Spray coagulation and tiny dust removal system

A technology for removing fine dust, applied in the direction of steam condensation, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of secondary flying of fine dust, low dust removal efficiency of spray tower, excessive emission concentration of fine dust, etc. To achieve the effect of preventing secondary flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

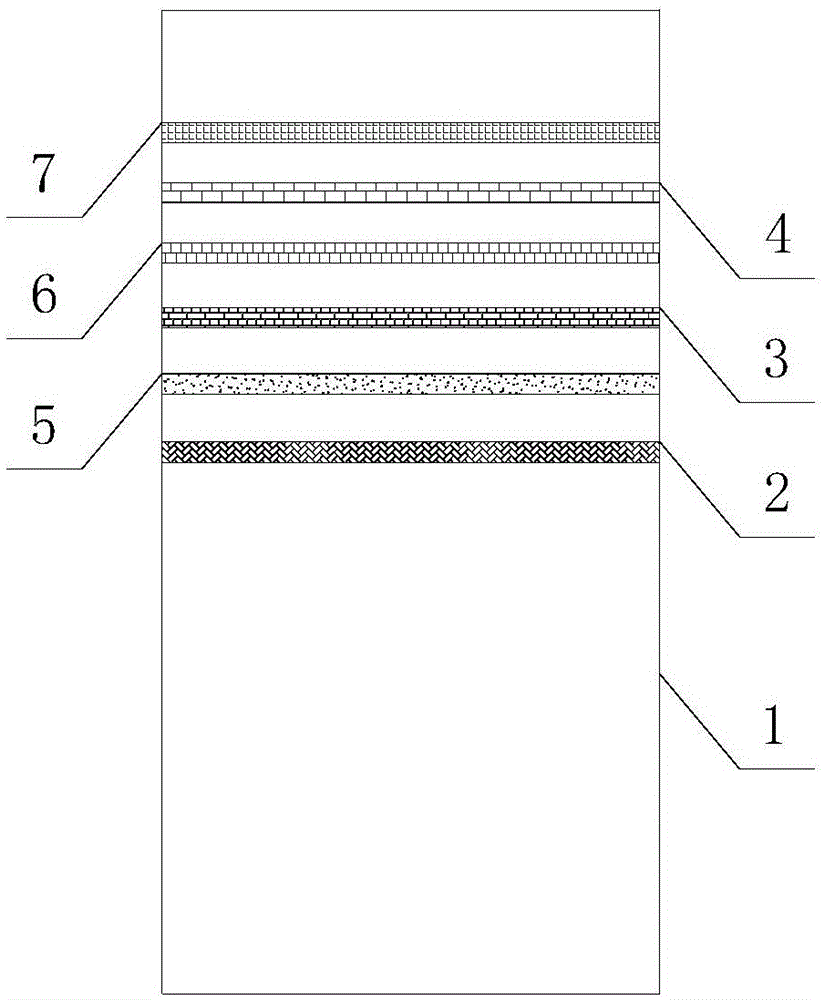

[0022] Embodiment 1 of the present invention: as figure 1 As shown, a spray condensate and fine dust removal system includes a first-stage turn-back type demist device 5, and the first-stage turn-back type demist device 5 is arranged in the spray tower 1, and the spray tower 1 is provided with a top The spray layer 2 and the first-stage turn-back demist device 5 are located above the top spray layer 2 .

[0023] It also includes a dual-fluid spray device 3 , which is located in the spray tower 1 , and which is located above the first-stage turn-back demist device 5 .

[0024] It also includes a second-stage turn-back demist device 6 , which is located in the spray tower 1 , and which is located above the two-fluid spray device 3 .

[0025] It also includes a condensing particle agglomeration device 4, which is located in the spray tower 1, and the condensing particle agglomeration device 4 is located above the second-stage turn-back demisting device 6.

[0026] It also inclu...

Embodiment 2

[0030] Embodiment 2: as figure 1 As shown, a spray condensate and fine dust removal system includes a first-stage turn-back type demist device 5, and the first-stage turn-back type demist device 5 is arranged in the spray tower 1, and the spray tower 1 is provided with a top The spray layer 2 and the first-stage turn-back demist device 5 are located above the top spray layer 2 .

[0031] It also includes a dual-fluid spray device 3 , which is located in the spray tower 1 , and which is located above the first-stage turn-back demist device 5 .

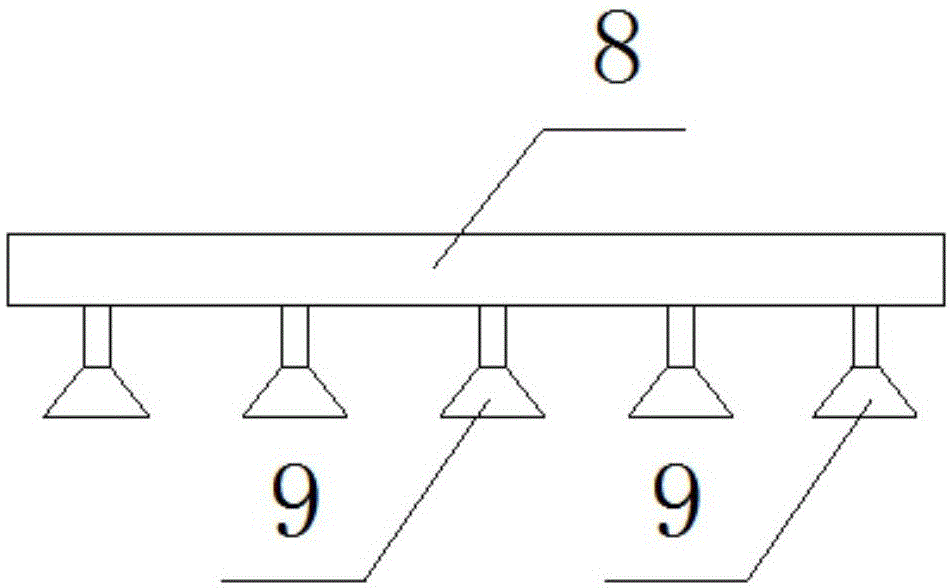

[0032] Such as figure 2 As shown, the two-fluid spray device 3 includes a pipe network 8 and a spray head 9 , the spray head 9 communicates with the pipe network 8 , and the spray head 9 is evenly arranged in the spray tower 1 .

[0033] It also includes a second-stage turn-back demist device 6 , which is located in the spray tower 1 , and which is located above the two-fluid spray device 3 .

[0034] It also includes a condensing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com