Turbine wheel for a radial turbine

A turbine impeller, radial flow technology, applied in the field of turbine impeller, to achieve the effect of high torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

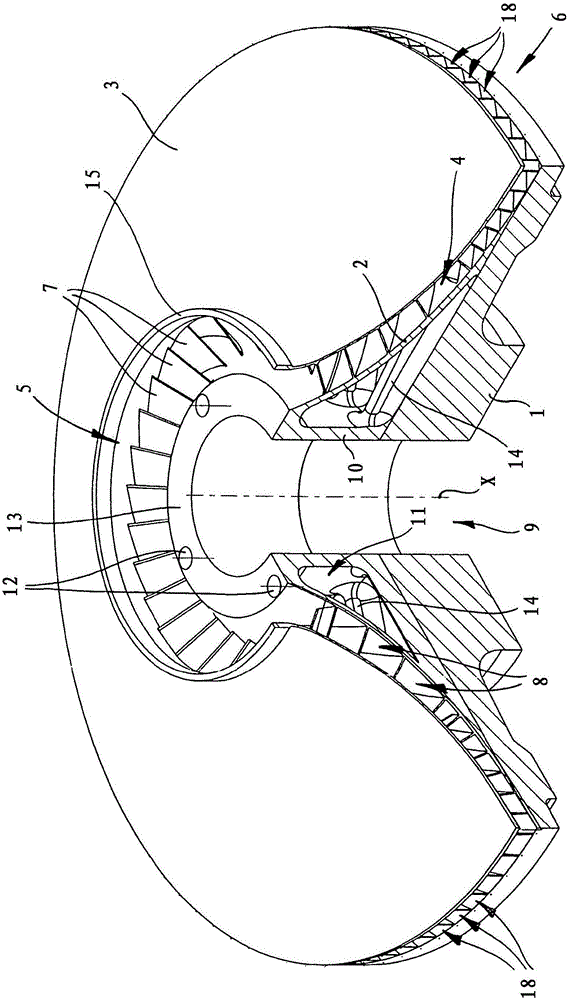

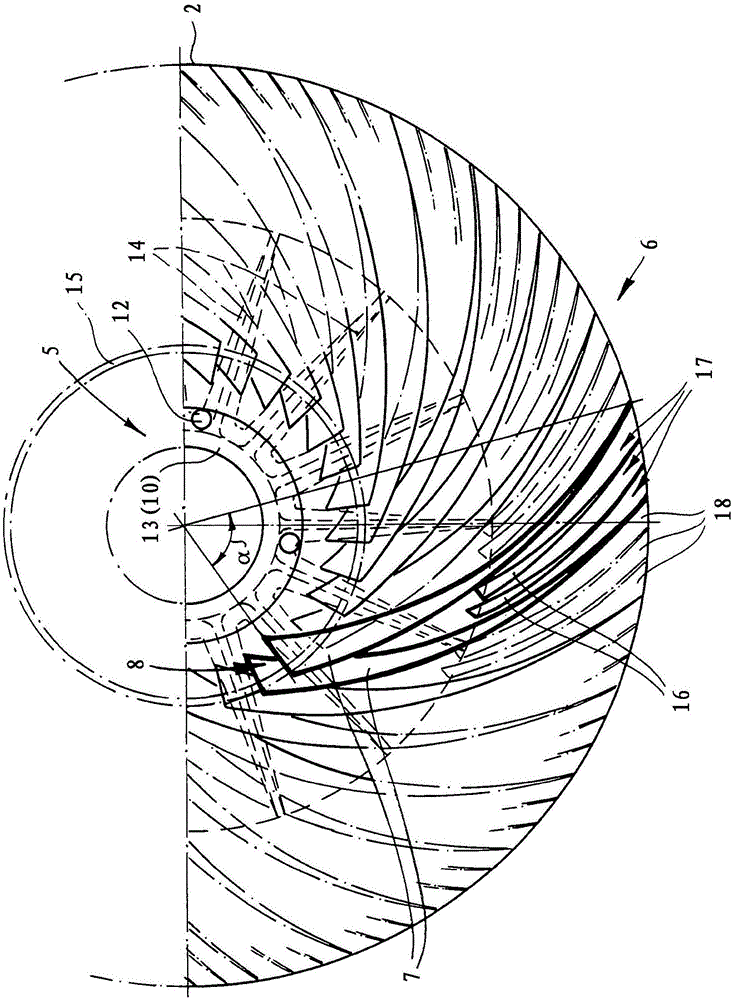

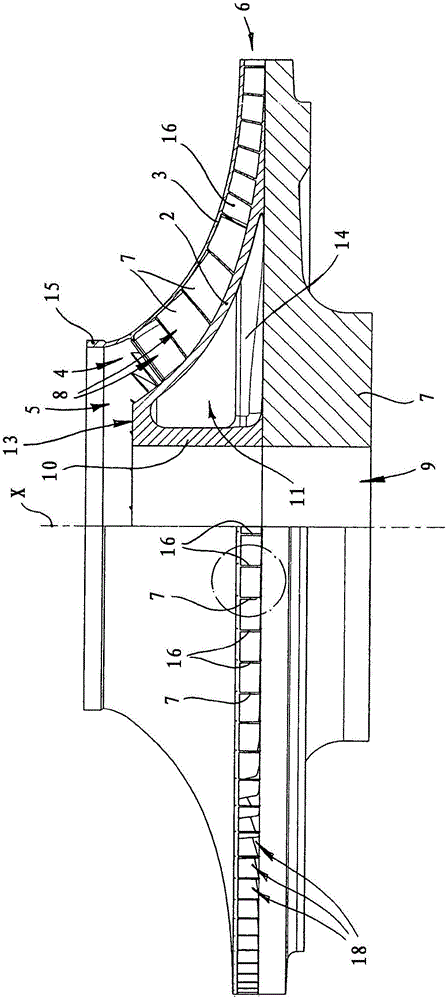

[0030] figure 1 A turbine wheel according to the invention is shown which comprises a base plate which is rotationally symmetrical about an axis of rotation x. For this purpose, a flow space 4 bounded by the hub disk 2 and the cover disk 3 is provided. The flow space connects the axial inner opening 5 with the radial circumferential outer opening 6 of the turbine wheel. It can be seen in a radial section that both the cover disk and the hub disk are formed with a substantially constant thickness in the direction from the inside to the outside. The hub disk 2 has a greater thickness than the cover disk 3 and merges into the base plate 1 in the radially outer region. The flow space 4 is divided into flow channels 8 by turbine blades 7 .

[0031] According to the invention, the hub disk 2 , the turbine blade 7 and the cover plate 3 are integrally formed on the base plate 1 by means of an additive manufacturing method.

[0032]The base plate 1 has a central hub guide passage 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com