Method for conducting leaching and flotation on ores in same leaching and flotation cells

A flotation tank and leaching technology, which is applied in the field of ore leaching and flotation in the same tank, can solve the problems of large equipment investment, high consumption of equipment and spare parts, and increase of post personnel, so as to improve the concentrate quality index and good technical and economic indicators , Improve the effect of recovery rate index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

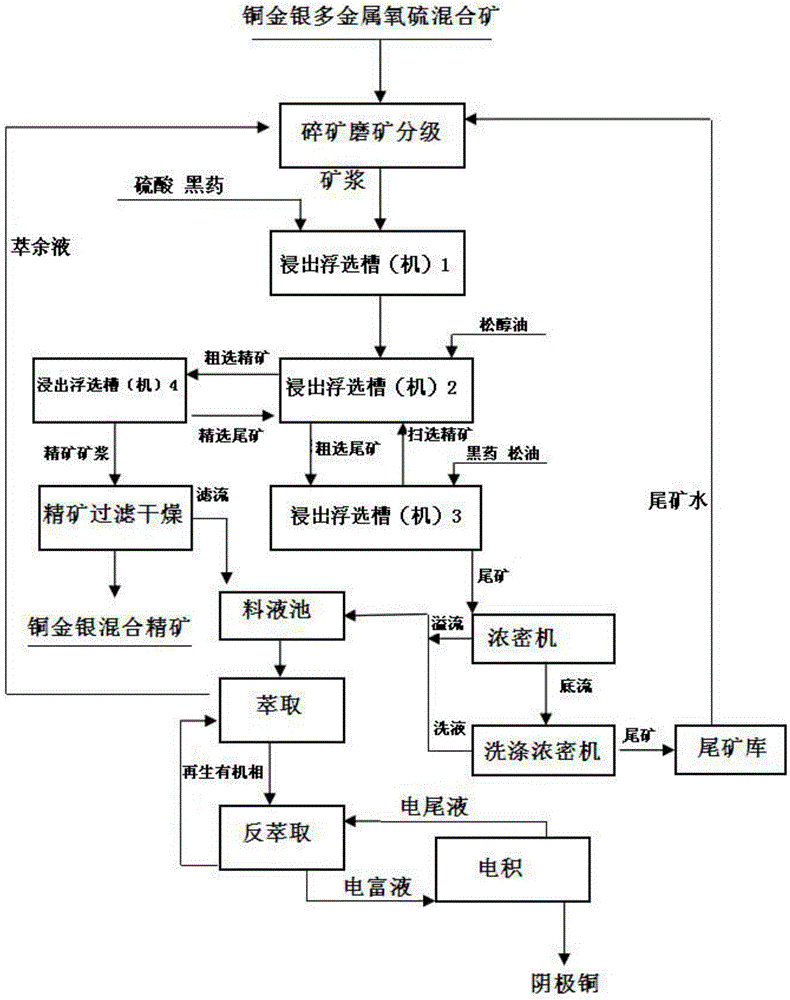

[0047] Such as figure 2 Shown, the method that copper-gold-silver multi-metal oxysulfur mixed ore leaching and flotation are carried out in the same tank in the leaching flotation cell (machine):

[0048] 1. Reaction mechanism in leaching flotation tank (machine)

[0049] 1.1 Leaching chemical reaction mechanism

[0050] CuCO 3 ·Cu(OH) 2 (Malachite)+H 2 SO 4 →2CuSO 4 +3H 2 O+CO 2

[0051] Cu 2 O(Cuprite)+H 2 SO 4 →CuSO 4 +Cu+H 2 o

[0052] Cu 3 (CO 3 ) 2 (OH) 2 (Azurite)+H 2 SO 4 →CuSO 4 +H 2 O+CO 2

[0053] (Cu, Al) 2 h 2 Si 2 o 5 (OH) 4 ·nH 2 O(chrysocolla)+H 2 SO 4 →CuSO 4 +Al 2 SO 4 +SiO2 2 .nH 2 O+H 2 O.

[0054] CaO+H 2 SO 4 →CaSO 4 +H 2 o

[0055] MgO+H 2 SO 4 → MgSO 4 +H 2 o

[0056] AL 2 o 3 +H 2 SO 4 →ALSO 4 +H 2 o

[0057] 1.2 Physicochemical reaction mechanism of flotation

[0058] CuS+ROCSS-Na→ROCSS-CuS+Na +

[0059] Cu2S+ROCSS-Na→ROCSS-Cu2S+Na +

[0060] Cu+ROCSS-Na→ROCSS-Cu+Na +

[0061] CuFeS 2 +ROC...

Embodiment 2

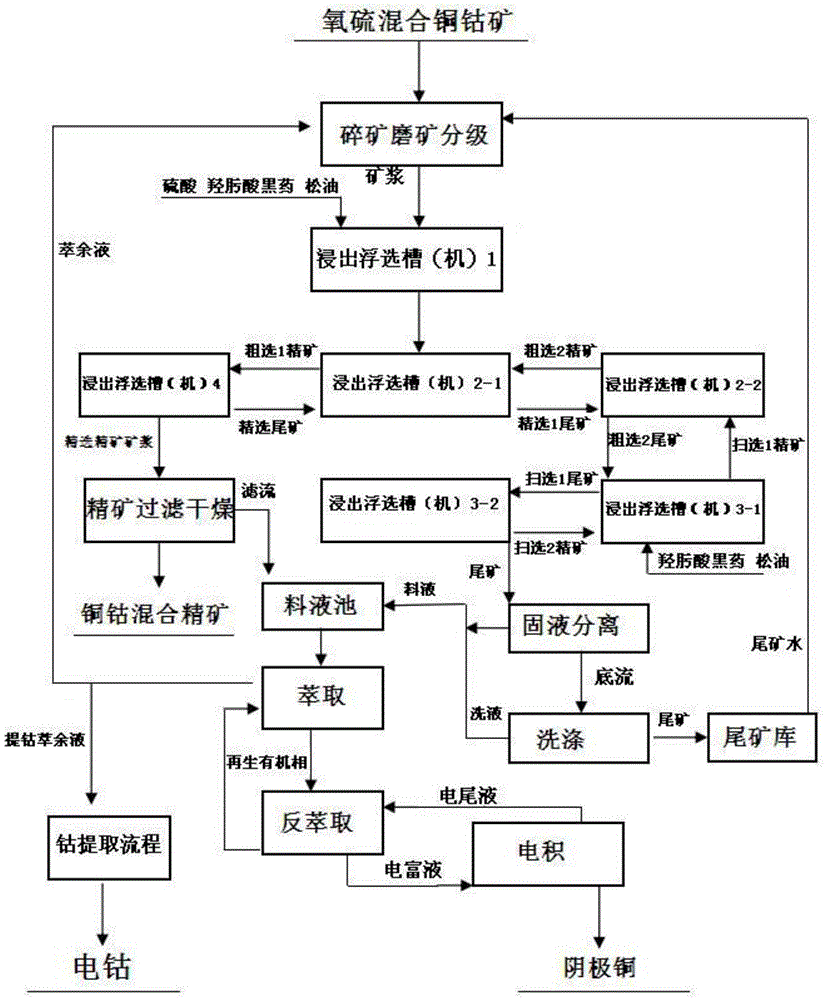

[0082] image 3 Shown is the process flow of stirring leaching and flotation of copper-cobalt-oxygen-sulfur mixed ore carried out in the same tank in the leaching flotation tank (machine).

[0083] 1. Reaction mechanism in leaching flotation tank (machine)

[0084] 1.1 Leaching chemical reaction mechanism

[0085] CuCO 3 ·Cu(OH) 2 (Malachite)+H 2 SO 4 →2CuSO 4 +3H 2 O+CO 2

[0086] Cu 2 O(Cuprite)+H 2 SO 4 →CuSO 4 +Cu+H 2 o

[0087] Cu 3 (CO 3 ) 2 (OH) 2 (Azurite)+H 2 SO 4 →CuSO 4 +H 2 O+CO 2

[0088] (Cu, Al) 2 h 2 Si 2 o 5 (OH) 4 ·nH 2 O(chrysocolla)+H 2 SO 4 →CuSO 4 +Al 2 SO 4 +SiO2 2 .nH 2 O+H 2 O.

[0089] CoO+H 2 SO 4 →CoSO 4 +H 2 o

[0090] CaO+H 2 SO 4 →CaSO 4 +H 2 o

[0091] MgO+H 2 SO 4 → MgSO 4 +H 2 o

[0092] AL 2 o 3 +H 2 SO 4 →ALSO 4 +H 2 o

[0093] 1.2 Physicochemical reaction mechanism of flotation

[0094] CuS+ROCSS-Na→ROCSS-CuS+Na +

[0095] Cu 2 S+ROCSS-Na→ROCSS-Cu 2 S+Na +

[0096] Cu+ROCSS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com