Method for removing vanadium impurity in crude titanium tetrachloride and method for refining crude titanium tetrachloride

A technology of crude titanium tetrachloride and titanium tetrachloride, which is applied in the direction of titanium halide, can solve the problems of insufficient research, high labor intensity, and the need for rectification again, and achieve high vanadium removal efficiency, no impact on quality, and titanium The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

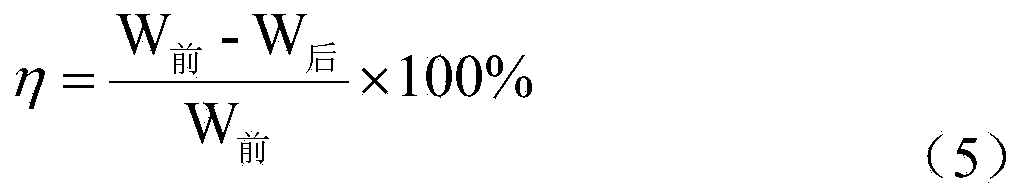

[0037]Select the refining system of a certain factory, the vanadium content in the crude titanium tetrachloride produced is 0.095%, in the vanadium removal system, add 0.5kg magnesium hydride powder per ton of crude titanium tetrachloride, the particle size is 45μm, stir Mix to make it fully react with crude titanium tetrachloride, and then obtain refined titanium tetrachloride after rectification in the refining system, and its vanadium content is 0.0005%. After calculation, the vanadium removal purification rate η is 99.5%.

example 2

[0039] The refined system of a certain factory is selected, and the vanadium content in the crude titanium tetrachloride produced by it is 0.095%. In the vanadium removal system, 0.8 kg of magnesium hydride powder is added per ton of crude titanium tetrachloride, and the particle size is 80 μm. Stir Mix to make it fully react with crude titanium tetrachloride, and then obtain refined titanium tetrachloride after rectification in the refining system, and its vanadium content is 0.0013%. After calculation, the vanadium removal purification rate η is 98.6%.

example 3

[0041] Select the refining system of a certain factory, the vanadium content in the crude titanium tetrachloride produced is 0.115%, in the vanadium removal system, add 0.6kg magnesium hydride powder per ton of crude titanium tetrachloride, the particle size is 10μm, stir Mix to make it fully react with crude titanium tetrachloride, and then obtain refined titanium tetrachloride after rectification in the refining system, and its vanadium content is 0.0003%. After calculation, the vanadium removal purification rate η is 99.7%.

[0042] Through the foregoing example, it can be seen that for the crude titanium tetrachloride containing vanadium in the mass percentage of 0.095% to 0.115%, the method of the present invention can effectively remove the vanadium element in the crude titanium tetrachloride ( For example, the vanadium removal purification rate η can reach more than 99.5%) to obtain refined titanium tetrachloride.

[0043] In summary, the present invention can provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com