Efficient multi-field-coordination fine particulate matter removal device and method

A fine particle and field synergy technology, applied in separation methods, chemical instruments and methods, electrostatic effect separation, etc., can solve the problems that the removal efficiency of fine particles cannot be effectively improved, and the agglomeration effect of fine particles is not obvious, so as to avoid Anti-corona and secondary dust, promote coagulation and growth, and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

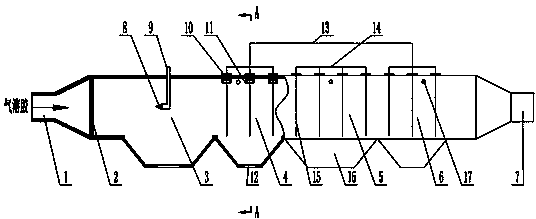

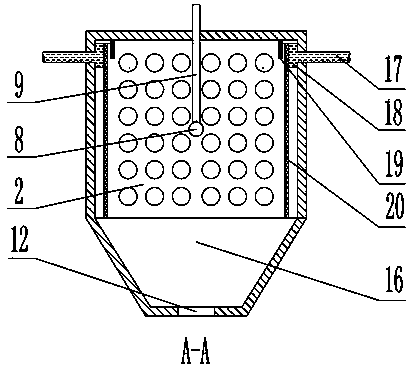

[0022] Such as figure 1 , 2 As shown, the multi-field collaborative fine particle efficient removal device includes aerosol particle inlet 1, air distribution plate 2, external field condensation area 3, direct current pre-dust collection area 4, pulse charge condensation area 5, direct current dust collection area 6, Aerosol outlet 7, nozzle 8, water vapor and chemical agglomerating agent access pipeline 9, PTFE insulator 10, PTFE insulator waterproof casing 11, ash hopper slurry outlet 12, negative DC high voltage wire 13, positive Pulse high-voltage wire 14, wire electrode 15, ash hopper 16, water film electrode external water source access pipeline 17, water tank 18, baffle plate 19, plate electrode 20; Combined zone 3, direct current pre-dust collection zone 4, pulse charged coagulation zone 5, direct current dust collection zone 6, and aerosol outlet 7 are connected in sequence; Inlet pipeline 9, ash hopper slurry outlet 12, ash hopper 16; the nozzle 8 adopts a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com