An automated mechanical painting equipment

A painting equipment and equipment technology, applied in the painting booth, spraying device, etc., can solve the problems of increasing the process, uneven painting of mechanical parts, unable to send mechanical parts into the drying room for drying, etc., and achieve the goal of improving the uniformity of painting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

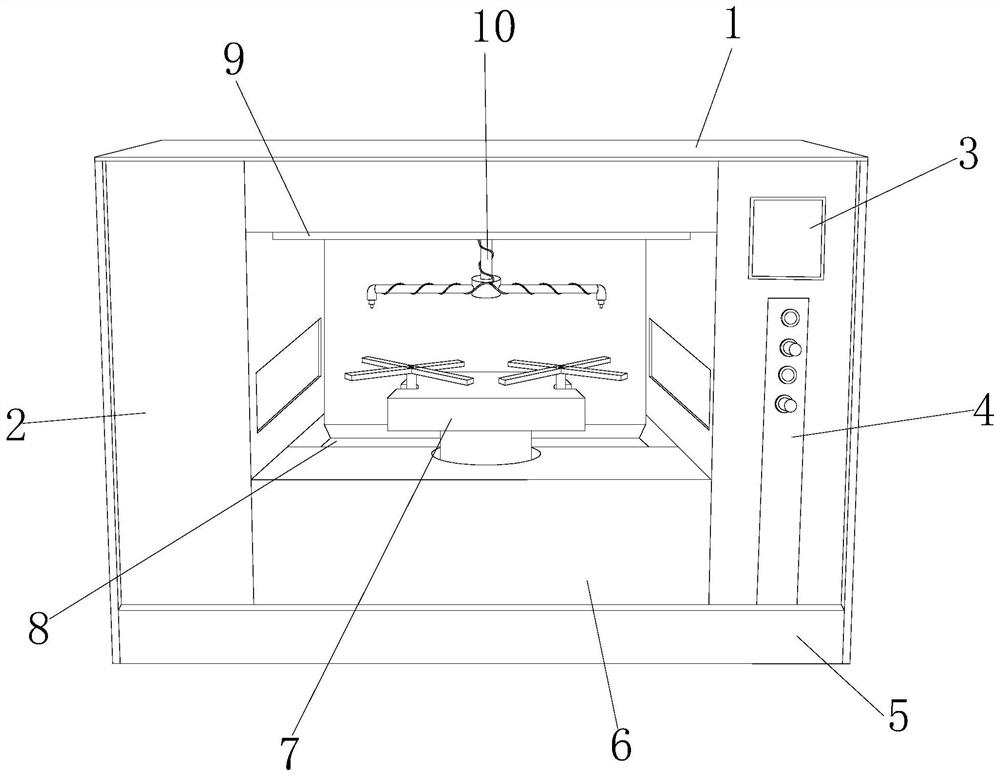

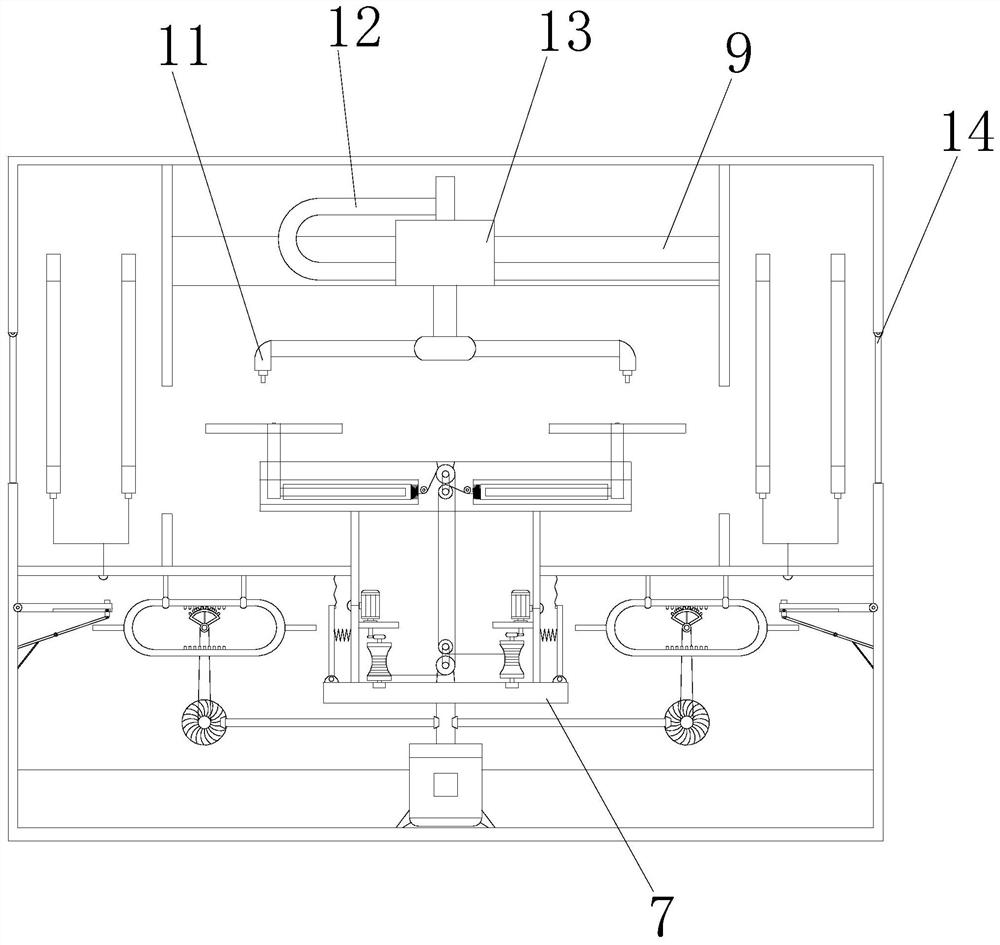

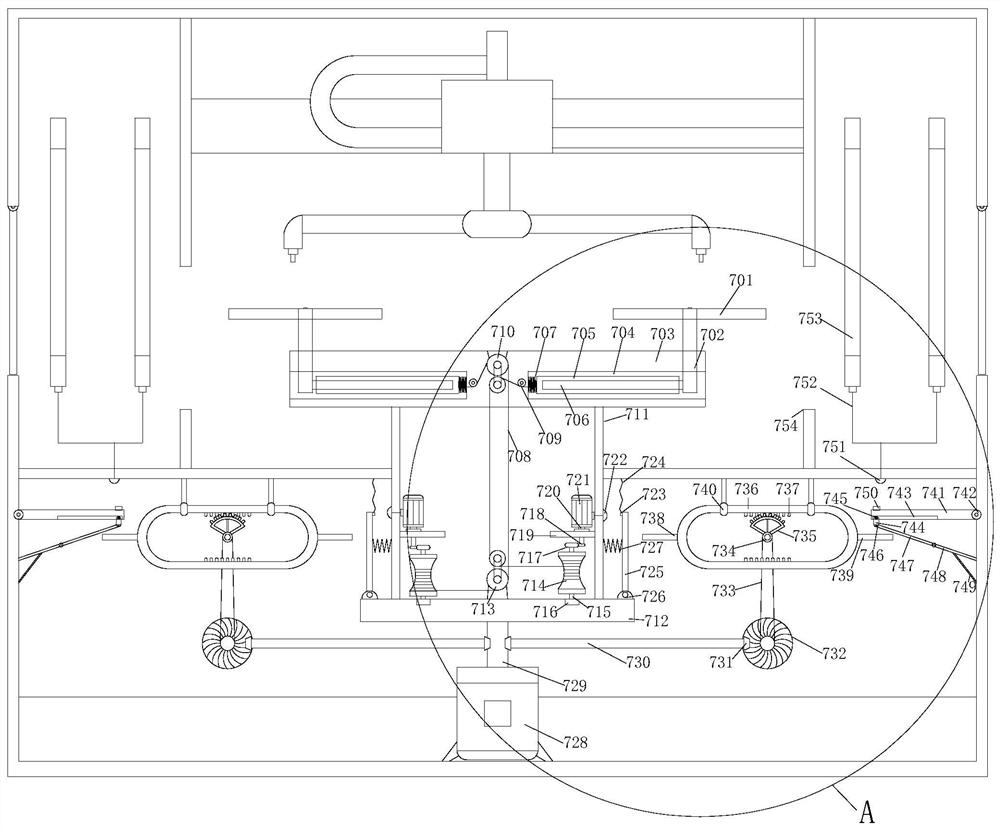

[0024] see Figure 1-Figure 8 , the present invention provides a technical scheme of automatic mechanical painting equipment: its structure includes equipment main body 1, support cabinet 2, digital display screen 3, control panel 4, equipment base 5, machine base 6, uniform spray paint drying mechanism 7, set Paint tank 8, front and rear sliding beams 9, paint spraying frame 10, high-pressure painting head 11, left and right sliding chain 12, reciprocating sliding block 13, operating window 14, two supporting cabinets 2 are arranged on the left and right sides of the equipment main body 1 It is an integrated structure with the equipment main body 1, the digital display screen 3 is inlaid on the upper part of the front surface of the right support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com