A kind of method and system for removing vanadium impurity in titanium tetrachloride

A technology of titanium tetrachloride and crude titanium tetrachloride, which is applied in the direction of titanium halide, etc., can solve the problems of easy blockage of pipelines and heat exchangers, fast scaling of heating coils, and large area of production equipment. Achieve the effect of reducing steam consumption, stable product quality and high effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

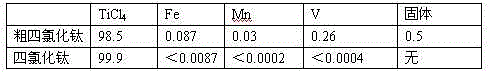

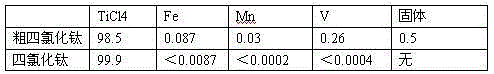

Embodiment 1

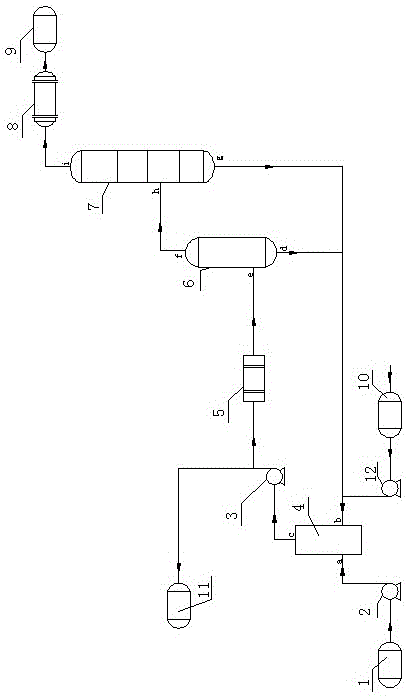

[0024] As shown in the figure, the vanadium impurity removal system in titanium tetrachloride has a crude titanium tetrachloride feed tank 1, and the crude titanium tetrachloride feed tank 1 passes through the feed port of the pipeline and the forced circulation pump tank 4 a is connected, the pipeline between the crude titanium tetrachloride feed tank 1 and the forced circulation pump tank 4 is provided with a feed pump I2, and the outlet c of the forced circulation pump tank 4 is connected to the heating heat exchanger 5 are connected through pipelines, and the pipeline between the forced circulation pump tank 4 and the heating heat exchanger 5 is provided with a forced circulation pump 3, and the discharge port of the forced circulation pump 3 is also connected with a mud tank 11. The heating heat exchanger 5 is communicated with the feed port e of the flash tank 6, and the discharge port f of the flash tank 6 is connected with the feed port h of the purification tower 7, an...

Embodiment 2

[0035] The system for removing vanadium impurities in titanium tetrachloride is the same as in Example 1.

[0036] During production, the specific steps are as follows:

[0037] (1) Put the crude titanium tetrachloride into the forced circulation pump tank 4 from the crude titanium tetrachloride supply tank 1 through the supply pump I2, and inject the fatty acid into the forced circulation from the fatty acid supply tank 10 through the supply pump II12 In the pump tank 4, the mass ratio of the crude titanium tetrachloride to the fatty acid is 1400:1, wherein the fatty acid is an unsaturated straight-chain fatty acid with a degree of unsaturation of 1 to 3 and a number of carbon atoms of 10 to 30;

[0038] (2) The forced circulation pump 3 drives the crude titanium tetrachloride in the forced circulation pump tank 4 into the heating heat exchanger 5 through the forced circulation pump 3 and heats it to 170°C. When the heating heat exchanger is heated, the heating heat exchanger...

Embodiment 3

[0046] The system for removing vanadium impurities in titanium tetrachloride is the same as in Example 1.

[0047] During production, the specific steps are as follows:

[0048] (1) Put the crude titanium tetrachloride into the forced circulation pump tank 4 from the crude titanium tetrachloride supply tank 1 through the supply pump I2, and inject the fatty acid into the forced circulation from the fatty acid supply tank 10 through the supply pump II12 In the pump tank 4, the mass ratio of the crude titanium tetrachloride to the fatty acid is 1200:1, wherein the fatty acid is an unsaturated straight-chain fatty acid with a degree of unsaturation of 1 to 3 and a number of carbon atoms of 10 to 30;

[0049] (2) The forced circulation pump 3 pumps the crude titanium tetrachloride in the forced circulation pump tank 4 into the heating heat exchanger 5 through the forced circulation pump 3 and heats it to 150°C. When the heating heat exchanger is heated, the heating heat exchanger ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com