Process optimization method for sintering vanadium-titanium magnetite concentrate by large-scale sintering machine

A vanadium-titanium-magnetite concentrate and process optimization technology, applied in the field of sintering, can solve the problems of frequent belt system accidents, many equipment accidents, and difficulty in maintaining production demand, and achieve excellent technical and economic indicators, improve utilization coefficient, and high drum index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

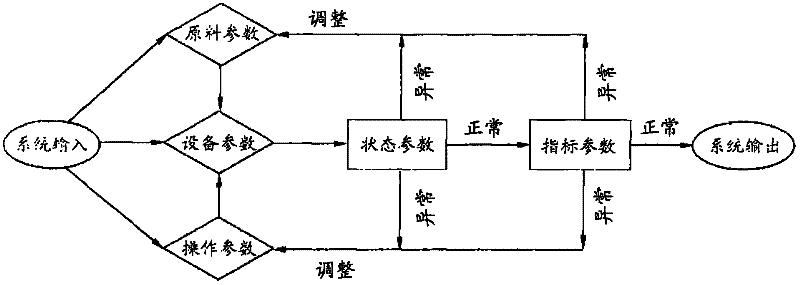

Method used

Image

Examples

Embodiment 1

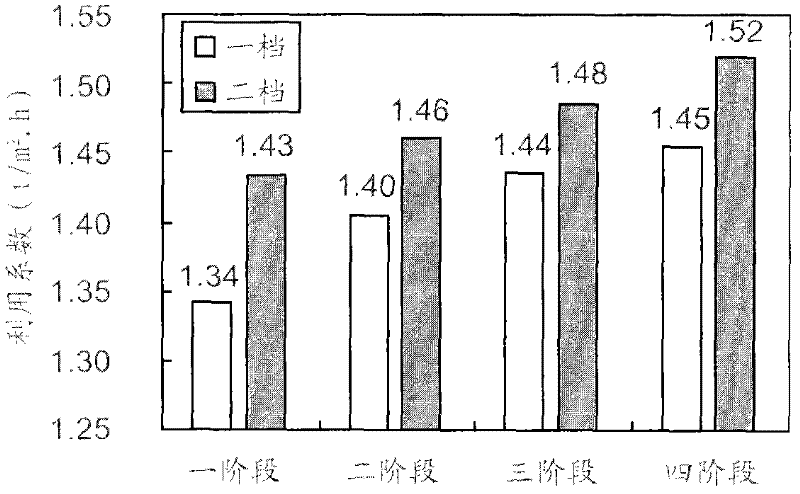

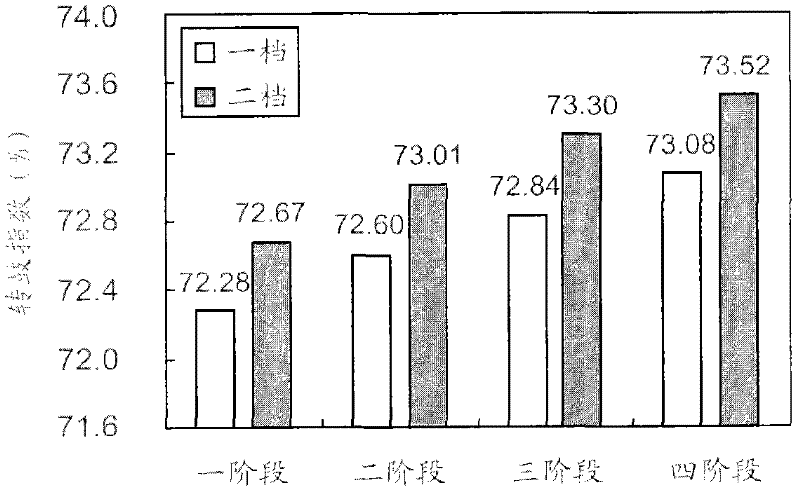

[0075] Below is the 360m of a steel plant 2 The sintering machine is taken as an example, and the optimization method of process parameters is explained in detail. Of course, sintering machines of other specifications can also be optimized according to this method.

[0076] Table 1 Correlation coefficient (r) between utilization coefficient, drum index and various influencing factors

[0077]

[0078]

[0079] The production data of the plant's new 1# sintering machine from September 6, 2010 to December 31, 2010 were collected and analyzed, and the correlation between the utilization coefficient and the drum index was analyzed. The correlation coefficient r is shown in Table 1. It can be seen that there is no factor (or parameter) that has an absolute impact on the sintering utilization coefficient and the drum index. Therefore, it shows that the influencing factors of the sintering system are complicated and numerous, which is the result of the joint action of many fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com