Liquid steel slag wind quenching granulation production line and production technology thereof

A liquid steel slag production line technology, applied in the liquid steel slag air-quenching granulation production line and its production process, can solve the problems of inability to adjust, affect the flight trajectory of liquid steel slag, and unfavorable cooling of steel slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

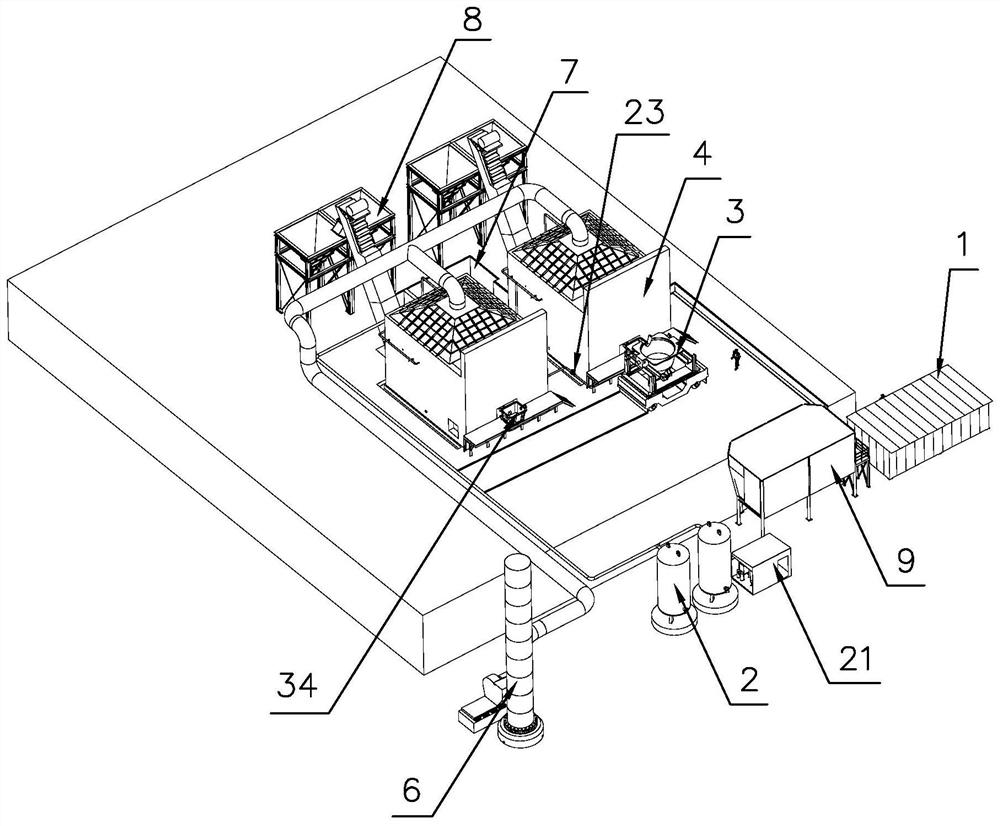

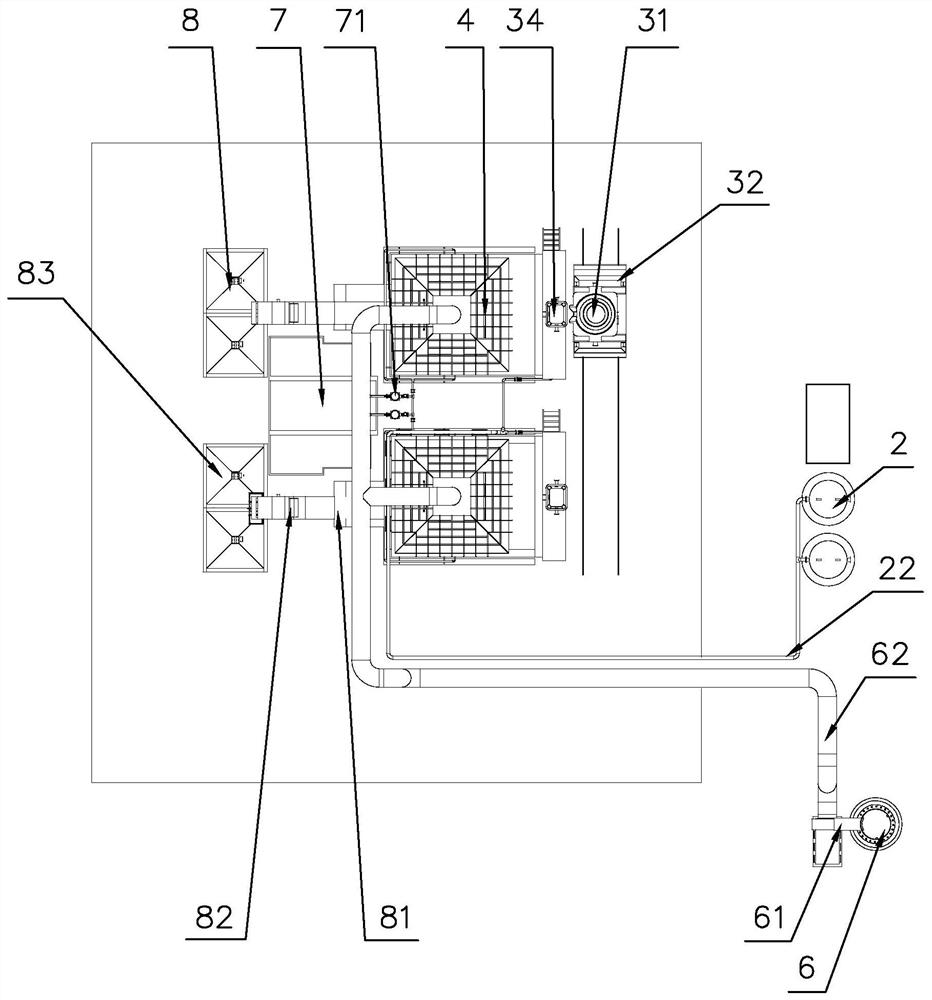

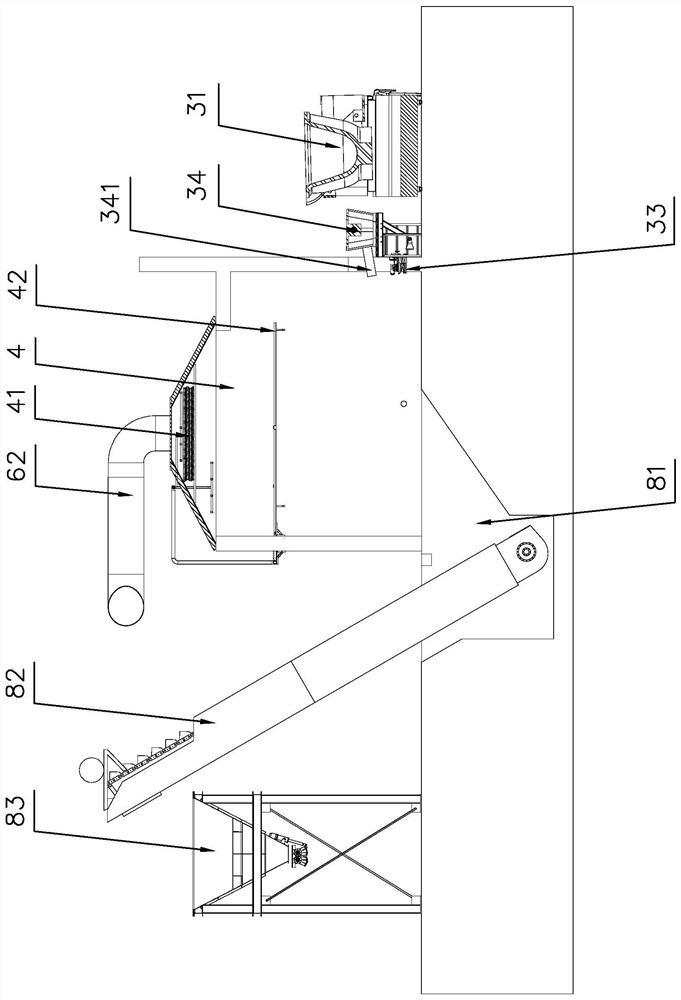

[0034] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-5 , to further specifically describe the technical solution of the present invention.

[0035] A liquid steel slag air-quenching granulation production line and its production process, including an electric control room 1, a compressed air source 2, an air pipeline 22, a steel slag granulation mechanism 3, a steel slag treatment room 4, an exhaust purification tower 6, and an exhaust pipeline 62 , a cooling circulation pool 7, a slag recovery mechanism 8, a slag extraction pool 81, an observation room 9, a steel slag granulation mechanism 3 is provided on one side of the steel slag treatment room 4, and a cooling circulation pool is provided on one side of the steel slag treatment room 4 7. The other side of the steel slag treatment chamber 4 is provided with a slag recovery mechanism 8, one side of the slag recovery mechanism 8 is provided with a slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com