Composite adhesive type dust flying inhibitor and preparation method thereof

A technology of inhibitors and additives, applied in chemical instruments and methods, other chemical processes, coatings, etc., can solve the problems that the treatment effect cannot last for a long time, fly ash is easy to be blown by strong winds, and atmospheric environment pollution, etc. , to achieve good environmental adaptability, promote bonding, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a composite bonded dust inhibitor, prepared through the following steps:

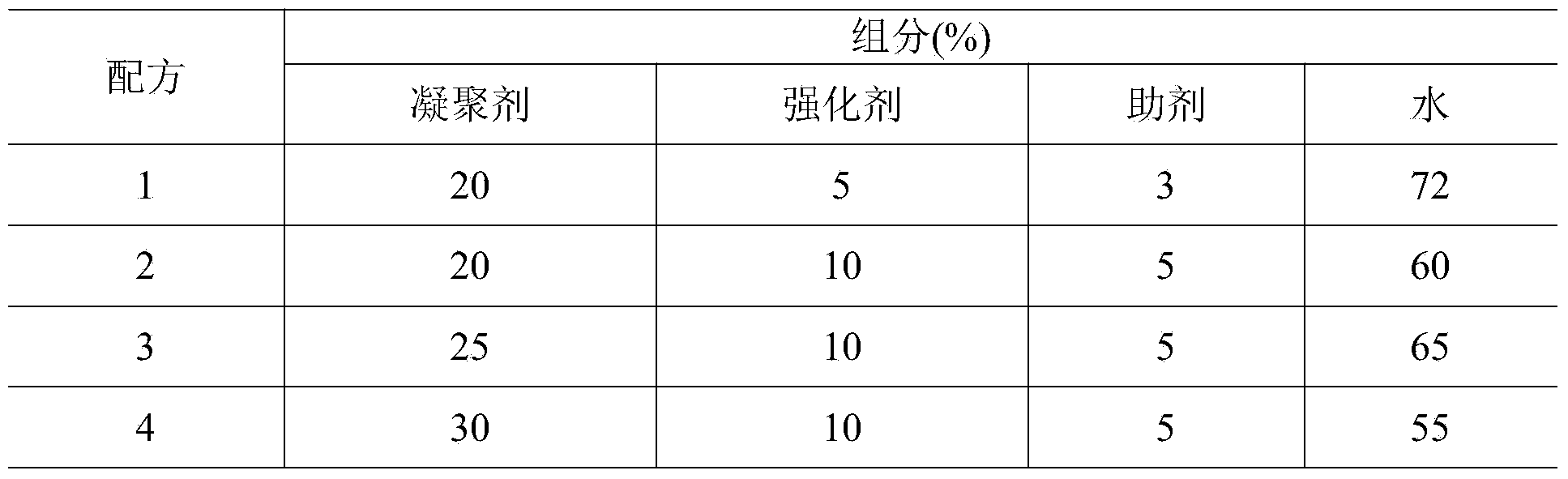

[0021] (1) Put enough water into the preparation tank; (2) Add the coagulant into the water, heat the reaction kettle to 70-90°C, start stirring until the coagulant is completely dissolved; (3) Put the strengthening agent and auxiliary agent in sequence Proportionally added to the container, stirred at room temperature until the product is completely dissolved; wherein by weight percentage: 20-30% of coagulant, 5-10% of strengthening agent, 3-5% of auxiliary agent, and the balance is water; The coagulant is lignosulfonate, and the strengthening agent is selected from one or more mixtures of sodium polyacrylate, polyvinyl alcohol, and polyacrylamide; the auxiliary agent includes sodium carbonate, sodium hydroxyethylene diphosphate mixture, or a mixture of borax and sodium hydroxyethylene diphosphate.

[0022] The lignosulfonate is M t =2500~5000 sodium lignosulfonate or / an...

Embodiment 1

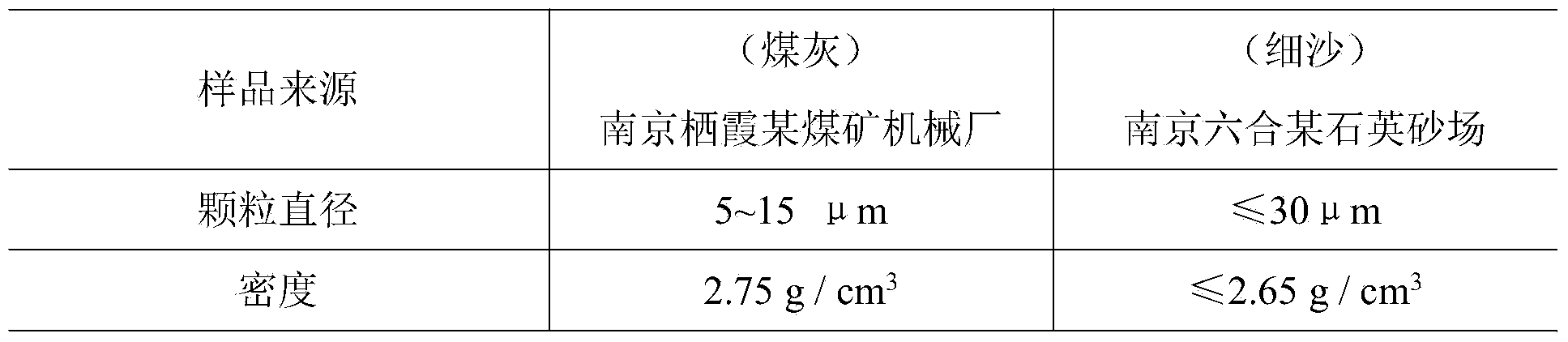

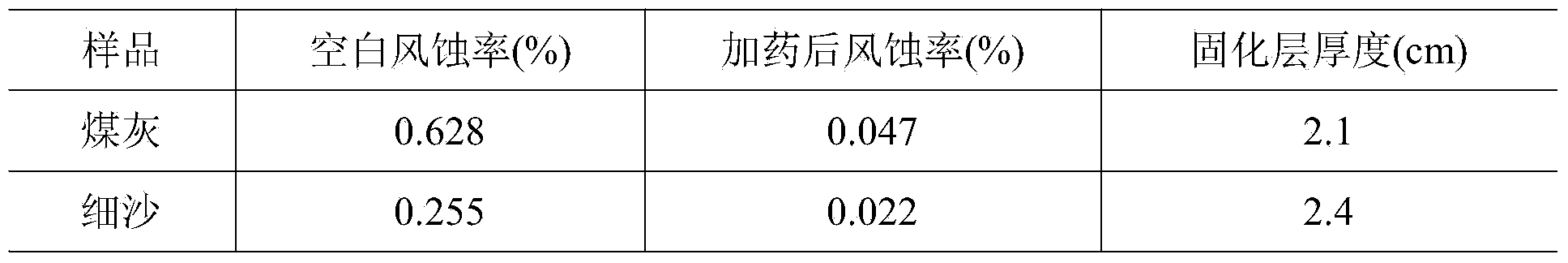

[0034] Embodiment 1 selects formula 1, tests its effect on coal ash and fine sand shown in table 2, and the results are shown in the table below:

[0035]

Embodiment 2

[0036] Embodiment 2 selects formula 2, tests its effect on coal ash and fine sand shown in table 2, and the results are shown in the table below:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com