Liquid flow water wash static combined type gas purification method and device thereof

A gas purification device and gas purification technology are applied in the direction of combined devices, chemical instruments and methods, electrostatic separation, etc., which can solve the problems of high equipment requirements, low purification efficiency, and high investment costs, and achieve the elimination of high-voltage static electricity pollution. Dust accumulation phenomenon, the effect of increasing the flow rate of gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

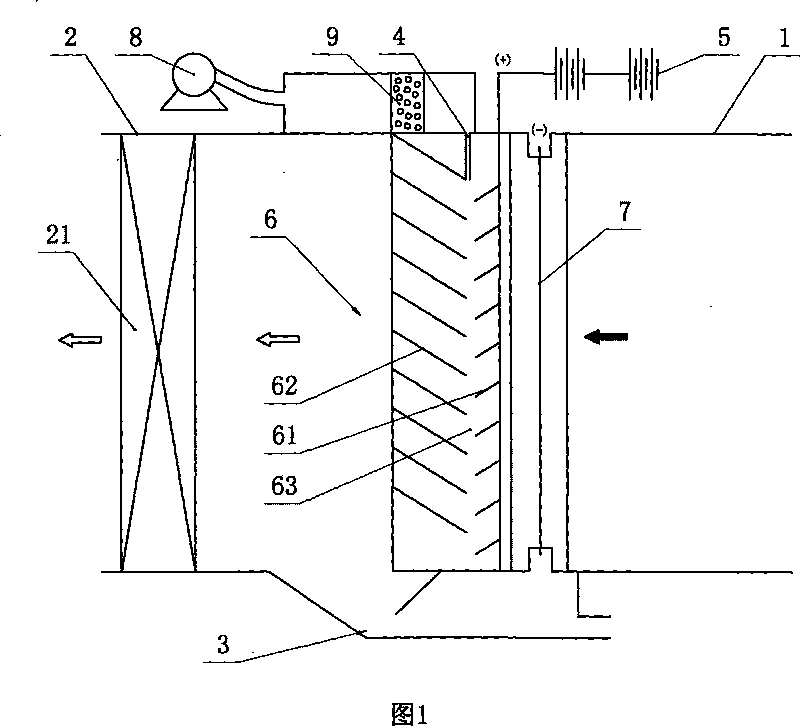

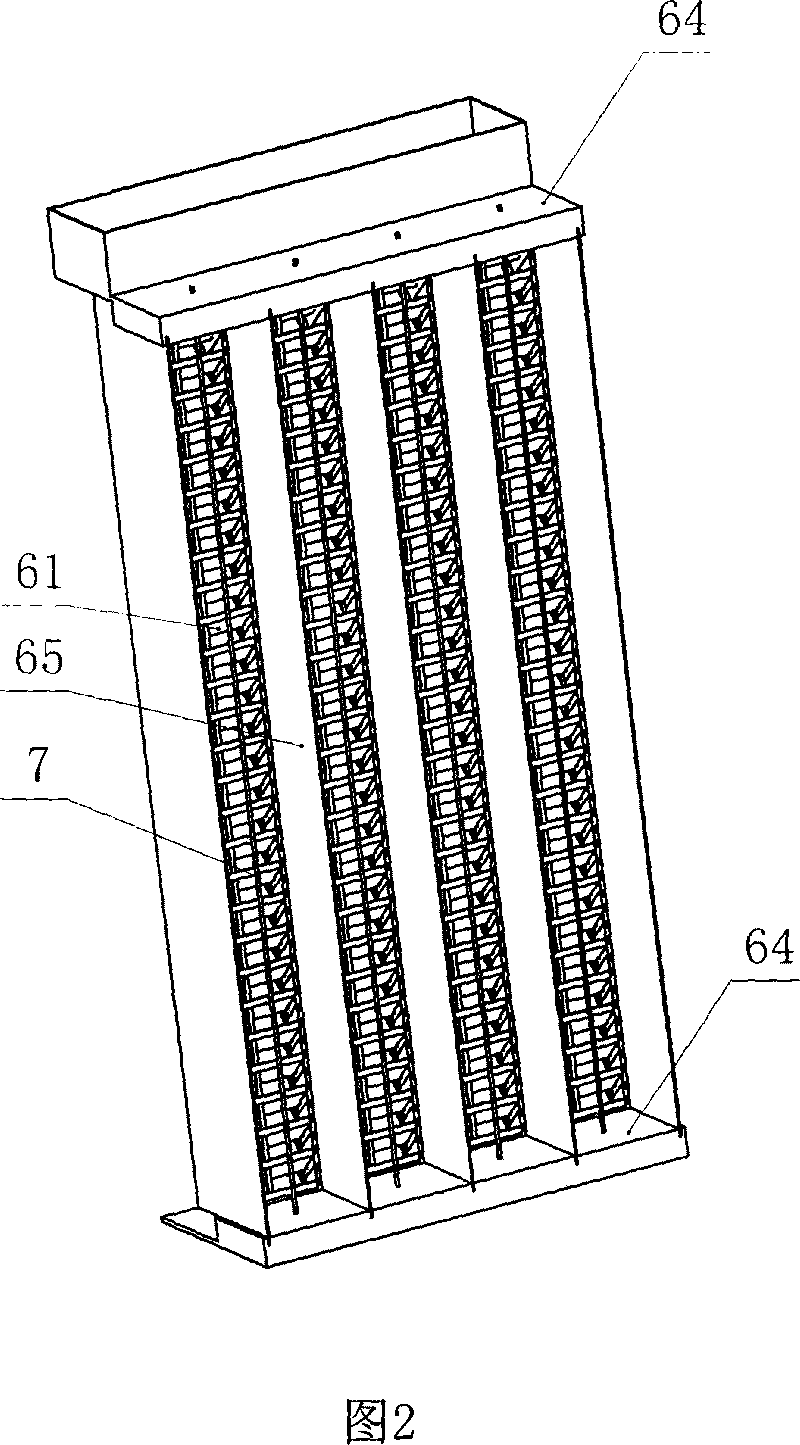

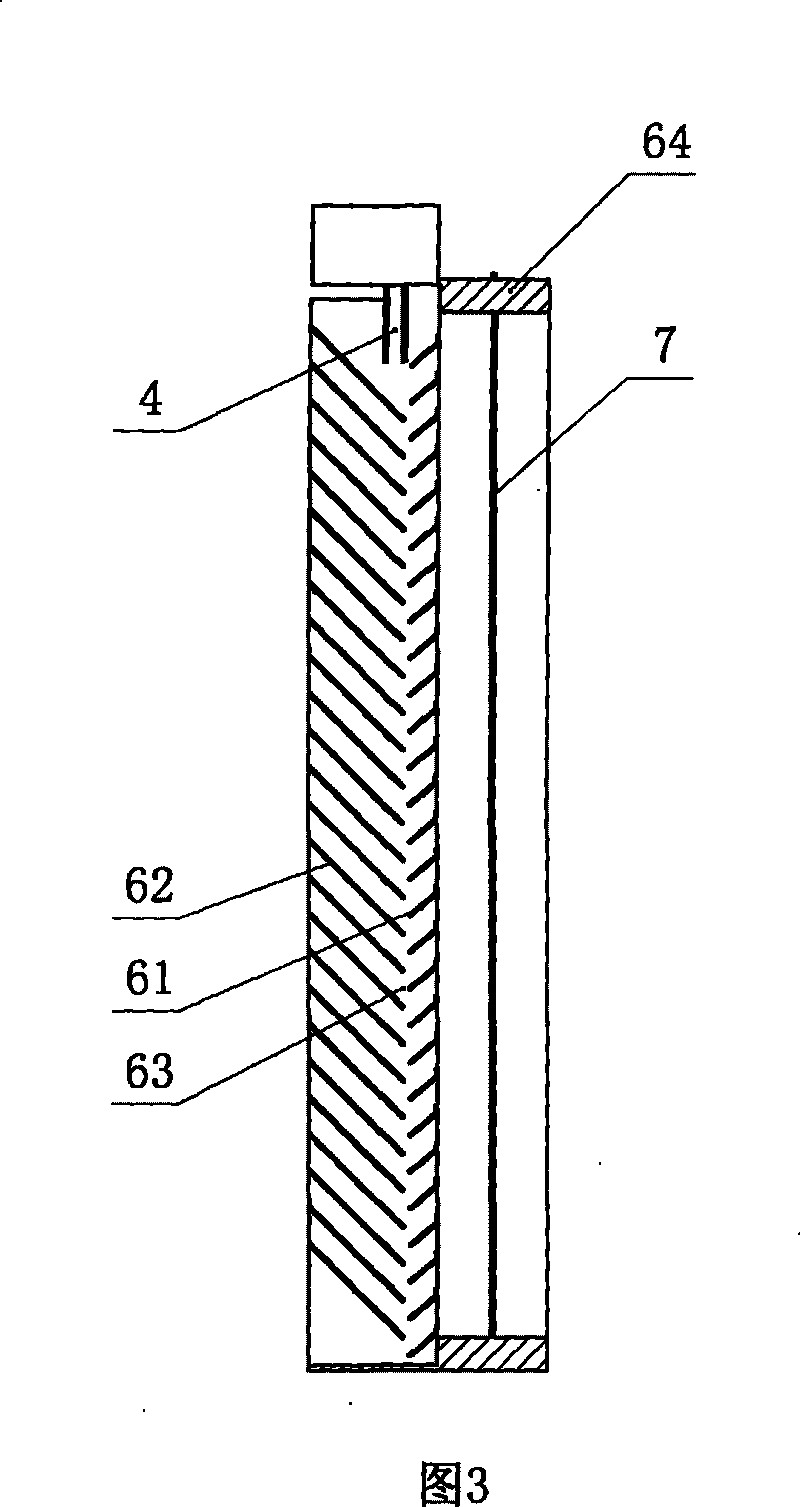

[0022] Such as Figure 1-3 The specific embodiment of the present invention shown includes air intake pipe 1, exhaust pipe 2, liquid outlet 3, cleaning liquid inlet 4, DC high-voltage power supply 5, cleaner 6, and the exhaust pipe is provided with Exhaust fan 21, the cleaner 6 is located in the intake pipe 1, the exhaust pipe 2 is connected to the other side of the cleaner 6 relative to the inlet pipe 1, and the cleaner 6 is provided with two vertical rows The inner and outer interlayer dust-collecting plates 61, 62 are spaced apart from each other, and the outer row of inter-layer dust-collecting plates 62 and the inner row of inter-layer dust-collecting plates 61 are arranged in a staggered direction obliquely downward, forming a louver-like "V"-shaped air duct, The dust-collecting boards of the inner and outer rows of compartments described in this embodiment are both made of corrosion-resistant metal materials. The upper and lower support seats 64 provided by the cleaner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com