Three-roller oil scraping device of Sendzimir twenty-high rollling mill

A twenty-roll rolling and oil scraping device technology, which is applied in the field of oil scraping of rolling mills, can solve problems such as oil pollution, high incidence of corrosion, poor rust resistance, and poor oil scraping effect, so as to reduce process downtime and reduce rolling Effects of residual oil production and capacity release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

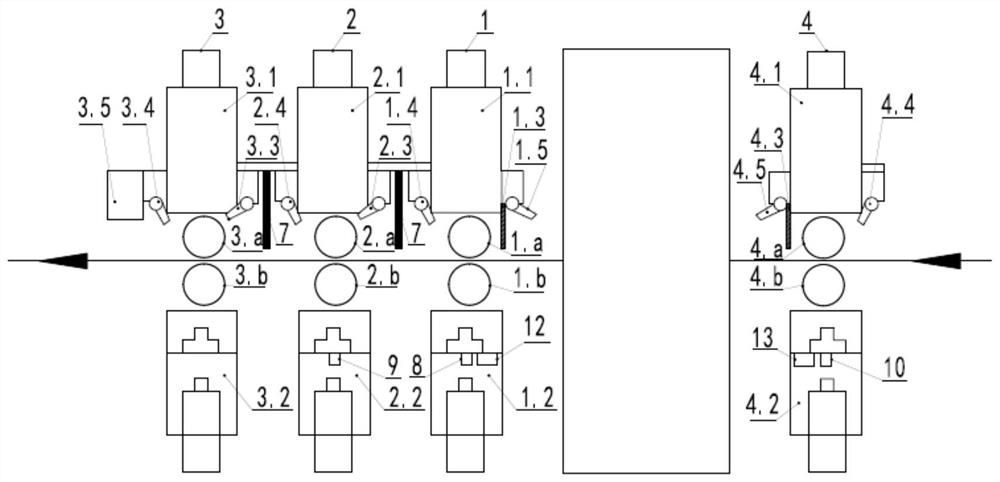

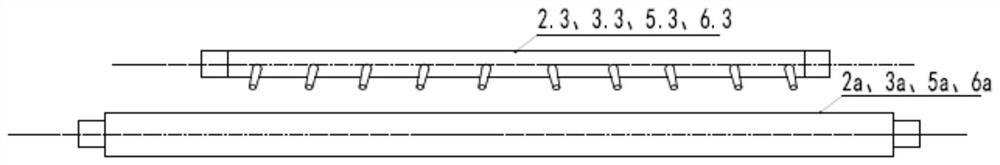

[0031] like figure 1 The three-roll oil scraping device of the Sendzimir 20-high rolling mill shown in the figure, when producing conventional non-oriented high-grade grades, the rolling program participates in automatic control, and the outlet side of the rolling mill archway is put into 1# rough oil scraping roller device 1 and 2# fine scraper Oil roller device 2 and 3# fine oil scraper roller device, 1# coarse oil scraper roller device 4 is put into the entrance side of the rolling mill archway. The length of each oil scraping roller is 1400mm, the diameter is 150mm, and the roughness is in the range of 0.2-0.4μm. Each group of oil scraping roller devices adopts the form of hydraulic cylinder pressing up and down.

[0032]The 1# rough oil scraping roller device 1 on the exit side of the rolling mill archway includes an upper platform frame 1.1 and a lower platform frame 1.2, and a rough oil scraper that can rotate around its own axis is respectively installed under the uppe...

Embodiment 2

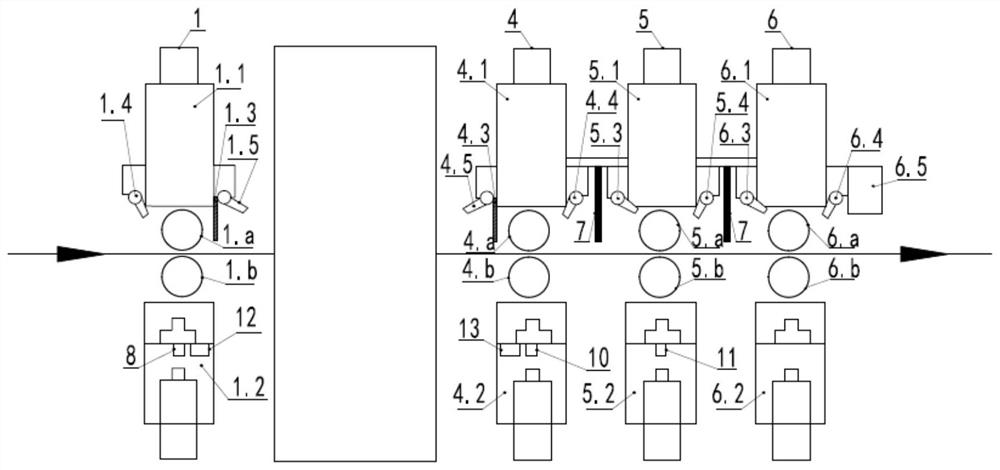

[0040] Since the rolling mill is a reversible rolling mill, after the silicon steel plate rolling direction is switched, the oil scraping roller device on the entrance and exit side of the rolling mill archway also needs to be adjusted accordingly.

[0041] like figure 2 The three-roll oil scraping device of the Sendzimir 20-high rolling mill shown in the figure, when producing conventional non-oriented high grades, the rolling program participates in automatic control, and 1# rough oil scraping roller device 1 is put into the outlet side of the rolling mill archway, and the input side of the rolling mill archway is put together Put in 1# rough oil scraping roller device 4, 2# rough oil scraping roller device 5 and 3# rough oil scraping roller device 6. The length of each oil scraping roller is 1400mm, the diameter is 150mm, and the roughness is in the range of 0.2-0.4μm. Each group of oil scraping roller devices adopts the form of hydraulic cylinder pressing up and down.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com