Recycled-ABS toughened foam material and preparation method thereof

A foam material and toughening technology, applied in the field of toughened foam material and its preparation, can solve the problems of difficulty in improving the overall performance of recycled materials, loss of economic value of waste plastics, failure to achieve beneficial effects of recycling, etc. Achieve the effects of improved flame retardancy, reduced smoke concentration, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention also provides a preparation method of recycled ABS toughened foam material, which includes the following steps.

[0034] Step 1, weigh 5-50 parts of polyvinyl chloride, 0.5-15 parts of hollow glass microspheres, 0.5-20 parts of plasticizer, 0.5-20 parts of lubricant, 0.1-20 parts of flame retardant, smoke suppressant Dose 0.1~10 parts.

[0035] Step 2: Mix the raw materials obtained in Step 1 at 40°C-60°C for 1-10 minutes.

[0036] Step 3: Weigh 100 parts of recovered ABS and 0.1-5 parts of antioxidant and add them to the mixture obtained in Step 2 and mix for 10-20 minutes.

[0037] Step 4, mixing and granulating the mixture obtained in Step 3 in an open mill, internal mixer or screw extruder.

[0038] Further, the mixture obtained in the above step 3 can be directly extruded, or flat-pressed, or injected; or, the mixture obtained in step 4 can be directly extruded, or flat-pressed, or injected.

Embodiment 1

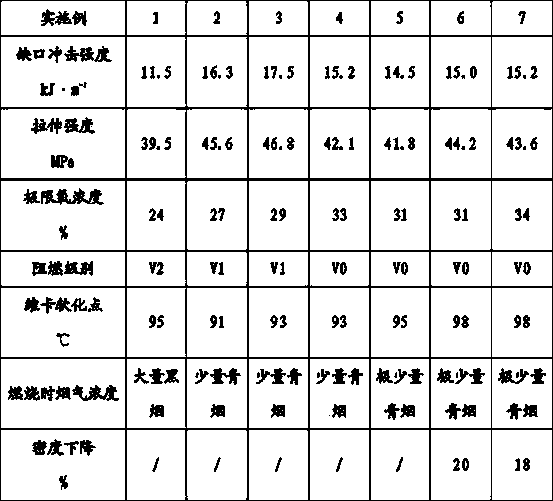

[0039] Example 1: After melting and mixing recycled ABS with an internal mixer, test samples were prepared as required, and tested for notched impact strength, tensile strength, flame retardancy, and Vicat softening point. The material properties are shown in Table 1.

Embodiment 2

[0040]Embodiment 2: 100g reclaims ABS, 35g polyvinyl chloride, 5g chlorinated polyethylene wax, 1g zinc stearate, 1g dibutyl phthalate, 0.5g antioxidant 1010 utilizes internal mixer to melt and mix after, Prepare test samples as required for notched impact strength test, tensile strength test, flame retardant performance test, and Vicat softening point test. The material properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com