High-heat-preservation windproof broken bridge aluminum alloy door and window

An aluminum alloy door and window, high thermal insulation technology, applied in windows/doors, buildings, climate sustainability, etc., can solve problems such as shaking at the joint, taking away indoor heat, unreasonable windproof design of aluminum alloy doors and windows, etc. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

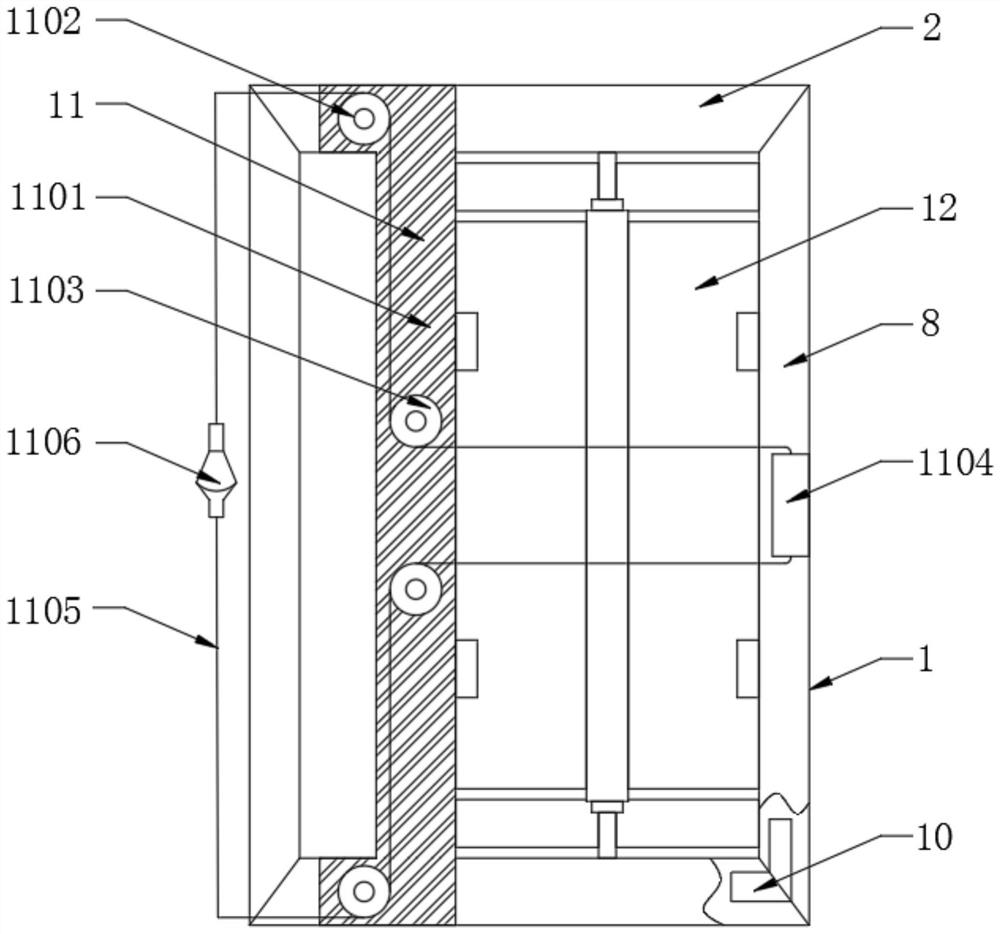

[0029] see figure 1 , the present invention provides a technical solution: a high thermal insulation and windproof type broken bridge aluminum alloy door and window, the inner cavity of the window frame 1 is provided with a pulling mechanism 11, and the pulling mechanism 11 includes a slider 1101 and an end wheel 1102, and the slider 1101 has two upper and lower parts. The end wheel 1102 is installed symmetrically at the ends, and the cross section of the slider 1101 is C-shaped with the opening facing to the left. In the wire bin 1104, the middle wheel 1103 is rotatably installed on both sides of the middle of the slider 1101, and the right side of the slide block 1101 is provided with a wire take-up bin 1104. The take-up bin 1104 is fixedly installed in the middle of the longitudinal beam 8, and the pulling mechanism 11 also includes a pull rope 1105 With the pull ring 1106, a pull rope 1105 is slidably arranged inside the take-up bin 1104, and the pull rope 1105 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com