Ultra-fine magnetized foam drilling dust collector

A technology of dust collector and foam, which is applied in the field of ultra-micro magnetized foam drilling dust collector, which can solve the problems of unsatisfactory dust removal effect of dust collector, unoptimistic dust reduction efficiency of respirable coal dust, and deterioration of working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

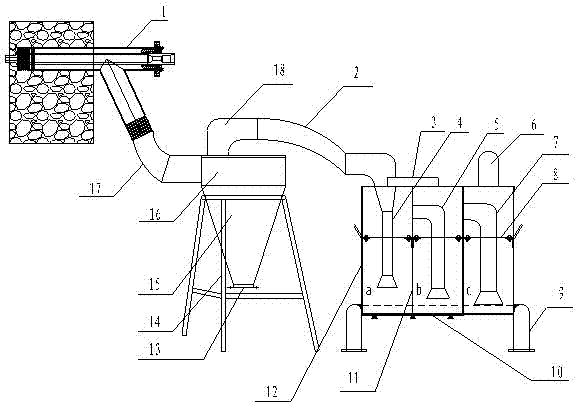

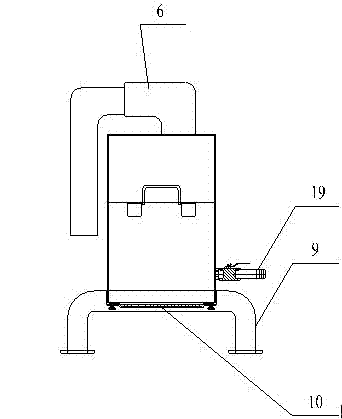

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

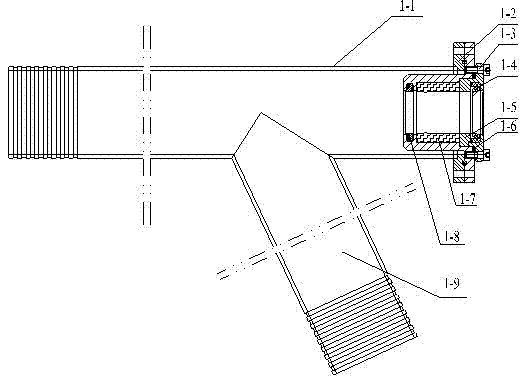

[0013] Such as figure 1 , 2 As shown, the ultra-fine magnetized foam drilling dust collector is mainly composed of a drilling blocker 1, a first-stage dust suppression device and an ultra-fine magnetization foam dust collection device. The device is connected, and the first-level dust suppression device is connected with the ultra-micro magnetized foam dust collection device through the connecting pipe 2; the borehole plugging device 1 includes a casing 1-1 with an external thread at the front, and the casing 1- The rear part of 1 is provided with a discharge pipe joint 1-9 arranged obliquely, and the rear end of the casing 1-1 is provided with a U-shaped gland 1-2 matched with the drill pipe, and the inner hole of the U-shaped gland 1-2 is There is a polytetrafluoroethylene packing 1-7 for sealing the drill pipe, a sealing ring 1-8 is provided at the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com