Surface water recycling system for sponge city and construction method of surface water recycling system

A sponge city and construction method technology, applied in waterway systems, chemical instruments and methods, and sewage removal, etc., can solve problems such as low rainwater utilization efficiency, increased urban maintenance costs, and worsened river water quality, black and odor, and achieve good mixing. Coagulation effect, ideal treatment effect, no side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

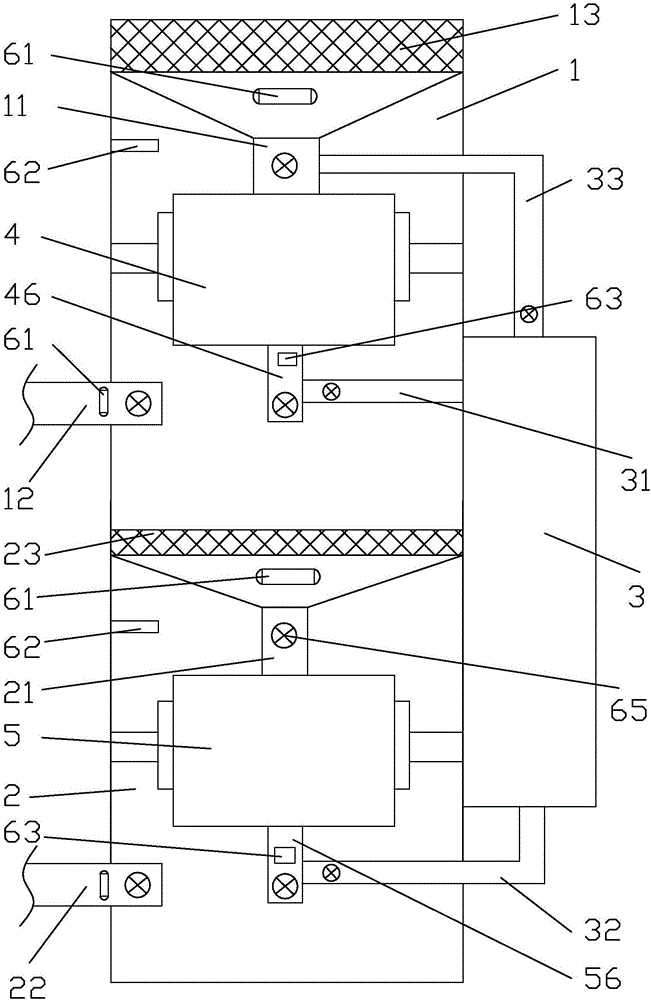

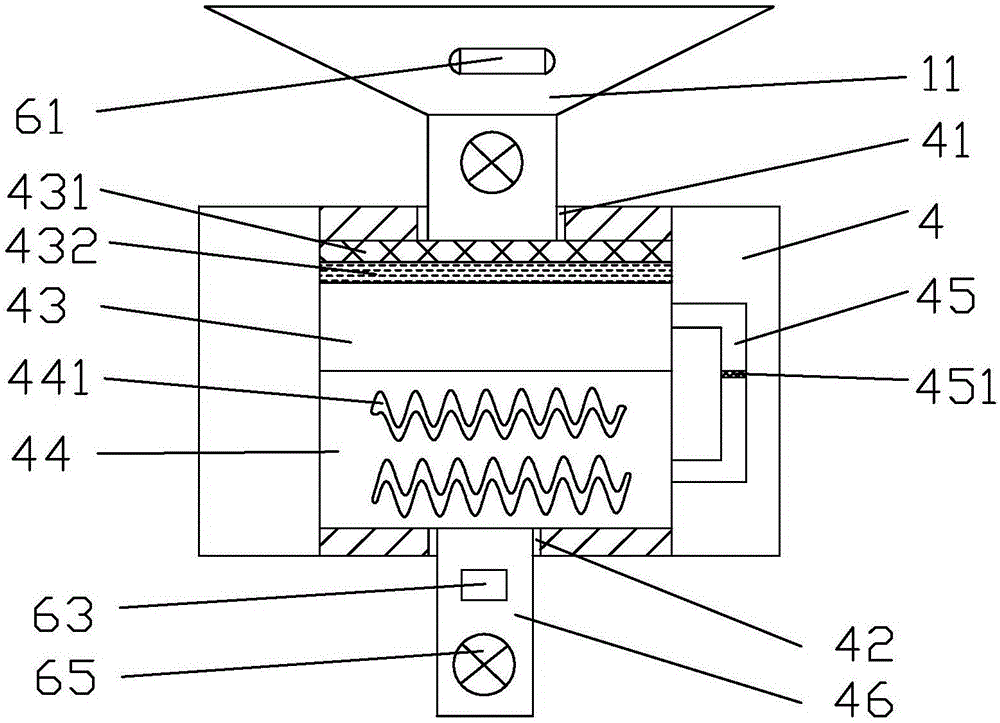

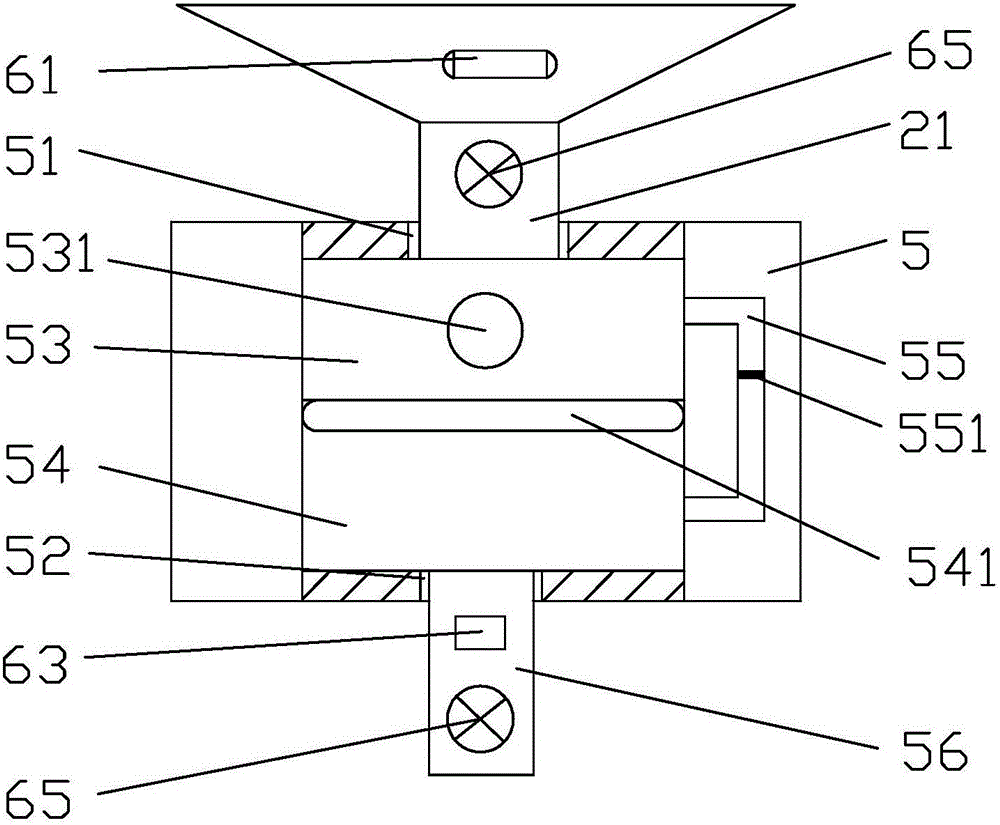

[0048] Such as Figure 1-4As shown, it is a recycling system for surface water in a sponge city of the present invention, including a clean water storage system, a sewage treatment system and a water flow control system 6, and the clean water storage system includes a first water storage well 1 and a second water storage well 2 and circulation well 3, the first water storage well 1 is located above the second water storage well 2, the first water storage well 1 is provided with the first water inlet pipe 11 and the first water outlet pipe 12, and the second water storage well 2 A second water inlet pipe 21 and a second water outlet pipe 22 are provided. The second water inlet pipe 21 communicates with the first water storage well 1 and the second water storage well 2. A primary filter layer 13 is laid above the first water storage well 1. A water inlet pipe 11 is located below the primary filter layer 13 , a fine filter layer 23 is provided between the first water storage well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com