of insufficient vehicle collection and secondary dust flying, and achieve the effects of increasing adaptability, long service life and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

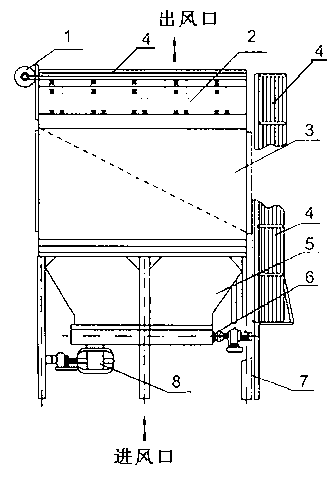

[0008] Such as figure 1 As shown, the air box pulse bag dust collector of the present invention includes a column (7), a box body (3) fixed on the upper part of the column (7), an ash hopper (5) fixed on the lower part of the column (7), and a box The air storage tank (1) connected to the body (3), a plurality of filter bags arranged in the box body (3), the poppet valve (2) connected to the filter bag, the impeller (8) connected to the ash hopper (5) ) and screw conveyor (6), guardrails (4) are provided on the outside of the column (7) and on the top of the box, and the filter bags and lift valves (2) are connected one by one.

[0009] The working method of the air box pulse bag dust collector of the present invention is as follows:

[0010] After the dust-laden gas enters from the air inlet and passes through the ash hopper (5), the large particles of dust in the airflow are separated by the inertial force and fall directly into the ash hopper (5), and the dust-laden gas pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com