Sea boat smoke evacuation washing device and its washing method

A washing device and washing method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the contradiction of increasing pressure loss, anti-corrosion, reducing operating costs and increasing manufacturing costs, and increasing the manufacturing cost of the device. and other problems, to achieve the effect of reducing manufacturing and operating costs, excellent technical and economic indicators, and prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

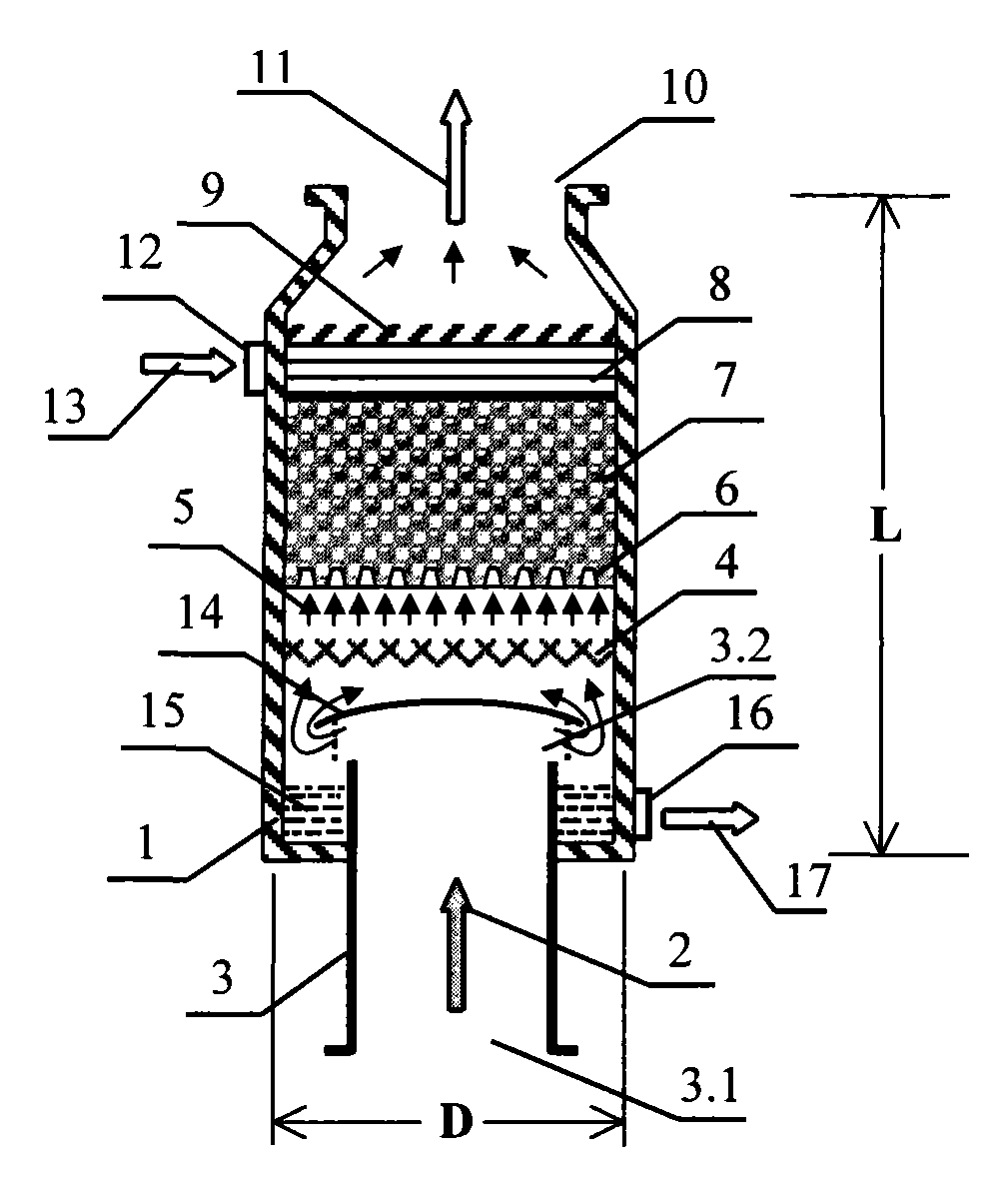

[0086] As shown in Figure 1, the flue gas inlet 3.2 in the casing is an embodiment that is fixed at the bottom of the casing 1 and extends to the outlet of the flue gas inlet pipe 3 inside the casing 1, and can always keep the flue gas inlet 3 in the liquid collecting position. Above the liquid surface of the acidic seawater in the pool 15, that is, the flue gas does not enter into the acidic seawater, and is suitable for introducing flue gas vertically. It has a shell 1, the washing layer 7 with packing is fixed on its inside, and the liquid sump 15 with seawater discharge port 16 is below its inside; The outside of the casing 1 is introduced into the flue gas conduit 3 inside the casing 1. One end of the flue gas conduit 3 is the flue gas inlet 3.1 outside the casing, and the other end is the flue gas inlet 3.2 inside the casing; the flue gas inlet 3.2 in the casing extends to Inside the casing 1, it is located between the washing layer 7 and the liquid sump 15; the cooler 4...

Embodiment 2

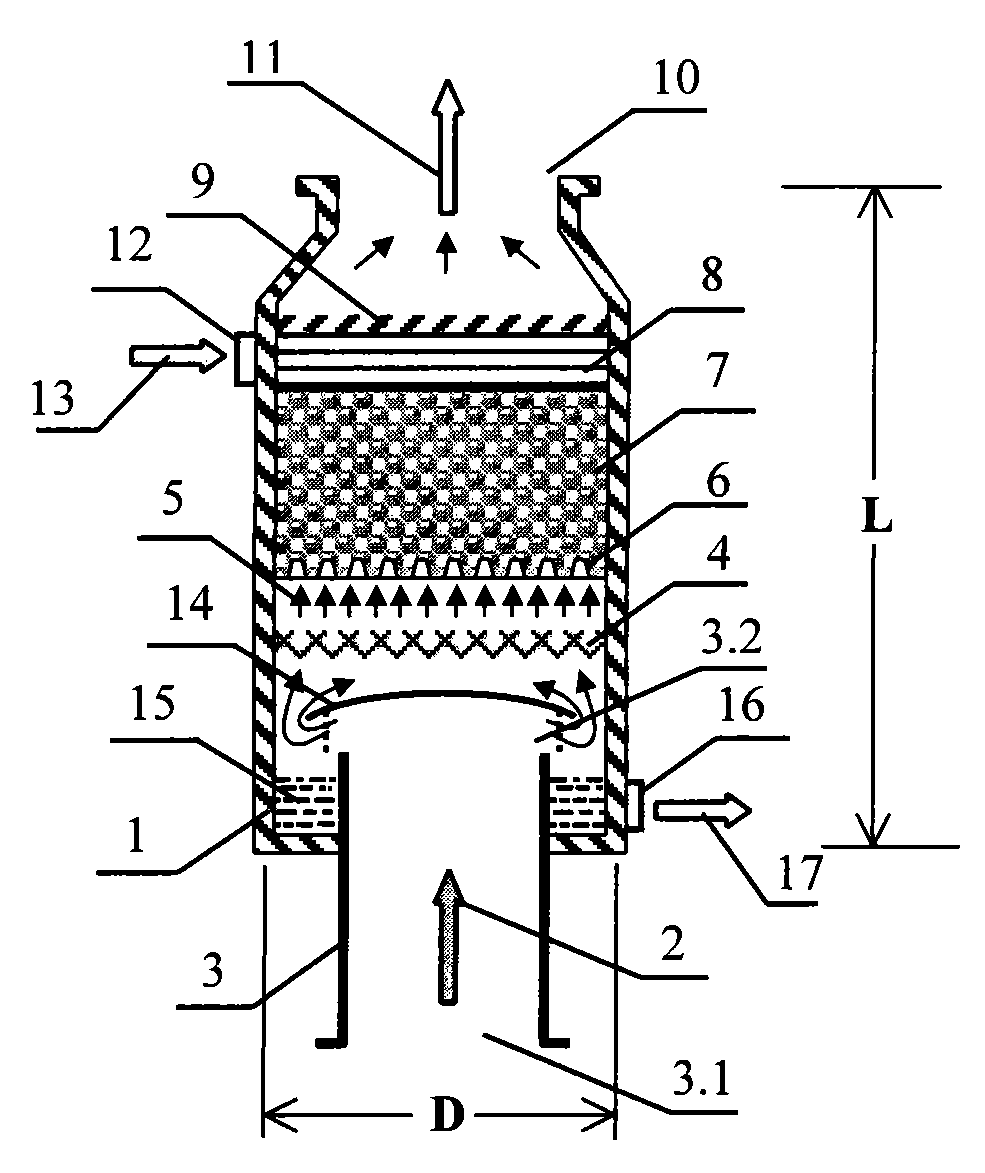

[0100] Embodiment 2: As shown in Figure 2, it is another embodiment of the smoke exhaust washing device for seagoing ships. The difference from Example 1 is that the flue gas inlet 3.2 in the casing is on the inner wall of the casing 1, which is the outlet of the flue gas conduit 3 fixedly connected to the side wall of the casing 1, and the flue gas inlet 3 can always be kept in the liquid sump 15 above the acidic seawater liquid level, that is, the flue gas does not enter the acidic seawater, and is suitable for introducing flue gas laterally; the liquid collection pool 15 is the side of the shell below the horizontal cross section where the lower edge of the flue gas inlet 3.2 in the shell is located wall and bottom.

Embodiment 3

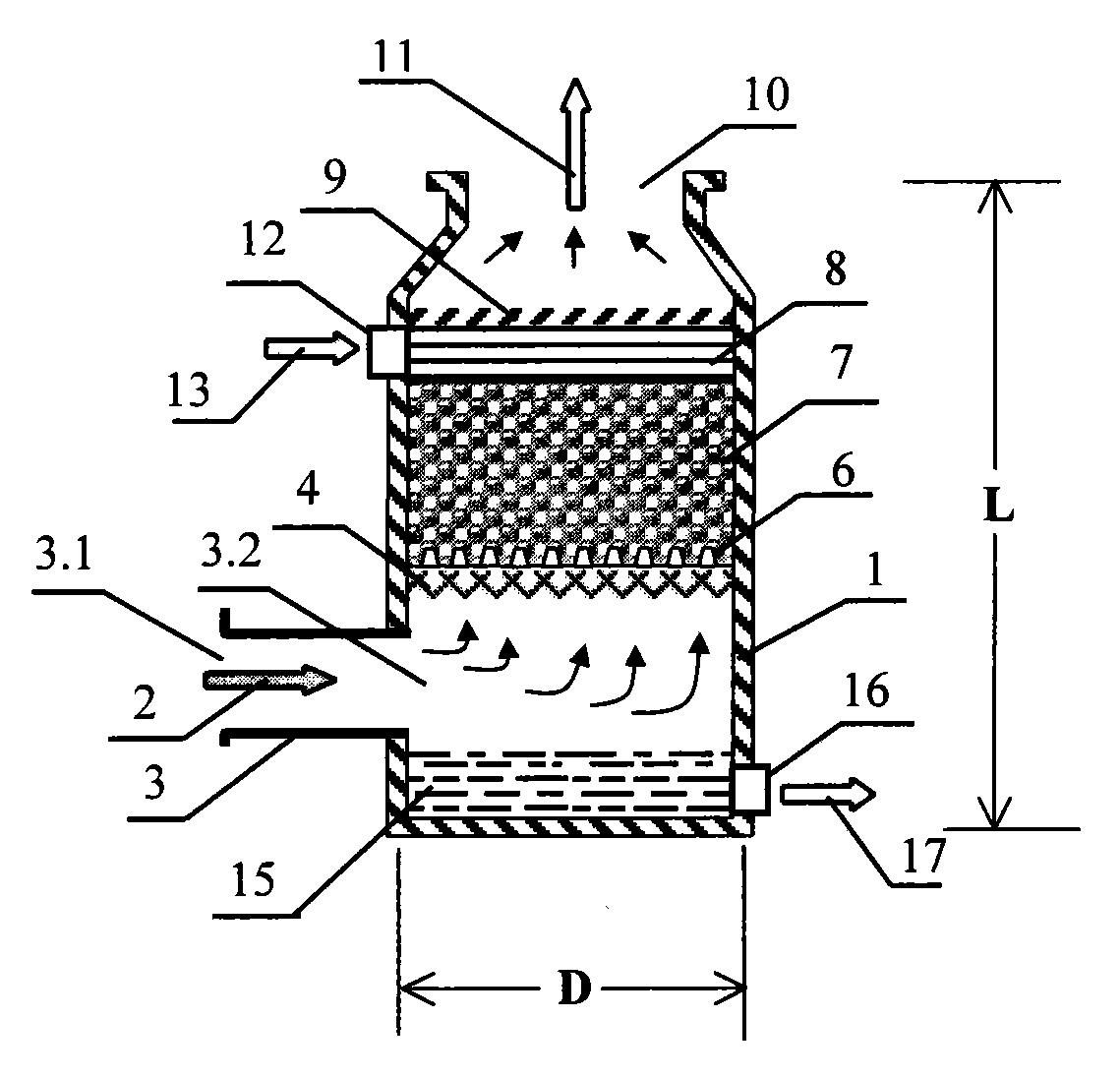

[0101] Embodiment 3: It is another embodiment of the smoke exhaust washing device for seagoing ships. The difference from the above embodiments is that the cooler 4 is installed on the flue gas duct 3, and may also be a cooling pipe or a cooling fin in the lumen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com