Blasting vibration test device for measuring slope stability and evaluation and early warning method

A technology of blasting vibration and testing equipment, which is applied in measuring equipment, vibration testing, testing of machine/structural components, etc. It can solve the problems of high production cost, easy corrosion of wooden side walls, and inability to work together, so as to shorten the test time. , save test cost, and ensure the effect of slope safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

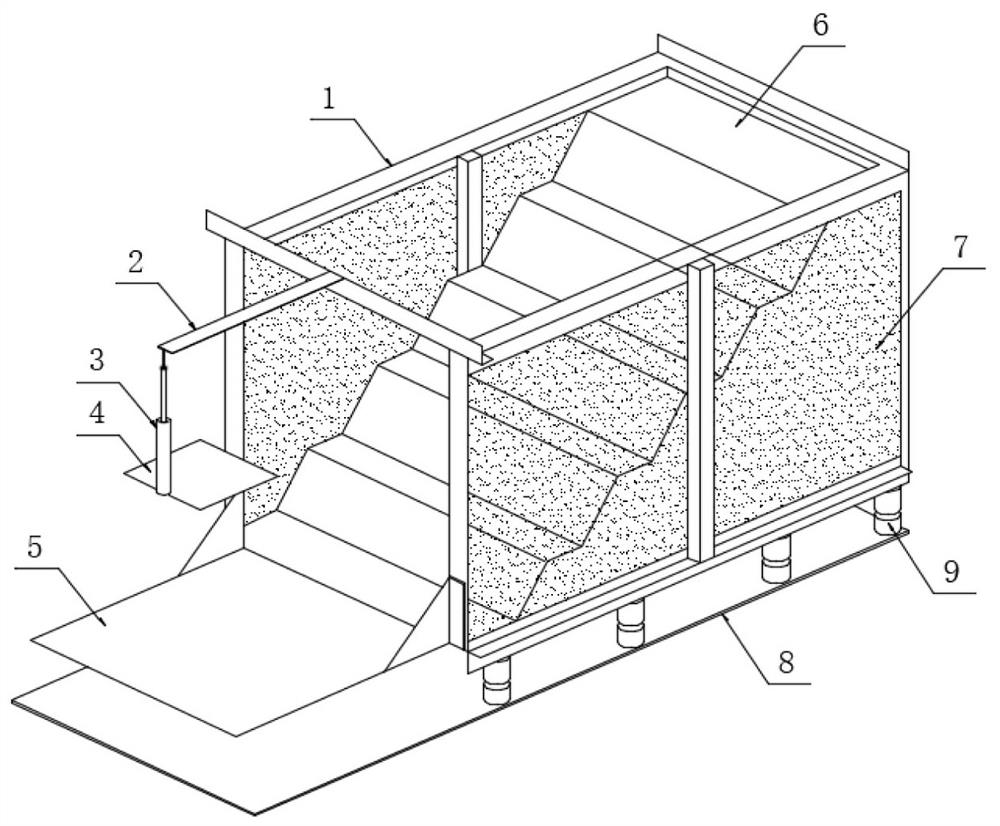

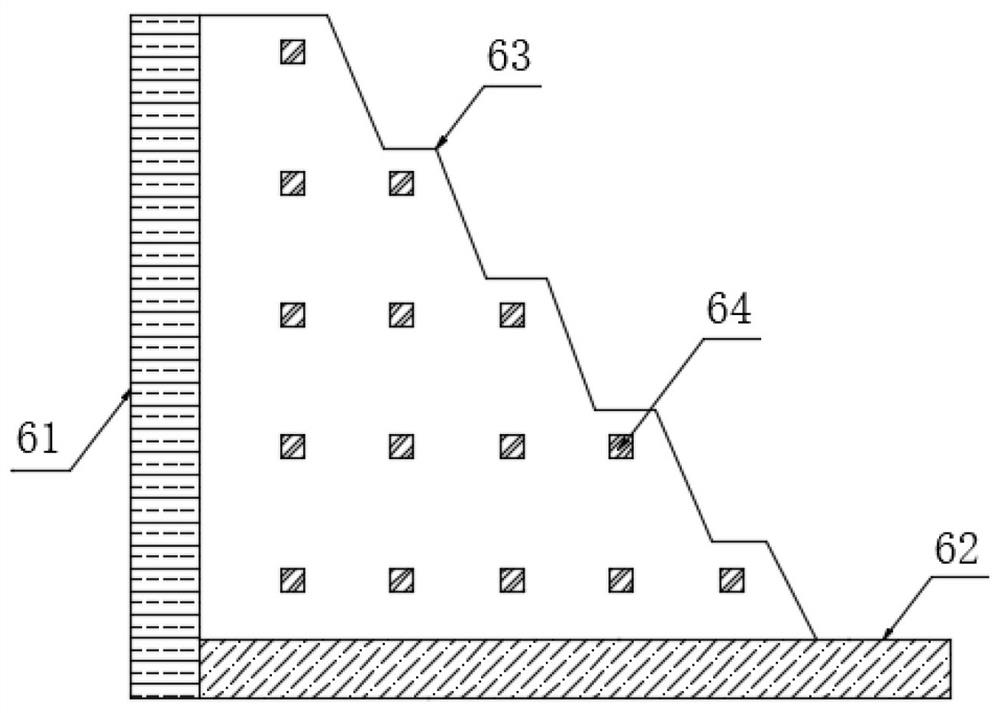

[0033] Such as Figure 1-Figure 3 As shown, a blasting vibration test device for measuring slope stability of the present invention includes a steel structure box 1, and the inside of the steel structure box 1 is provided with a slope model 6 and a front opening of the steel structure box 1. The bottom is fixed with a load-bearing steel plate 5, the bottom of the steel structure box 1 is fixed with a vibration-damping base, and the upper frame of the steel structure box 1 is fixed with a telescopic mechanism;

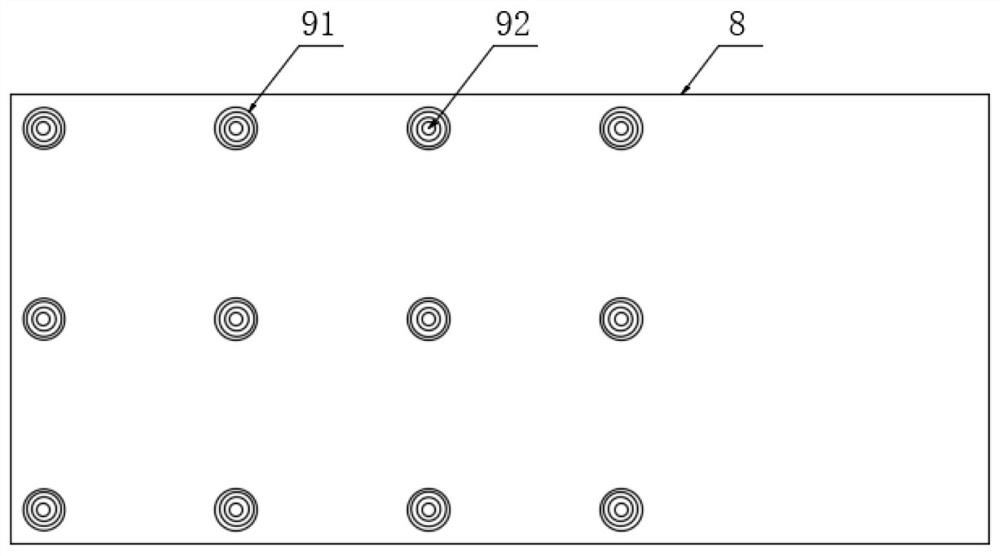

[0034] The damping base includes a damping base plate 8 and a plurality of damping spring assemblies 9. One end of a plurality of evenly distributed damping spring assemblies 9 is fixedly arranged on the upper surface of the rear portion of the damping base plate 8, and the other end is connected to the bottom of the steel structure box 1. fixed connection;

[0035] The telescopic mechanism of the present invention includes an extension arm 2, a threaded telescopic ass...

Embodiment 2

[0044] The present invention also provides an evaluation and early warning method for measuring slope stability, which is characterized in that it specifically includes the following steps:

[0045] S1. Collect the geometric structure parameters of the stope slope, the position parameters of the monitoring instruments in the slope and the monitoring data of the position of the monitoring instruments. The geometric structure parameters of the stope slope and the position parameters of the monitoring instruments in the slope include: slope height, thickness, slope Angle, geometric shape, position of speed sensor and acceleration sensor, the monitoring data of monitoring instrument position includes the speed and acceleration data measured on site;

[0046] S2. Collect the rock mass samples of each layer of the stope slope, test and determine the physical and mechanical parameters of the rock mass of each layer of the slope, and then calculate and determine the physical and mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com