Spraying equipment for forging and stamping die for automobile axles

A technology for spraying equipment and vehicle axles, which is used in lighting and heating equipment, coatings, spray booths, etc., can solve the problems of uneven thickness of the cover layer, difficulty in controlling the spraying amount, and the spraying surface is not compact, so as to improve the spraying density. , The effect of compact spray surface and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

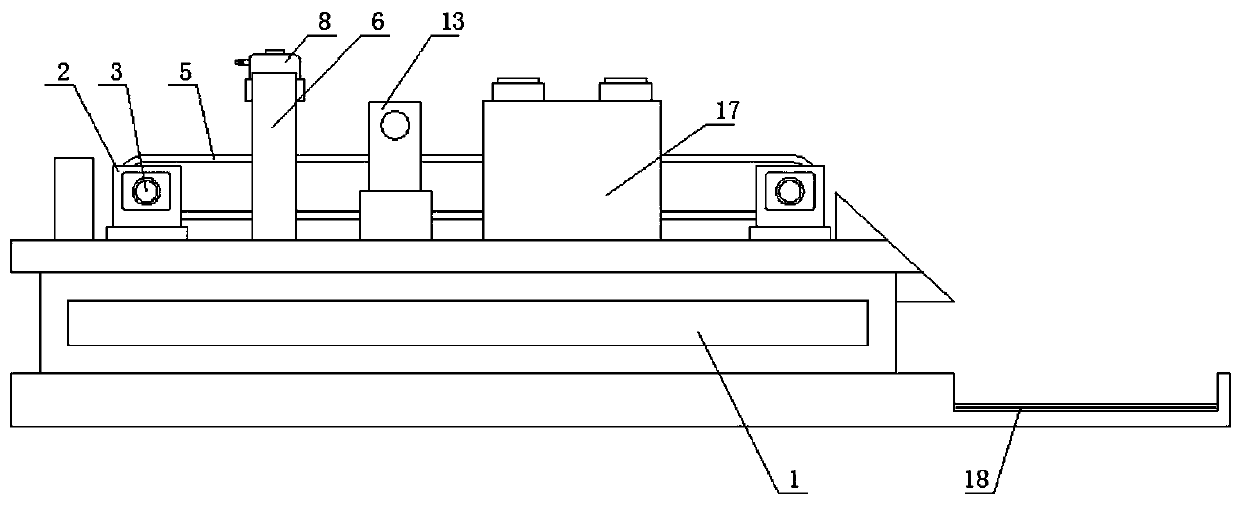

[0028] refer to Figure 1-6 , an automobile axle forging die spraying equipment, including a workbench 1, the top of the workbench 1 is fixed with four driving seats 2 symmetrically arranged in pairs, and the two driving seats 2 on the same side are rotatably connected to the same The drive assembly, the outer sides of the two drive assemblies are provided with the same belt 5, and the top of the workbench 1 is fixedly installed with two support seats 6 symmetrically arranged, and the belt 5 is located on the two support seats 6, and the two support seats 6 are mutually The same connecting plate 7 is fixedly installed on the close side, and the cleaning assembly is arranged on the connecting plate 7. Two mounting seats 13 are arranged symmetrically on the top of the worktable 1, and the same side of the two mounting seats 13 close to each other is fixedly installed. Welding plate 14, the welding plate 14 is provided with drying assembly, the top of workbench 1 is fixedly insta...

Embodiment 2

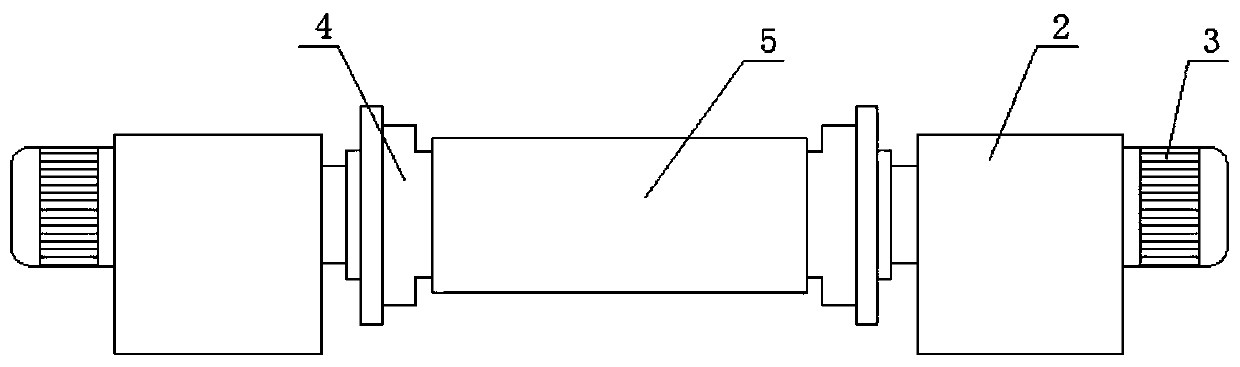

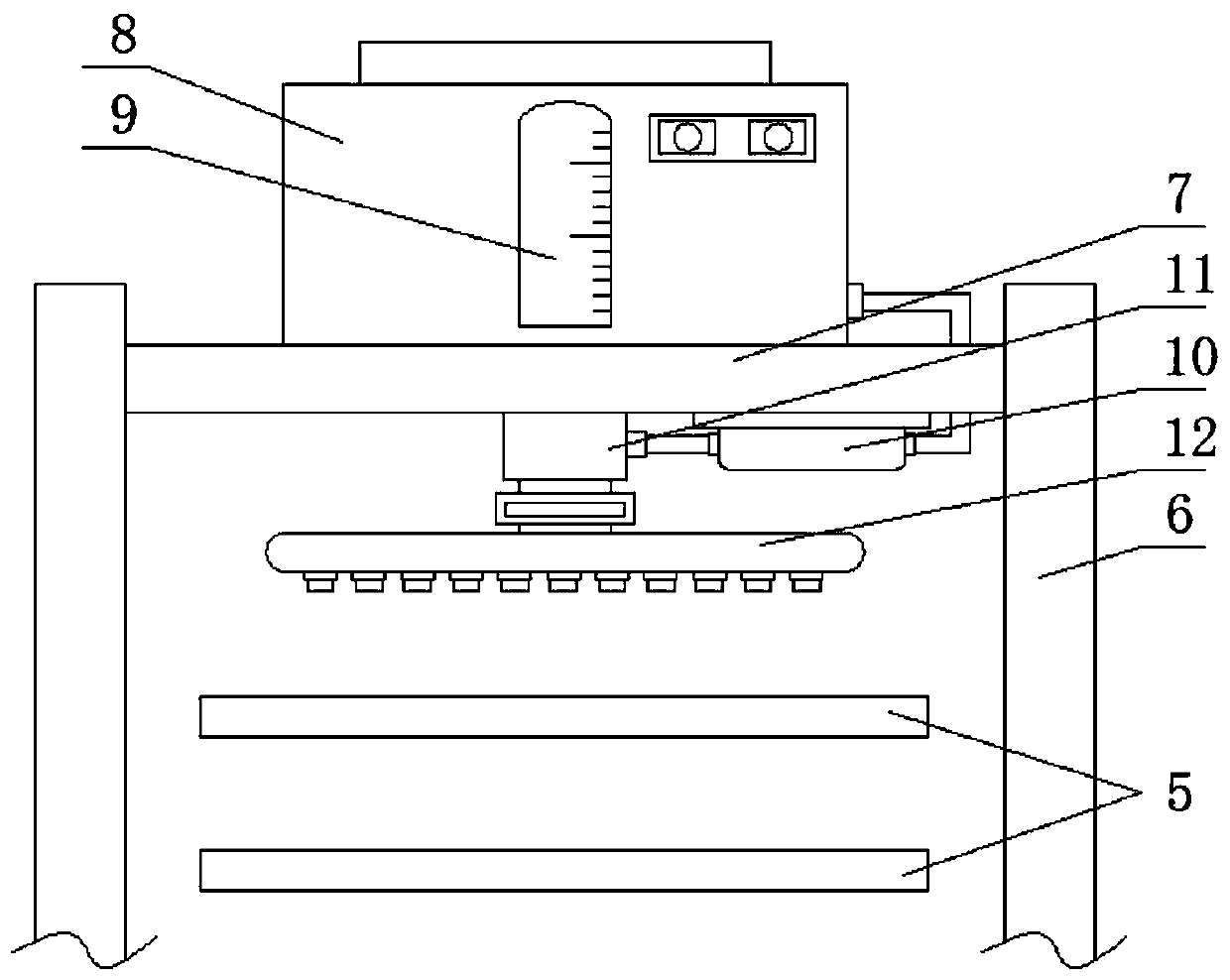

[0030]The drive assembly includes two drive motors 3 fixedly mounted on the sides of the two drive bases 2 that are far away from each other. One side of the two output shafts close to each other is fixedly installed with the same driving roller 4, and the belt 5 is sleeved on the outside of the two driving rollers 4, and the driving roller 4 can be driven to rotate by starting the driving motor 3, and the rotating driving roller 4 can be Drive the belt 5 to rotate, so the belt 5 has the function of transporting the car; the cleaning assembly includes a water tank 8 fixedly installed on the top of the connecting plate 7, a liquid level gauge 9 is arranged on one side of the water tank 8, and the bottom of the connecting plate 7 is fixedly connected with a The first liquid pump 10, the liquid inlet pipe of the first liquid pump 10 communicates with the water tank 8, the liquid outlet pipe of the first liquid pump 10 is fixedly connected with a connecting pipe 11, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com