Power electrical distribution cabinet for factory production and processing

It is a technology for electric power and factory production, which is applied in the substation/power distribution device shell, cooling/ventilation of substation/switchgear, etc. It can solve the problems of flying, affecting the factory working environment, and occupying factory space, so as to improve the working environment, The effect of preventing secondary flying and reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

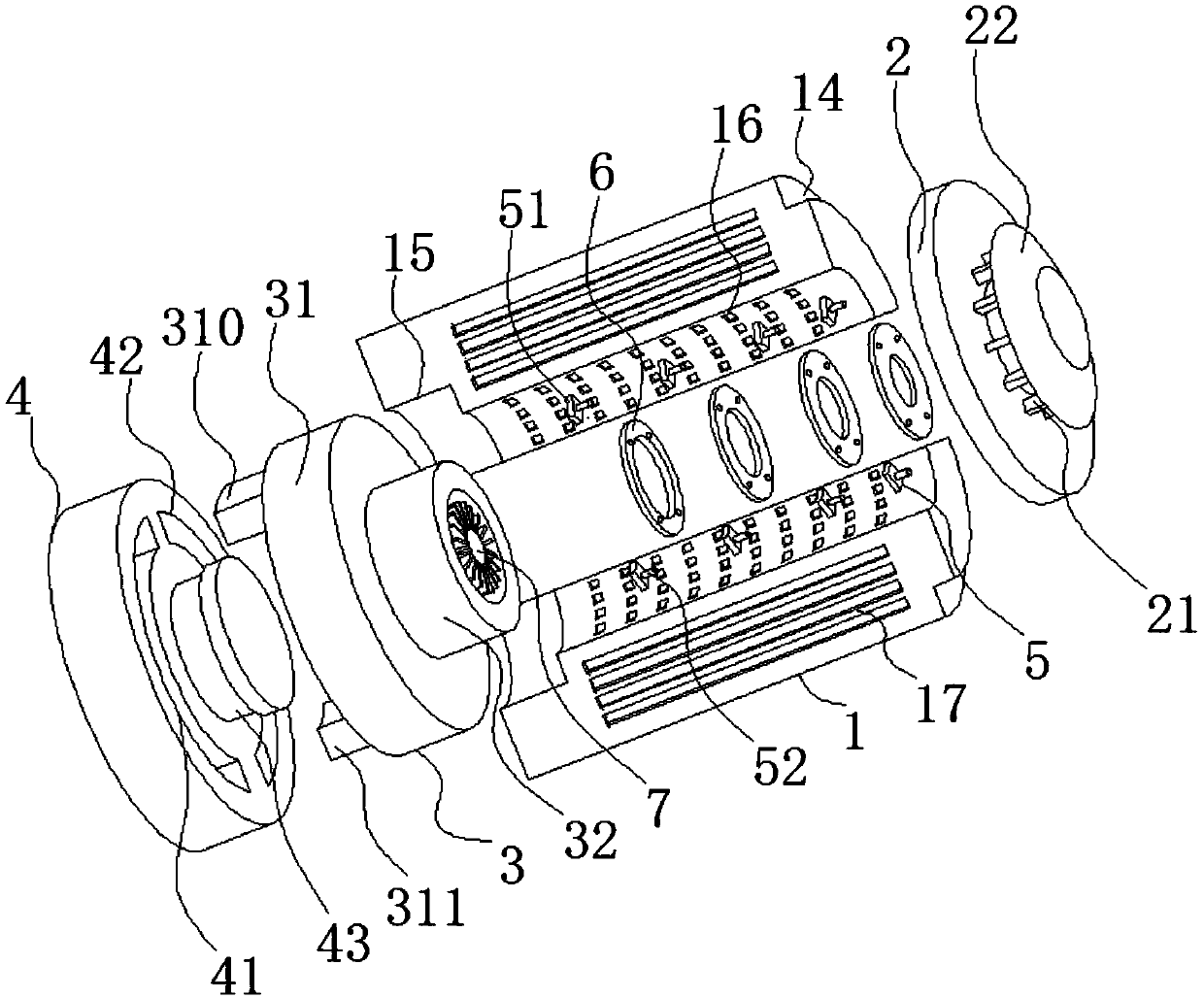

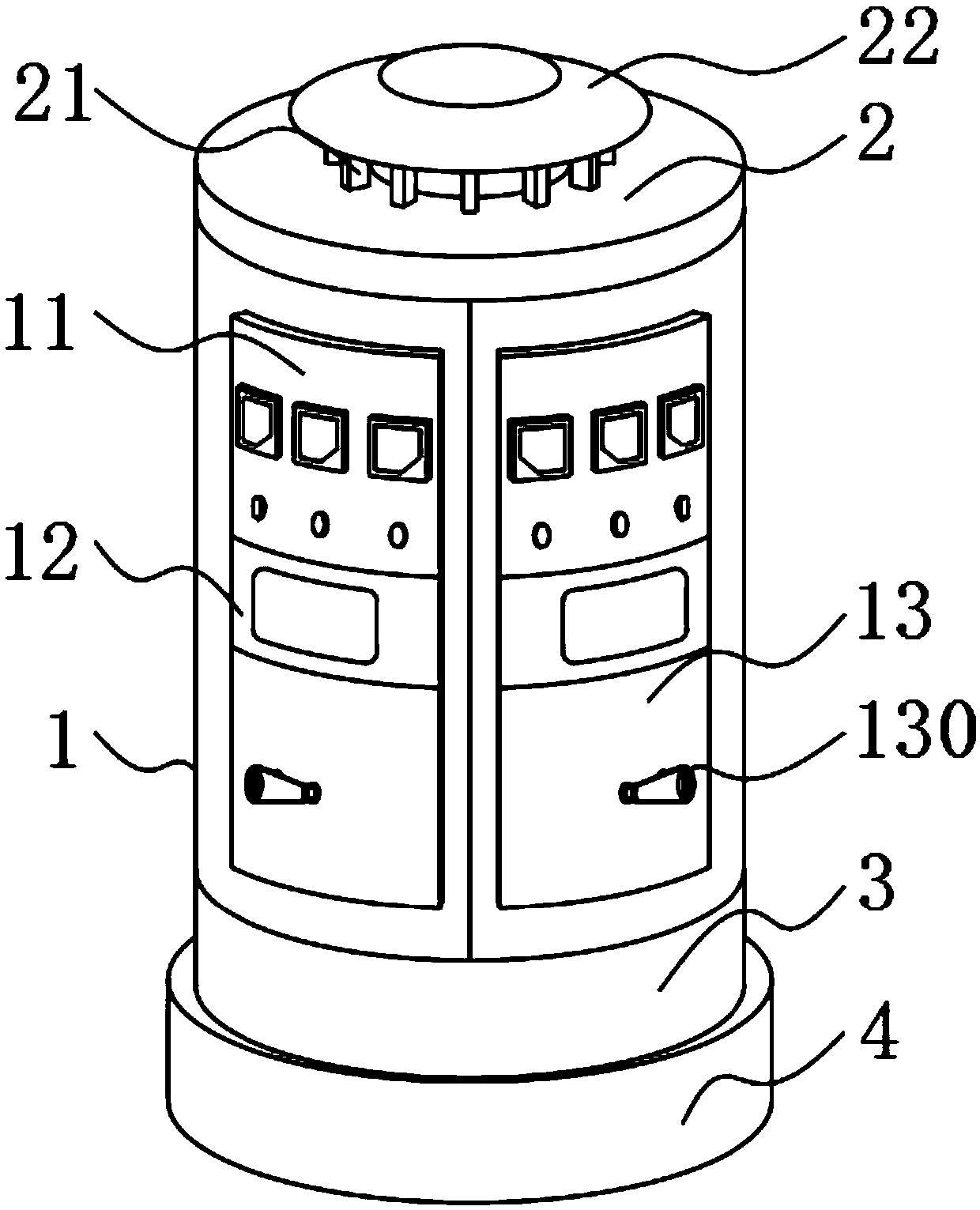

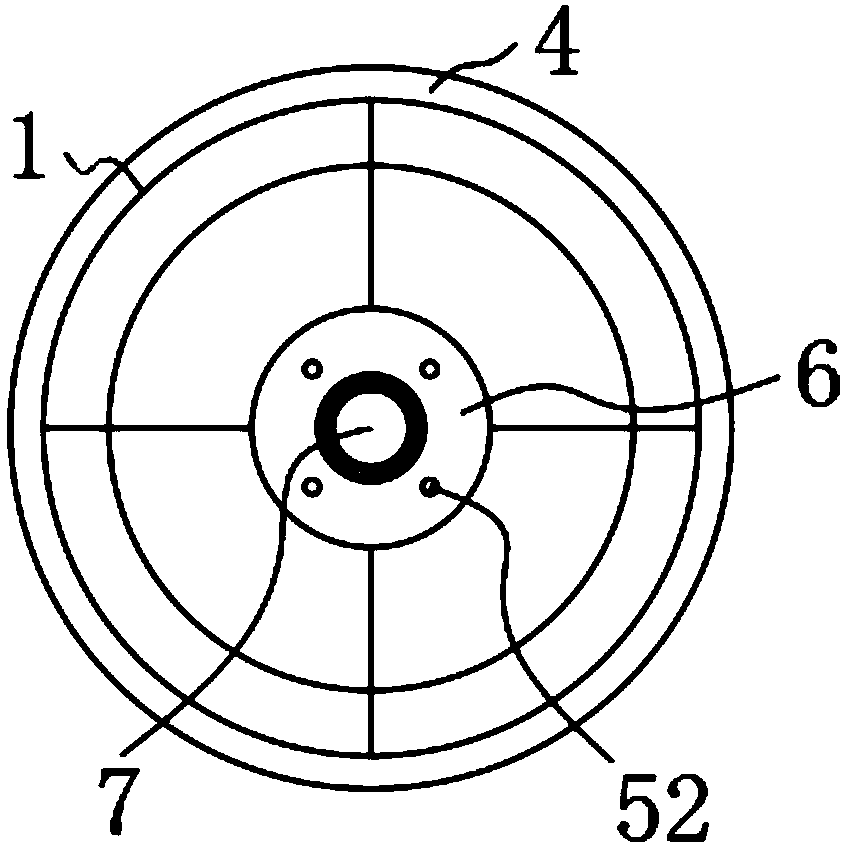

[0024] see Figure 1 to Figure 6 , the present invention provides a technical solution: an electric power distribution cabinet for factory production and processing, including a cabinet 1, a top cover 2 fixedly installed on the top of the cabinet 1, and an installation chassis 3 fixedly installed on the bottom of the cabinet 1, which is rotatably connected to Install the fixed chassis 4 at the bottom of the chassis 3, the fixed seat 5 fixedly connected to the inner side wall of the cabinet 1, and the partition ring 6 fixedly installed on the inner side wall of the cabinet 1, the number of cabinets 1 is four, and the four cabinets 1 form a hollow cylinder The outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com