Inertia gravity dust collector

A dust collector and gravity technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of high operating resistance, investment, high operating cost, and large volume of bag dust collectors, and achieve dust collection Remarkable effect, reduced operating cost, and low operating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

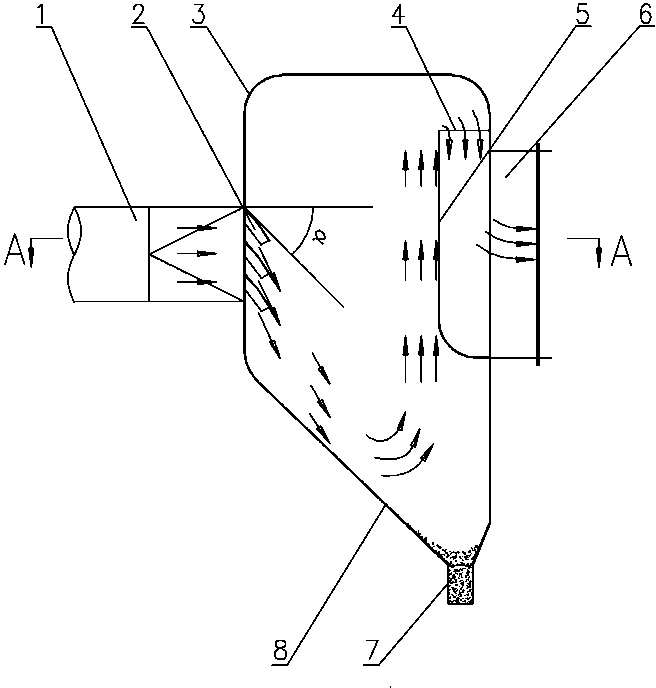

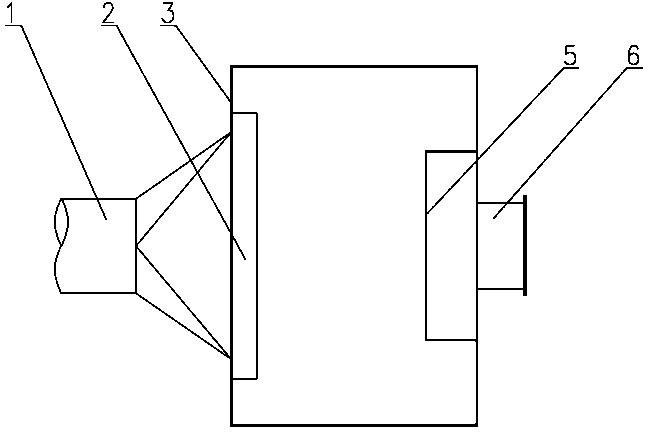

[0022] Example 1: see figure 1 , 2 , the structure of the present invention has a housing 3, especially: a smoke inlet pipe 1 is installed in the left middle part of the housing 3, an ash outlet pipe 7 is installed at the bottom of the housing 3, and an ash outlet pipe 7 is installed on the right side wall of the housing 3. A smoke exhaust pipe 6 is provided, and a guide coaming plate 5 is provided at the inner mouth of the smoke exhaust pipe 6 to form an upper entrance structure, and the upper entrance is higher than the smoke inlet pipe 1; the housing 3 is located on the smoke inlet pipe 1 There are three layers of arc-shaped deflectors 2 at the mouth of the nozzle (the number of layers is designed according to the furnace type, working conditions and other conditions, and at least one layer is guaranteed), which is directed downward, and the tangent direction of the starting point of the arc-shaped deflectors 2 is in line with the horizontal direction. The direction of smo...

example 2

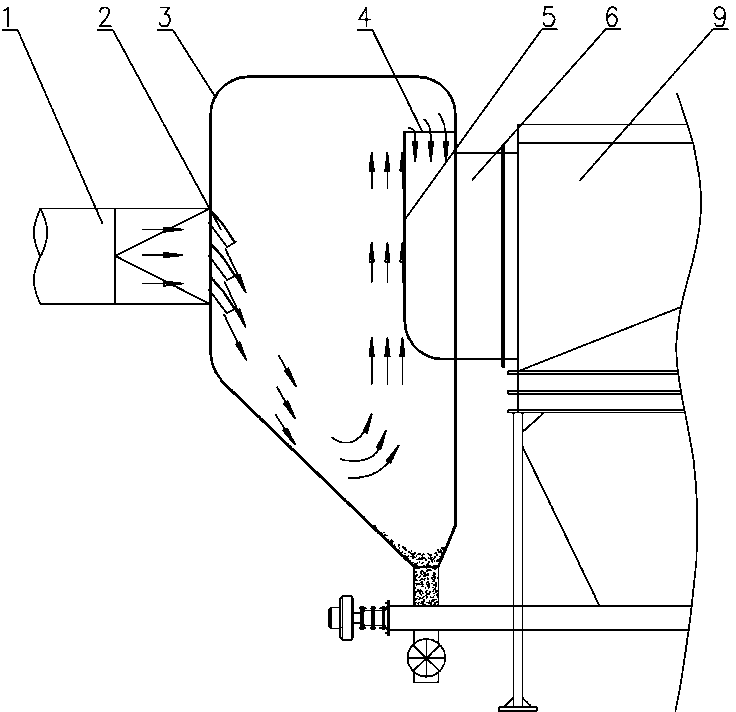

[0025] Example 2: structure two of the present invention, see Figure 4 , it has a housing 3, in particular: a smoke inlet pipe 1 is installed in the middle of the left side of the housing 3, an ash outlet pipe 7 is installed at the bottom of the housing 3, and a smoke exhaust pipe 6 is arranged on the top of the housing 3 and a five-layer arc-shaped deflector 2 is arranged at the nozzle of the smoke inlet pipe 1 on the shell 3, which is directed downward, and the tangent direction of the starting point of the arc-shaped deflector 2 is α' to the horizontal smoke flow direction =35° angle arrangement.

[0026] In this embodiment, the lower part of the right side wall of the housing 3 is an inclined wall surface 10 .

[0027] The second structure of the present invention can be directly placed at the outlet end of the dryer cylinder where the material brought out by the increase of the wind speed in the output lifting cylinder increases sharply, which can reduce the pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com