Spontaneous combustion reduction method iron-smelting method and smelting device

A technology for smelting device and charge, applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve problems such as failure to obtain large-scale production, high requirements for iron-containing grades, and complex procedures, so as to achieve no thermal pollution and improve smelting strength. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0067] The first embodiment of the present invention relates to the ironmaking method of spontaneous combustion reduction method, which is carried out according to the following steps:

[0068] (1) Charge preparation:

[0069] The iron-containing raw materials (such as iron powder), coal, flux and binder are respectively ground into powder, and the batching is completed at one time according to the proportion; the batching is mixed with water, and extruded to obtain a charge block; air-dried.

[0070] Iron fine powder is an oxide of iron with an iron grade greater than 55% (mass percentage).

[0071] The fixed carbon in coal is both a reducing agent and a fuel. There are no strict requirements for the type of coal, coke, bituminous coal, and anthracite are all available. The content of harmful impurities (sulfur, phosphorus, etc.) in the coal used is subject to national standards. The feeding amount of the above-mentioned iron concentrate powder and coal makes the mass rati...

no. 2 approach

[0102] The second embodiment of the present invention relates to a smelting device.

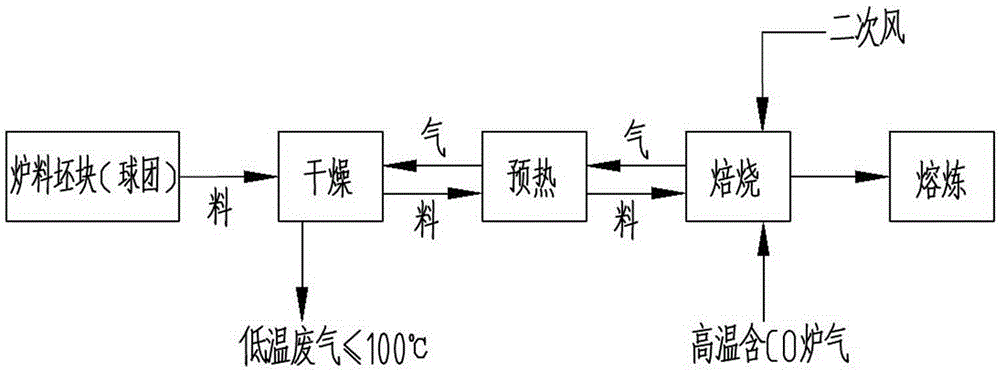

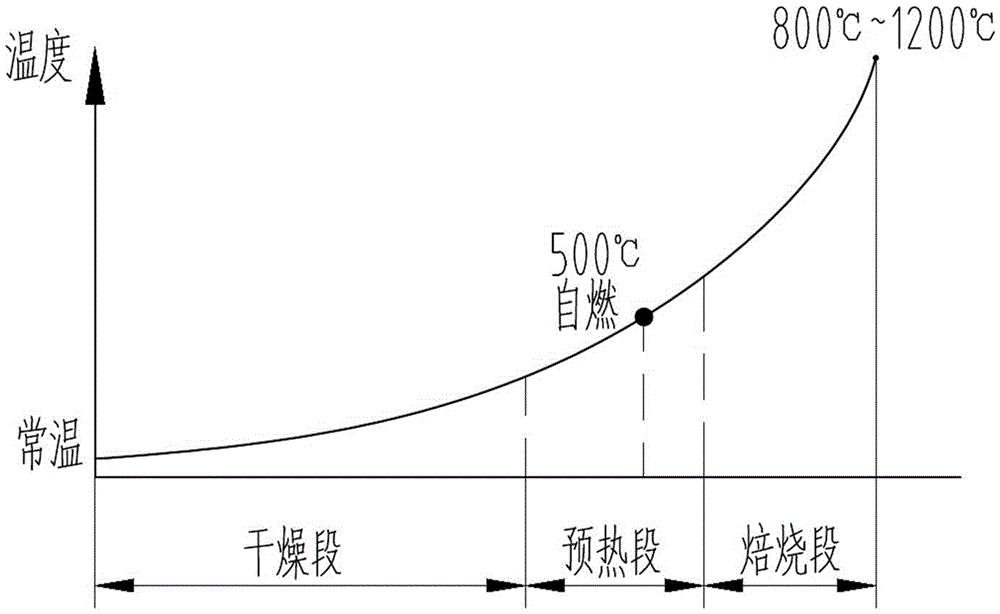

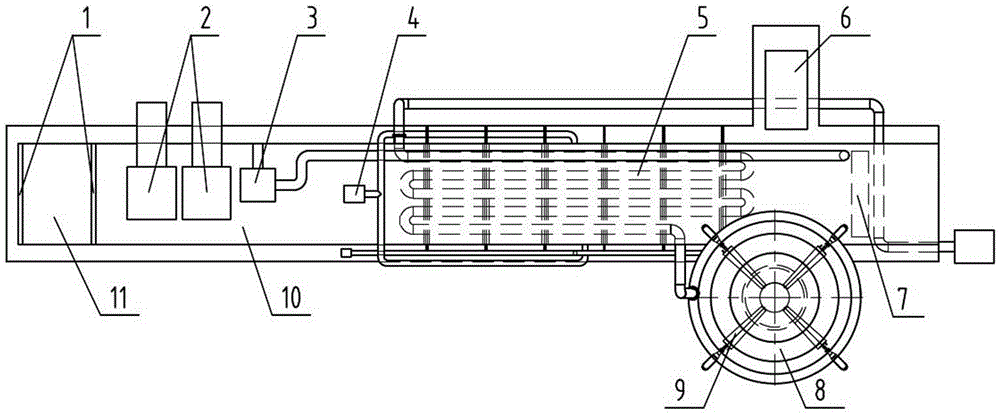

[0103] The smelting device of the present invention mainly comprises tunnel kiln 10 and melting furnace 8 (see attached Figure 3-4 ). The tunnel kiln includes a kiln chamber, the bottom of the kiln chamber is equipped with a kiln car traveling track, and the kiln car 17 loaded with furnace material blocks runs on the track; the two ends of the tunnel kiln are provided with sealing devices 1 and 7; the kiln head is provided with an induced draft fan 2 to pull the wind, a high-temperature unloading device 6 is provided at the kiln tail, and the high-temperature unloading device can adopt push rods, push plates and other similar devices. A secondary air blowing system 4 is provided inside the tunnel kiln for blowing in fresh air or oxygen-enriched gas to promote the complete combustion of carbon monoxide in the furnace gas. The tunnel kiln is divided into a drying section, a preheating sectio...

no. 3 approach

[0114] The drying, preheating, and roasting methods (processes) used in the above-mentioned ironmaking methods can be used in other metallurgical processes besides the ironmaking process. This embodiment further proposes a method (process) for drying, preheating and roasting charge in the metallurgical process on the basis of the previous invention. Make full use of the heat emitted when the charge is preheated and roasted when the temperature reaches spontaneous combustion to dry, preheat and roast the charge. At the same time, the heat generated by the combustion of carbon monoxide in the high-temperature furnace gas is used to feed air or oxygen-enriched gas into the kiln chamber to dry, preheat and roast the furnace material. This process does not use other heat, and the production process no longer produces gas.

[0115] The above process is completed in the kiln chamber of the tunnel kiln, and the heat exchange is carried out through the reverse convection of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com