Patents

Literature

37results about How to "Improve application features" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

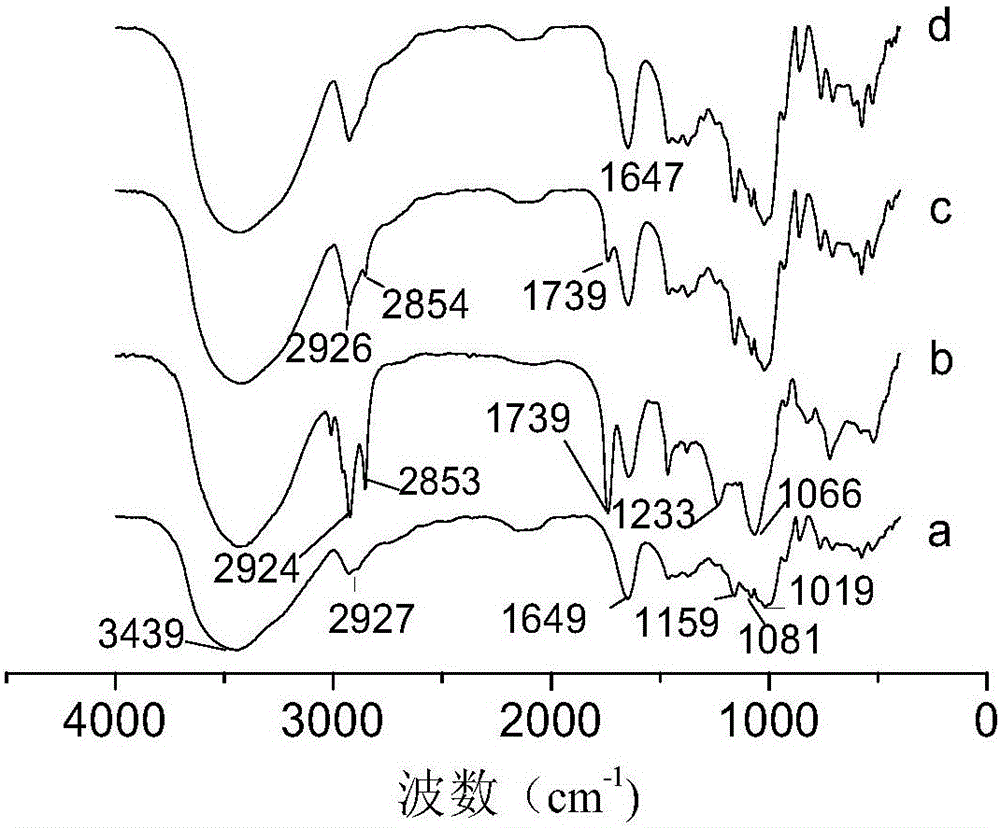

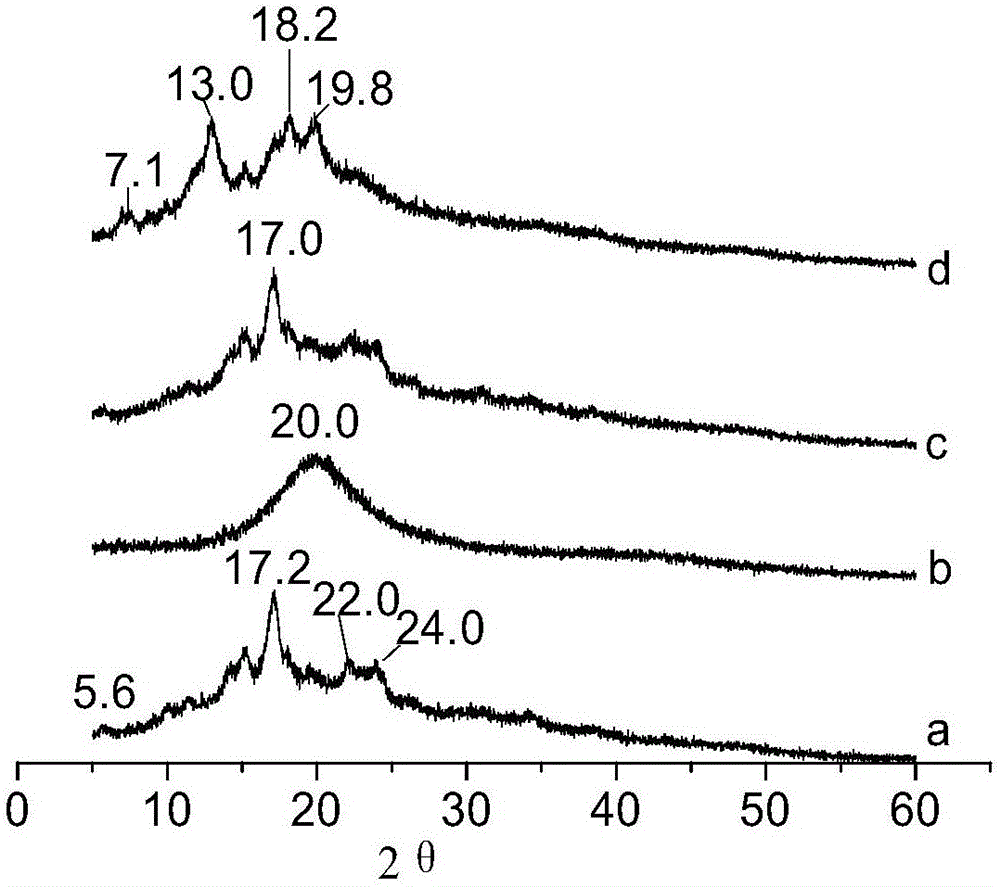

Peach gum polysaccharide, its extractive, preparation method and application thereof

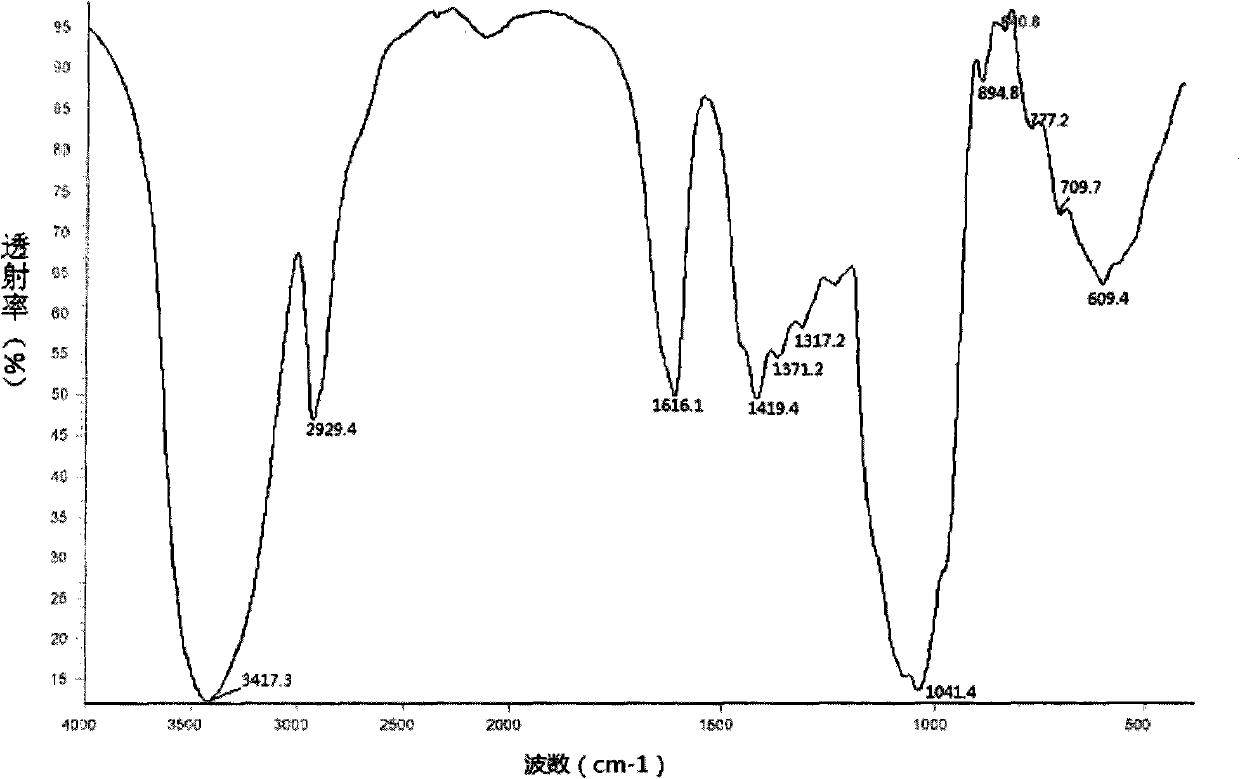

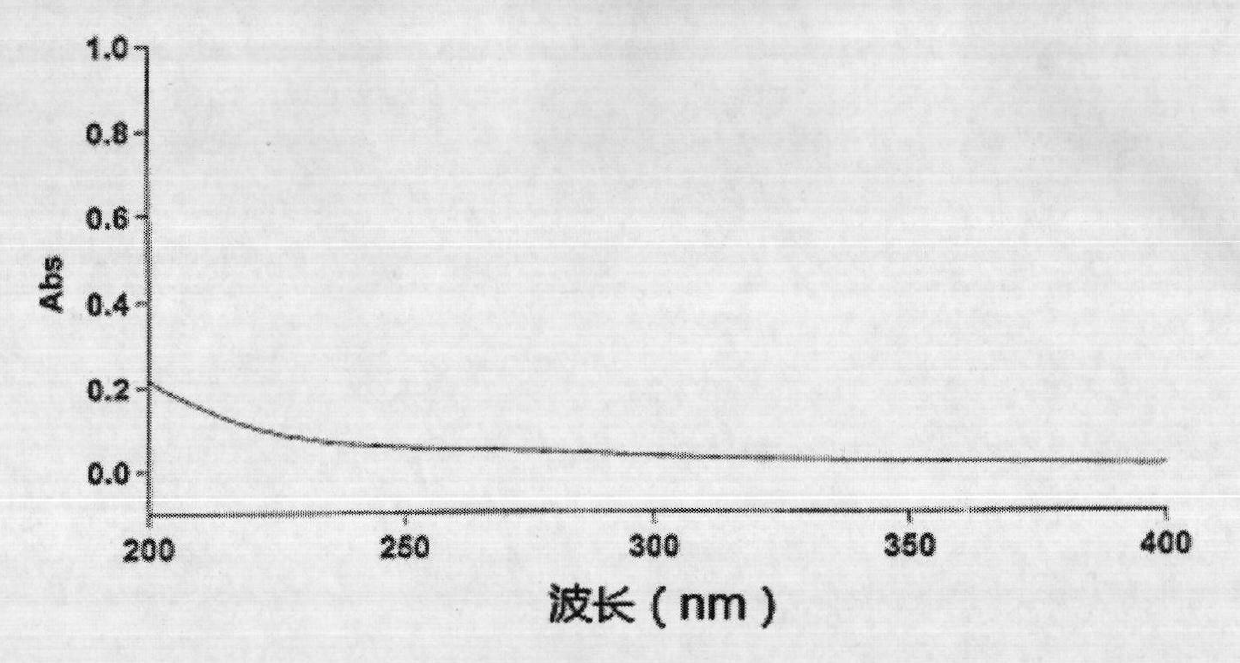

ActiveCN102372789AMeet the use requirementsAvoid decompositionCosmetic preparationsToilet preparationsNatural stateSpecific rotation

The invention discloses a peach gum polysaccharide, comprising 70-98 wt% of neutral total sugar and no nucileic acid, protein, tannin, dextrin, starch and other impurities, wherein, the content of glucuronic acid in the neutral total sugar accounts for 5-30 % of the content of the peach gum polysaccharide, the average molecular weight of the peach gum polysaccharide is more than 3000 dalton, and an aqueous solution of the peach gum polysaccharide has a dynmaic viscosity of 0.5-4.0 pa. s, a pH value of 4.0-6.5, and a specific rotation defined in the description. The invention also provides an extractive of the peach gum polysaccharide, and a preparation method of the peach gum polysaccharide and the extractive, and an application as a stabilizing agent. The preparation method of the peach gum polysaccharide and the extractive can ensure that various physicochemical properties of the peach gum polysaccharide satisfy the requirements of use in food, medicines, cosmetics, and light industry field, keeps natural state of the peach gum polysaccharide, has no effluence on the product properties of the peach gum polysaccharide, ensures the safety, stability, validity and controllability of the product, and has a wide commercial prospect and application future.

Owner:SHANGHAI HUIWEN BIO TECH

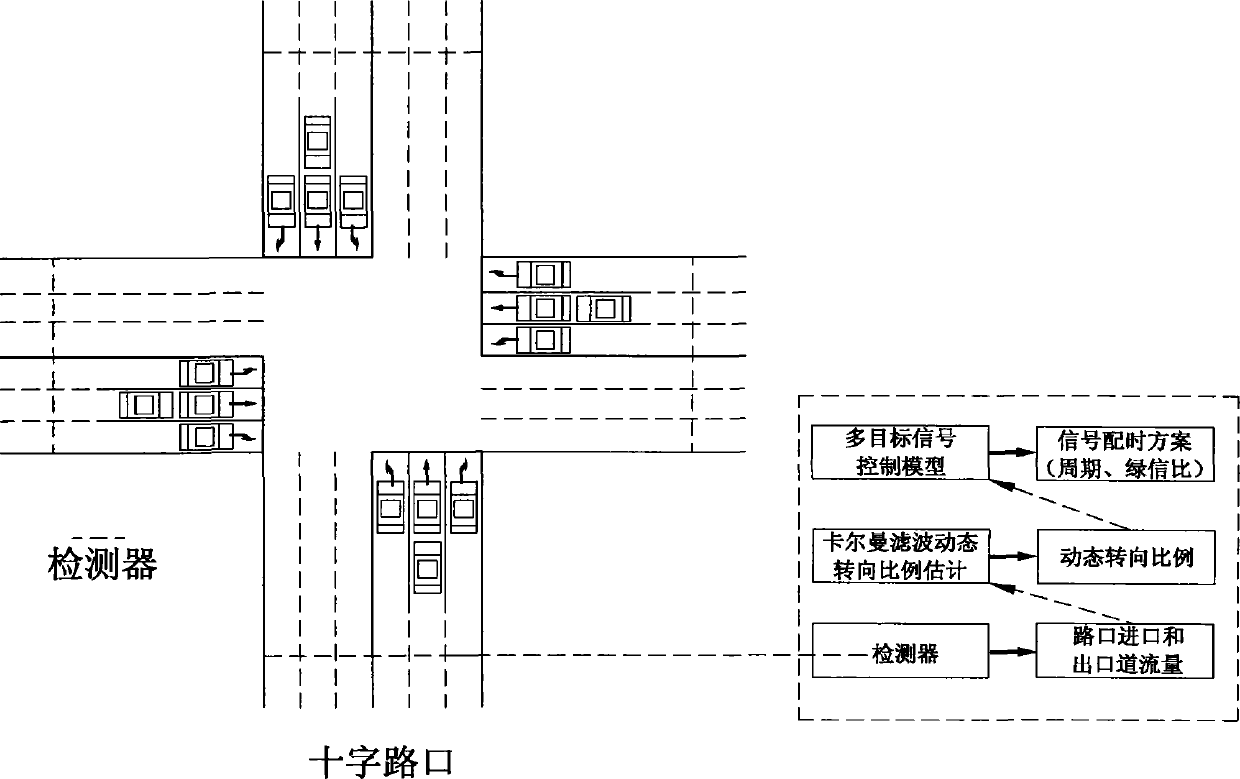

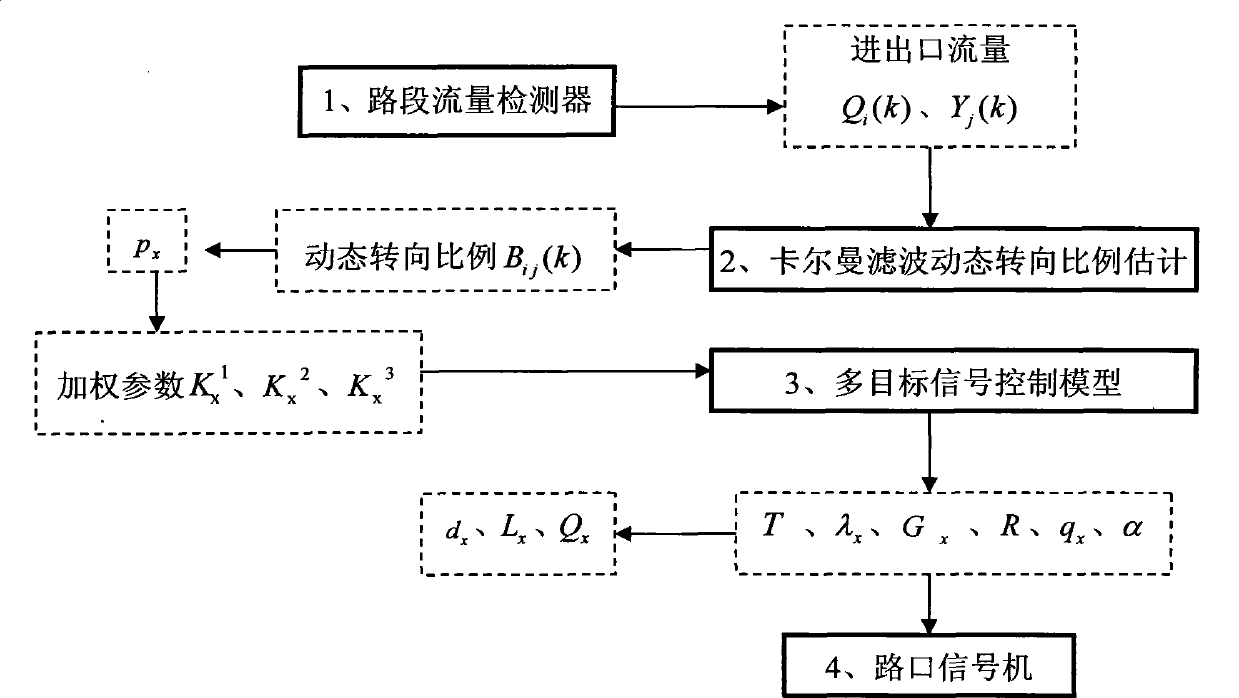

Intersection signal control method based on dynamic steering proportion estimation

ActiveCN103810869AImprove operational efficiencyImprove effective traffic capacityControlling traffic signalsTraffic capacityState space

The invention discloses an intersection signal control method based on a dynamic steering proportion estimation, and aims at a four phase control intersection. The intersection signal control method based on the dynamic steering proportion estimation includes: establishing a state space model based on Kalman filtering; designing an improved sequence Kalman filtering algorithm to solve an intersection dynamic steering proportion; further establishing a multiple target signal control model which minimizes delay and queuing length and maximizes effective traffic capacity based on the above two steps so as to solve a timing parameter and an evaluation index for a intersection real-time signal. Case researches show that the intersection signal control method based on the dynamic steering proportion estimation has high efficiency and accuracy, and can achieve real-time signal control of the intersection. In allusion to the current situation that a study of combining the dynamic steering proportion estimation with signal control is basically in a blank state, the intersection signal control method based on the dynamic steering proportion estimation has the advantages of being dynamic and timely, high in efficiency, high in accuracy, optimal in multiple targets, used on line and the like.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

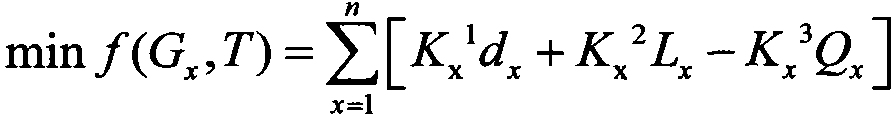

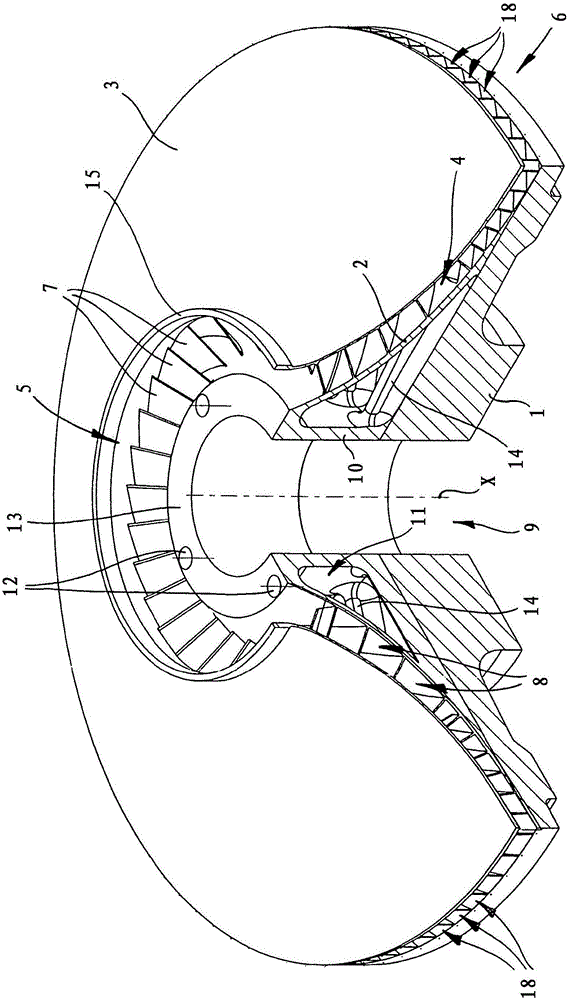

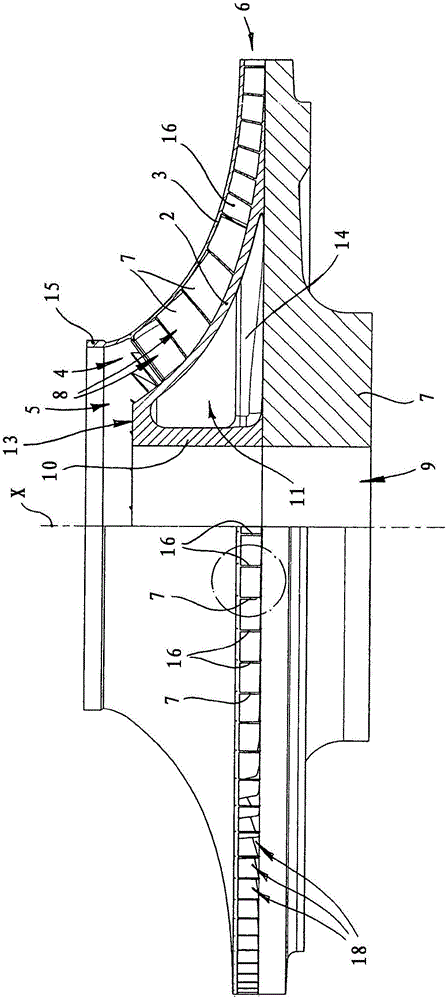

Turbine wheel for a radial turbine

InactiveCN106593945ASave materialReduce manufacturing costTurbinesAdditive manufacturing apparatusImpellerTurbine wheel

The invention relates to a turbine wheel for a radial turbine. A turbine wheel for a radial turbine includes a rotationally symmetrical base plate (1) and a flow chamber (4) delimited by a hub disk (2) and a cover disk (3), wherein the flow chamber connects an axial inner opening (5) to a radial outer opening (6) and is subdivided by turbine blades (7) into flow channels (8). In a method for producing such a turbine wheel, the hub disk (2), the turbine blades (7) and the cover disk (3) are integrally formed on the base plate (1) using additive production methods.

Owner:ATLAS COPCO ENERGAS

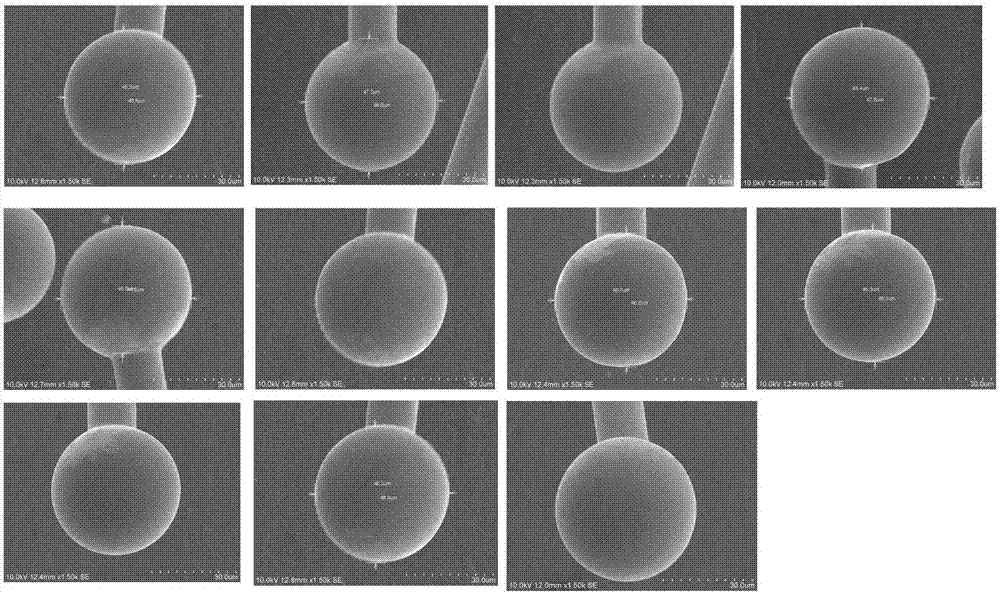

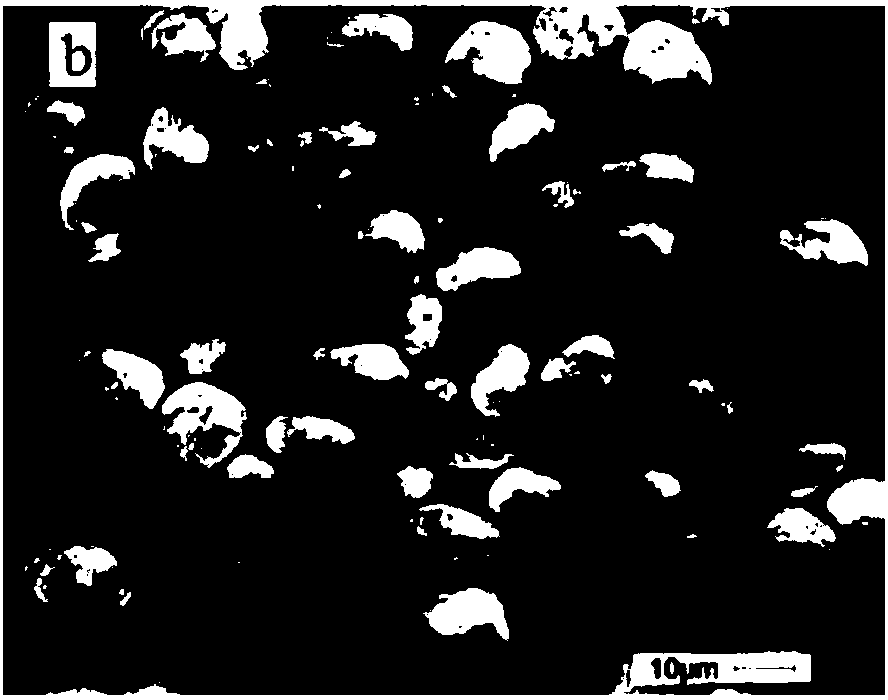

Ultra-high molecular weight polyethylene ultrafine fiber and preparation method thereof

InactiveCN102634862AWell-arranged structure of macromoleculesImprove application featuresFilament/thread formingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses an ultra-high molecular weight polyethylene ultrafine fiber. The invention is characterized in that the ultra-high molecular weight polyethylene ultrafine fiber is prepared from polyethylene with the molecular weight of more than 1 million, and the diameter of the ultrafine fiber is 80 nanometers-2 micrometers. The preparation method comprises the following steps: adding 0.1-5 wt% polyethylene with the molecular weight of more than 1 million and 0.005-2 wt% antioxidant into a corresponding solvent to prepare a polyethylene spinning liquid at 130-180 DEG C; and carrying out ultrasonic processing on the prepared spinning liquid, spinning into an extractant under certain electrostatic spinning conditions to obtain a jelly fiber, and storing the jelly fiber in the extractant for 1-5 days until the solvent in the fiber is leached out, thereby obtaining the ultra-high molecular weight polyethylene ultrafine fiber of which the diameter is 80 nanometers-2 micrometers.

Owner:JIANGNAN UNIV

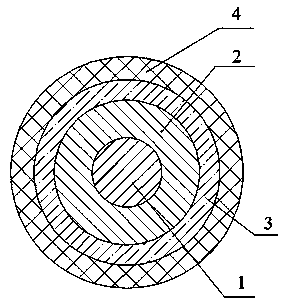

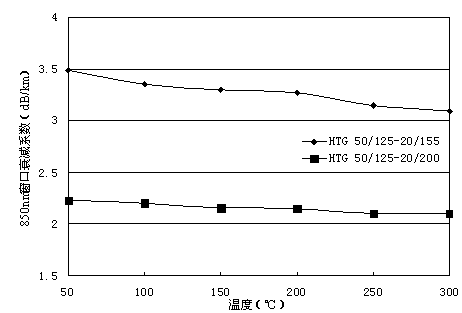

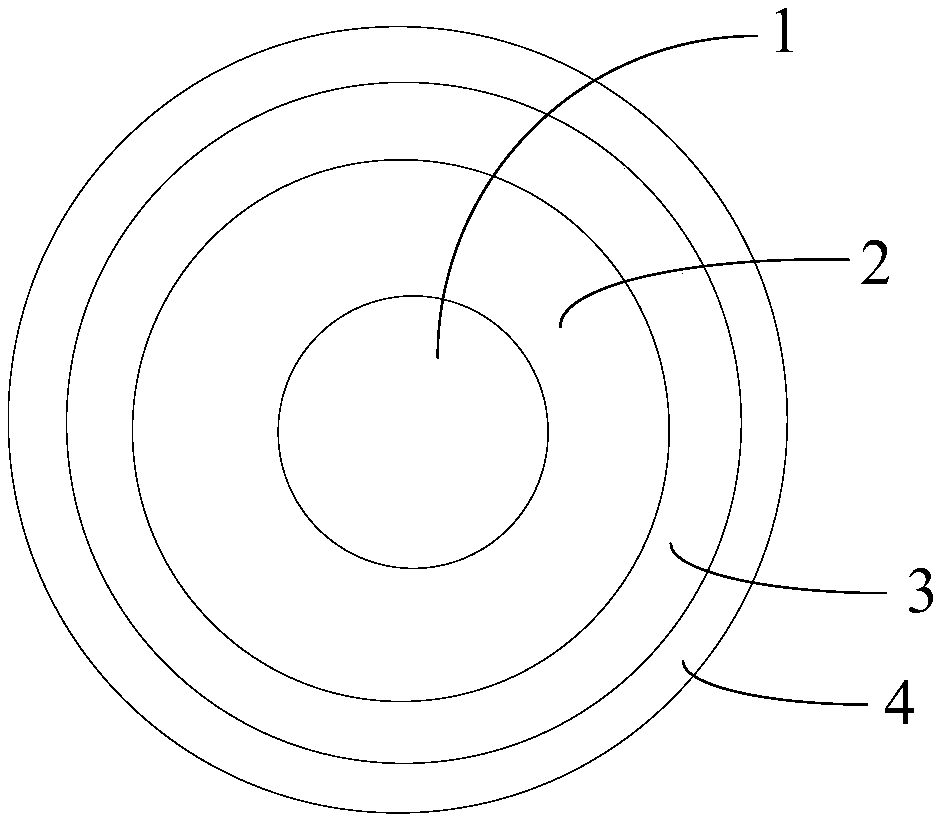

Low-attenuation high temperature resistance optical fiber

ActiveCN103472531AEffective protectionImprove transmission characteristicsOptical fibre with multilayer core/claddingTemperature resistanceMechanical property

The invention relates to a low-attenuation high temperature resistance optical fiber which comprises a silica fiber. An inner coating and an outer coating wraps the outer surface of the silica fiber from inside to outside in sequence. The low-attenuation high temperature resistance optical fiber is characterized in that the inner coating is made of modified silicone rubber coating materials, the outer coating is made of polyimide coating materials, the inner coating and the outer coating are both formed through thermal curing, and the thickness of the radial single edge of each coating is 16-25microns. According the low-attenuation high temperature resistance optical fiber, the inner coating is small in modulus, high in tensile strength and capable of playing a good buffering role, effectively protecting the silica fiber, improving the mechanical properties of the silicon fiber and optimizing the transmission characteristics of the optical fiber; by means of the recombination of the inner high temperature resistance coating and the outer high-temperature resistance coating, the silica fiber is made to be work normally and maintain low attenuation in environments with 300DEG C high temperature, and thus the application characteristics of the silicon fiber are improved greatly, the silicon fiber can be applied to high-temperature severe working environments, the long-period using temperature reaches 300DEG C, and thus the application field of the silica fiber is expanded; the low-attenuation high temperature resistance optical fiber is simple in coating structure and easy and convenient to manufacture.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

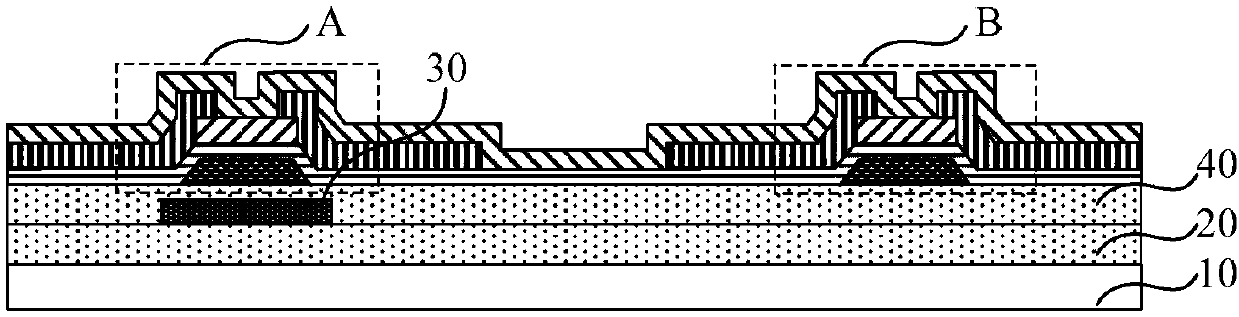

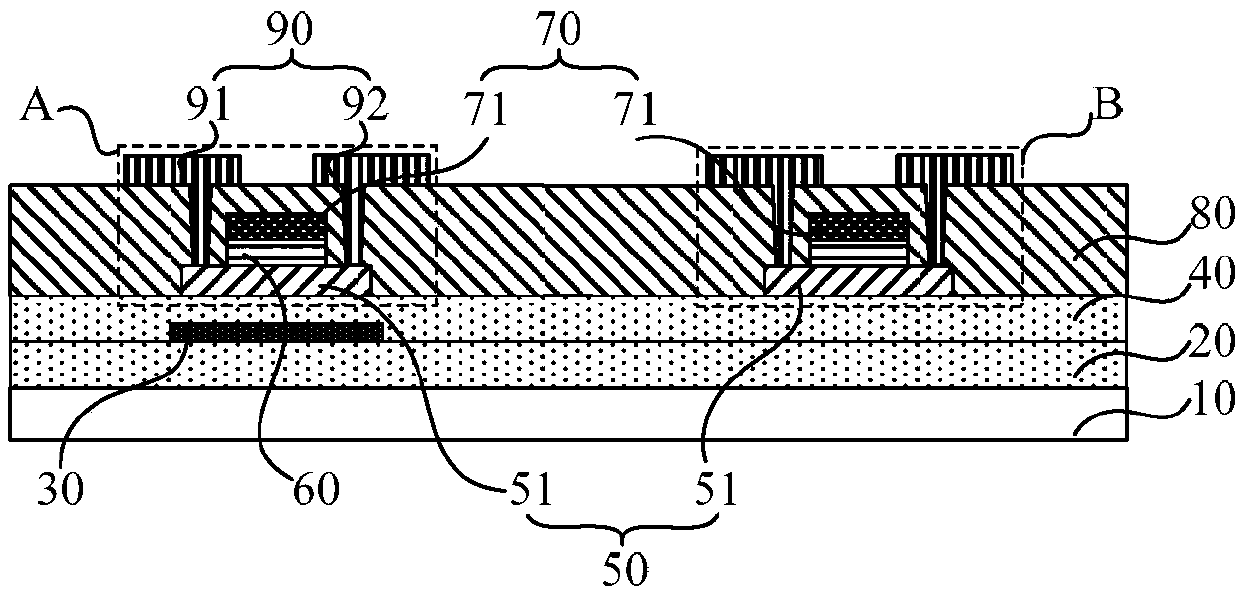

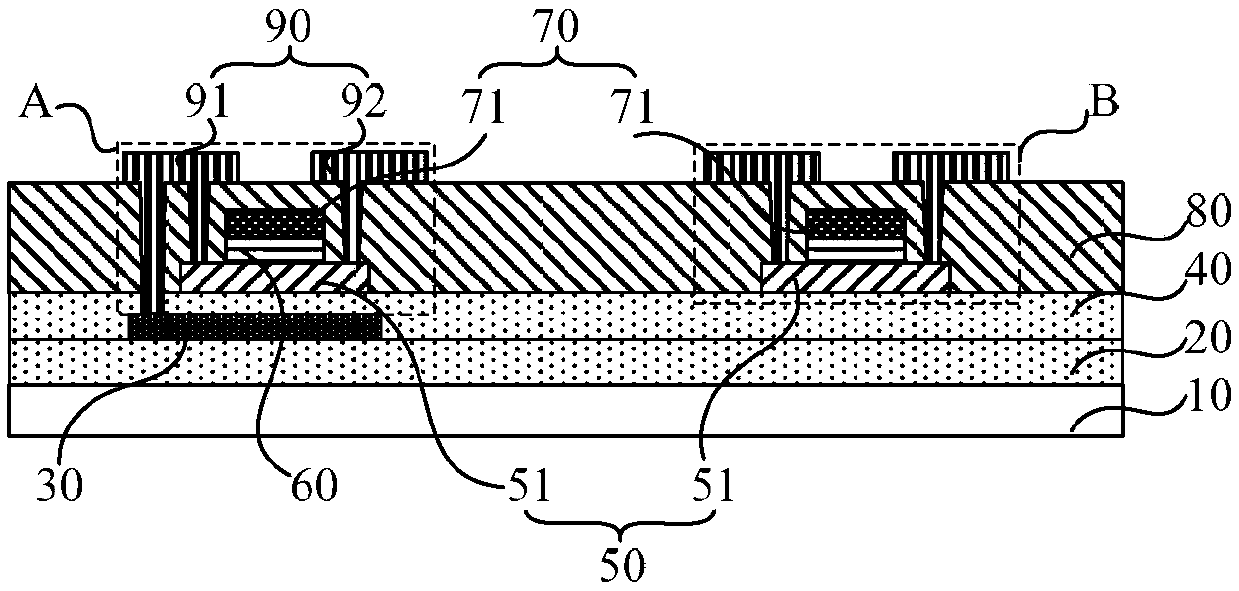

Array substrate and preparation method thereof, and display device

ActiveCN108039351AImprove the temperature stability of negative bias lightNegative bias light temperature stability guaranteeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen content

The embodiments of the invention provide an array substrate and a preparation method thereof and a display device, which relate to the technical field of display. The problem that the multiple thin film transistors in the existing array substrate need different oxygen-bearing environments because of different application needs and it is difficult to balance the working stability of the thin film transistors at the same time can be solved. The array substrate includes a base substrate, and further includes a first buffer layer, an oxygen barrier pattern and a second buffer layer arranged on thebase substrate in sequence, and a first thin film transistor and a second thin film transistor arranged on the second buffer layer. The orthographic projection of the channel region of the first thinfilm transistor on the base substrate falls within the boundary range of the orthographic projection of the oxygen barrier pattern on the base substrate. The oxygen content of the first buffer layeris higher than that of the second buffer layer.

Owner:BOE TECH GRP CO LTD

Production of polymer apple pectin

Production of polymer malic pectin is carried out by selecting raw material, cleaning raw material, hydrolyzing, separating, concentrating, drying, de-coloring, cleaning and vacuum drying to obtain final product. It raises molecular weight of pectin up to 130000g / mol and increases pectin solution viscosity and can be used as thickener of beverage and food. It adopts strong oxidant sodium chlorite to bleach and de-color, it's cheap and convenient, has excellent de-coloring effect and various usages.

Owner:YANTAI ANDRE PECTIN

Pre-formed gel sheet

InactiveCN1367680AGood mechanical propertiesAppropriate amount of syneresisCosmetic preparationsHair cosmeticsMannoseChemistry

A preformed sheet device comprising: (a) less than 10% of a polysaccharide mixture consisting of: (i) red algae polysaccharide; (ii) mannose-containing polysaccharide selected from the group consisting of Mannan, glucomannan, and derivatives or mixtures thereof, and; (iii) fermented polysaccharides, or derivatives thereof; and (b) from about 30% to about 99.5% water; wherein the device contained The total amount of polysaccharides is less than 10%. The preformed sheet device of the present invention is suitable for topical application and exhibits a desired amount of syneresis and / or improved mechanical properties such as strength and elasticity, and exhibits excellent moisturizing, hydrating and cooling effects Beneficial effect. In addition, the device of the present invention is easy to handle when applied, has permeability, and can conform to the contour of the applied surface.

Owner:THE PROCTER & GAMBNE CO

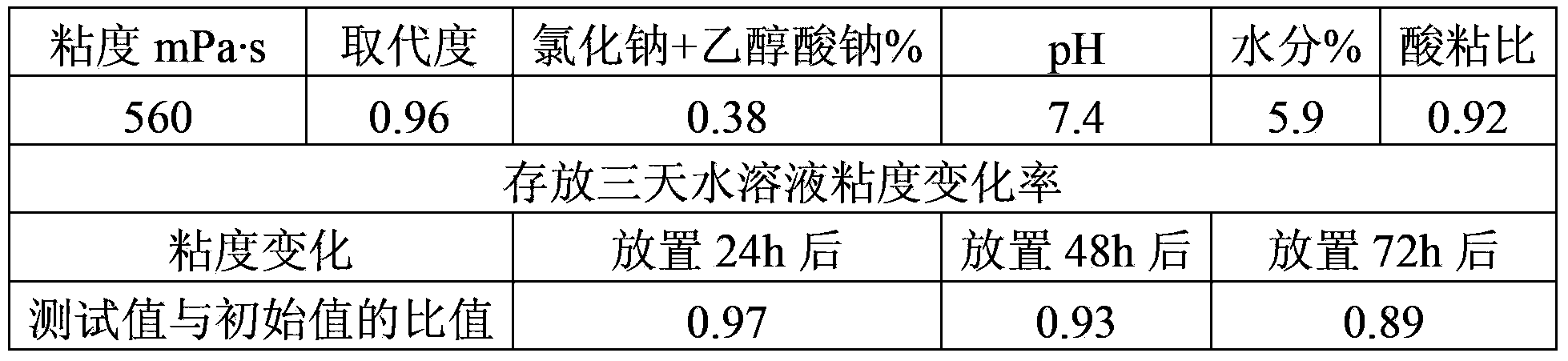

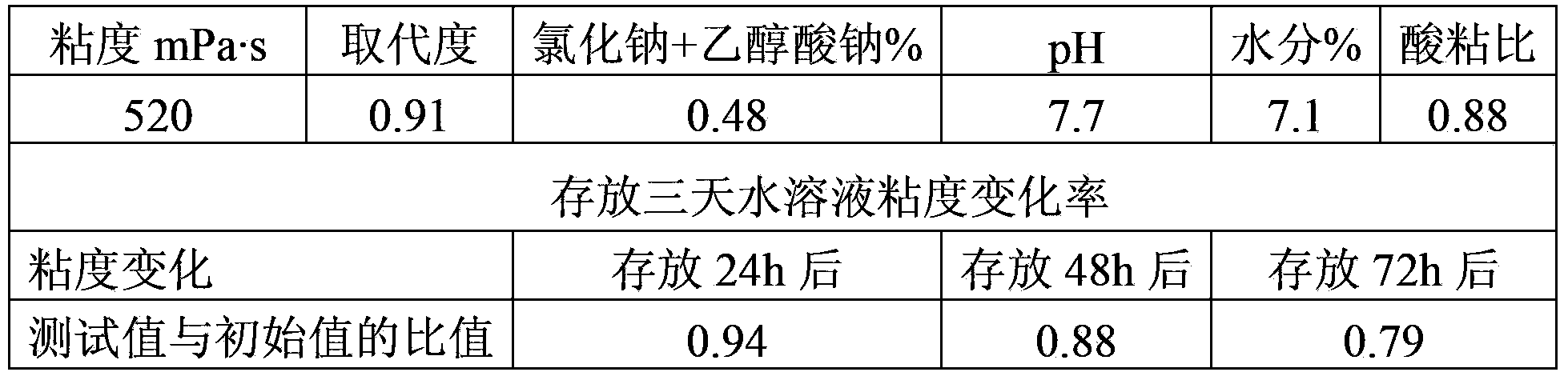

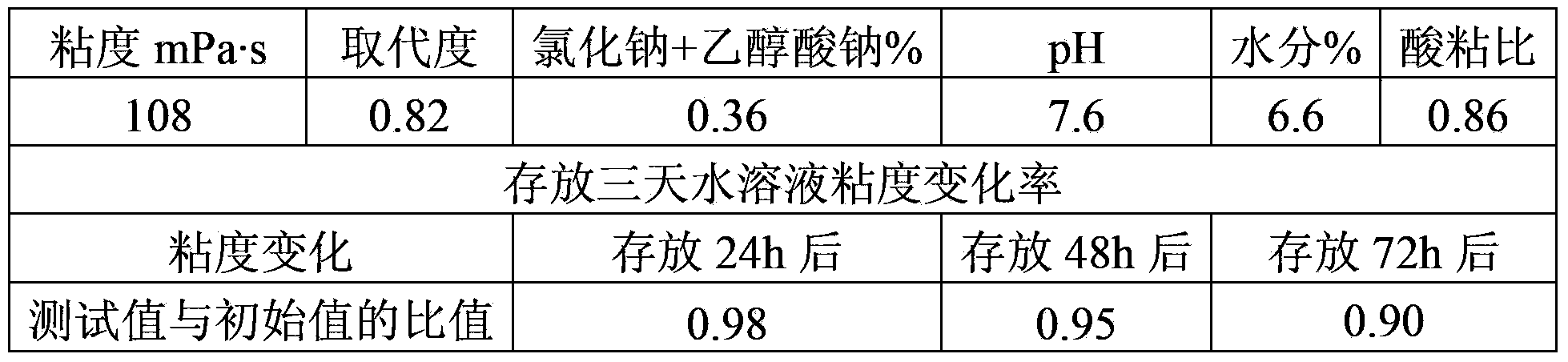

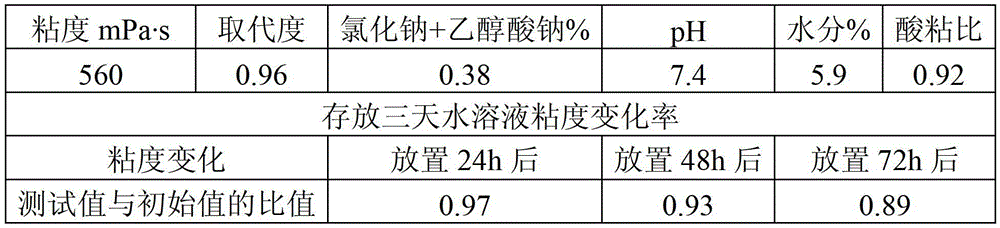

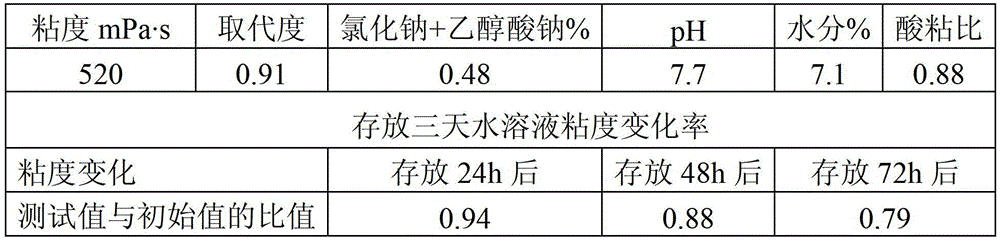

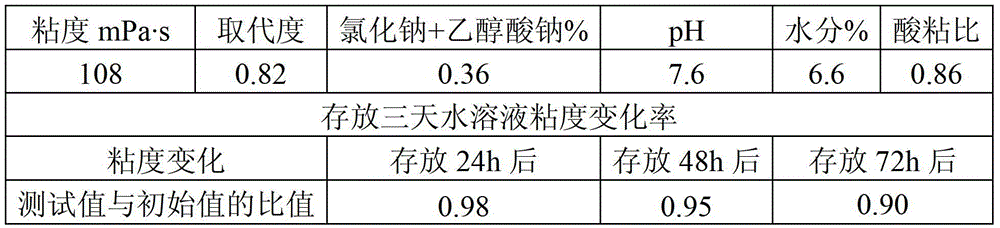

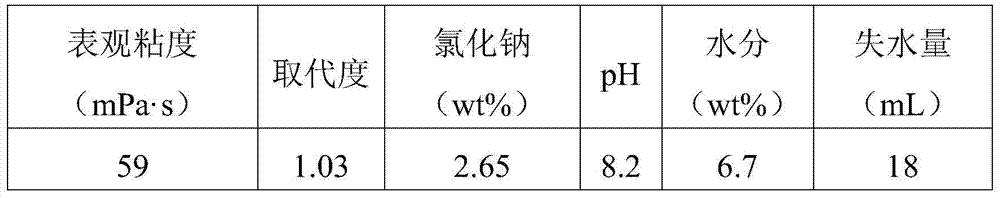

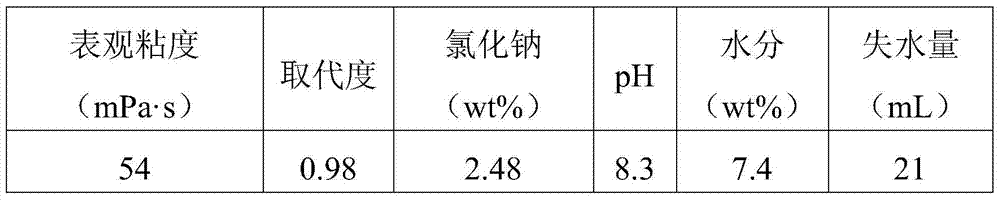

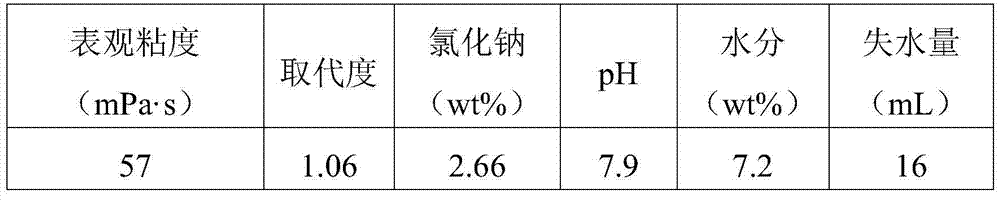

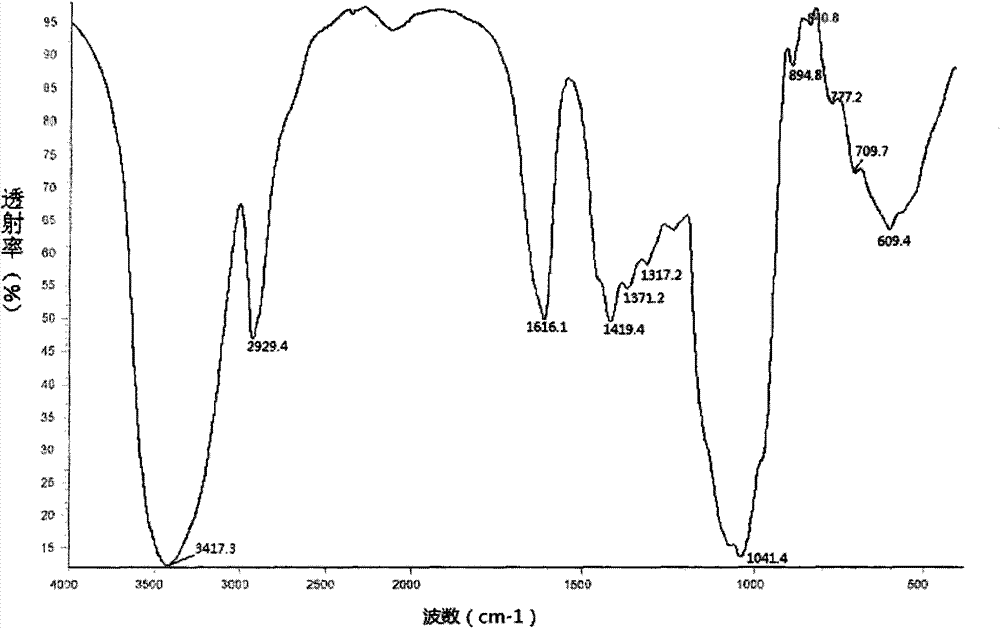

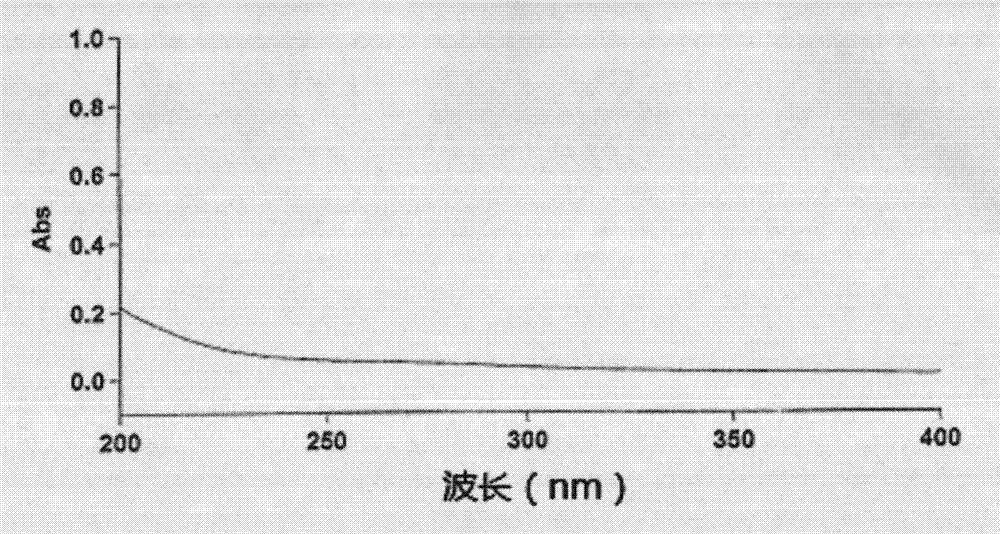

Preparation method of edible-grade sodium carboxymethylcellulose

The invention discloses a preparation method of edible-grade sodium carboxymethylcellulose. The preparation method comprises the following steps of 1, carrying out alkalization treatment on cellulose by NaOH to obtain alkali cellulose, 2, mixing the alkali cellulose and an etherifying agent in 10-50min and carrying out stirring at a temperature of 15-40 DEG C for 10-25min to obtain a mixture B, wherein the etherifying agent is an ethanol aqueous solution of chloroacetic acid, 3, mixing the mixture B and an etherifying agent in 5-20min and carrying out stirring at a temperature of 15-40 DEG C for 10-30min to obtain a mixture C, wherein the etherifying agent is an ethanol aqueous solution of chloroacetic acid, and 4, carrying out etherifying on the mixture C and then carrying out neutralization washing and / or aftertreatment. The preparation method improves edible-grade sodium carboxymethylcellulose application performances, effectively reduces a cellulose degradation rate, improves application characteristics and has specific performances in food production application.

Owner:上海长光企业发展有限公司

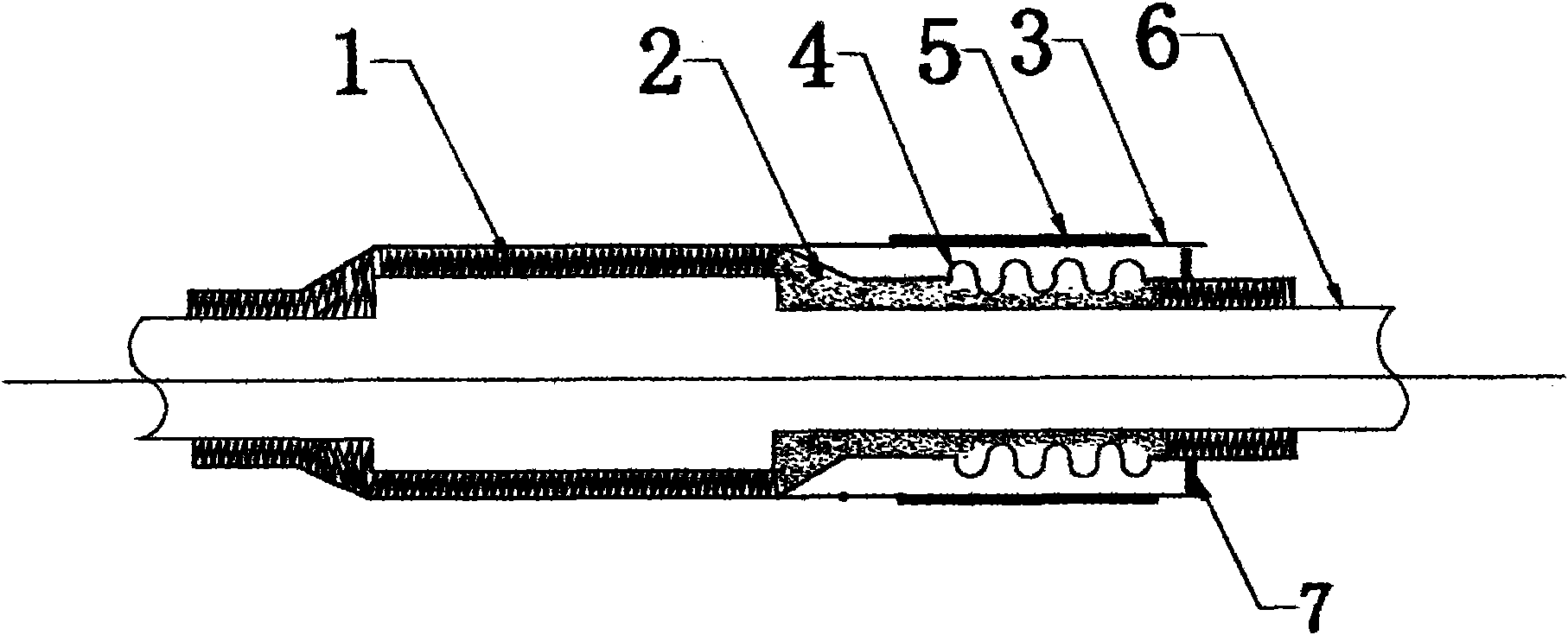

PE (poly ethylene) corrugated compensator for high-temperature water

InactiveCN102734587AImprove performanceImprove insulation effectPipeline expansion-compensationThermal insulationIonThermal insulation

The invention discloses a compensator used in a concentrated-heating hot water network, and concretely relates to a PE (poly ethylene) corrugated compensator for high-temperature water. The compensator comprises an operating tube compensator and an outer polyethylene sleeve, wherein the operating tube compensator is externally sleeved with a hard thermal insulation layer and a soft thermal insulation layer, the outer polyethylene sleeve is tightly wrapped on the outsides of the hard thermal insulation layer and the soft thermal insulation layer, and the hard thermal insulation layer is tightly wrapped on one end of the operating tube compensator and raised parts; the soft thermal insulation layer is tightly wrapped on the other end of the operating tube compensator; and the outer edge of the soft thermal insulation layer is provided with a corrugated pipe. The compensator disclosed by the invention is extremely compact in structure; the compensator is strong in bearing capacity, has the characteristics of acid, alkali and chloride ion corrosion resistance, and prevents the rupturing of an outer pipe in the process that an operating tube is drawn, thereby prolonging the service life of the compensator and saving energy; meanwhile, because of the setting of a protective cover, the heat preservation effect can be further increased; due to the selection of materials, the compensator is more practical; and because of the simple structure and process, the installation process is easier, thereby solving the problem of inconvenience in installation.

Owner:QINGDAO JINBANG ANTI CORROSION INSULATION PIPELINE

High-efficient and stable-state preparation method of soybean lecithin

ActiveCN105777919AHigh inclusion rateImprove application featuresFermentationUltrafiltrationMoisture absorption

The invention discloses a high-efficient and stable-state preparation method of soybean lecithin. The method takes natural starch as a raw material, and comprises the following steps: debranching through enzymatic hydrolysis to obtain an amylose solution; filtering the amylose solution through membranes (including five ultrafiltration membranes of which the molecular weights are 5 K to 100 K) to obtain amyloses of different molecular weights, then adjusting the temperature of the amylose solution to be 50 to 80 DEG C, dropping a soybean lecithin phosphate buffer saline (PBs) solution of which the soluble mass percentage is 5% to 20%, stirring for 1 to 4 hours at constant temperature, adding 1 to 6 grams of the soybean lecithin PBs solution into per gram of dry starch; cooling to room temperature, and placing in a refrigerator of 2 to 6 DEG C to carry out refrigeration for 12 to 24 hours; carrying out centrifugation, washing, drying and grinding to obtain a light yellow powder product. The product is higher in content of the soybean lecithin and better in stability, so that the storage stability of the soybean lecithin is improved, the possibilities of moisture absorption and oxidization are low, and the use characteristics and the application range of the soybean lecithin are improved.

Owner:广州海莎生物科技有限公司

Method for preparing ultraviolet excited or vacuum ultraviolet excited green emitting phosphor

InactiveCN102888224AHigh luminous intensityHigh retention rateLuminescent compositionsMass ratioPhosphor

The invention discloses a method for preparing ultraviolet excited or vacuum ultraviolet excited green emitting phosphor. The method comprises the following steps of: weighing Al2O3, MgO, Tb3O4 and CeO2 in a mass ratio, sieving all raw materials by using a 100-mesh sieve, mixing by a dry method, introducing one or more of BaCO3, MgCl2, AlF3, MgF2, BaF2 and H3BO3 into the uniformly mixed raw materials, and fully mixing; loading the mixed powder into an alumina crucible; firing at high temperature at reducing atmosphere; crushing the fired fluorescent powder blocks, and sieving by using the 100-mesh sieve; dispersing by a wet method to obtain slurry; controlling the particle size to be 2 to 12 mu m; sieving the slurry which is obtained by wet-method dispersing by using a 500-mesh sieve; removing the sieving residues on the 500-mesh sieve; washing with water; and suction-filtering, drying and screening to obtain the green emitting phosphor. The green emitting phosphor has the characteristics of controllable particle size, high brightness, light failure, color development and low color bleaching.

Owner:CAIHONG GRP ELECTRONICS CO LTD

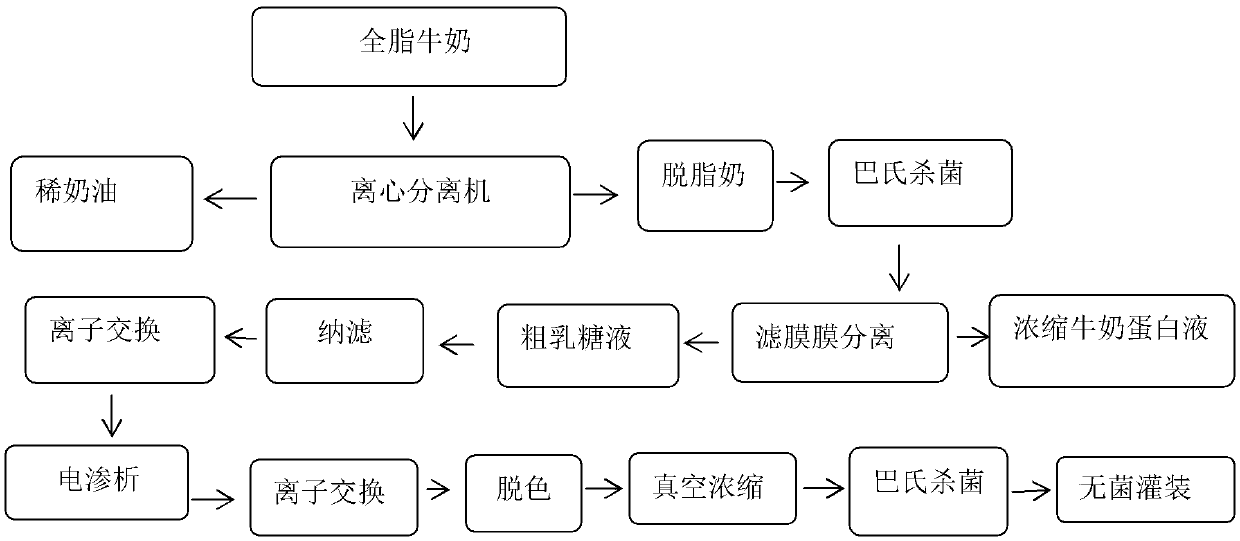

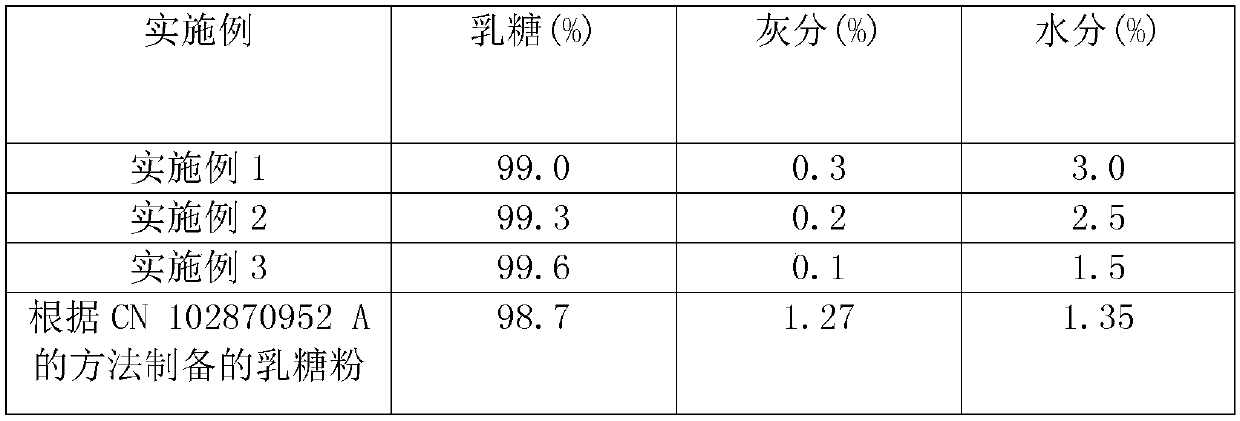

Concentrate lactose solution and preparation method thereof

PendingCN111205339AHigh yieldImprove application featuresSugar derivativesDisaccharidesActivated carbonIon exchange

The invention provides a method for preparing a lactose solution. The method for preparing the lactose solution comprises the following steps: preparing skim milk; carrying out ultra-filtration; carrying out nano-filtration; carrying out primary ion exchange; carrying out electrodialysis; carrying out secondary ion exchange; and carrying out activated carbon decolorization. The method for preparing the lactose solution can be used for producing the lactose solution; and the produced lactose solution can be processed into lactose powder.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

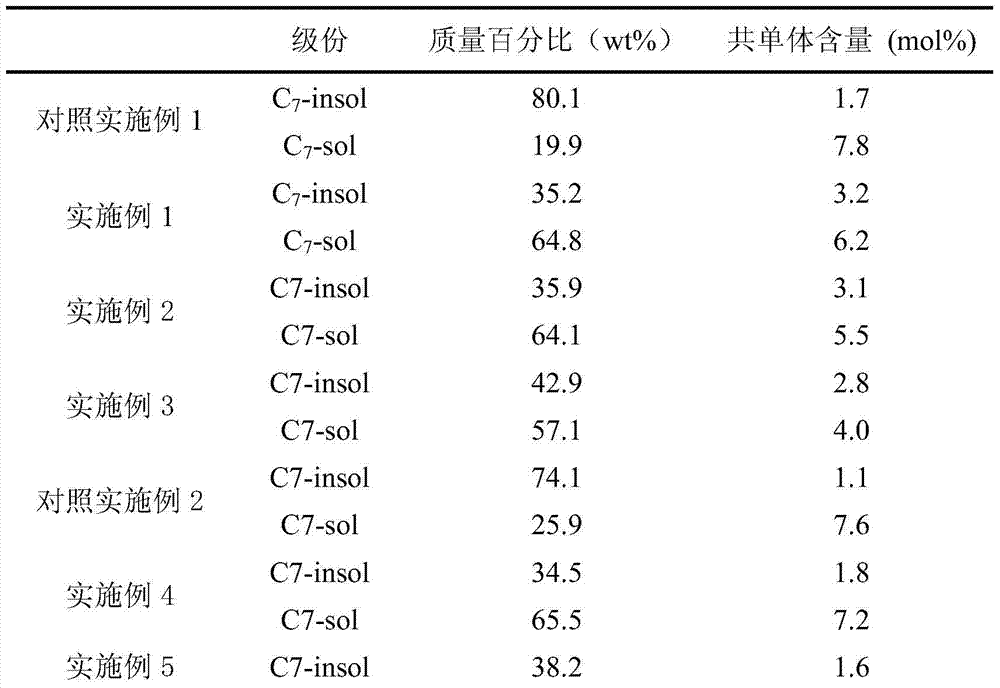

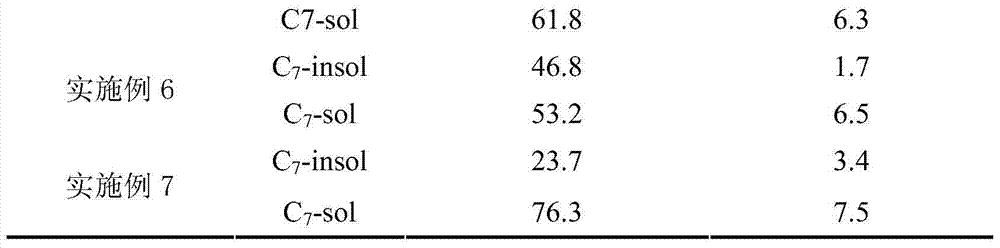

A kind of preparation method of linear low density polyethylene

ActiveCN105017454BReduce dosageHigh insertion volumeLow-density polyethyleneLinear low-density polyethylene

The invention discloses a preparation method of linear low density polyethylene. By using an alkylaluminium-preactivated supported TiCl4 / MgCl2 catalyst as a main catalyst, using alkylaluminium as a cocatalyst and using H2 as a molecular weight modifier, ethene and alpha-olefin undergo a slurry polymerization reaction so as to obtain the linear low density polyethylene. The preparation method of the linear low density polyethylene is suitable for a production device of linear low density polyethylene with the supported TiCl4 / MgCl2 catalyst used as a main catalyst. In comparison with a metallocene catalysis system, the production process of the invention is easy to control, use amount of the cocatalyst is low, production cost is low, insert quantity of alpha-olefin in the prepared linear low density polyethylene is high, composition and distribution of a copolymer are uniform, tensile property of the copolymer is good, and the copolymer has better application characteristics.

Owner:SINOPEC YANGZI PETROCHEM +1

A kind of heavy calcium carbonate powder surface modification method

InactiveCN103421142BImprove application featuresExcellent performance indexPigment treatment with macromolecular organic compoundsParaffin waxIn situ polymerization

The invention discloses a method for modifying heavy calcium carbonate powder (referred to as heavy calcium carbonate powder, the same below). The composition of the heavy calcium powder modifier of the present invention is polymaleic anhydride-acrylamide-n-butyl methacrylate and stearic acid, that is, a composite compatibilizer, through two modifications, the first modification is wet In-situ polymerization method, the hair modifier is polymaleic anhydride-acrylamide-n-butyl methacrylate, the second time is dry method, the modifier is stearic acid, and the simple method is to mix it fully first and dissolve it In the mixture of liquid paraffin and waste oil, the total amount of the above-mentioned organic matter in the heavy calcium powder accounts for about 1-3% (mass fraction) of the heavy calcium powder. The volume ratio of paraffin wax and waste oil is about 1, the mass ratio of polymaleic anhydride-acrylamide-n-butyl methacrylate and stearic acid is about 2, and the active heavy calcium powder of the present invention can be used as chlorinated polyvinyl chloride , polyvinyl chloride, polyethylene filler. The active heavy calcium powder of the present invention has good dispersion uniformity and low cost in the above resin, and is oriented to industrial production.

Owner:HEZHOU UNIV +1

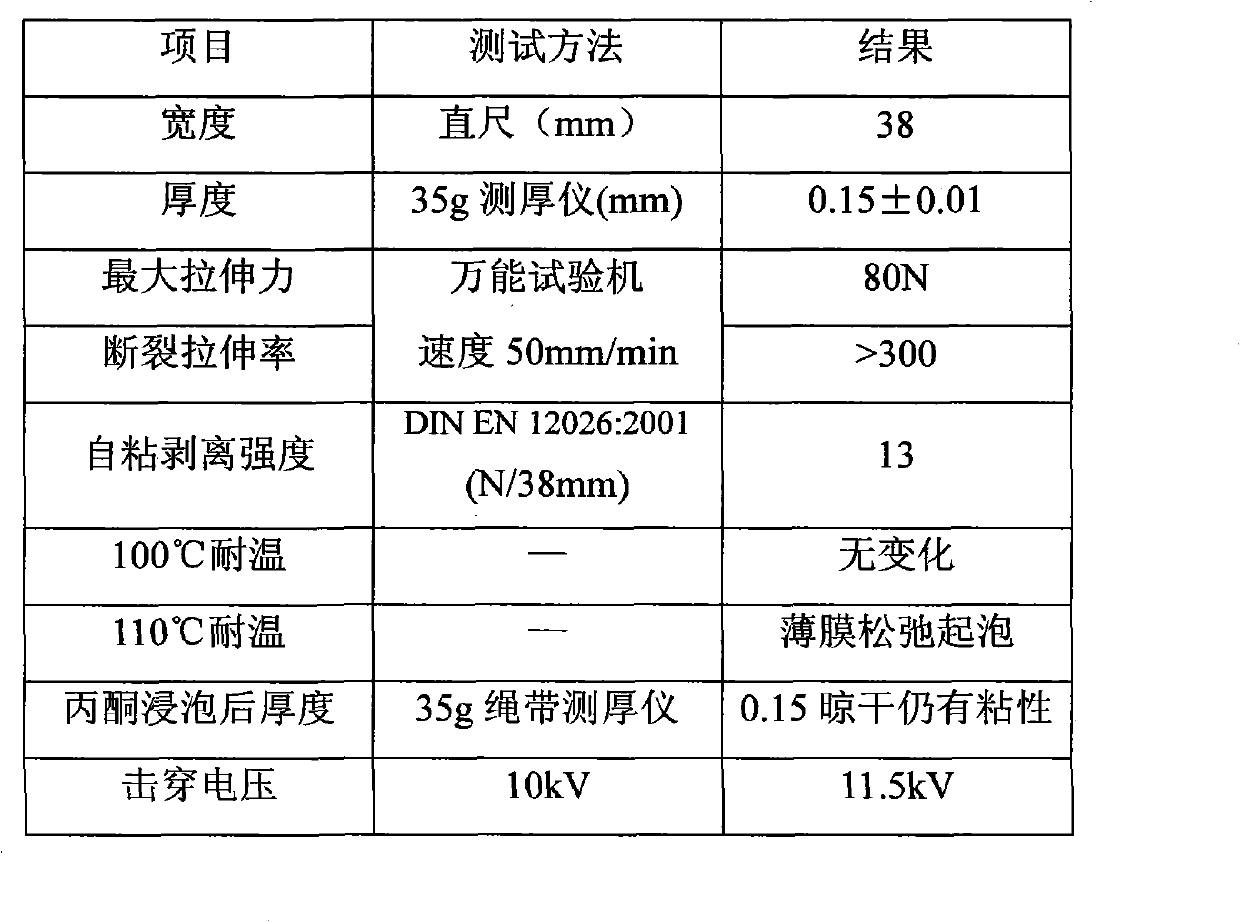

Polyethylene film adhesion tape and preparation method thereof

InactiveCN102580906ASimple production processShorten the production cycleFilm/foil adhesivesPretreated surfacesTetrafluoroethylenePolymer science

The invention provides a polyethylene film adhesion tape and a preparation method thereof. A polyethylene film and adhesive are compounded to form the polyethylene film adhesive tape. The polyethylene film adhesion tape and the preparation method have the advantages that processing technology is simple and convenient, performances of a product are excellent, and the product is remarkably superior to a teflon film and a polyimide film in terms of price.

Owner:JINTAN HUARONG INSULATING MATERIAL CO LTD

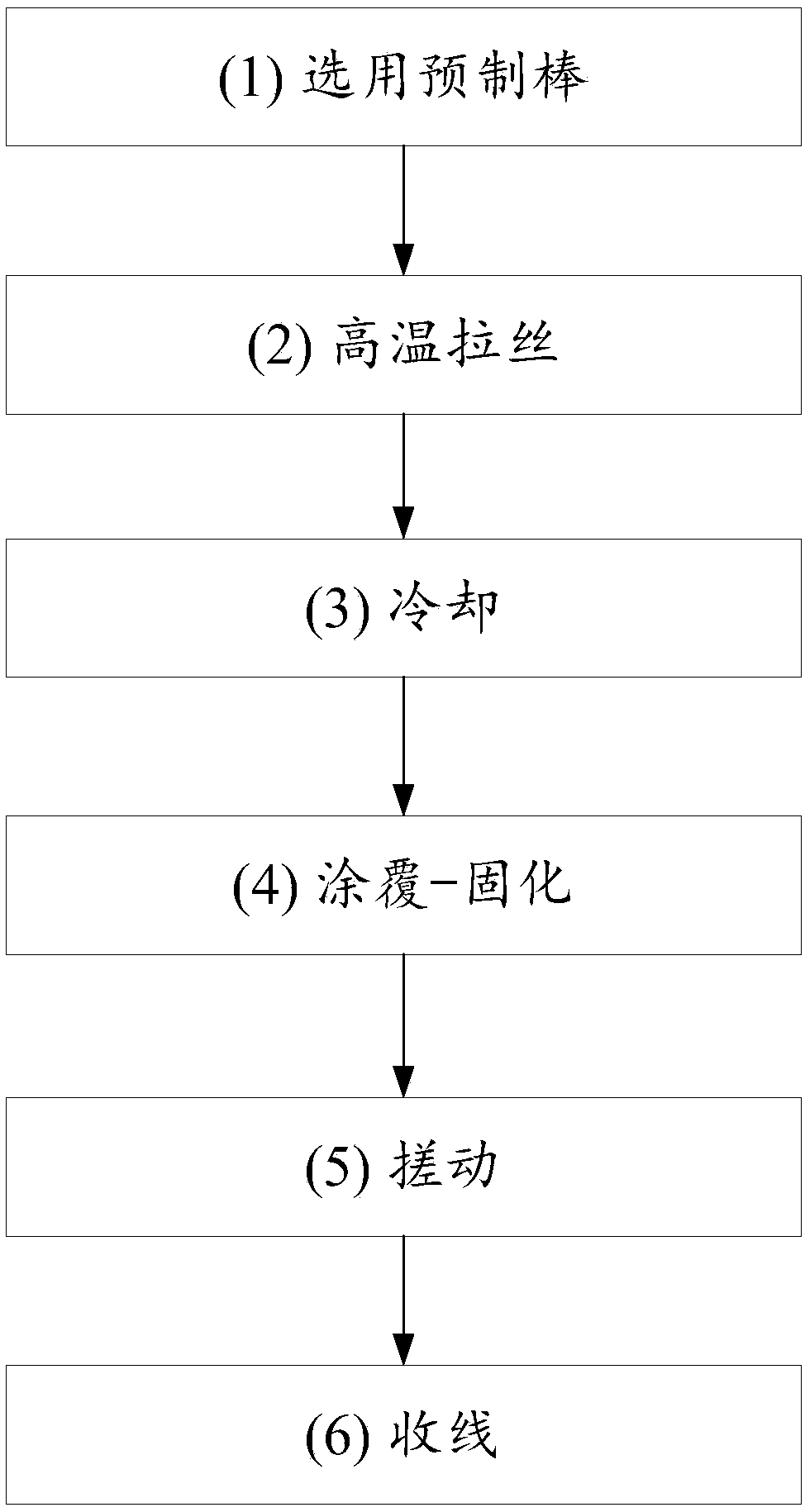

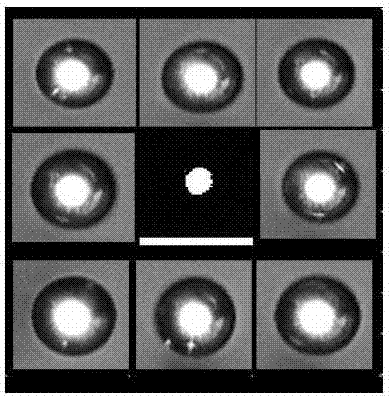

Optical fiber and preparation method thereof

PendingCN108802896AGood technical effectGood attenuation performanceGlass optical fibreGlass making apparatusUltravioletRefractive index

The invention discloses an optical fiber and a preparation method thereof and belongs to the optical fiber field. The optical fiber comprises a quartz optical fiber; the outer surface of the quartz optical fiber is coated with an inner coating and an outer coating sequentially from inside to outside. The optical fiber is characterized in that the glass-transition temperature of a coating materialused for the inner coating ranges from -50 DEG C to -70 DEG C, the refractive index of the coating material used for the inner coating ranges from 1.4 to 1.5, and the post-curing elastic modulus of the coating material of the inner coating ranges from 0.3 to 0.5 MPa; the refractive index of a coating material used for the outer coating ranges from 1.5 to 1.6, and the post-curing elastic modulus ofthe coating material used for the outer coating is 800 MPa or more; the coating material used for the inner coating and the coating material used for the outer coating have different refractive indexes; and the inner coating and the outer coating are both formed by means of ultraviolet curing. The optical fiber can satisfy low attenuation performance and good coating performance required by national standards, can be applicable to a low temperature environment of -70 DEG C to -80 DEG C, and therefore, the temperature application range of the optical fiber can be extended; the preparation process of the optical fiber involves the extremely cold-resistant optical fiber coating materials, the drawing process of the optical fiber is improved, and curing time is reduced, and therefore, preparation process time can be shortened, and preparation efficiency is higher. The preparation method is suitable for continuous production in large quantities.

Owner:ZHONGTIAN TECH FIBER OPTICS +4

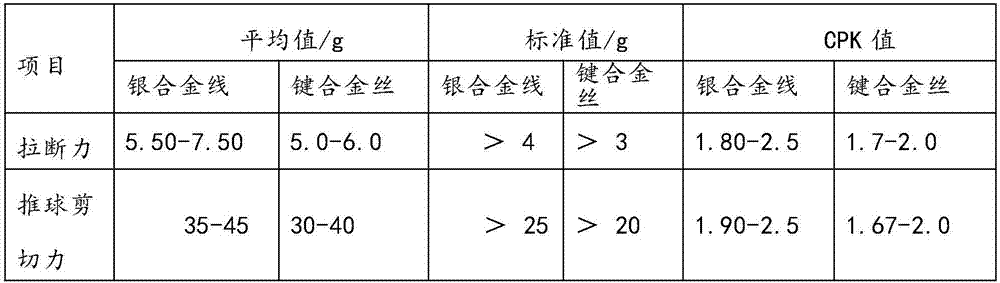

Sliver alloy wire used for semiconductor packaging and preparation method thereof

The invention discloses a silver alloy wire for semiconductor packaging and a preparation method thereof. The weight percentages of the components of the silver alloy wire are: 0.1-1.5% gold, 0.5-6.0% palladium, 0.003-0.006% cobalt, and the rest Top up 100% for silver. The silver alloy wire prepared by the invention has low cost, stable physical properties, good oxidation resistance and high reliability when used for welding on LEDs and semiconductor ICs and devices, and can replace expensive bonding gold wires and be used on LEDs and semiconductor packages.

Owner:河北乐通金属材料有限公司

A kind of preparation method of food grade sodium carboxymethylcellulose

The invention discloses a preparation method of edible-grade sodium carboxymethylcellulose. The preparation method comprises the following steps of 1, carrying out alkalization treatment on cellulose by NaOH to obtain alkali cellulose, 2, mixing the alkali cellulose and an etherifying agent in 10-50min and carrying out stirring at a temperature of 15-40 DEG C for 10-25min to obtain a mixture B, wherein the etherifying agent is an ethanol aqueous solution of chloroacetic acid, 3, mixing the mixture B and an etherifying agent in 5-20min and carrying out stirring at a temperature of 15-40 DEG C for 10-30min to obtain a mixture C, wherein the etherifying agent is an ethanol aqueous solution of chloroacetic acid, and 4, carrying out etherifying on the mixture C and then carrying out neutralization washing and / or aftertreatment. The preparation method improves edible-grade sodium carboxymethylcellulose application performances, effectively reduces a cellulose degradation rate, improves application characteristics and has specific performances in food production application.

Owner:上海长光企业发展有限公司

Efficient and stable preparation method of soybean lecithin

ActiveCN105777919BHigh inclusion rateImprove application featuresFermentationUltrafiltrationMoisture absorption

The invention discloses a high-efficient and stable-state preparation method of soybean lecithin. The method takes natural starch as a raw material, and comprises the following steps: debranching through enzymatic hydrolysis to obtain an amylose solution; filtering the amylose solution through membranes (including five ultrafiltration membranes of which the molecular weights are 5 K to 100 K) to obtain amyloses of different molecular weights, then adjusting the temperature of the amylose solution to be 50 to 80 DEG C, dropping a soybean lecithin phosphate buffer saline (PBs) solution of which the soluble mass percentage is 5% to 20%, stirring for 1 to 4 hours at constant temperature, adding 1 to 6 grams of the soybean lecithin PBs solution into per gram of dry starch; cooling to room temperature, and placing in a refrigerator of 2 to 6 DEG C to carry out refrigeration for 12 to 24 hours; carrying out centrifugation, washing, drying and grinding to obtain a light yellow powder product. The product is higher in content of the soybean lecithin and better in stability, so that the storage stability of the soybean lecithin is improved, the possibilities of moisture absorption and oxidization are low, and the use characteristics and the application range of the soybean lecithin are improved.

Owner:广州海莎生物科技有限公司

Production of polymer apple pectin

Production of polymer malic pectin is carried out by selecting raw material, cleaning raw material, hydrolyzing, separating, concentrating, drying, de-coloring, cleaning and vacuum drying to obtain final product. It raises molecular weight of pectin up to 130000g / mol and increases pectin solution viscosity and can be used as thickener of beverage and food. It adopts strong oxidant sodium chloriteto bleach and de-color, it's cheap and convenient, has excellent de-coloring effect and various usages.

Owner:YANTAI ANDRE PECTIN

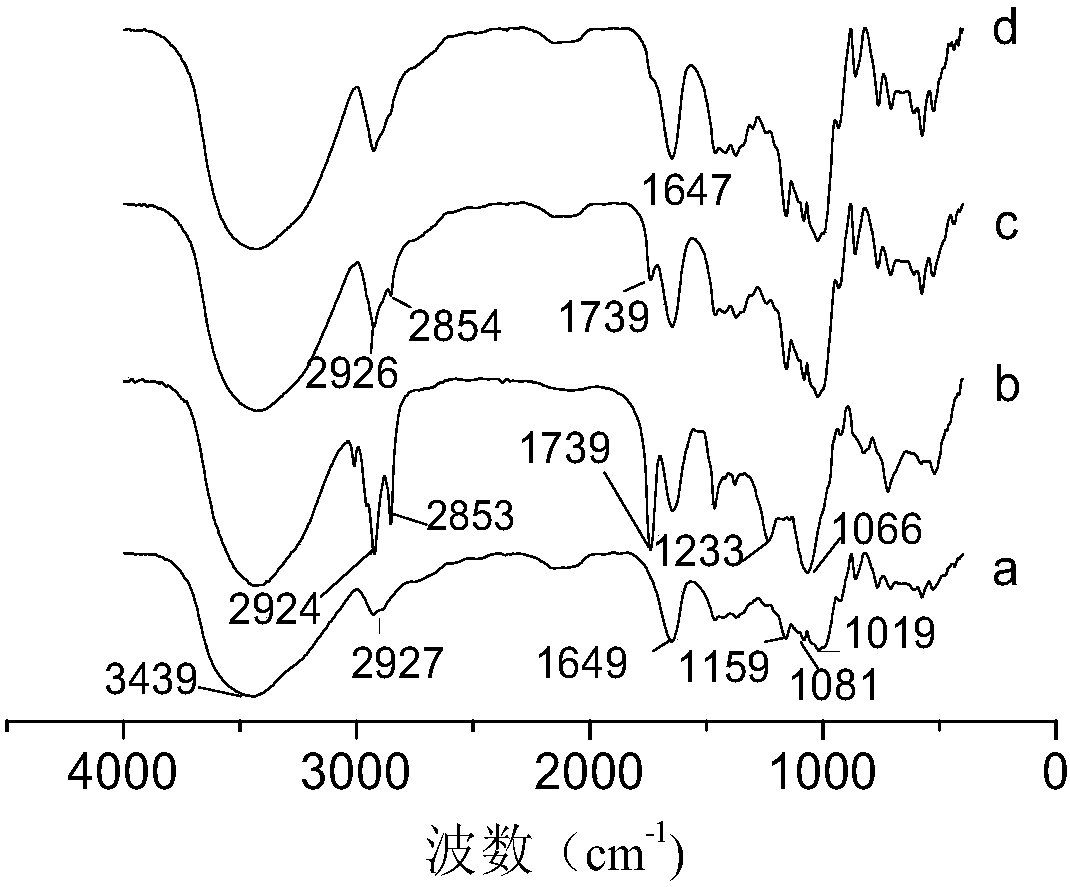

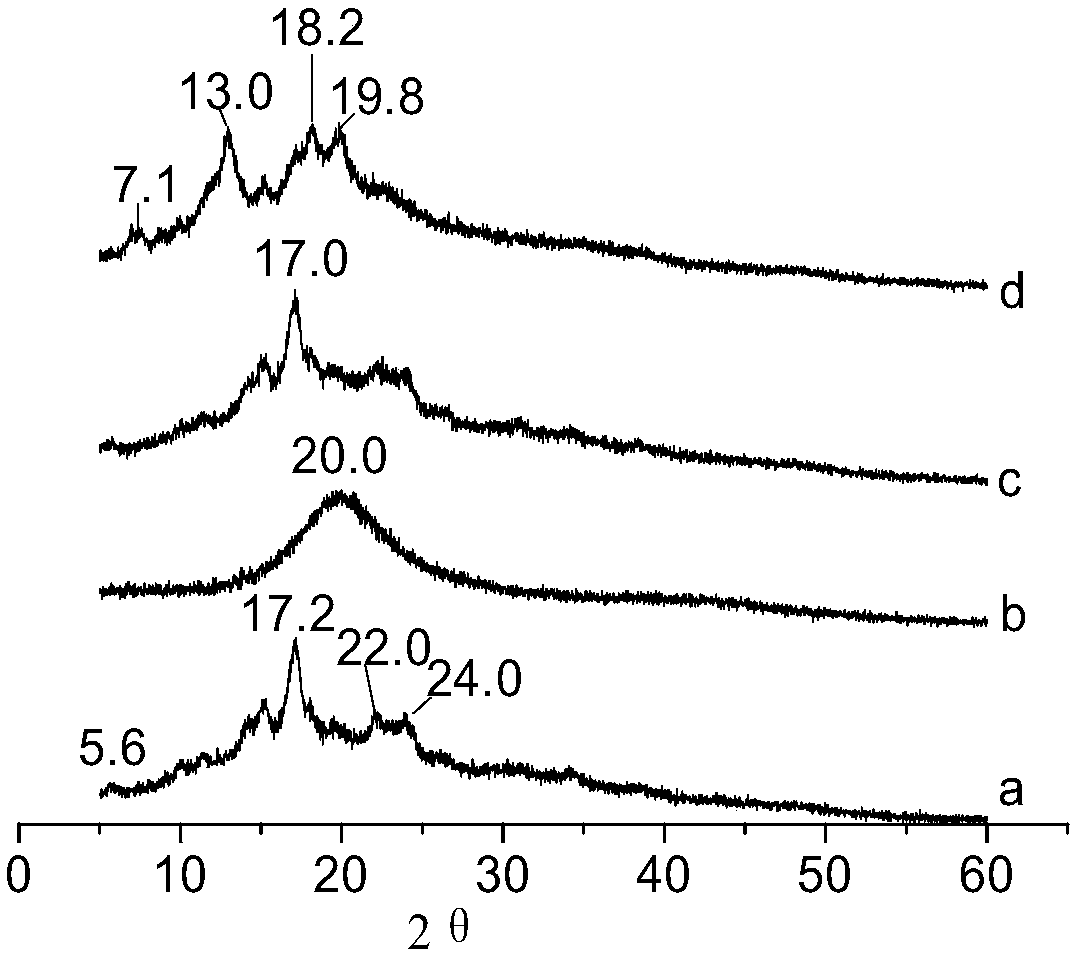

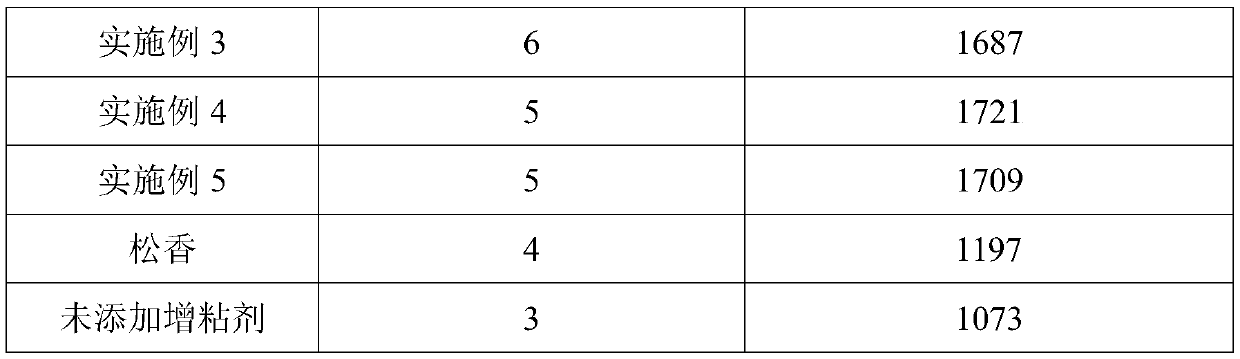

Epoxy-based alkene and alkene ether modified rosin phenol resin

InactiveCN109943234AHigh reactivityGood viscosity increasing effectMacromolecular adhesive additivesNatural resin chemical modificationEpoxySolvent

The invention discloses epoxy-based alkene and alkene ether modified rosin phenol resin and a preparation method thereof. The preparation method comprises the following steps: reacting a phenol-sourced reagent and rosin under the acid catalyzing condition to prepare rosin phenol resin acid; adding 100 weight parts of the rosin phenol resin acid prepared in S1 into a solvent B, and heating to 50-150 DEG C; melting the rosin phenol resin, adding 0.2-6 weight parts of an organic alkali ammonium catalyst; dropwise adding epoxy-based alkene and alkene ether raw materials for 0.5-1 hour, regulatingthe temperature to 50-180 DEG C, and stopping reacting when the acid value of the product is not more than 6mg KOH / g; supplementing a solvent B after the reaction is stopped, and adding acid to neutralize the organic alkali ammonium catalyst; rinsing to obtain substrate, and distilling the substrate at reduced pressure at 50-180 DEG C to obtain epoxy-based alkene and alkene ether modified rosin phenol resin. The epoxy-based alkene and alkene ether modified rosin phenol resin have the characteristics of high reaction activity and good tackifying effect.

Owner:广西藤县通轩立信化学有限公司

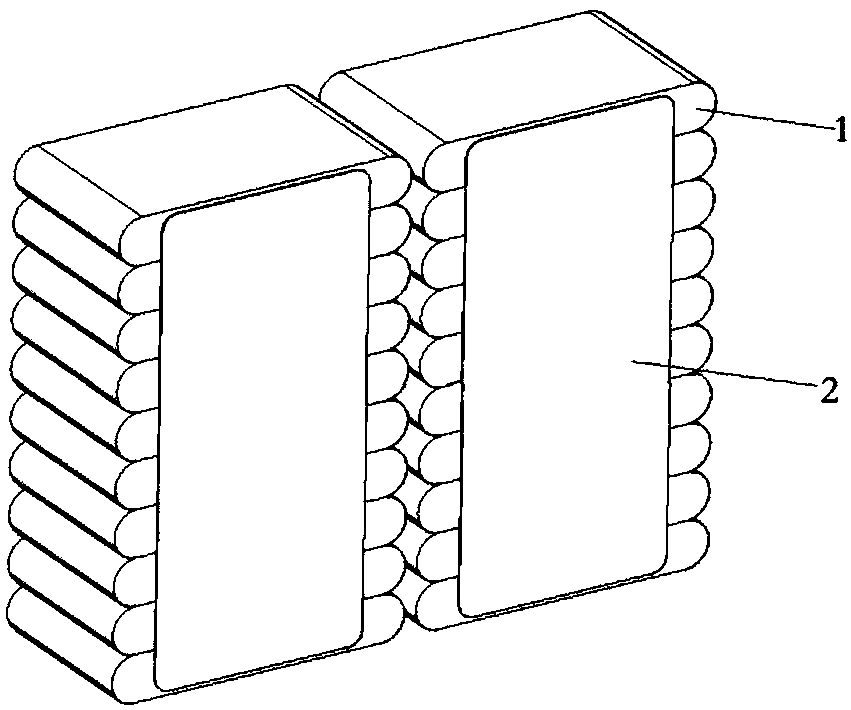

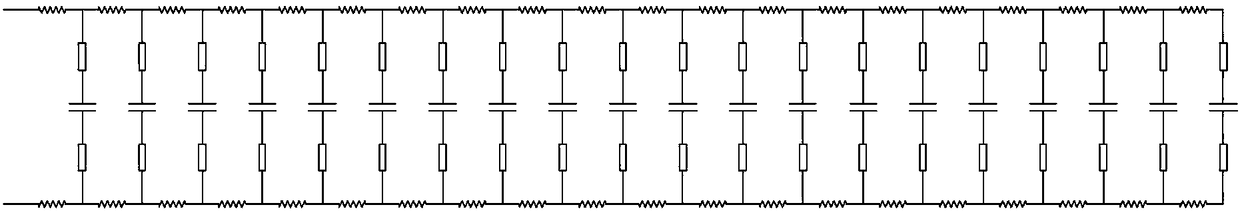

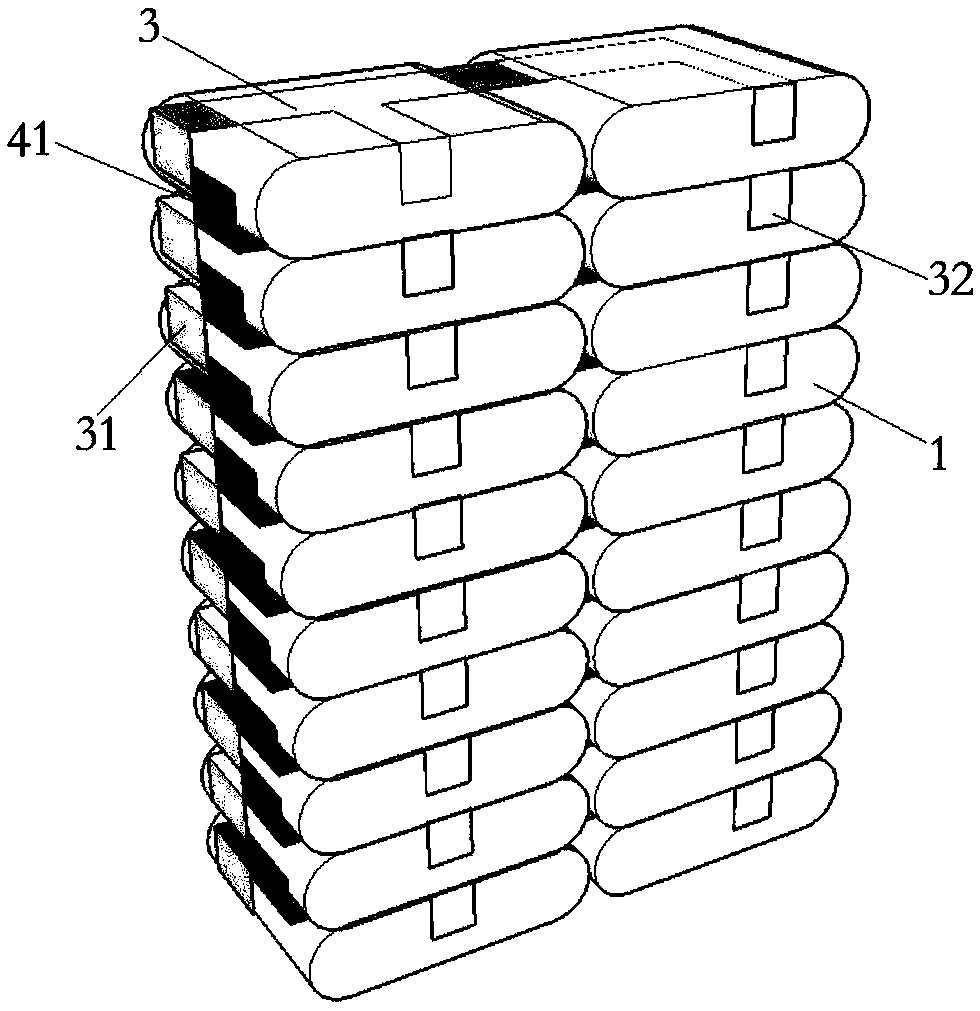

A capacitive connection structure to reduce inductance

ActiveCN107039176BIncrease capacityLower self-esteemMultiple fixed capacitorsFixed capacitor detailsCapacitanceBusbar

The invention discloses a capacitance connecting structure for reducing inductance. The capacitance connecting structure comprises capacitance cores arranged in a layered stacking manner, and busbars used for connecting the capacitance cores, wherein the busbars comprise lead-out parts and connecting parts; the lead-out parts are used for connecting positive and negative lead-out conductors; the connecting parts are used for connecting the capacitance cores; an upper busbar is arranged at the top of each capacitance core; a lower busbar which has vertical flip with each upper busbar is arranged at the bottom of each capacitance core; and connecting parts of the upper busbars and the lower busbars are respectively connected with metal spraying surfaces on the two sides of the capacitance cores. The capacitance connecting structure is an internal structure of a power capacitor; a high-capacity power capacitor can be obtained by adjusting the quantity and an arrangement manner of the capacitance cores as required; self-inductance of the power capacitor can be reduced by a connecting manner of the busbars; circuit equilibrium of the capacitor at high frequency can be ensured; passing current of each capacitance core is stable; and an application characteristic of the capacitor at the high frequency can be greatly improved.

Owner:NINGBO JIANGBEI GOFRONT HERONG ELECTRIC

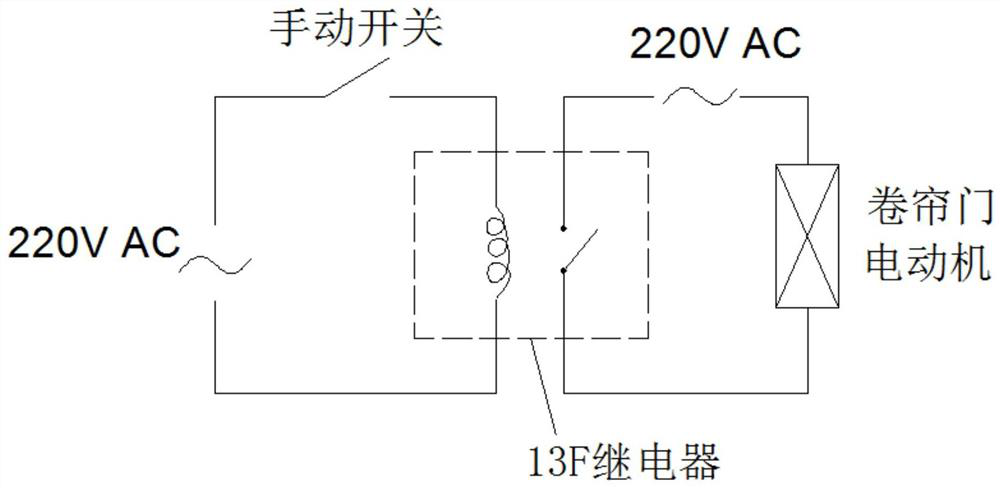

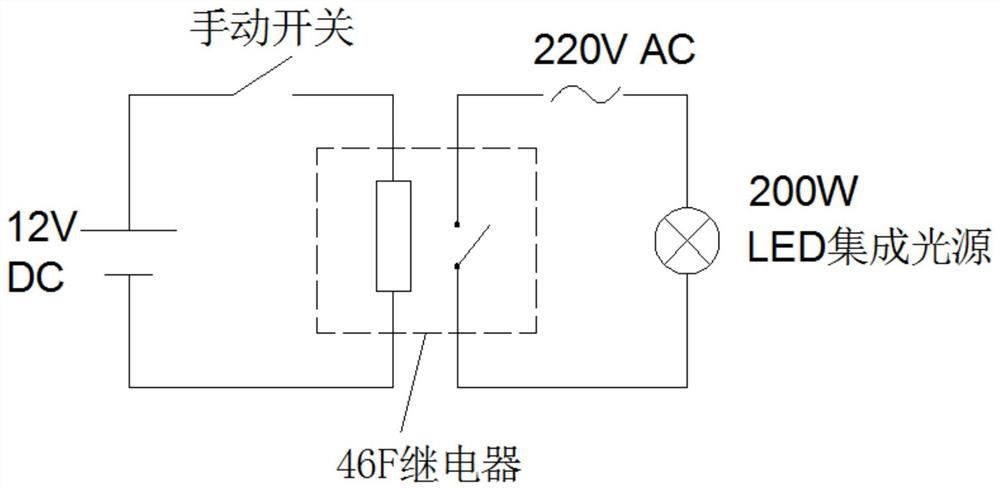

Relay contact combinations for inductive and capacitive loads

ActiveCN111415843BImprove application featuresSolve bonding problemsElectromagnetic relay detailsContactsControl theoryElectrical contacts

Relay contact combinations suitable for inductive and capacitive loads, involving electrical contact materials. Provides a relay contact combination that can solve the problem of contact bonding and failure during the relay action process, and can be combined according to the size of the electronic work function and the complementary performance advantages to adapt to inductive and capacitive loads. The relay contact combination adapted to inductive and capacitive loads is a combination of dynamic and static contacts using different composite materials, and the composite materials include AgSnO 2 , AgCdO, AgZn, AgNi, etc. The combination can choose the electrical contact combination with different electronic energy according to the requirements of the electronic work function, and the static and dynamic contacts of the relay. It effectively improves the application characteristics of the original relay, produces complementary effects and new contact electric effects; and effectively solves the bonding problem of the relay, greatly prolonging the service life of the relay under inductive and capacitive load conditions. Adapt to various relays, according to the use requirements of various relays, select different material contacts for combination.

Owner:厦门奕力飒科技有限公司

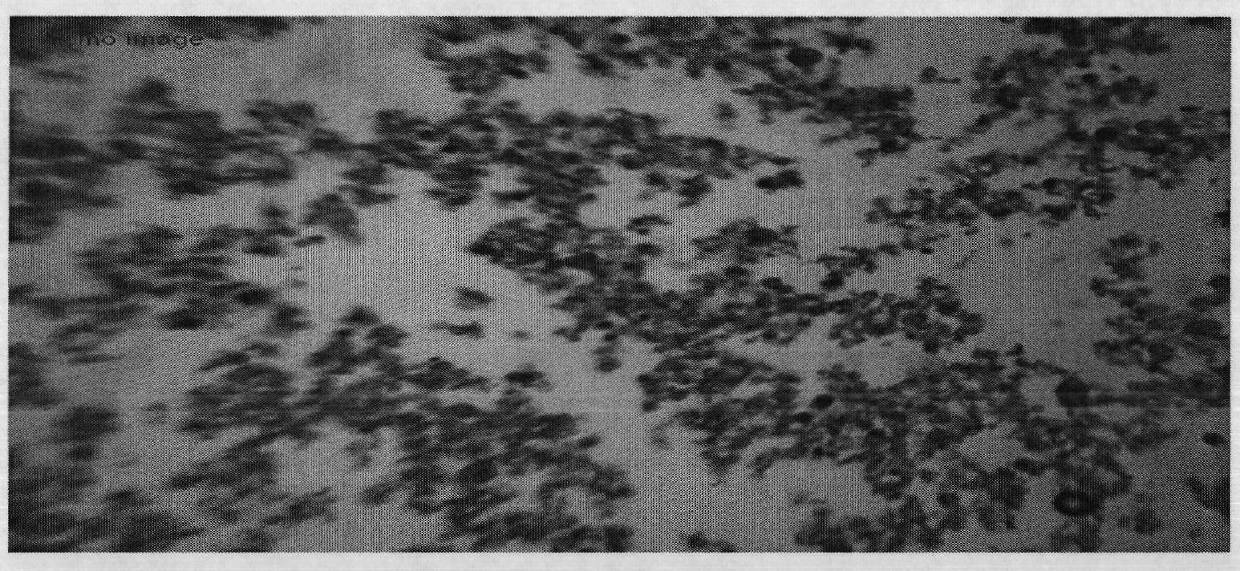

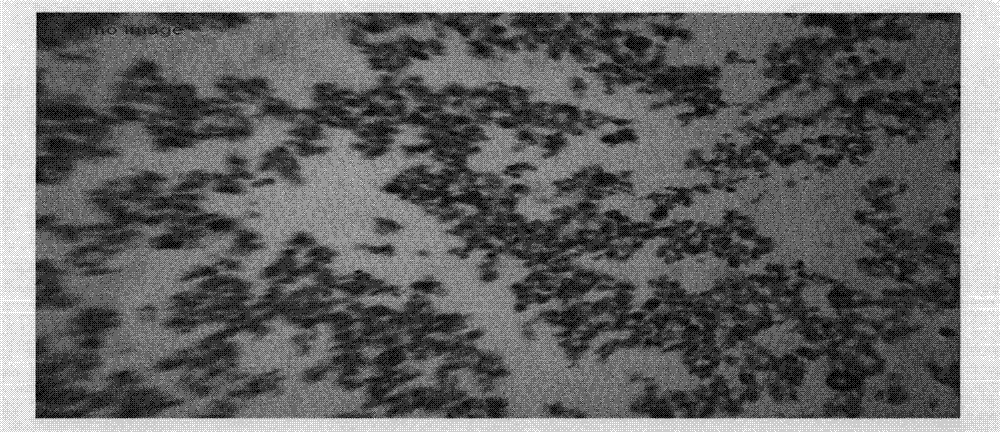

Method for making nano-grade size chitin

The method for making nano size chitin is characterized by that it utilizes ultrasonic technique, inversed phase microemulsion technique and sol-gel technique, etc. to synthesize chitin with nano structure. The detection by using transmission electron microscope with a magnification of 10 ten thousand times shows that said product is of network formed from sphere-like particles connected together, the size of said particle and network vein is mainly in 19-50 nm, and the size of more than 97% of particles and network vein is in 100 nm. Said product possesses good biological compatibility, network structure, microbiostatic power and stability.

Owner:广汉恒宇新材料有限公司

Method for preparing spherical CaAl2O4:Eu,Nd luminescent powder

InactiveCN107603607AGood dispersionImprove application featuresLuminescent compositionsSpherical morphologyAmmonium carbonate

The invention provides a method for preparing spherical CaAl2O4:Eu,Nd luminescent powder. The method comprises the steps of: preparing an aluminum salt solution which contains Al<3+>, preparing a mixed salt solution which contains Ca<2+>, Eu<3+> and Nd<3+>, mixing an ammonium carbonate salt solution with the aluminum salt solution and the mixed salt solution in a state of stirring to form a reaction system, and performing a reaction at 15-65 DEG C for 10-20 hours to obtain a precipitate; washing the precipitate, drying the washed precipitate, calcining the dried precipitate in a carbon reduction atmosphere at 1250-1450 DEG C for 2-6 hours, and cooling calcined products to obtain the spherical CaAl2O4:Eu,Nd long-lasting luminescent powder. The long-lasting luminescent powder prepared by themethod has purity of 99.99% or above, spherical morphology and good dispersibility, the problems that an existing long-lasting luminescent material has poor fluidity and uneven dispersion in a mediumare solved, and the application characteristics of the long-lasting luminescent material can be greatly improved.

Owner:中铝山东有限公司

Linear low-density polyethylene and preparation method thereof

InactiveCN109354760ALess raw material consumptionReduce manufacturing costParaffin waxHigh-density polyethylene

The invention relates to linear low-density polyethylene and a preparation method thereof. The linear low-density polyethylene is composed of, by weight, 50-60 parts of linear low-density polyethylene, 30-40 parts of chlorinated paraffin, 20-26 parts of solid paraffin, 7-11 parts of catalyst, 4-7 parts of dispersant, 1-2 parts of initiator, 2-4 parts of antioxidant, 50-60 parts of deionized waterand 1-3 parts of anti-adhesion agent. The preparation method is low in raw material consumption and production cost, and prepared linear polyethylene copolymer is uniform in composition distribution,high in tensile performance and better in application characteristic.

Owner:南京安伦化工科技有限公司

Preparation method of polyanionic cellulose

The invention discloses a preparation method of polyanionic cellulose. The preparation method comprises the following steps of (1) alkalinizing cellulose by using a mixed solution A of a NaOH water solution and an ethanol water solution to obtain alkali cellulose; (2) mixing the alkali cellulose obtained in the step (1) and an etherifying agent and stirring to obtain a mixed material B; (3) mixing the mixed material B and solid NaOH and stirring to obtain a mixed material C; and (4) mixing the mixed material C and an etherifying agent, stirring to obtain a mixed material D, carrying out etherification reaction, then, purifying and aftertreating to obtain the polyanionic cellulose. The etherifying agents in the steps (2) and (4) are respectively an ethanol water solution of chloroacetic acid. The preparation method disclosed by the invention is simple in process, low in cost and suitable for industrial production; the polyanionic cellulose obtained by using the preparation method is high in substitution degree as well as good in salt tolerance and leaching resistance, and all indexes of the polyanionic cellulose can meet the requirement of the eighteenth edition of the drilling fluid material standard ANSI / API Spec13A.

Owner:上海长光企业发展有限公司

Peach gum polysaccharide, its extract, preparation method and application thereof

ActiveCN102372789BMeet the use requirementsAvoid decompositionCosmetic preparationsToilet preparationsNatural stateSpecific rotation

Owner:SHANGHAI HUIWEN BIO TECH

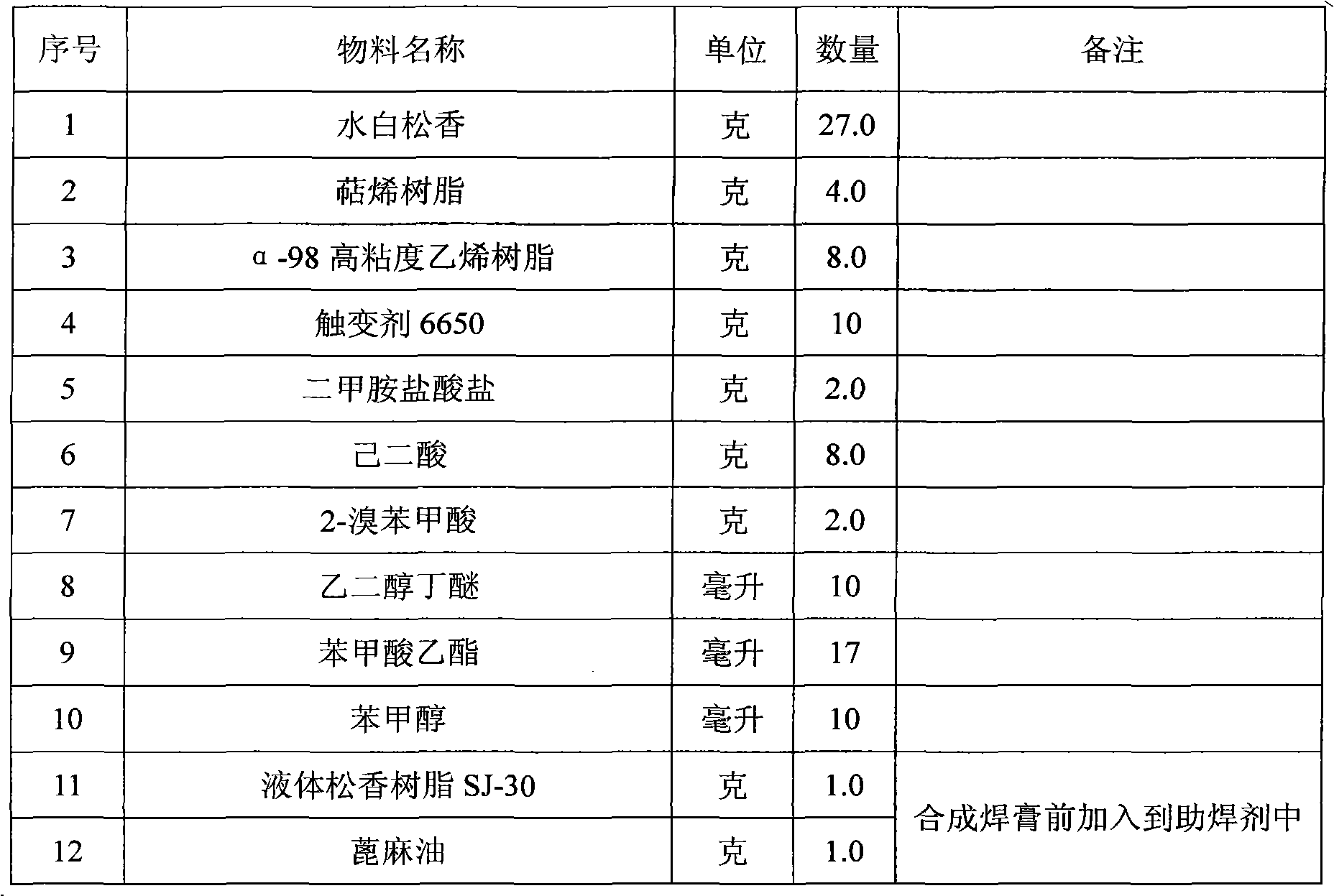

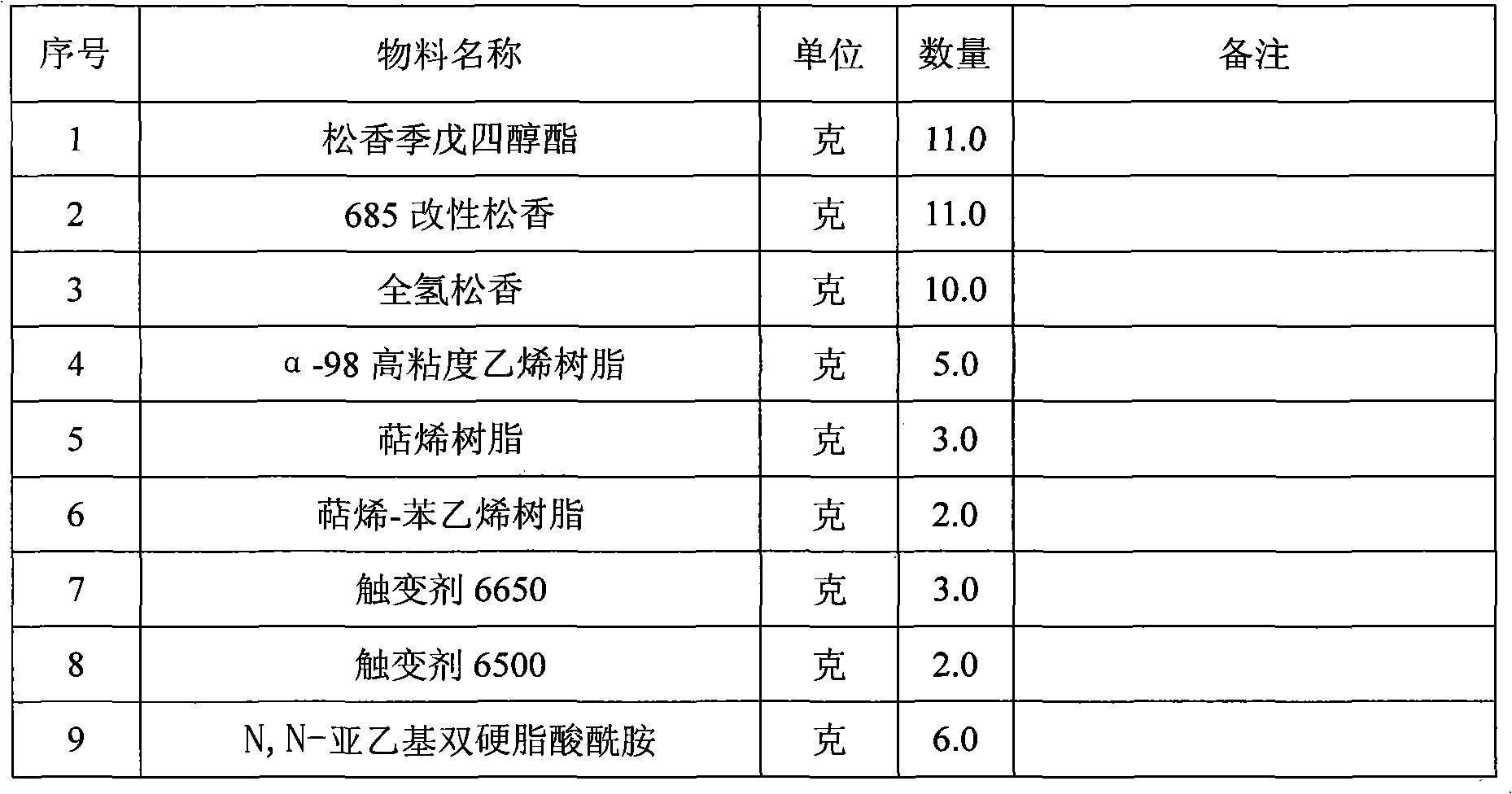

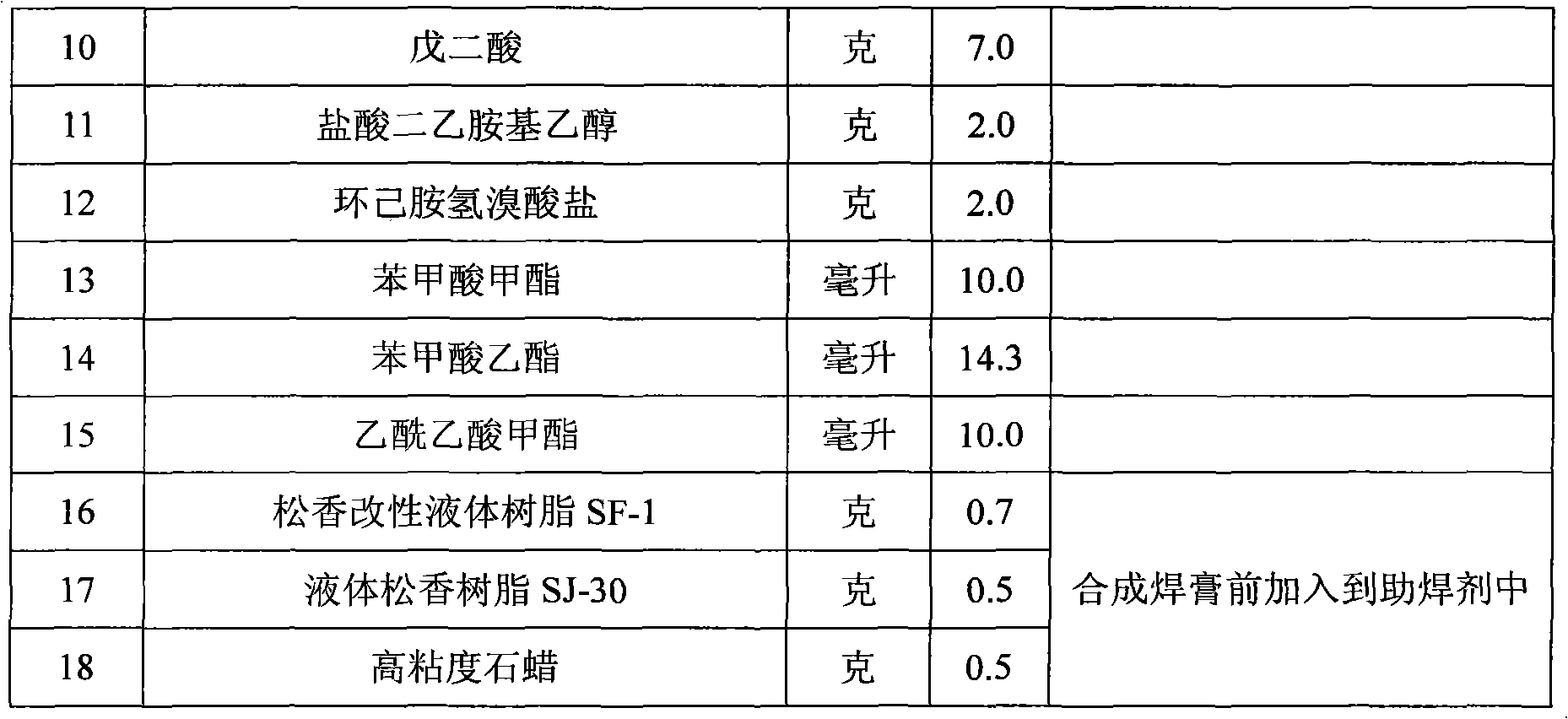

Wash-free soldering flux for leadless low-temperature soldering paste and preparation method thereof

ActiveCN101966632BImprove liquidityImprove thixotropyWelding/cutting media/materialsSoldering mediaOrganic solventAlloy

The invention discloses a wash-free soldering flux for leadless low-temperature soldering paste, which comprises the following components in percentage by weight: 27 to 37 percent of modified abietic resin, 10 to 12 percent of thixotropic agent, 8 to 12 percent of tackifier, 10 to 12 percent of organic activator, 0.5 to 2.0 percent of lube and the balance of organic solvent. The invention also discloses a preparation method of the wash-free soldering flux for the leadless low-temperature soldering paste. The soldering flux in the invention can keep high application characteristics for a long time under the working conditions of an environmental temperature of less than or equal to 30 DEG C and humidity of more than or equal to 80 percent and is particularly suitable for preparing the low-temperature soldering paste from high Bi content-containing alloy systems such as Sn-58Bi, Sn-57Bi-1.0Ag, Sn-35Bi-1.0Ag.

Owner:GUANGZHOU SOLDERWELL ADVANCED MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com