Six-rod-tetrahedral-module-unit assembled cover-plate-and-bolt-connected sphere joint and assembling method thereof

A six-bar tetrahedron and modular unit technology, which is applied in the direction of construction and building construction, can solve the problems of unsuitability and weakness, and achieve the goals of reducing labor force on the construction site, excellent performance, and reducing welding workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

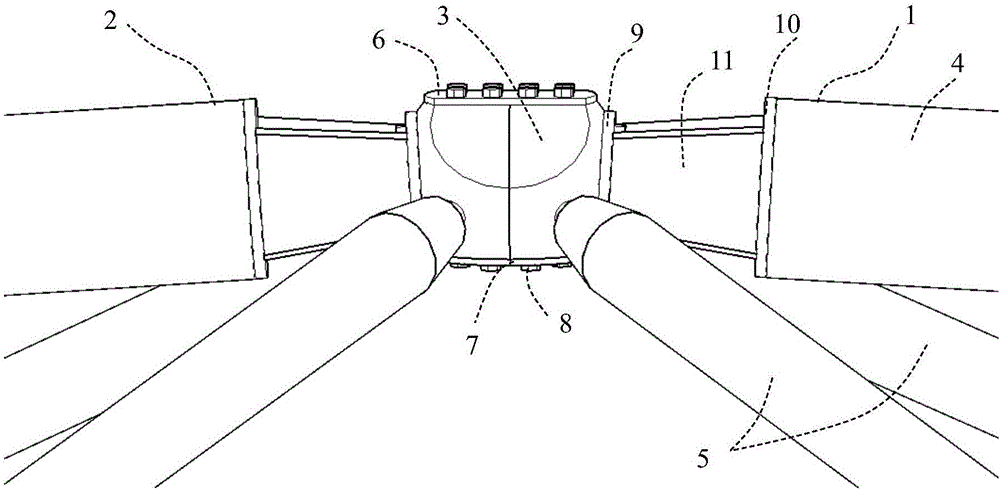

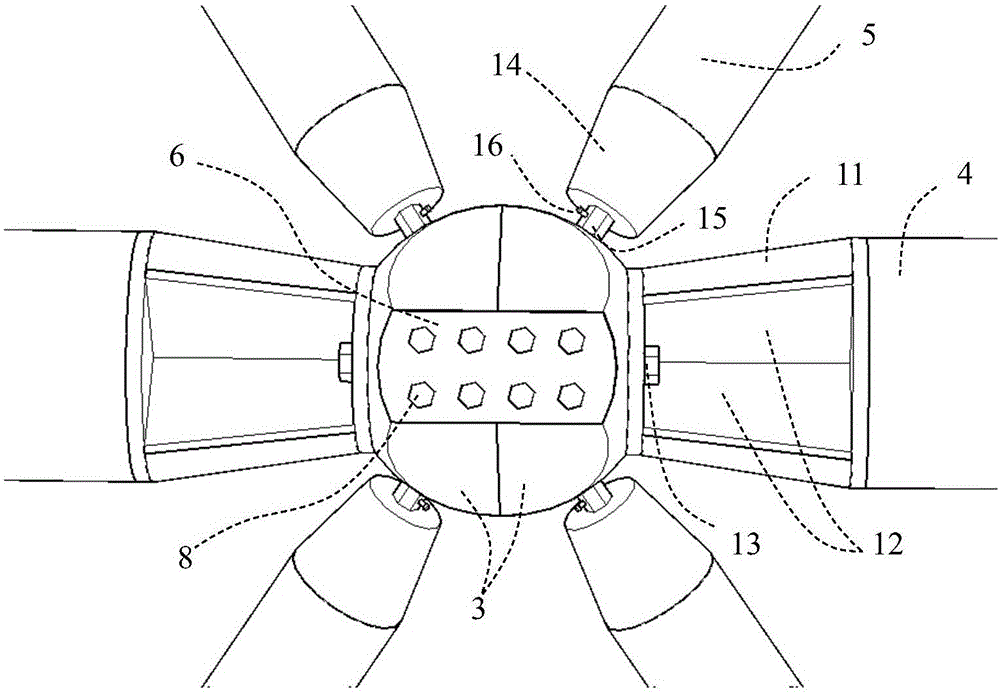

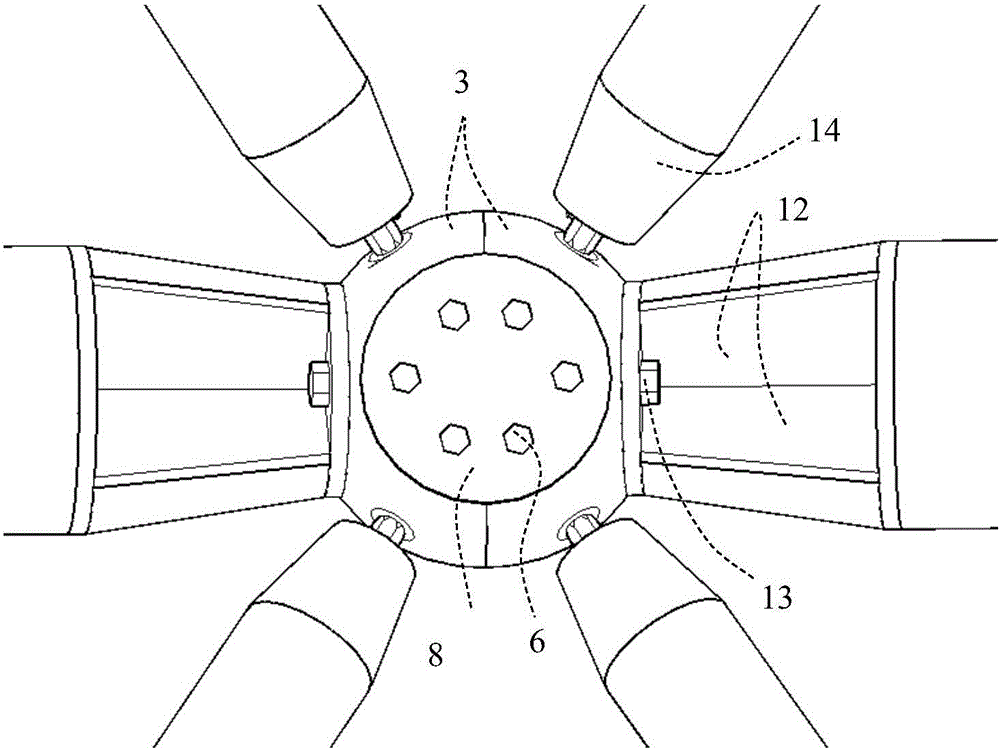

[0053] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown in the figure, a six-bar tetrahedron modular unit assembled cover plate is connected to a bolt ball joint, including a left connecting body 1 and a right connecting body 2, and the left connecting body 1 and the right connecting body 2 are spliced end to end;

[0054] The left connecting body 1 and the right connecting body 2 are respectively composed of a hemisphere 3, a front circular plate 9, a rear circular plate 10, a conical cross plate 12 and a chord 4, and the head of the conical cross plate 12 passes through the front The circular plate 9 is fixed to the outer end of the hemisphere 3, and the tail of the tapered cross plate 12 is fixed to the chord 4 through the rear circular plate 10;

[0055] The inner end surfaces of the two hemispheres 3 are attached to each other to form a spliced assembly;

[0056] The hemispherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com