A multi-purpose mechanized bridge with detachable vehicle and bridge and its erection method

A multi-purpose, vehicle-bridge technology, applied in the direction of construction, etc., can solve the problems of low crossing height, unable to meet the requirements of crossing fire barriers, and affecting the repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

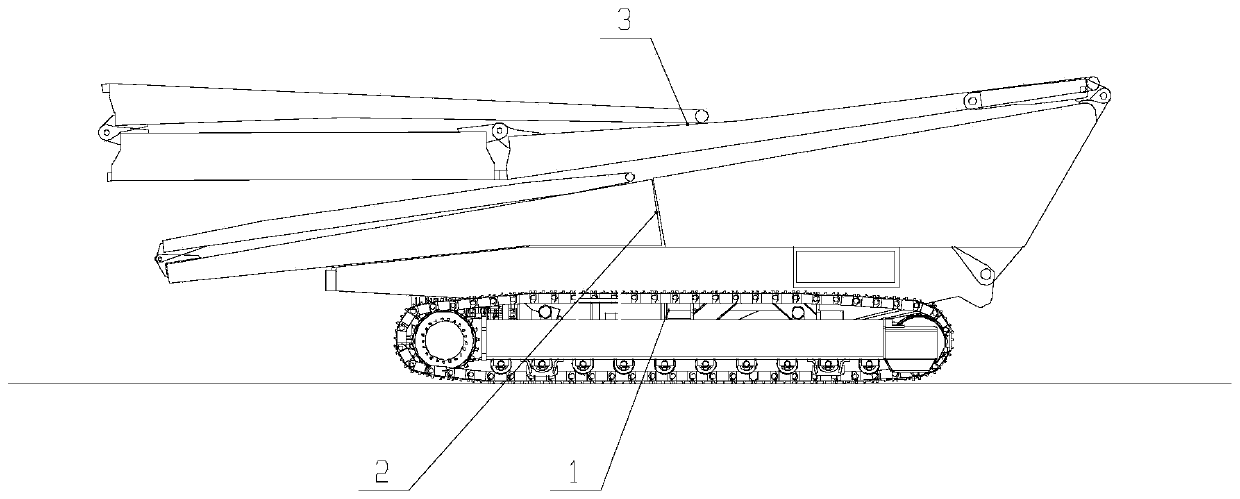

[0020] See attached figure 1 , a multi-purpose mechanized bridge with detachable axles, which includes: a crawler chassis vehicle 1, a connecting bridge 2 and a detachable bridge 3;

[0021] The crawler chassis vehicle 1 includes: a vehicle body 4 and a walking system 5 and a power drive system 6 installed under the vehicle body 4;

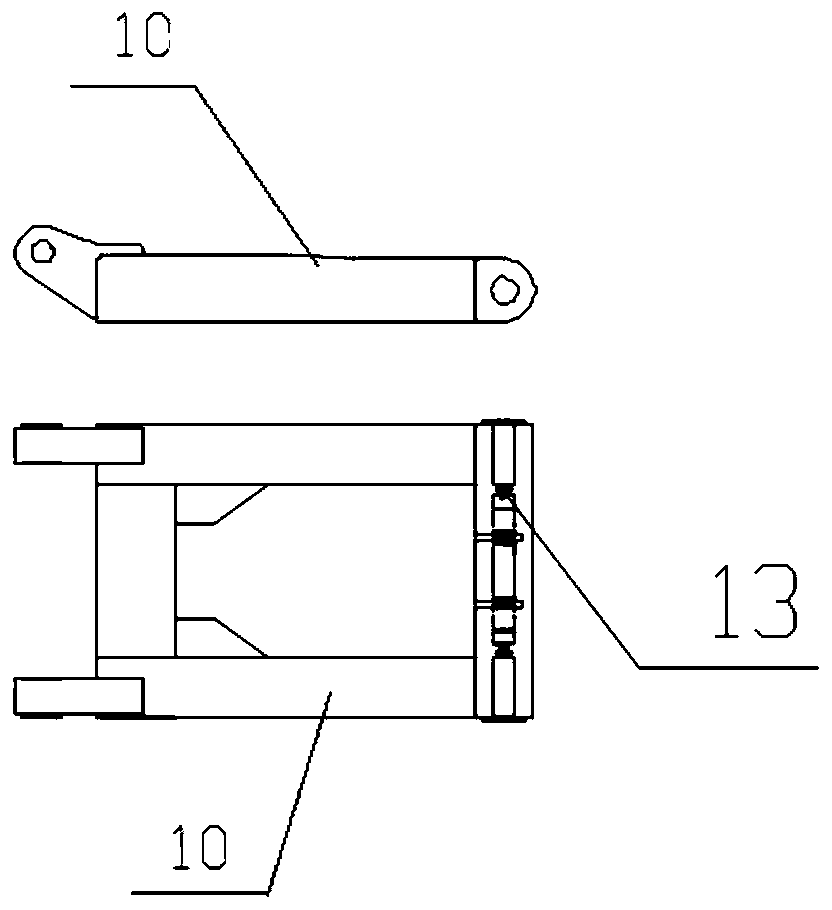

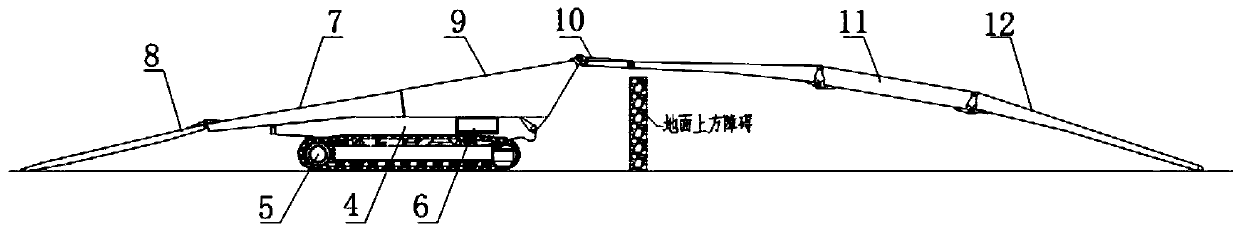

[0022] See attached Figure 2-3 , the connecting bridge 2 includes: a fixed bridge body 7, a rear springboard 8, an overturned bridge body 9, a connecting bridge mechanism 10, and a lateral telescopic mechanism 13; One end of the springboard 8 is hinged with the tail of the fixed bridge body 7, and can be turned around the joint point under the drive of external force, so that the tail springboard 8 can be stacked on the top of the fixed bridge body 7; The lugs are hinged to the car body 4, and the flip bridge body 9 can be turned around the hinge point under the drive of external force. When not turned over, the flip bridge body 9 is stacked on...

Embodiment 2

[0027] A method for erecting a detachable multi-purpose mechanized bridge, based on the detachable multi-purpose mechanized bridge as described in Embodiment 1, its technical scheme is:

[0028] In transport state: both the connecting bridge 2 and the detachable bridge 3 are folded, such as figure 1 As shown, at this time, the tail springboard 8 in the connecting bridge 2 is folded on the upper end surface of the fixed bridge body 7, the tail end surface of the inverted bridge body 9 is fitted with the head end surface of the fixed bridge body 7, and the connecting bridge mechanism 10 is folded on the flipped surface. The upper end surface of the bridge body 9; the detachable bridge 3 is folded above the connecting bridge 2, wherein the tail bridge section 12 is flipped and folded above the middle bridge section 11.

[0029] See attached image 3 , when the vehicle and bridge are erected in one piece, the connecting bridge mechanism 10 in the connecting bridge 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com