Advanced water treatment method for micro-polluted water source

A technology for advanced treatment and micro-pollution, applied in multi-stage water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Insufficient supply and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] The preferred embodiment of the micro-polluted water source water advanced treatment method of the present invention is:

[0014] Including steps:

[0015] A. The effluent from the sedimentation tank enters the ozone pre-oxidation tank, and a pure titanium metal aeration head is installed in the bottom of the tank. The tank body is divided into two sections, the ratio of the tank volume of the two sections is 3:2, and the ozone concentration in the tank is 1~ 3mg / L, the residence time of the water in the pool is 10-15min, the macromolecular organic matter in the water is decomposed into small molecular organic matter through the strong oxidation of ozone;

[0016] B. The effluent of the ozone pre-oxidation tank is upgraded to a high-efficiency biological filter, the filtering speed of the high-efficiency biological filter is 6-10m / h, and the filter material includes two filter materials, one is briquette and crushed charcoal, granular The diameter range is 1.2~1.3mm, located ...

specific Embodiment

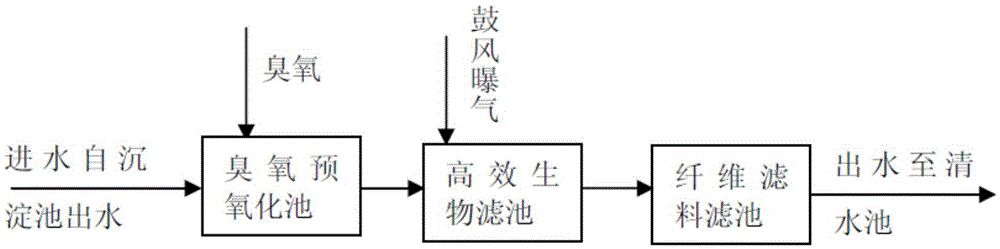

[0021] Such as figure 1 As shown, the steps are as follows:

[0022] (1) The inlet water of the ozone pre-oxidation tank is discharged from the flocculation sedimentation tank, and the pure titanium metal aeration head is installed in the bottom of the tank. The tank body is divided into two sections before and after, and the volume ratio of the two sections is 3:2; the ozone concentration is 1~3mg / L, the residence time is 10-15min; the macromolecular organic matter in the water is decomposed into small molecular organic matter through the strong oxidation of ozone.

[0023] (2) The effluent from the ozone pre-oxidation tank is upgraded to a high-efficiency biological filter. The filtration rate of the high-efficiency biological filter is 6-10m / h, and the filter material is composed of two kinds of filter materials, one is briquette crushed charcoal, with a particle size range of 1.2-1.3mm, located in the upper layer, with a layer height of 1.8m; the other is ceramsite The filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com