Long-span long-narrow concrete honeycomb open-web sandwich floor covering and manufacturing method

A concrete, narrow and long technology, applied in the direction of floor slabs, building structures, building components, etc., can solve problems such as uneven stress and failure to meet technical and economic indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

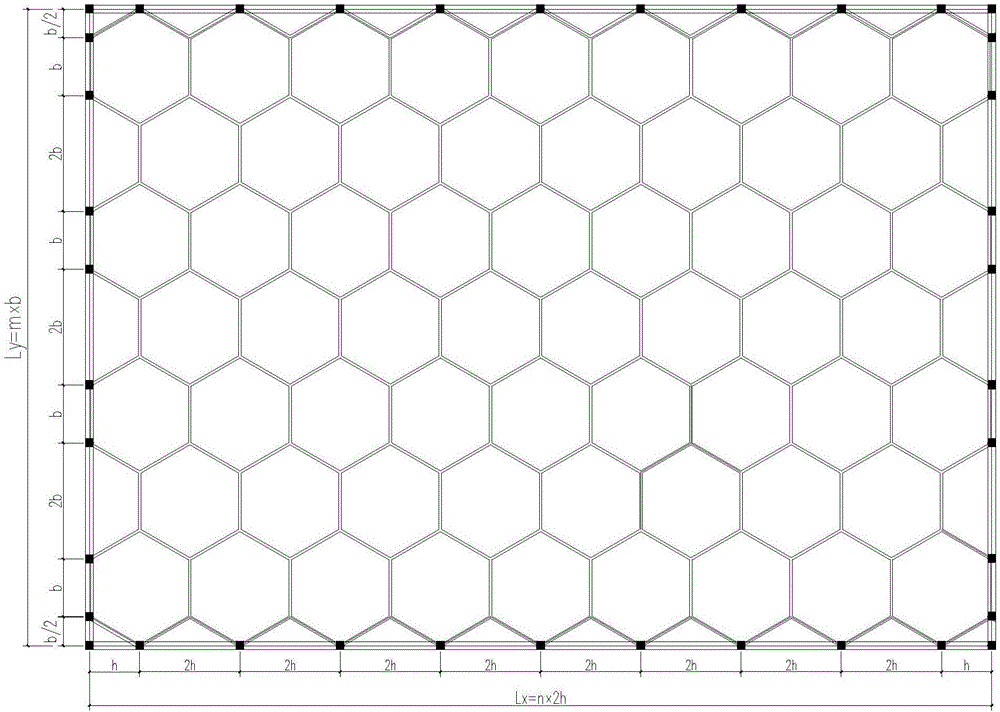

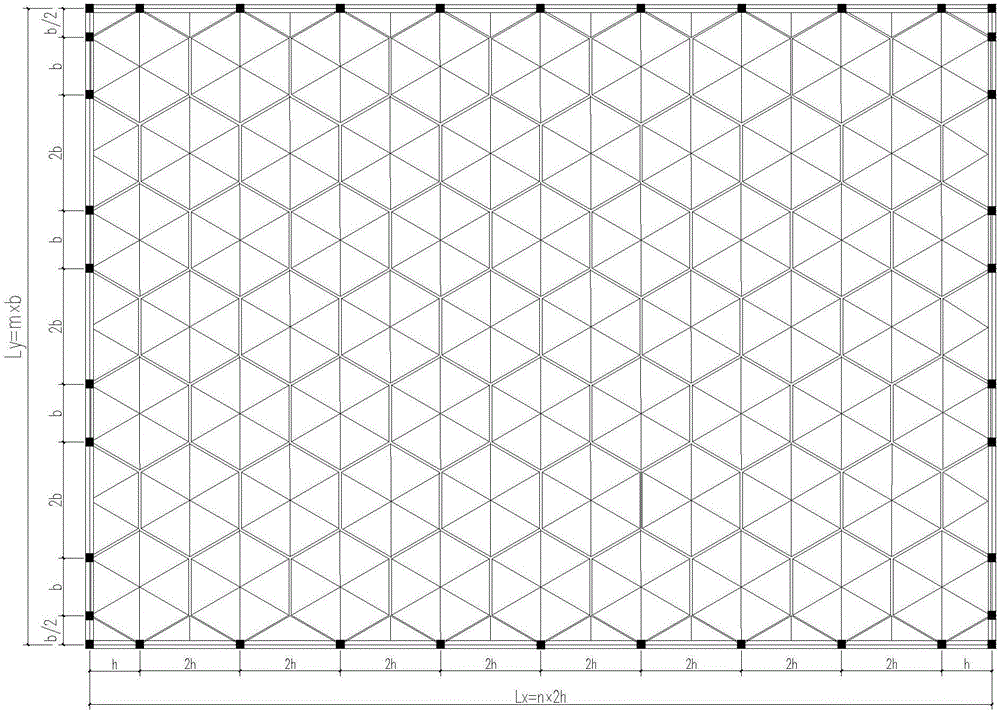

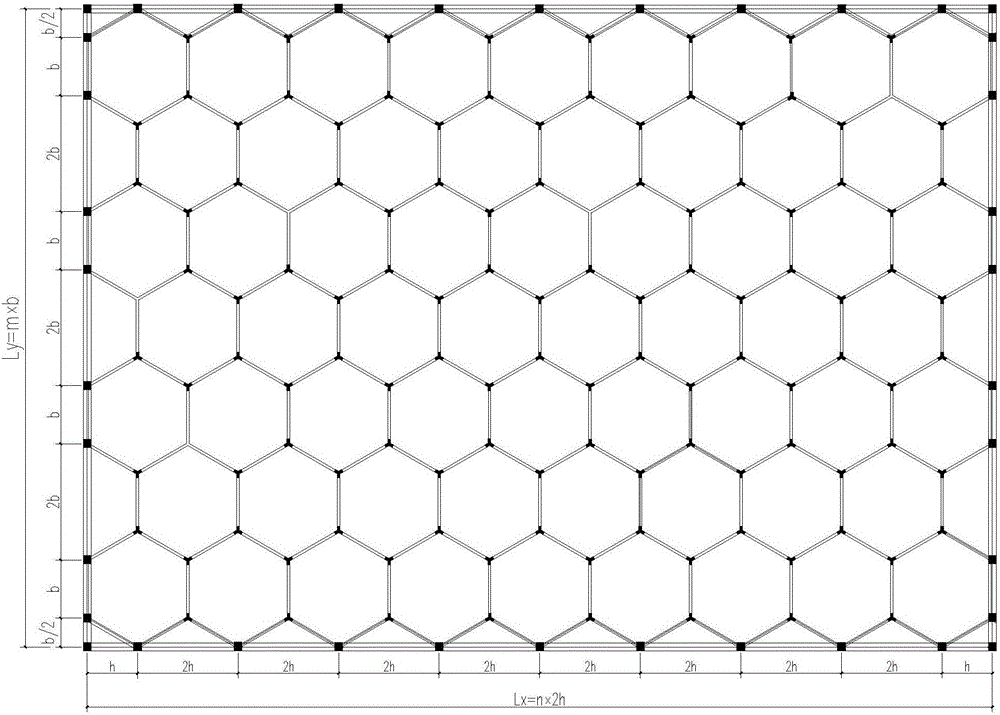

[0025] The floor of the present invention is a large-span narrow and long concrete honeycomb-shaped hollow sandwich slab floor, its long side is marked as Lx, and its short side is marked as Ly, Lx / Ly>1.5, Ly=nb, wherein n represents along the direction of the short side The number of regular triangles above, b represents the side length of a regular triangle or regular hexagon, the long side Lx=m2h, where m represents the number of regular hexagons along the long side, and 2h represents the height of the regular hexagon. Specifically in this embodiment, b=2.8m, h=0.866×2.8m=2.425m, the short side span is Ly=nb=11×2.8m=30.8m, Lx=m2h=10×2×2.425m=48.5 m, Lx / Ly=48.5 / 30.8=1.575>1.5, the floor area of each floor is 1493.8m 2

[0026] see figure 1 with figure 2 , the floor of the present invention comprises an upper string layer and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com