Middings magnetic separator tailings classifying separation recovery system and middings magnetic separatortailings classifying separation recovery technology for dense medium coal preparation plant

A technology of magnetic separator and coal preparation plant, applied in the direction of swirl device, etc., can solve the problems of increasing difficulty in flotation operation, increasing construction and production costs of coal preparation plant, waste of non-renewable coal resources, etc., and reducing flotation The effect of agent consumption, reducing the number of flotation equipment, and improving floatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

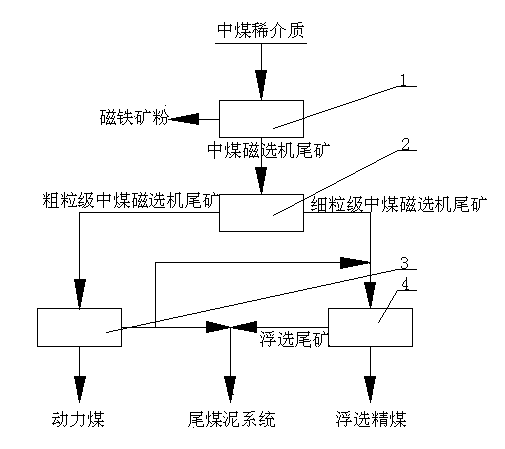

[0026] Example 1 system

[0027] The equipment used in this embodiment includes: a medium coal magnetic separator 1 , a coal slime classification device 2 , a coarse coal slime recovery device 3 , and a flotation device 4 . The coal slime classification device 2 of this embodiment uses a VOSB362060 vibrating curved screen with a screen surface width of 3.8m, a sieve plate sieve size of 0.5mm, and a classification particle size of 0.25mm. The coarse coal slime dehydration recovery device 3 uses a LLL930×470B vertical scraper The unloading coarse coal slime centrifugal dehydrator has a centrifugal strength of 72G, and the moisture content of the dehydrated product is 7% to 11%. The flotation device 4 uses XJM-S16 mechanical agitation flotation machine. Its connection structure see figure 1 , the tailings outlet of China Coal Magnetic Separator 1 is connected to the inlet of the feeding box of the coal slime classification device 2 VOSB362060 type vibrating arc screen, and...

Embodiment 2

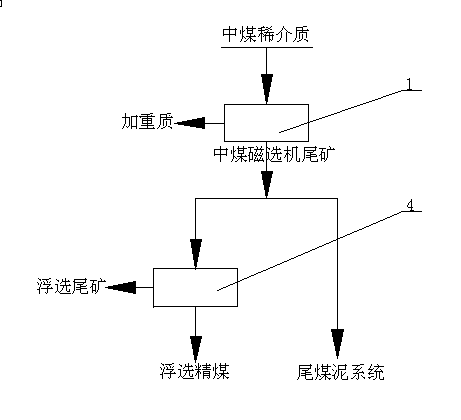

[0030] Embodiment 2 Grading and sorting recovery process

[0031] The tailings outlet of the China Coal Magnetic Separator 1 is connected to the inlet of the feeding box of the coal slime classification device 2 VOSB362060 type vibrating arc screen, and the oversize (coarse material) of the coal slime classifying device 2 VOSB362060 type vibrating arc screen The outlet is connected to the feed port of the coarse slime dehydration recovery device 3 LLL930×470B vertical scraper unloading coarse slime centrifugal dehydrator, and the undersize (fine material) of the slime classification device 2 VOSB362060 vibrating curved sieve The outlet is connected to the feed port of the flotation device 4 XJM-S16 mechanical agitation flotation machine, and the coarse coal slime dehydration recovery device 3 LLL930×470B vertical scraper unloads the centrifugal liquid of the coarse coal slime centrifugal dehydrator (coal slime water ) The outlet is connected to the inlet of the flotation devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com