Sintering smoke dust treating device

A technology for processing devices and dust, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc. It can solve problems such as valve jamming, difficulty in ash unloading, and reduction of flue dust suppression, so as to achieve reliable sealing and prevent secondary pollution. The effect of flying and reducing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

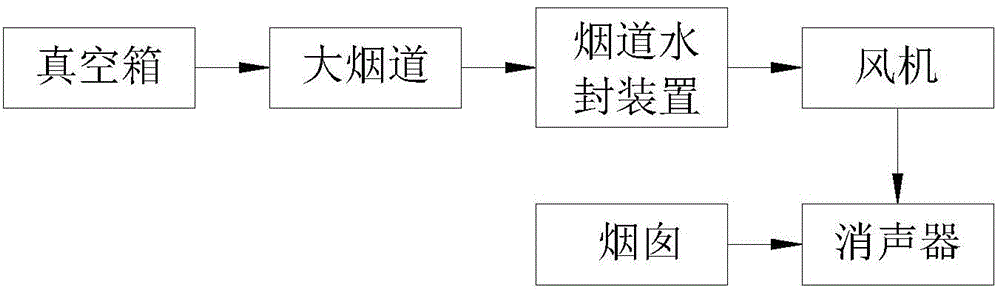

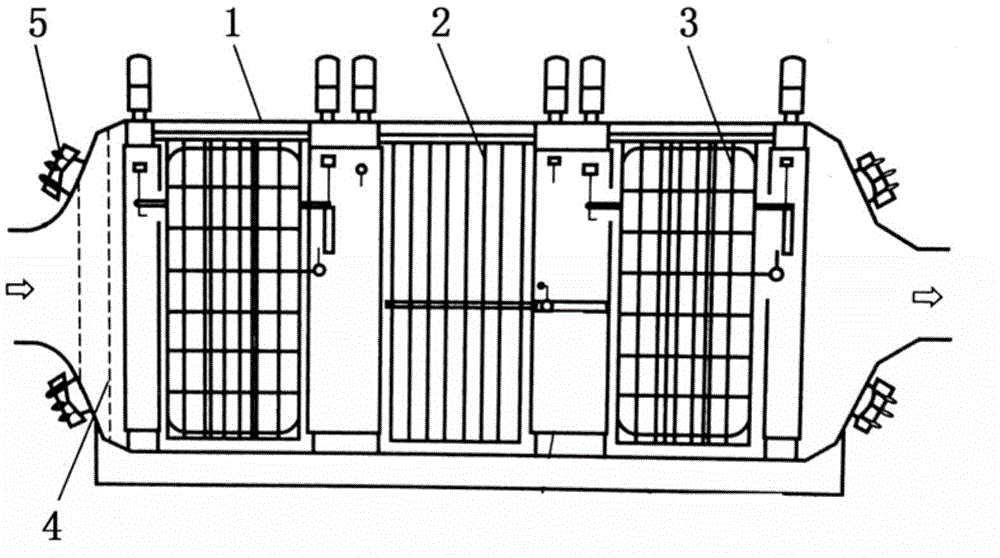

[0012] see figure 1 , a sintering dust treatment device, including a vacuum box, a large flue, a fan, a muffler, the output of the vacuum box is connected to the input of the large flue, the output of the large flue is connected to the input of the fan, and the input and output of the fan are connected to the The input end connection of the muffler also includes a flue water sealing device connected between the large flue and the fan. The flue water sealing device includes a flue body 1, ash collecting hopper 3 is arranged on the peripheral wall of the flue body, the ash collecting hopper 3 communicates with the flue, and the other end of the ash collecting hopper 3 is connected to an ash discharge pipe 4 One end is connected. It also includes a water-sealed zipper machine and tape conveyor 8, the output end of the water-sealed zipper machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com