Peach gum polysaccharide, its extractive, preparation method and application thereof

A technology of peach gum polysaccharide and extract, applied in application, food preparation, food science and other directions, can solve the problems of peach gum polysaccharide decomposition, narrow application field, difficult industrialized production, etc., and achieve good stability, high molecular weight, high The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0054] The model of the dialysis bag in Example 4 is R-25--3.5K, purchased from Jinan Haobo Biotechnology Co., Ltd.

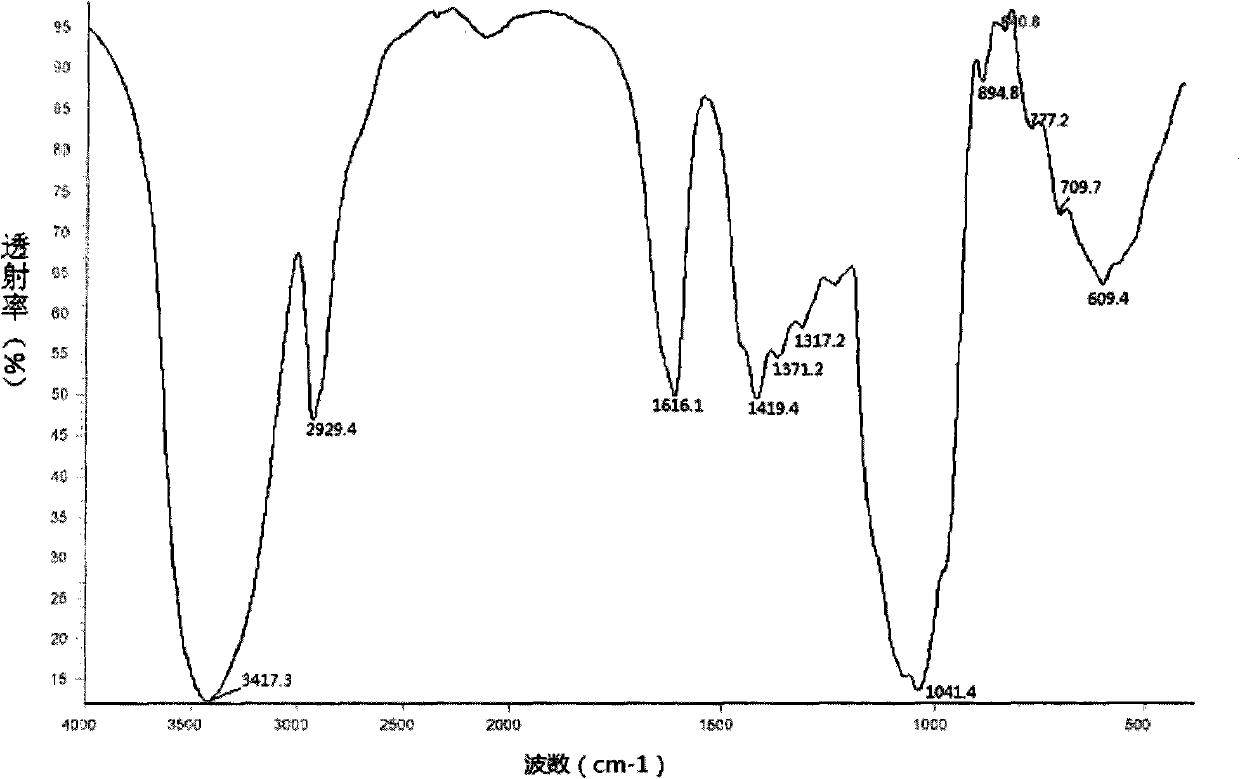

[0055] The test methods involved in the following examples are:

[0056] One, the determination method of peach gum polysaccharide content in the peach gum polysaccharide extract is:

[0057] Using xylose as a standard, the content of peach gum polysaccharides in peach gum polysaccharide extracts was determined by the phenol-sulfuric acid method (Zhang Weijie. Biochemical Research Technology of Glycosomes [M]. Zhejiang University Press. 2003).

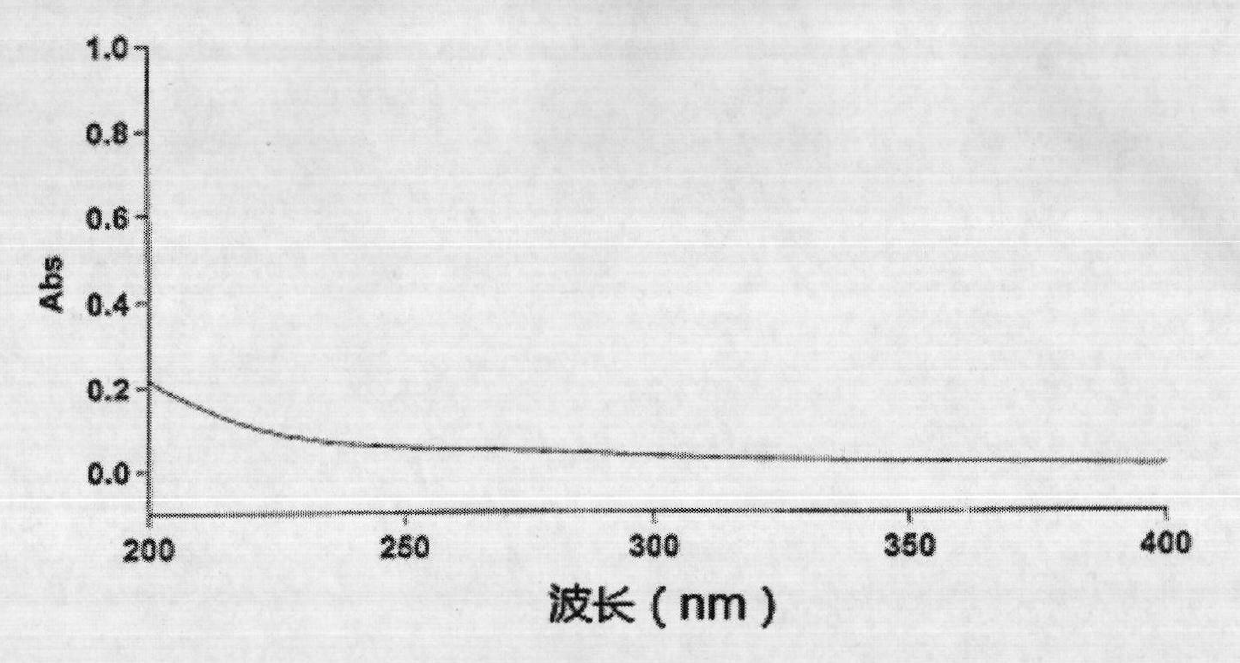

[0058] (1) draw xylose standard curve:

[0059] Using xylose as a standard, prepare standard solutions respectively. Take xylose standard solution, add 6% phenol solution, add concentrated sulfuric acid, let stand for 10 minutes, shake well, carry out color reaction until the solution is orange-red. Measure the absorbance value at a wavelength of 480nm, and use water after the same color development operation as a bl...

Embodiment 1

[0091] Example 1 peach gum polysaccharide extract

[0092] The preparation method of peach gum polysaccharide extract is:

[0093] (1) Pulverization: the natural raw peach gum is pulverized, and all pass through a 20-mesh standard sieve to obtain natural raw peach gum coarse powder, which is set aside. Said above-mentioned natural raw peach gum coarse powder 25g, pours in the 2000ml there-necked flask, adds pure water 125ml (5ml / g peach gum coarse powder) wherein, forms peach gum suspension;

[0094] (2) Biological enzymatic hydrolysis: heat the peach gum suspension to 40°C, add 0.63g of alkaline protease (0.005g / ml peach gum suspension) to it, keep warm and stir for 1h, carry out biological enzymatic hydrolysis, and obtain the material Liquid 1;

[0095] (3) Low-temperature hydrolysis: raise the temperature of feed liquid 1 to 40°C, add 12.5 g of solid sodium hydroxide (0.1 g / ml feed liquid 1) to it, keep warm and stir for 1 hour, and carry out low-temperature hydrolysis to...

Embodiment 2

[0103] Example 2 peach gum polysaccharide extract

[0104] The preparation method of peach gum polysaccharide extract is:

[0105] (1) Grinding: Cut and crush 30.0 g of wet peach gum picked from the tree trunk, add 700ml of pure water (23.3ml / g wet peach gum) to it, swell in pure water at 50°C for 24 hours, and grind to obtain peach The glue suspension is ready for use.

[0106] (2) Biological enzymatic hydrolysis: Pour the above-mentioned peach gum suspension into a 2000ml three-neck flask, heat to 50°C, add 22.5g of neutral protease (0.032g / ml peach gum suspension), keep warm and stir for 3h , carry out biological enzymolysis, obtain feed liquid 1;

[0107] (3) Low-temperature hydrolysis: raise the temperature of feed liquid 1 to 50° C., add 140 g of solid sodium hydroxide (0.2 g / ml feed liquid 1) to it, keep warm and stir for 3 hours, and carry out low-temperature hydrolysis to obtain feed liquid 2;

[0108] (4) Adjust the pH: add 1500ml of pure water (50ml / g wet peach g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com