Chemical reaction apparatus and chemical reaction method for removing vanadium from crude TiCl4

A crude titanium tetrachloride, titanium tetrachloride technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of low heat conduction efficiency, residue scarring, high energy consumption, and achieve simple device configuration and stable process control. , The effect of high vanadium removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

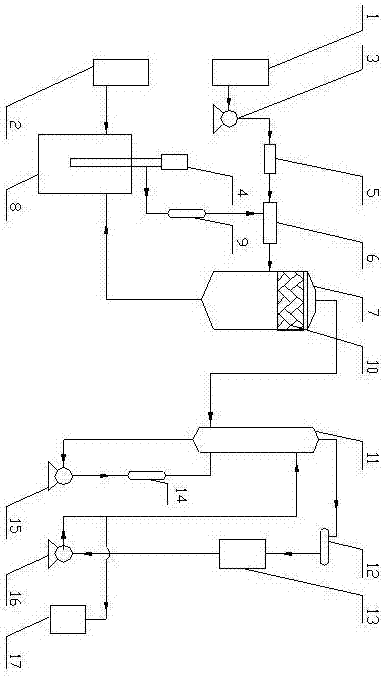

[0022] Such as figure 1 As shown, the chemical reaction device for removing vanadium from crude titanium tetrachloride of the present invention includes a mixed reactor (6), a flash tank (7), a valve tower (11), a cooler (12) and a reflux tank connected in sequence (13), also including crude titanium tetrachloride storage tank (2), white oil storage tank (1), and titanium tetrachloride storage tank after vanadium removal (17). The liquid inlet of the flash tank (7) is connected with the outlet of the mixing reactor (6), and the top of the flash tank (7) is connected with the float valve tower (11). The crude titanium tetrachloride storage tank (2) and the white oil storage tank (1) are connected with the mixing reactor (6). At the same time, a secondary reactor (8) and a double-tube-sheet heat exchanger (9) are sequentially arranged on the pipeline connecting the crude titanium tetrachloride storage tank (2) and the mixing reactor (6). The pipeline connecting the white oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com