Ultra-low emission absorption tower

An absorption tower and ultra-low technology, applied in the field of absorption towers, can solve the problems of inability to meet ultra-low emission requirements, excessive dust emission concentration, and low dust removal efficiency of absorption towers, so as to increase spray coverage and reduce maintenance and replacement. Cost and ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

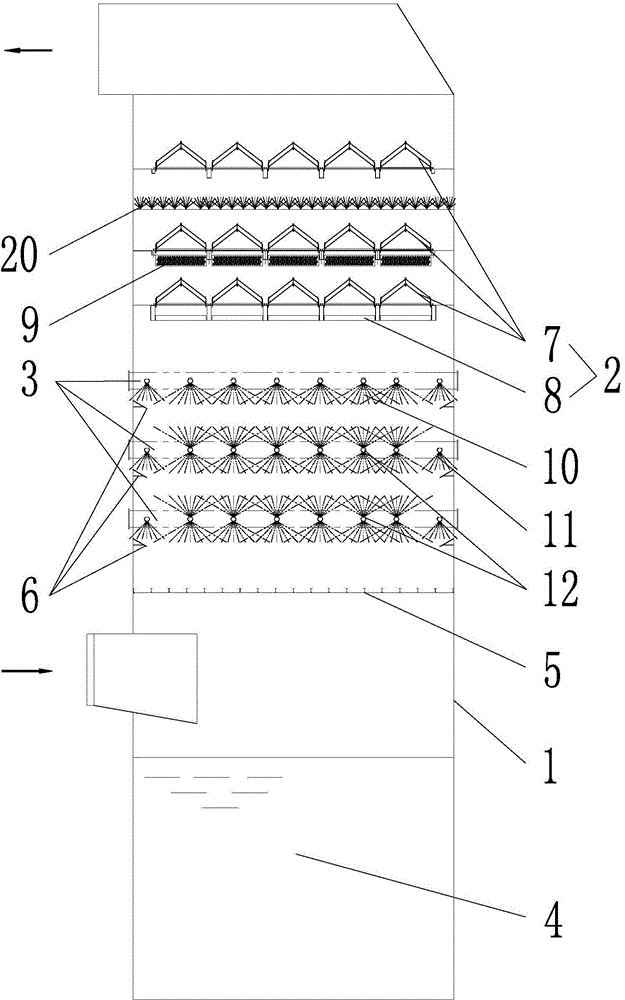

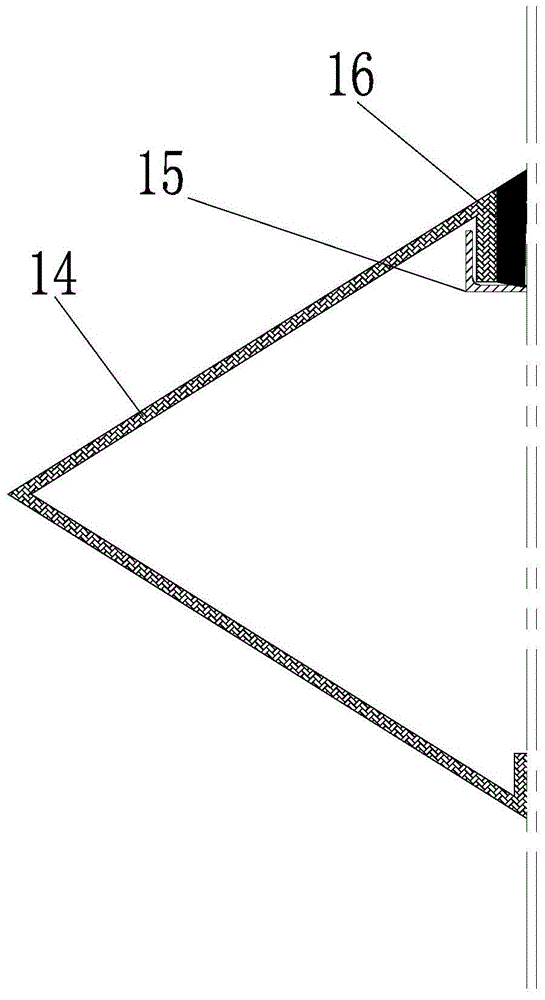

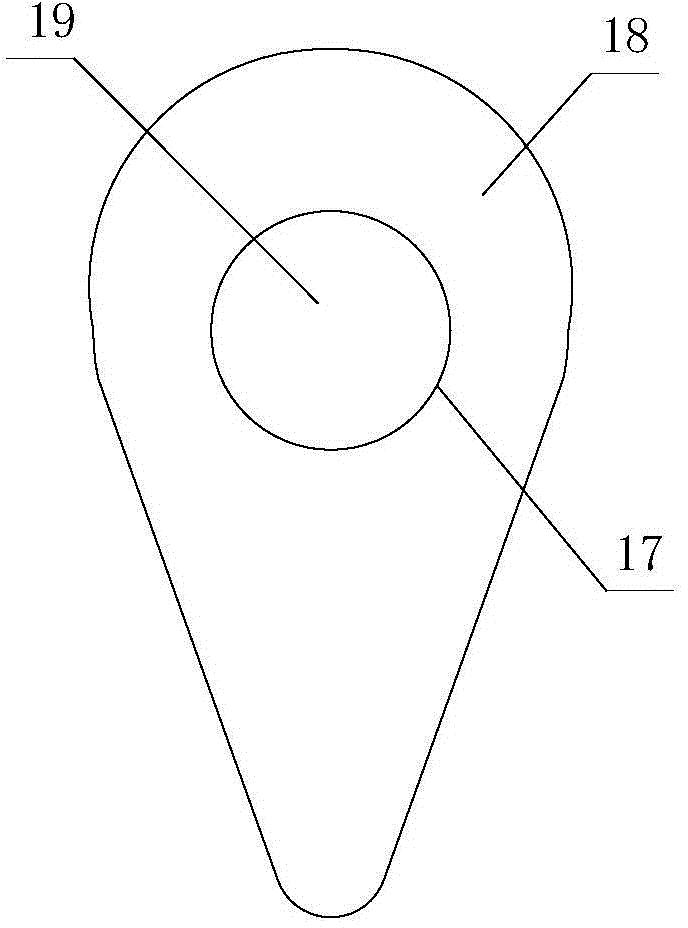

[0035] Embodiment 1 of the present invention: as figure 1As shown, an ultra-low emission absorption tower includes an absorption tower body 1, a mist eliminator 2, a spray layer 3 and a slurry pool 4, the slurry pool 4 is located at the bottom of the absorption tower body 1, and the mist eliminator 2 is located at the bottom of the absorption tower body 1. In the upper part of the absorption tower body 1, the spray layer 3 is set under the demister 2, and the bottom of the spray layer 3 is provided with a slurry distribution plate 5; the bottom of each spray layer 3 is equipped with a slurry guide Ring 6; mist eliminator 2 is composed of three sets of roof type mist eliminators 7 and one set of pipe type mist eliminators 8, the pipe type mist eliminators 8 are located below the bottom of the roof type A condensation system 9 is provided between the mist eliminator 7 and the middle roof ridge type mist eliminator 7 . The spray layer 3 is more than 2 layers, and the uppermost s...

Embodiment 2

[0040] Embodiment 2 of the present invention: as figure 1 As shown, an ultra-low emission absorption tower includes an absorption tower body 1, a mist eliminator 2, a spray layer 3 and a slurry pool 4, the slurry pool 4 is located at the bottom of the absorption tower body 1, and the mist eliminator 2 is located at the bottom of the absorption tower body 1. In the upper part of the absorption tower body 1, the spray layer 3 is set under the demister 2, and the bottom of the spray layer 3 is provided with a slurry distribution plate 5; the bottom of each spray layer 3 is equipped with a slurry guide Ring 6; mist eliminator 2 is composed of three sets of roof type mist eliminators 7 and one set of pipe type mist eliminators 8, the pipe type mist eliminators 8 are located below the bottom of the roof type A condensation system 9 is provided between the mist eliminator 7 and the middle roof ridge type mist eliminator 7 . The spray layer 3 is more than 2 layers, and the uppermost ...

Embodiment 3

[0045] Embodiment 3 of the present invention: as figure 1 As shown, an ultra-low emission absorption tower includes an absorption tower body 1, a mist eliminator 2, a spray layer 3 and a slurry pool 4, the slurry pool 4 is located at the bottom of the absorption tower body 1, and the mist eliminator 2 is located at the bottom of the absorption tower body 1. In the upper part of the absorption tower body 1, the spray layer 3 is set under the demister 2, and the bottom of the spray layer 3 is provided with a slurry distribution plate 5; the bottom of each spray layer 3 is equipped with a slurry guide Ring 6; mist eliminator 2 is composed of three sets of roof type mist eliminators 7 and one set of pipe type mist eliminators 8, the pipe type mist eliminators 8 are located below the bottom of the roof type A condensation system 9 is provided between the mist eliminator 7 and the middle roof ridge type mist eliminator 7 . The spray layer 3 is more than 2 layers, and the uppermost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com