Cyclone bag type dust collector for rotary chamber pulse jet system

A technology of bag filter and pulse injection, which is applied in the direction of separation method, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of complicated cyclone bag filter equipment, high difficulty of cleaning dust, cumbersome cleaning process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

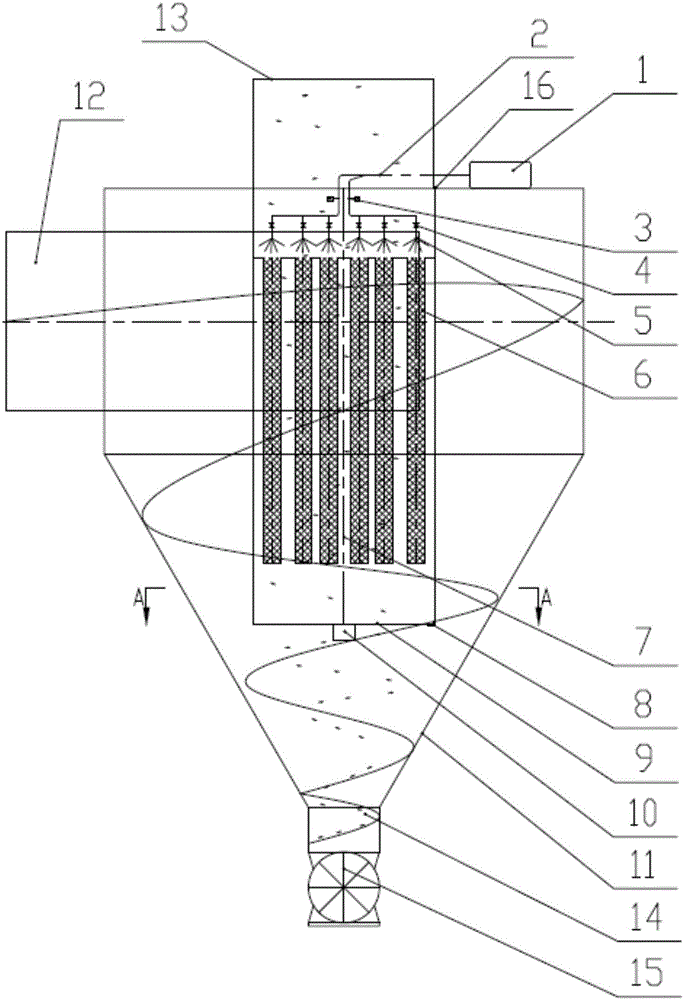

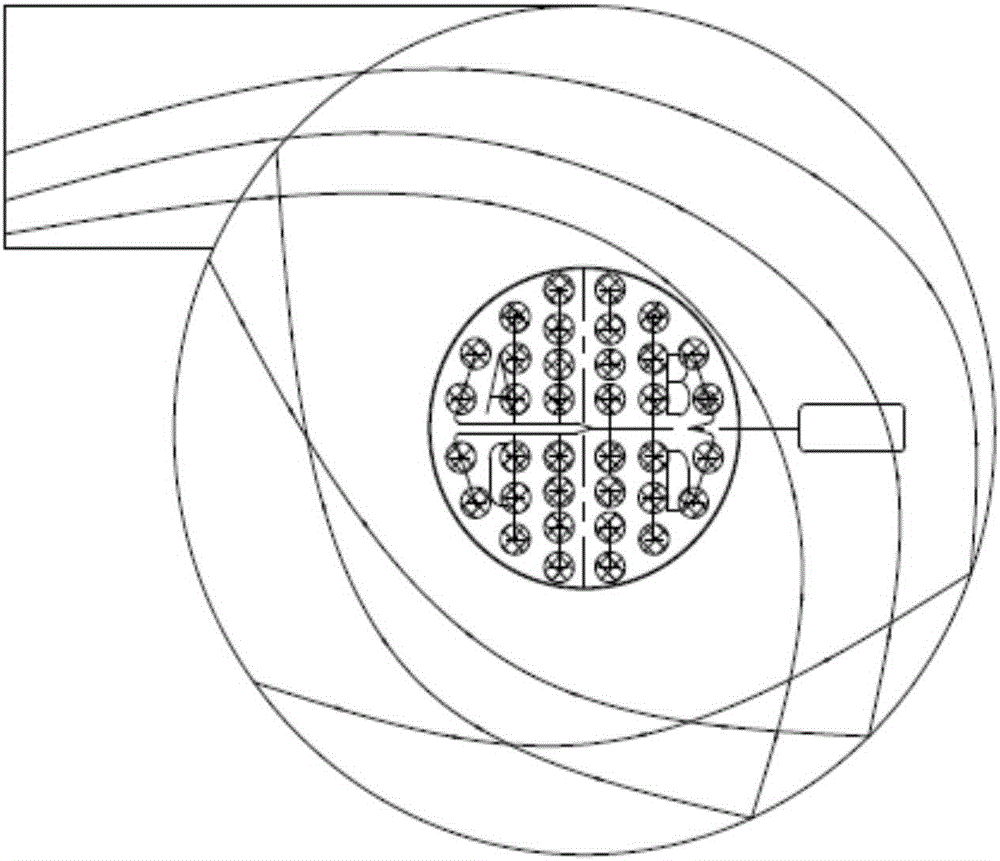

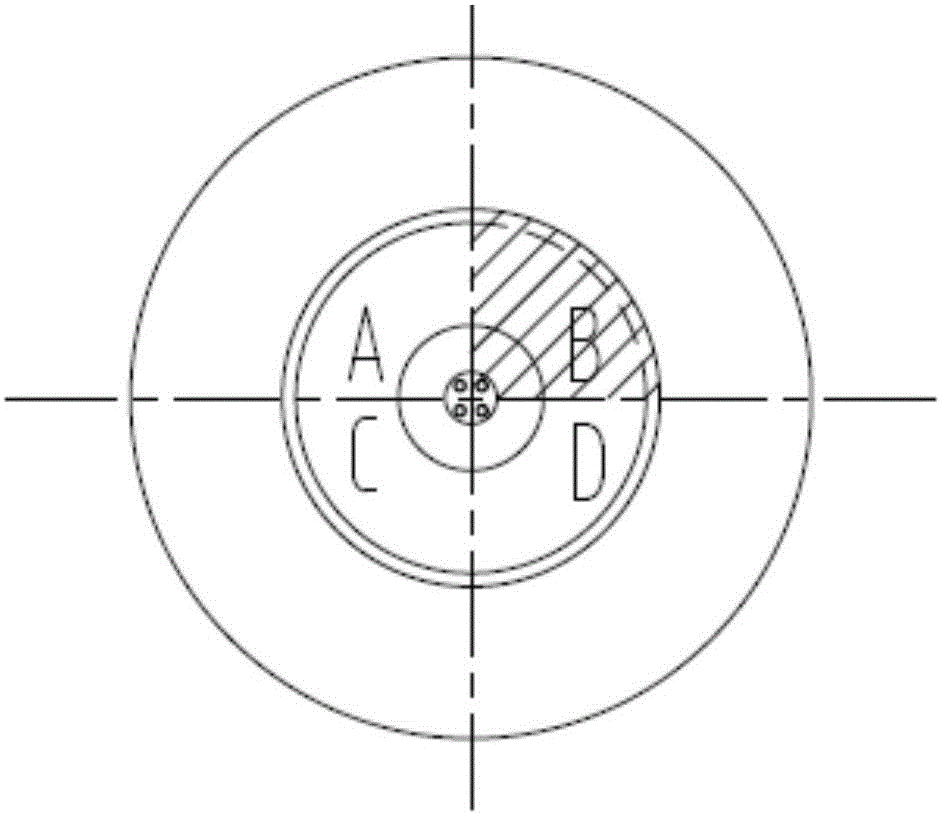

[0013] Referring to the accompanying drawings, a rotary compartment pulse injection system is used for cyclone bag type dust collector, including air storage tank 1, compressed air pipe 2, solenoid valve 3, pulse valve 4, air nozzle 5, filter bag 6, compartment partition 7. Door stopper 8, revolving door 9, stepper motor 10, outer wall of dust collector barrel 11, air inlet pipe 12, clean air pipe 13, ash discharge pipe 14, air locker 15, differential pressure transmitter 16, air storage tank 1. The compressed air pipe 2 is connected to the solenoid valve 3, the pulse valve 4, and the air nozzle 5 to form a system that provides compressed air from the air source to the air nozzle. The filter bag 6 is nested in the inner cylinder of the cyclone bag type dust collector. The plate 7 divides the filter bag into several areas, which is convenient for room cleaning. The revolving door 9 rotates around the middle shaft, and the other end is placed on the door stopper 8 to form a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com