Steel plate cooling method

A cooling method and steel plate technology, applied in the field of steel plate cooling, can solve the problems of increasing the production cost of the steel plate, reducing the weldability of the steel plate, reducing the comprehensive performance of the steel plate, etc., and achieving the effect of improving the delivery capacity, uniform performance and stable production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

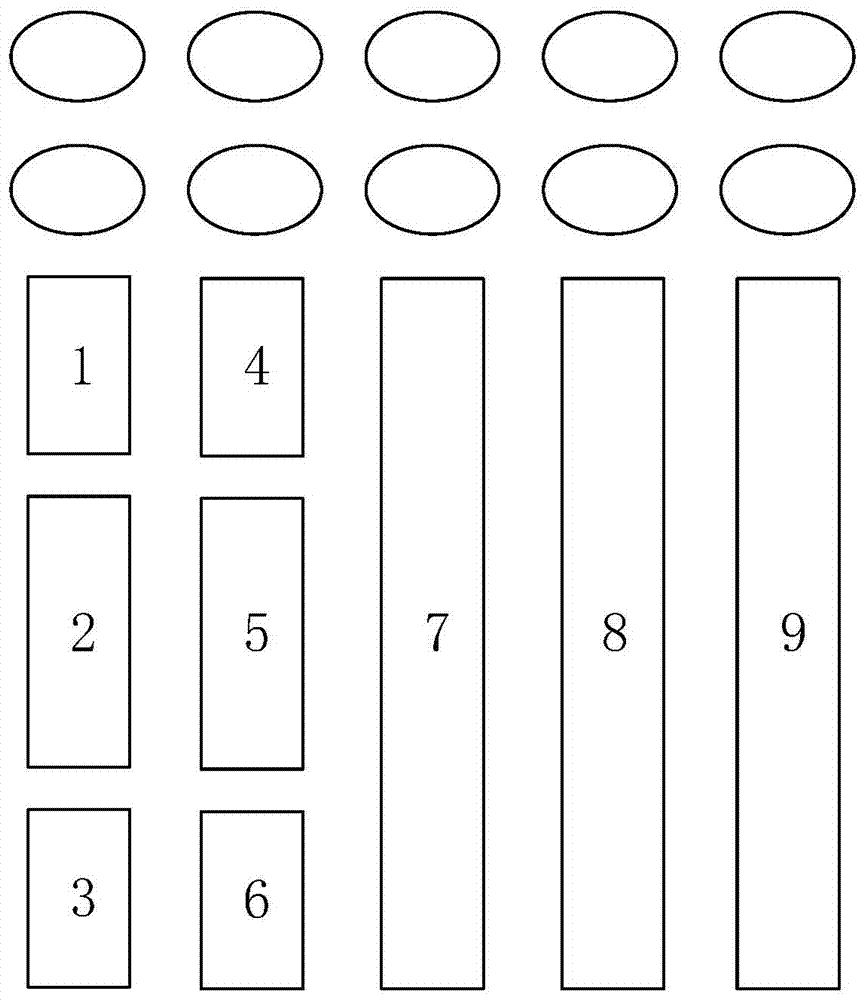

Method used

Image

Examples

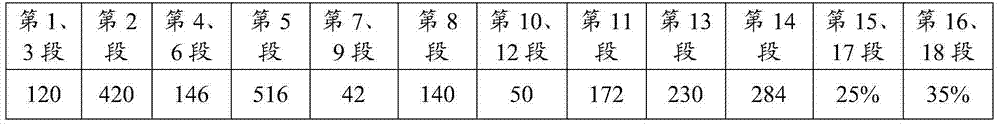

Embodiment 1

[0029] The steel plate produced in the experiment of this embodiment is a 60 mm thick Q345GJC steel plate. Firstly, the steel plate is normalized, and the normalizing process of the steel plate is as follows: the normalizing temperature is 870°C, and the holding time is 20 minutes. Then the steel plate is quenched in a water-cooled mode. Through the exploration of the water-cooling mode, the water-cooling process parameters of the steel plate in the quenching section are finally determined as shown in Table 1. The total flow of water in the 15th to 18th sections is 2000m 3. The steel plate enters the quenching section to cool at a speed of 60m / min, and the speed of the roller table of the quenching machine is 40m / min. After the steel plate is water-cooled, the reddening temperature of the steel plate is between 630 and 670°C. After inspection, the yield strength and tensile strength of the steel plate are 40-60MPa higher than the strength value of conventional normalizing ...

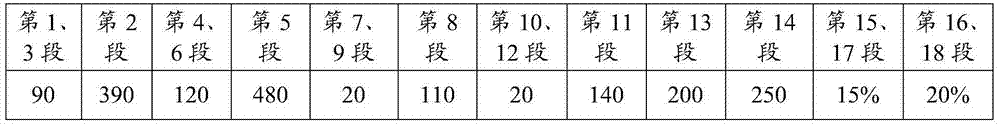

Embodiment 2

[0034] The steel plate in this embodiment is a 100 mm thick Q345C steel plate with a strength slightly lower than the standard after normalizing. The normalizing process of the steel plate is as follows: the normalizing temperature is 860°C, and the holding time is 30 minutes. The water-cooling process was further explored, and the parameters of the steel plate water-cooling process in the quenching section were finally determined as shown in Table 2. The total flow of water in the 15th to 18th sections is 1200m 3 . The steel plate enters the quenching section to cool at a speed of 40m / min, and the speed of the roller table of the quenching machine is 30m / min. After the steel plate is water-cooled, the reddening temperature of the steel plate is between 640 and 680°C. After inspection, the yield strength and tensile strength of the steel plate are 30-50MPa higher than those of conventional normalizing treatment, and the strength of the steel plate meets the standard require...

Embodiment 3

[0039] The steel plate in this embodiment is a 100 mm thick Q345C steel plate with a strength slightly lower than the standard after normalizing. The normalizing process of the steel plate is as follows: the normalizing temperature is 910°C, and the holding time is 50min. The water-cooling process was further explored, and the parameters of the steel plate water-cooling process in the quenching section were finally determined as shown in Table 3. The total flow of water in the 15th to 18th sections is 3600m 3 . The steel plate enters the quenching section to cool at a speed of 50m / min, and the speed of the roller table of the quenching machine is 35m / min. After the steel plate is water-cooled, the reddening temperature of the steel plate is between 640 and 680°C. After inspection, the yield strength and tensile strength of the steel plate are 30-50MPa higher than those of conventional normalizing treatment, and the strength of the steel plate meets the standard requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com