Vibration stirrer

A mixer and mixing shaft technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of insignificant vibration effect and limited improvement of concrete mixing quality, and achieve obvious vibration effect and ensure quality. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

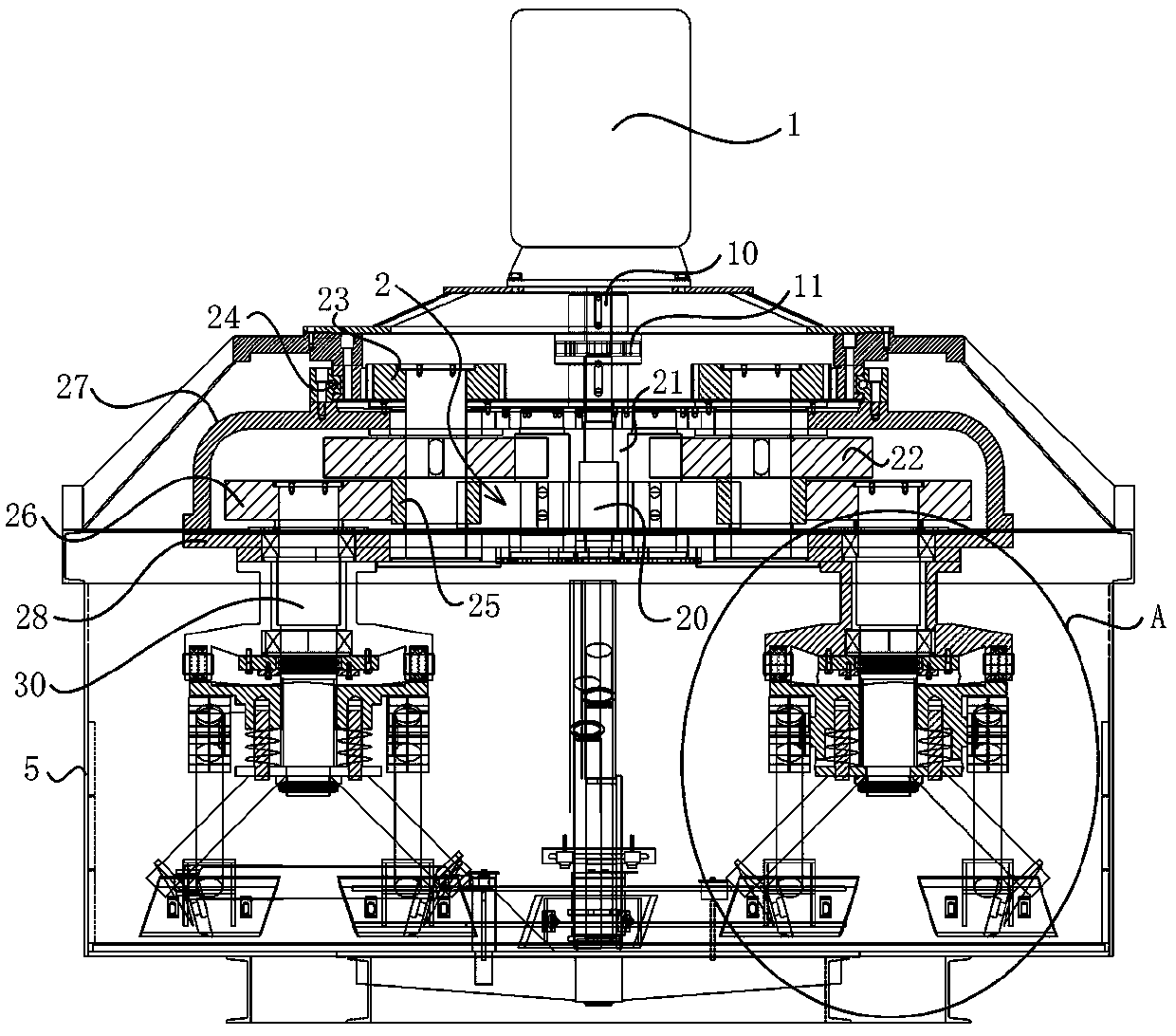

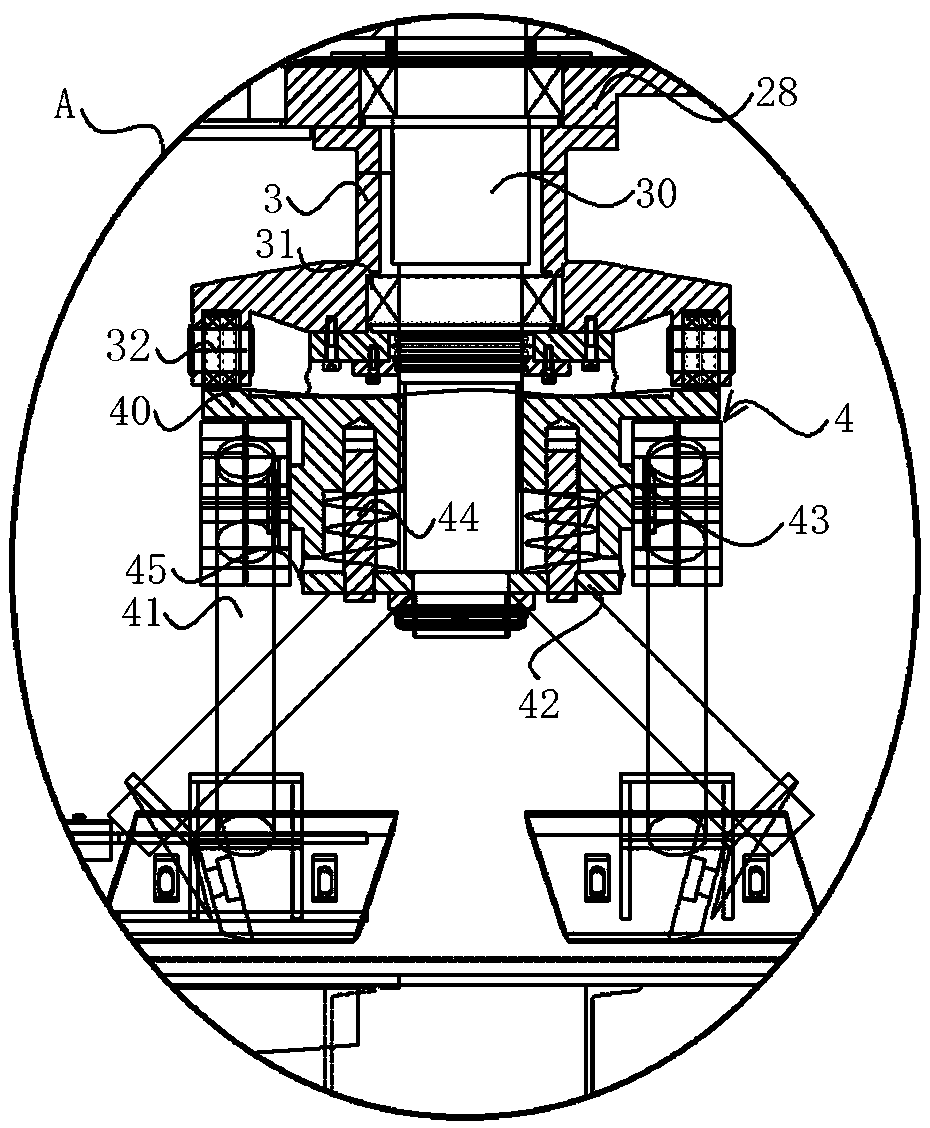

[0021] Specific embodiment 1 of vibrating mixer of the present invention, as Figure 1 to Figure 2 As shown, the vibrating mixer is a vertical vibrating mixer, including a drive motor 1, a planetary reducer 2, an excitation structure 3, a stirring assembly 4 and a stirring tank 5 arranged from top to bottom, and the motor output shaft 10 of the drive motor 1 passes through The quincunx elastic coupling 11 is in transmission connection with the sun gear shaft 20 of the planetary reducer 2, and after the planetary reducer 2 decelerates and increases torque, the power output is performed by a plurality of agitating shafts 30 distributed in the circumferential direction that both rotate and revolve around the input shaft. The stirring shaft 30 protrudes from the lower end surface of the reducer casing 28 of the planetary reducer 2 and extends into the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com