Electrical precipitator

A technology of electrostatic precipitator and electric field electrode, which is applied in the field of dust removal, can solve the problems of exacerbating dust emission exceeding the standard, dust is not easy to charge, adsorption, and emission exceeding the standard, so as to reduce economic losses and shorten process downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The core of the present invention is to provide an electric precipitator, which prolongs the time of dust in the rear electric field to reduce dust emission.

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

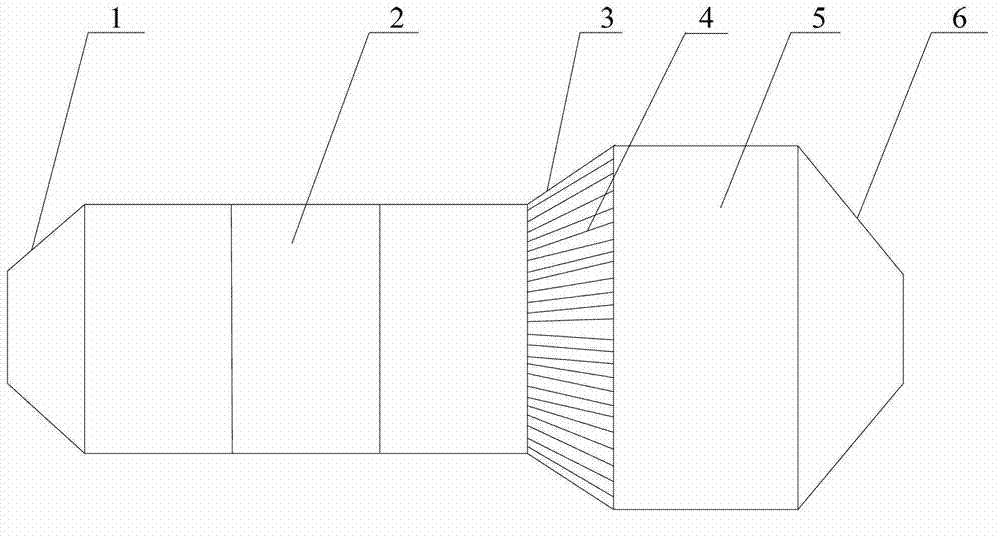

[0022] Please refer to figure 1 The embodiment of the present invention discloses an electric precipitator, which includes a dust removal main body and an inlet horn 1 and an outlet horn 6 arranged at both ends of the dust removal main body. The dust removal main body includes a plurality of sections close to the outlet horn 6 and has a larger cross-sectional area than the end close to the inlet horn 1. The cross-sectional area of the end of the dust removal split.

[0023] At work, after the flue gas enters the electrostatic precipitator through the inlet horn 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com