Air box type pulse bag dust collector

A dust collector and air box-type technology, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as insufficient dust cleaning strength, improve dust collection efficiency, prolong service life, and expand applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

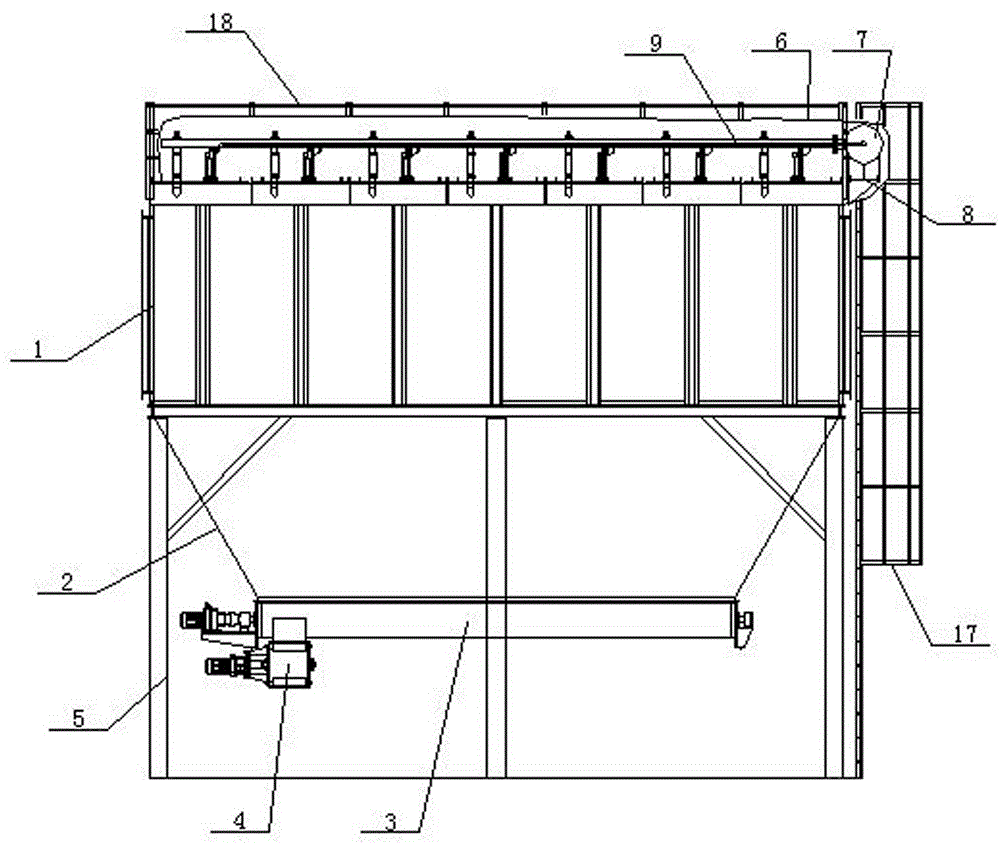

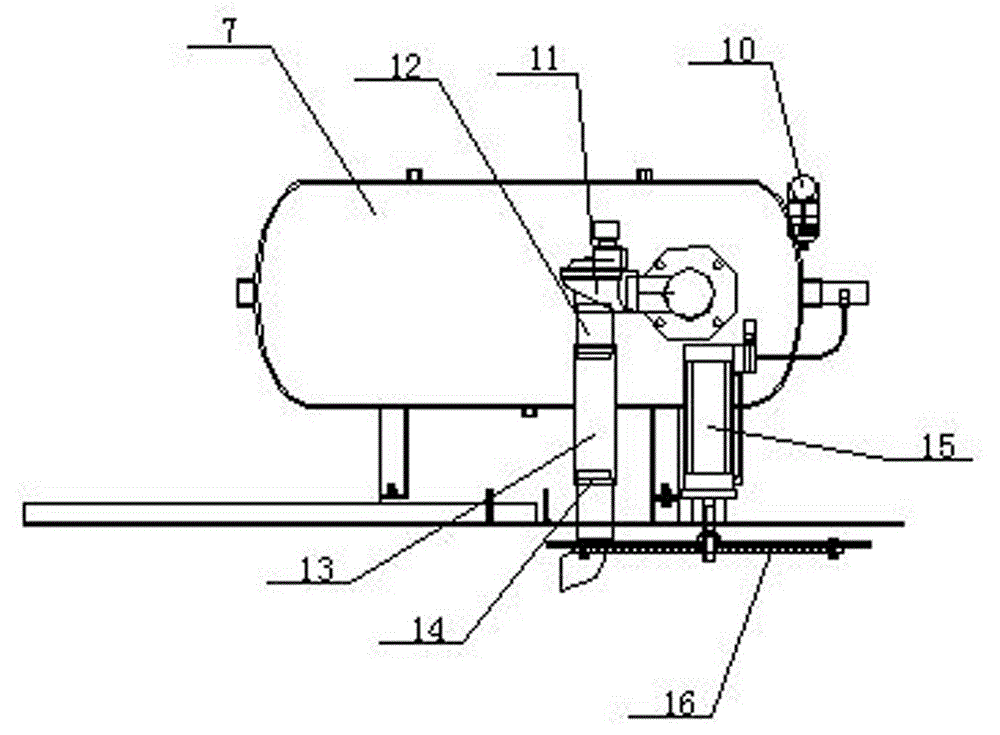

[0010] refer to figure 1 , figure 2 , the specific embodiment adopts the following technical solutions: an air box type pulse bag dust collector, which includes a dust collector box 1, a dust collecting bucket 2, a screw conveyor 3, an ash lowering valve 4, a bracket 5 and a pulse sprayer Blowing device 6, said pulse blowing device 6 includes air storage tank 7, air storage tank bracket 8, blowing pipe 9, air source part 10, electromagnetic pulse valve 11, non-standard joint 12, rubber tube 13, hoop 14 and Cylinder 15, the gas storage tank 7 is fixedly installed on the gas storage tank bracket 8, the gas storage tank 7 is provided with an air source part 10, and the gas storage tank 7 passes through the electromagnetic pulse valve 11, non-standard joint 12, rubber tube in turn 13 and the hoop 14 are connected with the blowing pipe 9, the cylinder 15 is connected with the air storage tank 7, and the bottom of the cylinder 15 is connected with a poppet valve plate 16.

[0011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com