Split-type pulse dust collector for drying and burning sludge

A pulse dust collector and sludge drying technology, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of bridges, installation difficulties, short service life of filter bags, etc., to reduce length and resistance, and ensure sealing. performance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

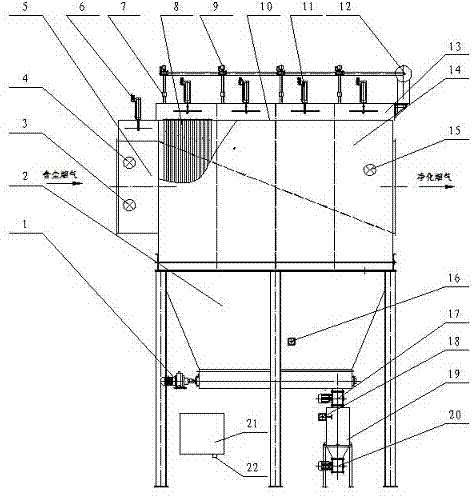

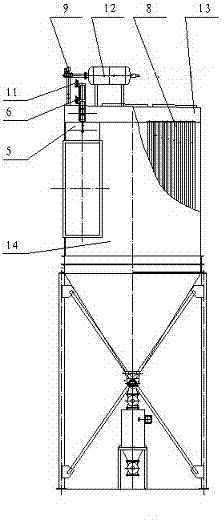

[0022] control figure 1 , figure 2 , a kind of box-type pulse dust collector for sludge drying, sending and burning, including an upper box body, a lower box body, and a control system. The upper box body is composed of at least one filter unit, and the upper layer of the filter unit is a clean air chamber 13, The lower layer is a filter chamber 14, which is separated by a porous plate 10 in the middle. A filter bag 8 is arranged in the filter chamber 14 for off-line dust cleaning. An electromagnetic pulse valve 9 is arranged above the clean air chamber 13, and the electromagnetic pulse valve 9 is connected to the cylinder in turn through the pipeline. Solenoid valves, cylinders, and compressed air sources are connected in series. An air inlet pressure sensor 4 and an air inlet temperature sensor 3 are installed at the air inlet of the upper box, and an air outlet pressure sensor 15 is installed at the air outlet. The bypass channel 5 extends to the outside of the box and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com