Gas desulfurizing-regenerating technological method and equipment with remarkable energy-saving effect by liquid-phase catalyzed oxidation

A liquid-phase catalysis and oxidation technology, applied in the field of desulfurization, can solve the problems of unstable process control, unstable air intake, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The object of the present invention is achieved by following technological process and method:

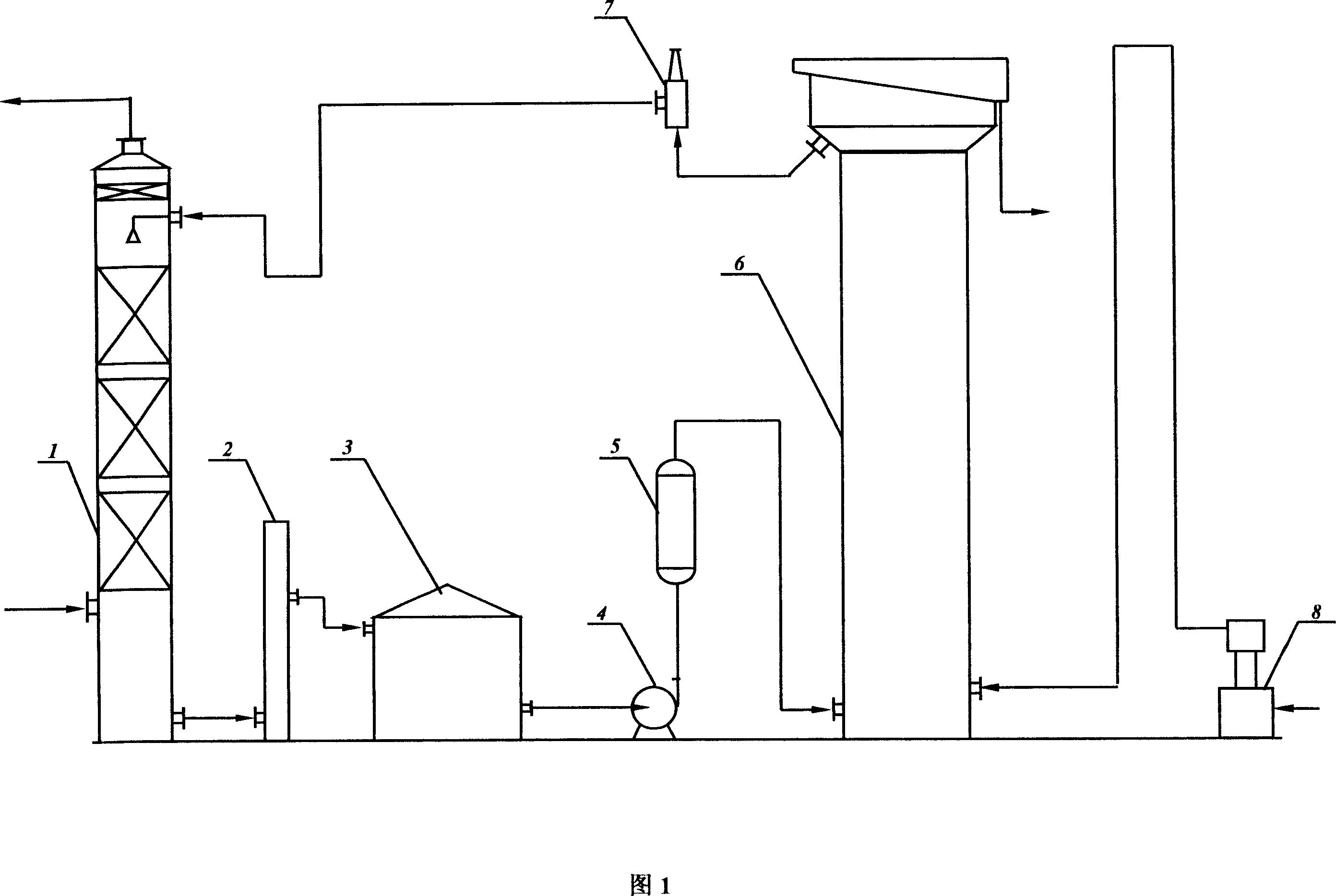

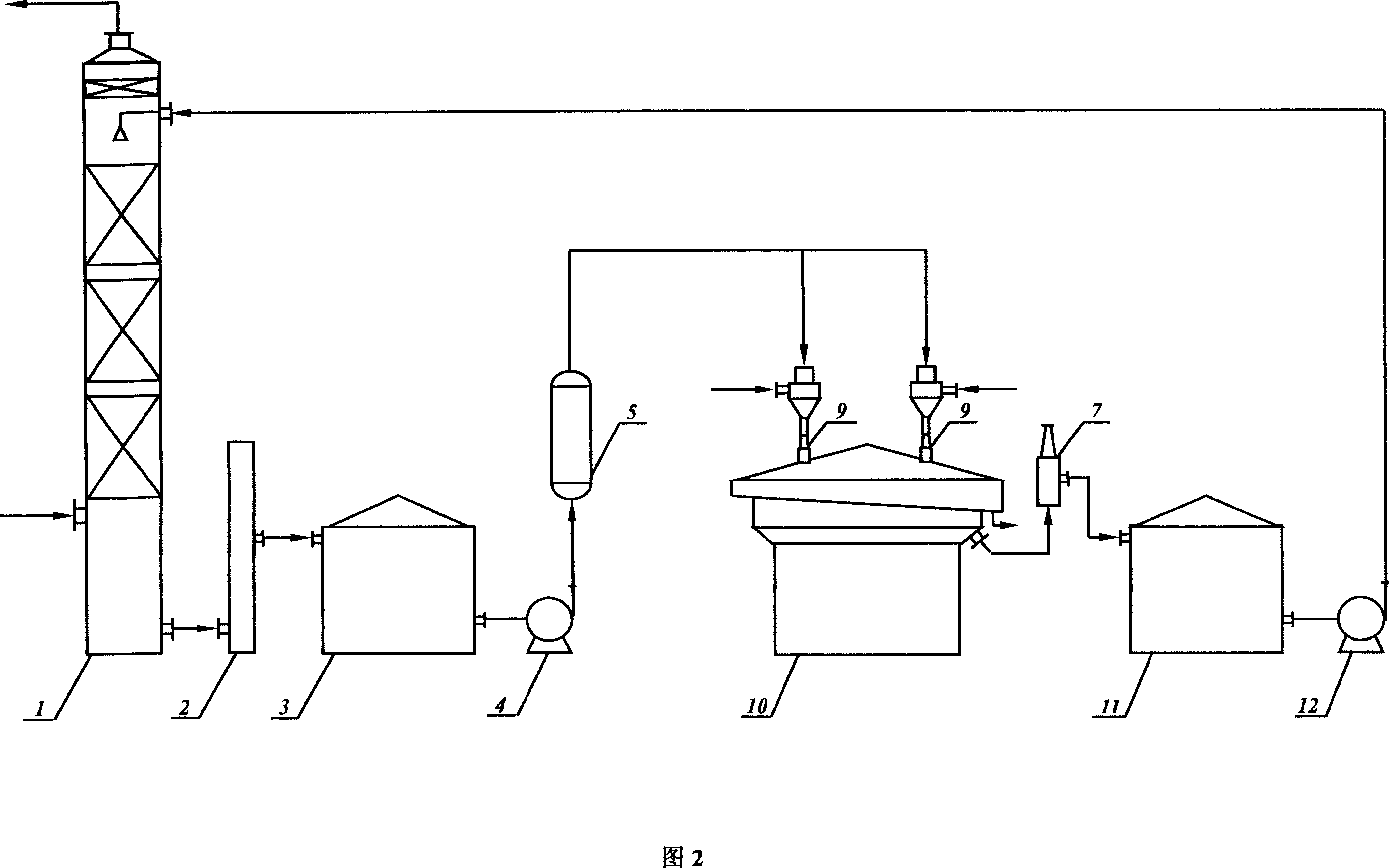

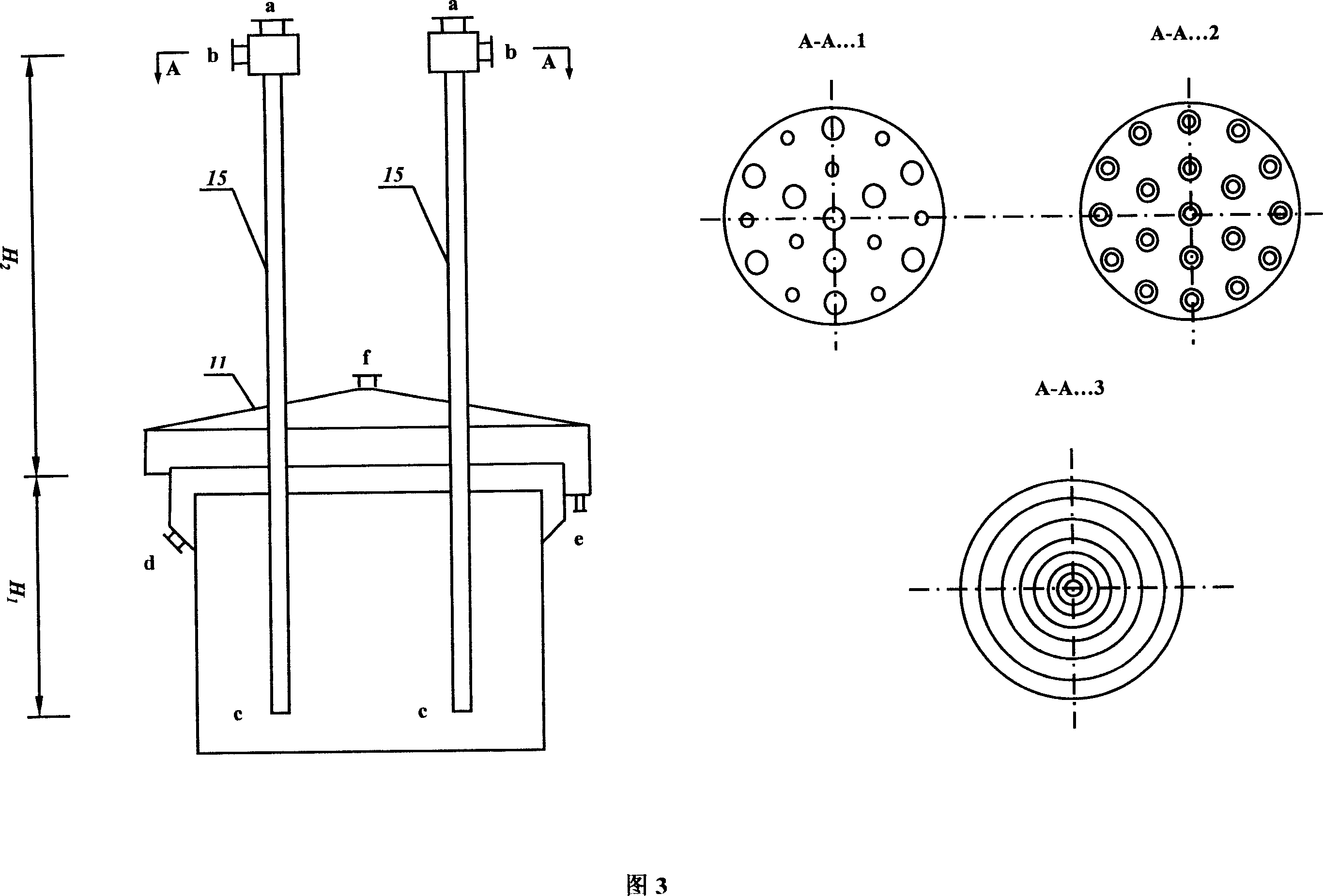

[0022] 1. New desulfurization regeneration process flow I (shown in Figure 4): process system consists of desulfurization tower 1, reaction tank 3, low-pressure double-jet regenerator 15, regeneration tank 10, liquid level regulator 7, lean mother liquor storage tank 11, lean Mother liquor pump 12, mother liquor heater 5, air blower 13 and other equipment. Gas desulfurization is the same as the typical process. The process flow of the circulating mother liquor is as follows: the mother liquor flows directly down from the high-position desulfurization tower 1 into the reaction tank 3, and the rich mother liquor reacted for a certain period of time enters the low-pressure double-jet regenerator 15 from the upper part of the reaction tank near the remaining head to form a jet flow and forced delivery. The incoming air jets are mixed in the low-pressure double-jet regenerator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com