Energy-saving chimney of thermal power plant

A technology for thermal power plants and chimneys, applied in the field of chimneys, can solve the problems of environmental pollution and low resource utilization, and achieve the effects of reducing pollution, improving efficiency, and reducing particulate matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

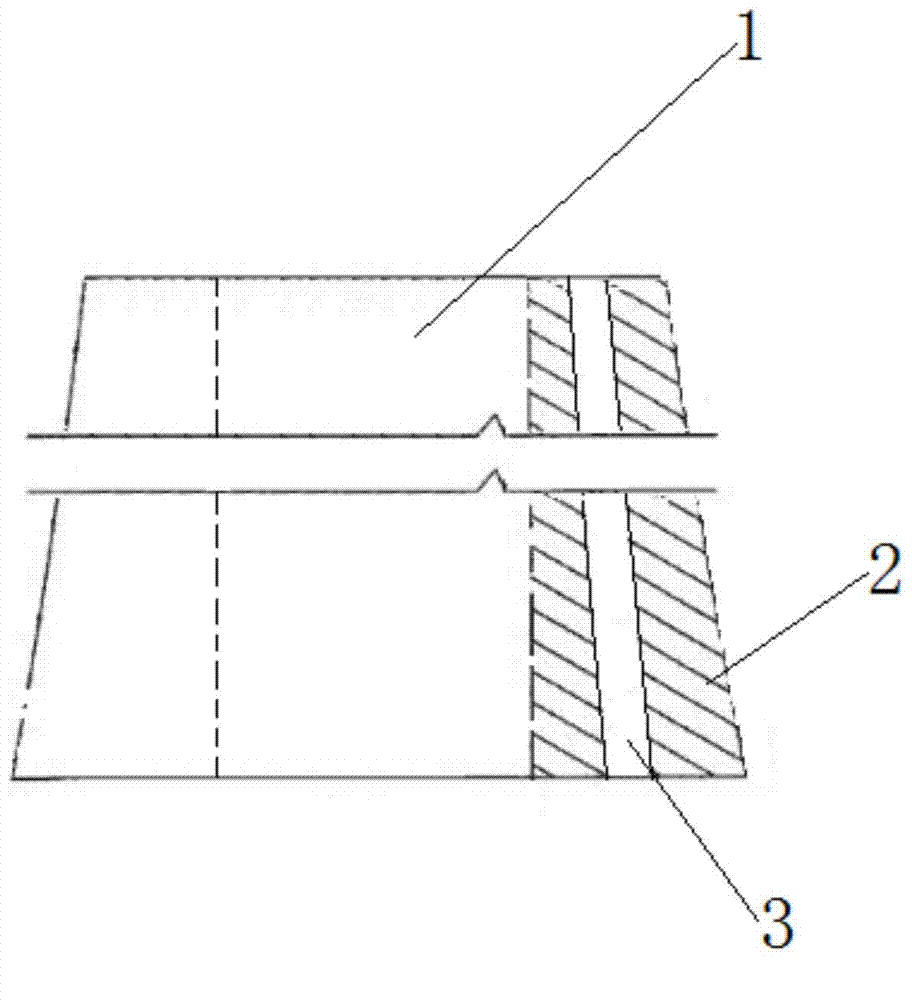

[0013] A kind of energy-saving chimney of thermal power plant, such as figure 1 As shown, the chimney wall 2 is formed into a cylindrical shape, and a flue 1 is formed inside the chimney wall 2. An interlayer 3 is arranged between the outer surface and the inner surface of the chimney wall 2, and the interlayer 3 is filled with water.

[0014] The heat carried by the flue gas exchanges heat with the water in the interlayer 3 through the chimney wall 2 to improve heat utilization efficiency. At this time, the thickness of the interlayer 3 and the inner side of the chimney wall 2 should be appropriate, otherwise the heat exchange efficiency will be reduced. In order to properly prolong the residence time of the flue gas in the flue 1 and improve the heat exchange efficiency, the flue 1 is spiral.

[0015] Likewise, in order to improve the heat exchange efficiency, the interlayer 3 is divided into helical flow channels.

[0016] The chimney of the invention can effectively exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com