Dust extraction and treatment system for discharging platform of aluminum oxide warehouse

A technology for unloading platform and ash treatment, which is applied in the direction of smoke removal, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems of personnel working environment pollution, dust secondary flying, and heavy workload of personnel, etc., and achieve improvement Effects of working environment, energy saving, and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

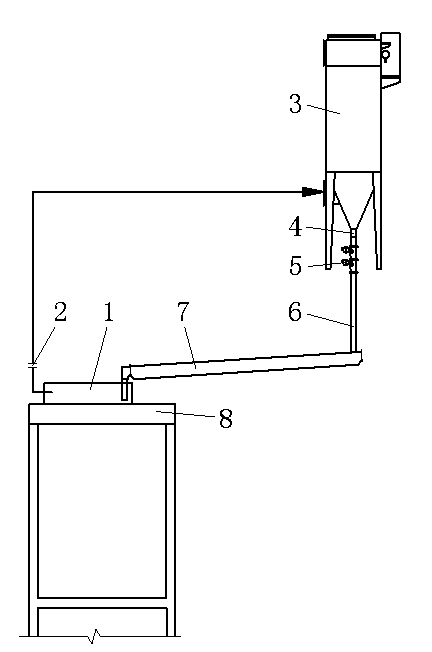

[0012] Embodiments of the present invention: the structural representation of the present invention is as figure 1 As shown, a dust removal and ash treatment system for an alumina warehouse unloading platform of the present invention includes a dust collection cover 1 arranged on the existing alumina warehouse process unloading platform 8, and the dust collection cover 1 is connected to the dust collector 3 through a pipeline. Connection, the connecting pipe between the dust collection cover 1 and the dust collector 3 is provided with an air volume regulating valve 2; the chute 4 at the bottom of the dust collector 3 passes through a double-layer rectangular air-locking weight to turn over the ash discharge valve 5, ash discharge pipe 6 and air The moving chute 7 is connected to the unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com