Patents

Literature

30results about How to "Reliable export" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

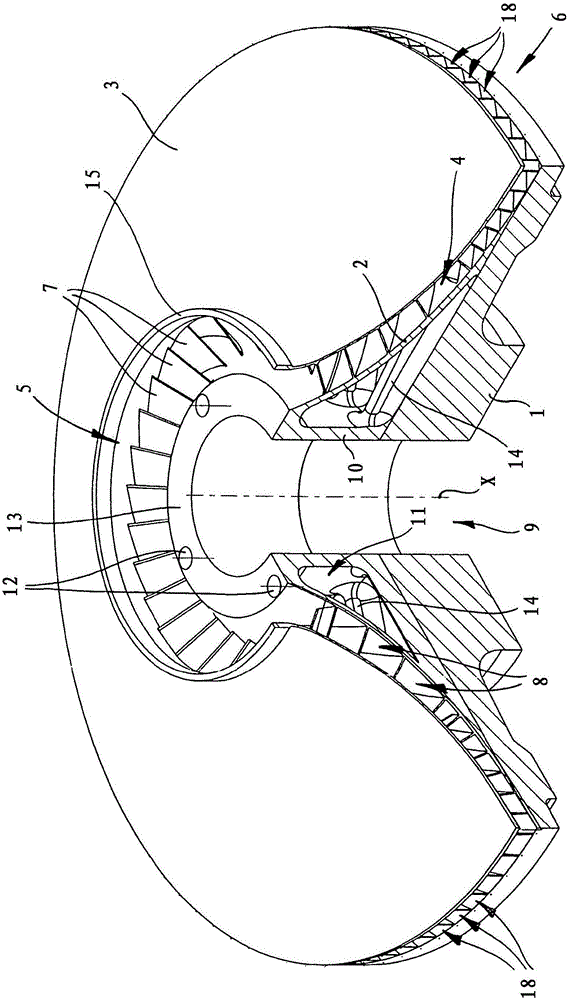

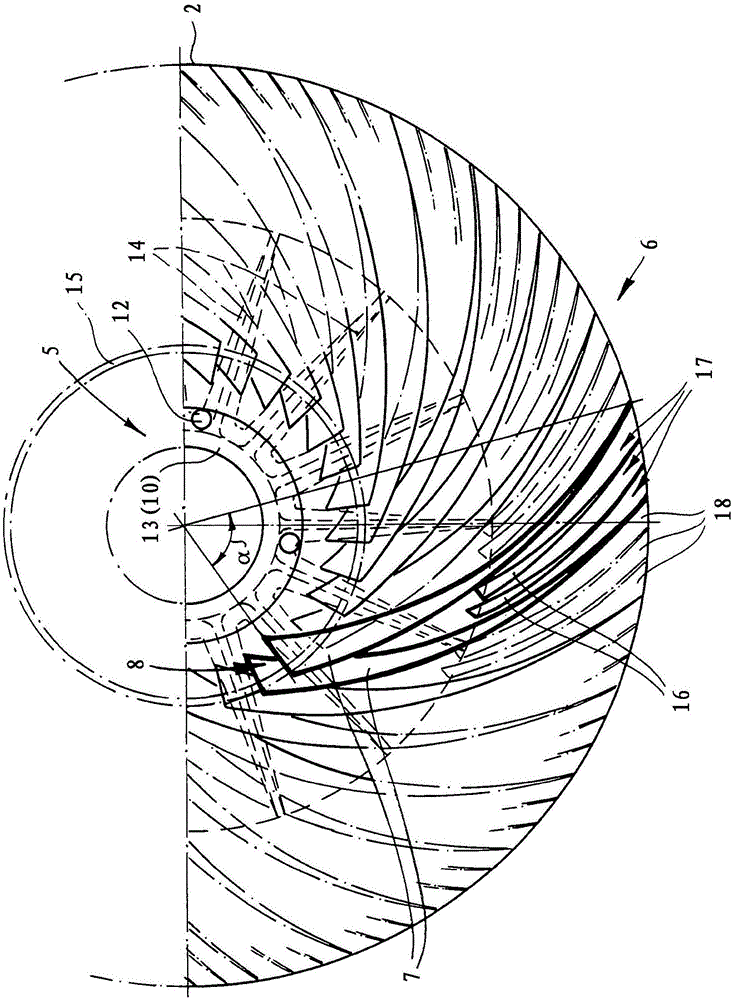

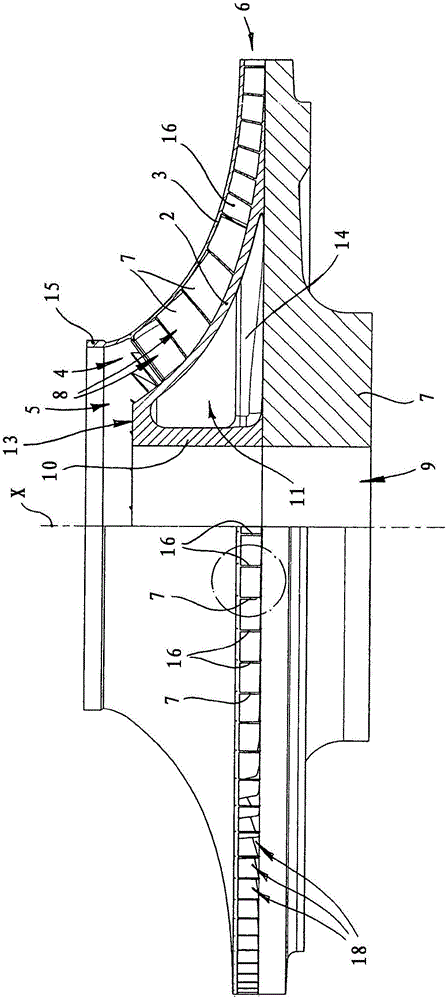

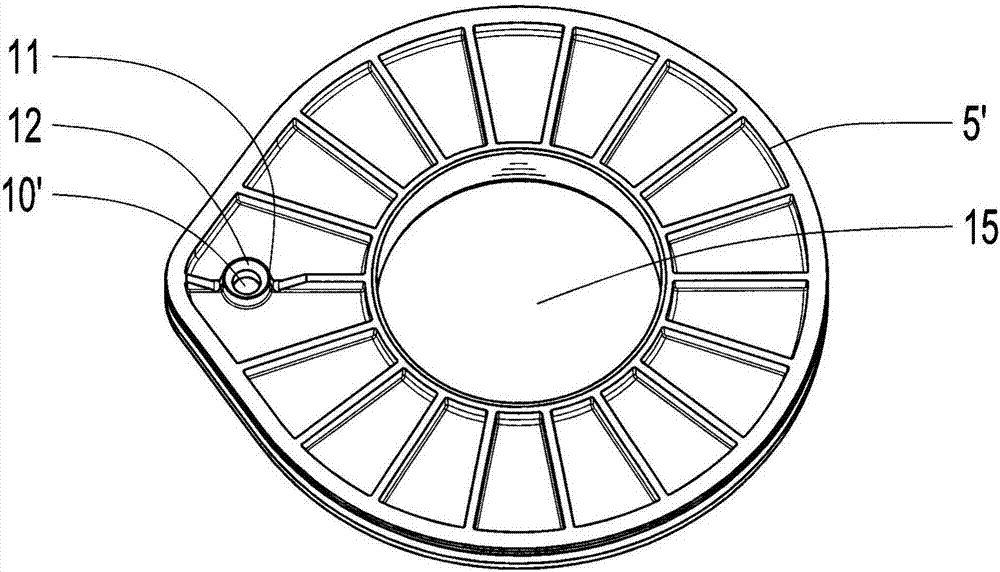

Turbine wheel for a radial turbine

InactiveCN106593945ASave materialReduce manufacturing costTurbinesAdditive manufacturing apparatusImpellerTurbine wheel

The invention relates to a turbine wheel for a radial turbine. A turbine wheel for a radial turbine includes a rotationally symmetrical base plate (1) and a flow chamber (4) delimited by a hub disk (2) and a cover disk (3), wherein the flow chamber connects an axial inner opening (5) to a radial outer opening (6) and is subdivided by turbine blades (7) into flow channels (8). In a method for producing such a turbine wheel, the hub disk (2), the turbine blades (7) and the cover disk (3) are integrally formed on the base plate (1) using additive production methods.

Owner:ATLAS COPCO ENERGAS

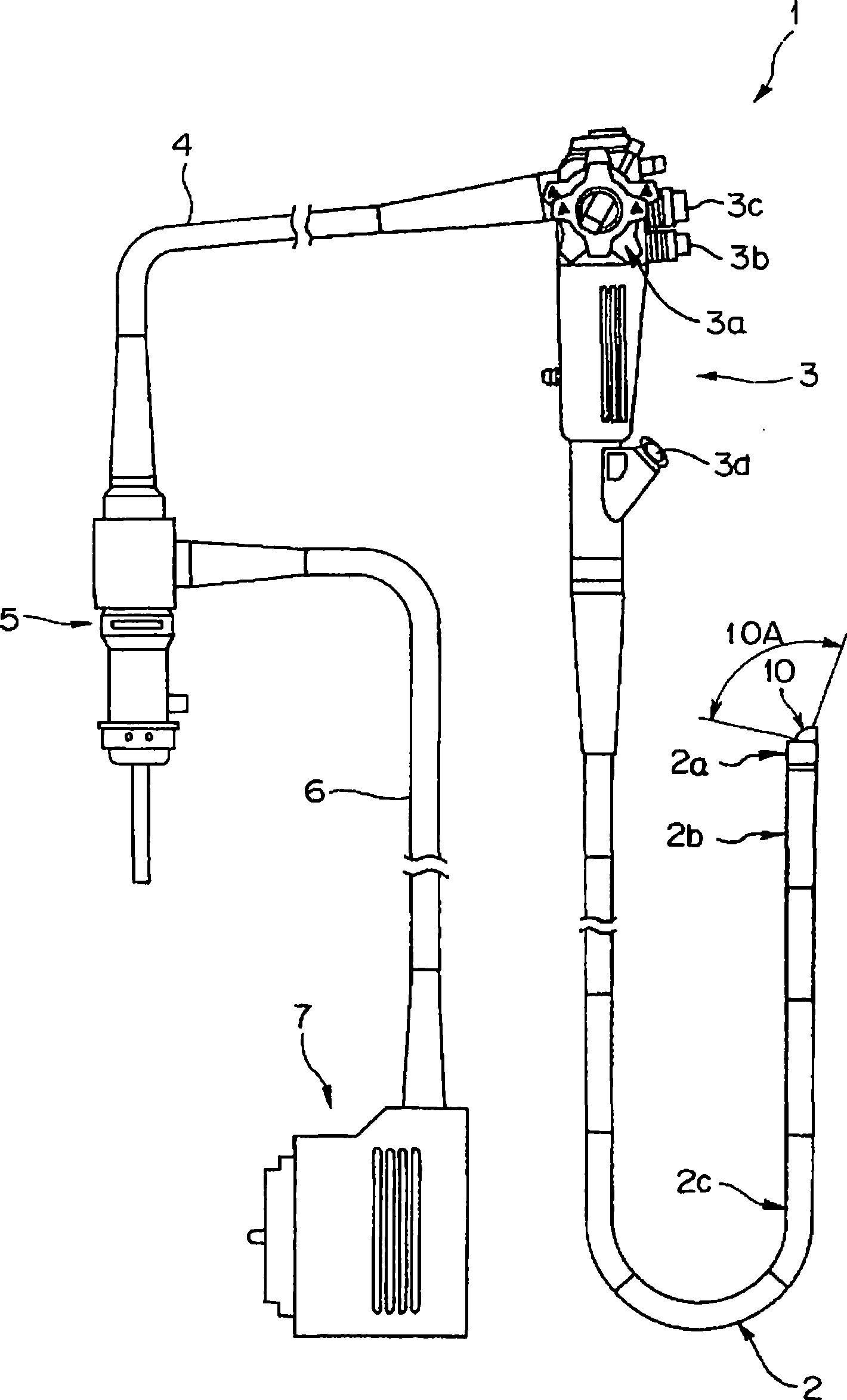

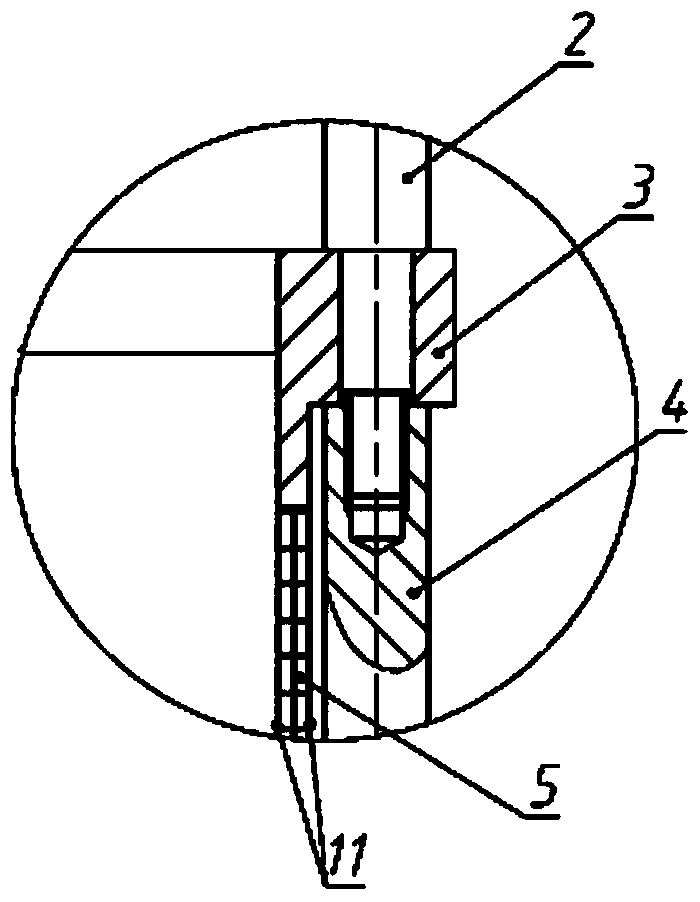

Ultrasonic endoscope

An ultrasound endoscope including, at a distal end of an insertion portion to be inserted to a body cavity, a distal rigid portion arranged forward of a flexible tube portion, an ultrasound transducer portion for scanning a plane which is parallel to forward side of a longitudinal center axis L1 of the distal rigid portion, and a treatment instrument insertion channel port opening in a distal-side end face of the distal rigid portion, with a longitudinal center axis L4 being parallel to the longitudinal center axis L1 of the distal rigid portion.

Owner:OLYMPUS CORP

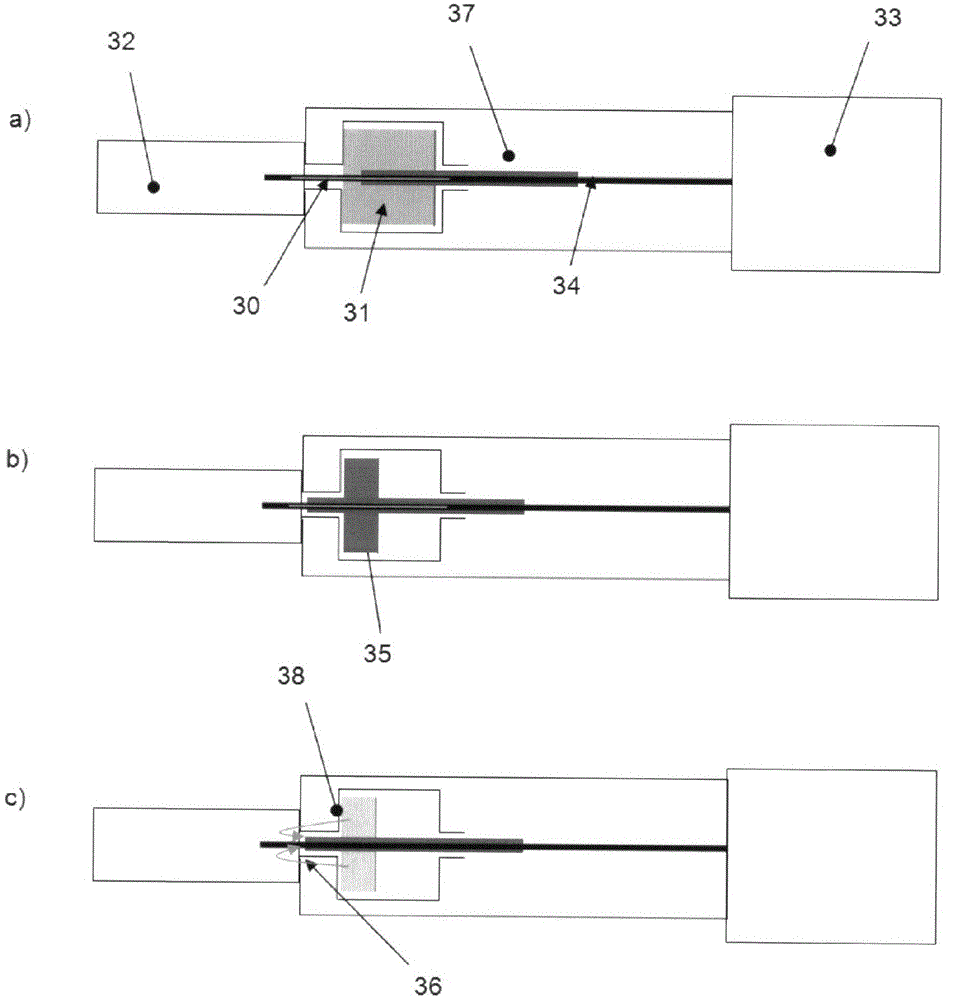

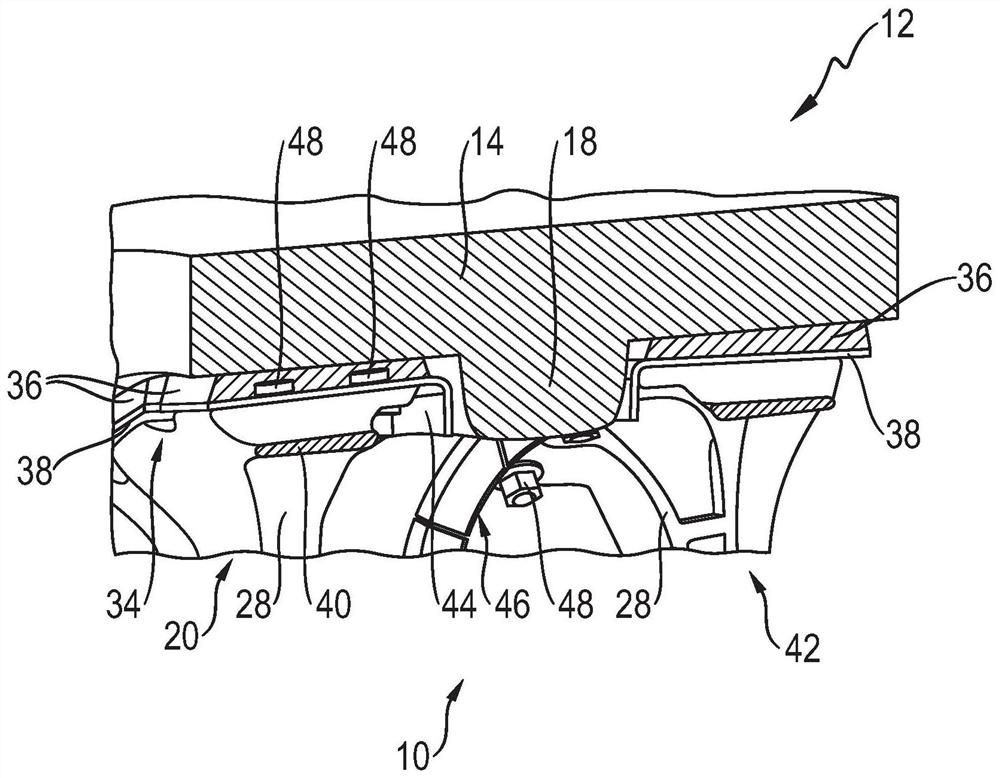

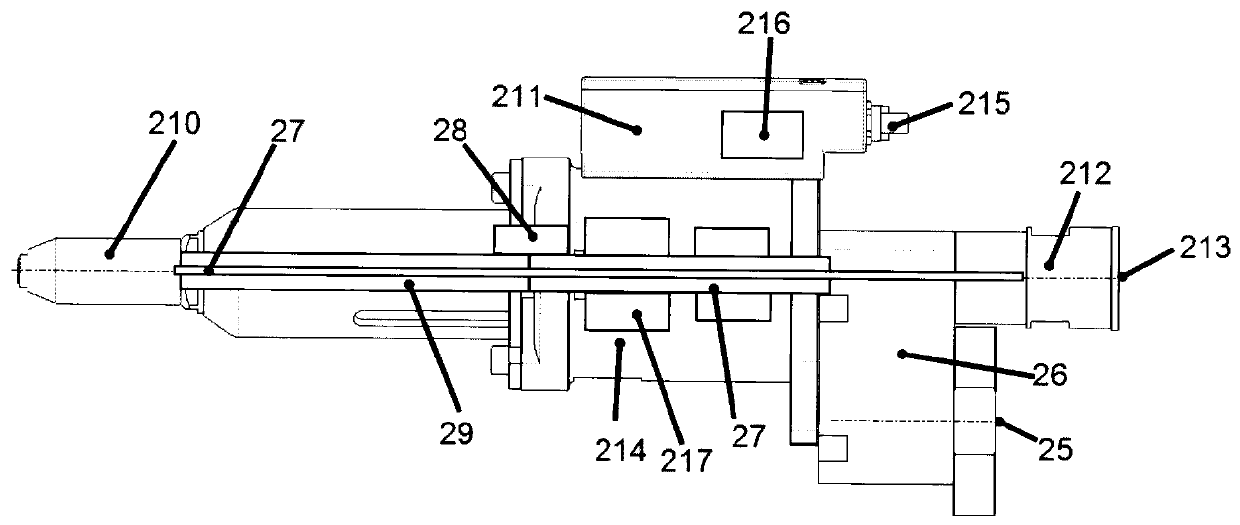

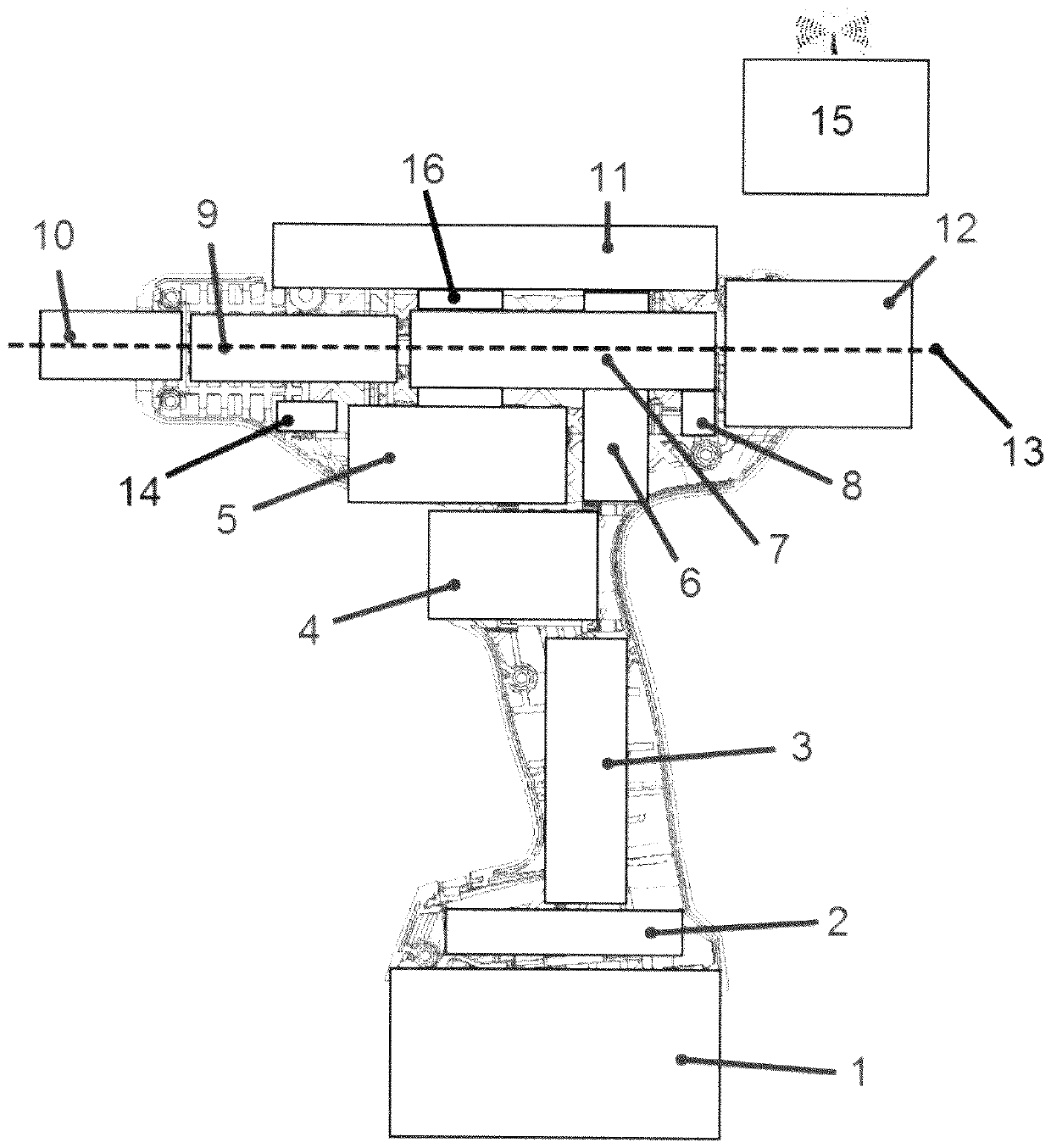

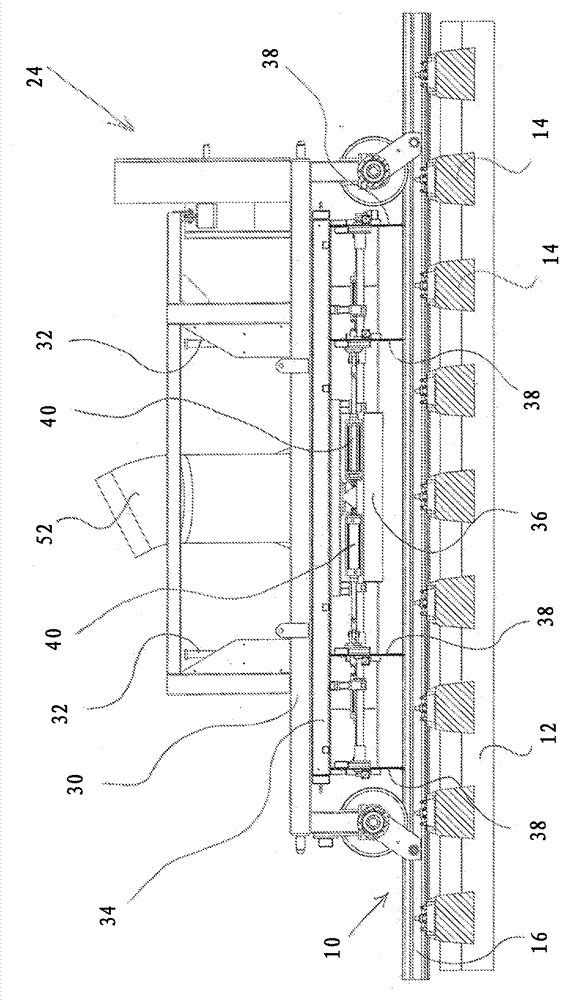

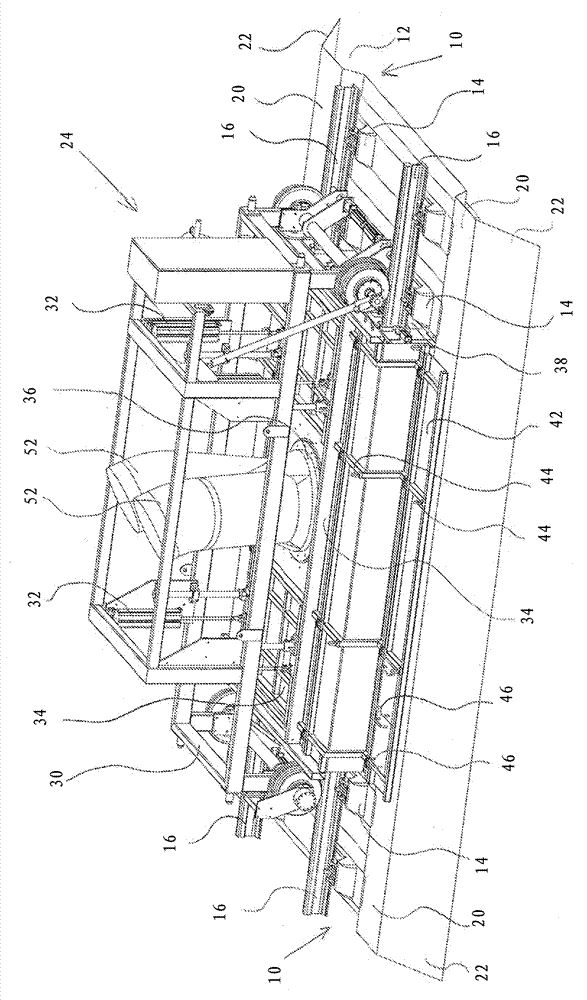

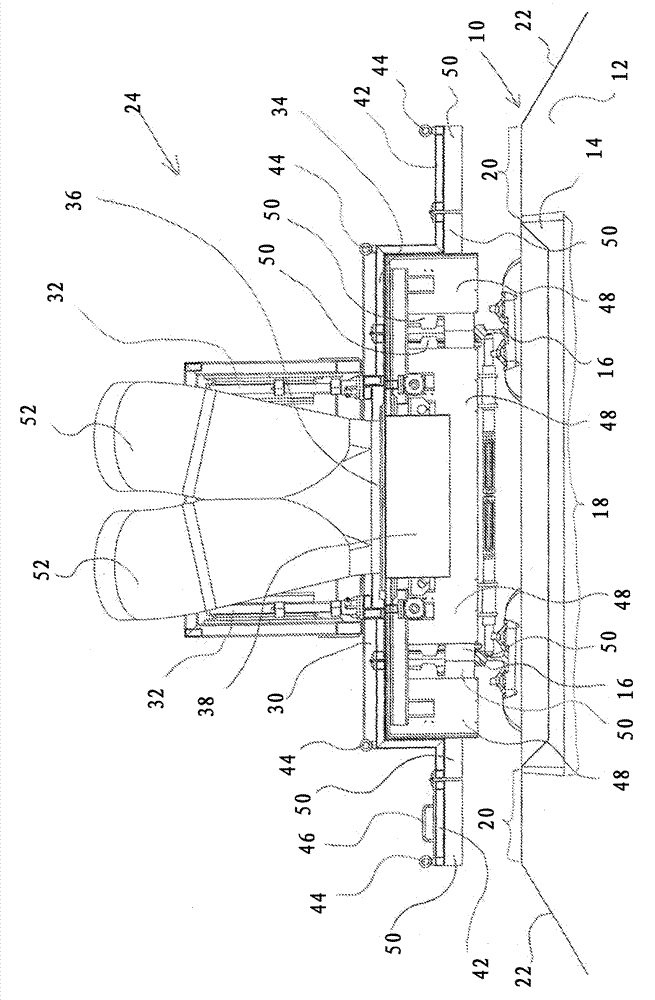

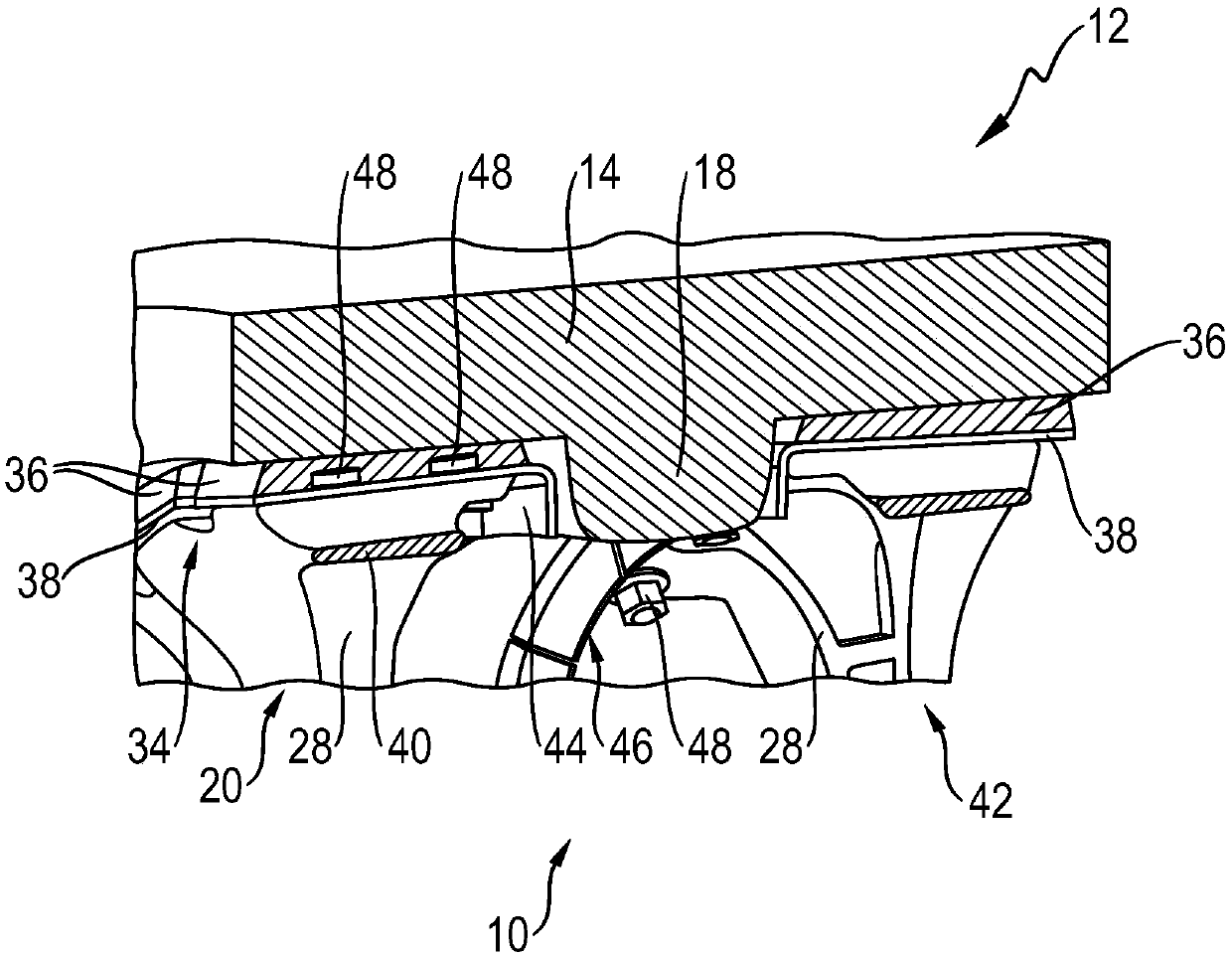

Conditioning device and method for drying and controlling the temperature of a ballast bed

Conditioning device (24) and method for drying and / or controlling the temperature of a ballast bed (12) of a railway track system (10), wherein the railway track system (10) has sleepers (14) resting on the ballast bed (12) and rails (16) resting on the sleepers, wherein the conditioning device has a bogie (30) for moving the conditioning device (24). An outlet nozzle (36) for blowing temperature-controlled air into the ballast bed (12) via at least one blowing-in region (26) positioned between two adjacent sleepers (14) is connected to the bogie (30), as is at least one cover plate (42) for essentially air-tight coverage of an upper side, pointing essentially in the direction counter to the direction of gravity, of a side strip (20), provided next to the sleepers (14) in the direction of travel, of the ballast bed (12). In a method for drying and controlling the temperature of a ballast bed (12) of a railway track system (10), an upper side of the ballast bed (12) and / or at least one sleeper (14) and at least one rail (16) are sealed in an essentially air-tight fashion outside a blowing-in region (26) before temperature-controlled air is blown into the ballast bed (12) via the blowing-in region (26).

Owner:COVESTRO DEUTSCHLAND AG

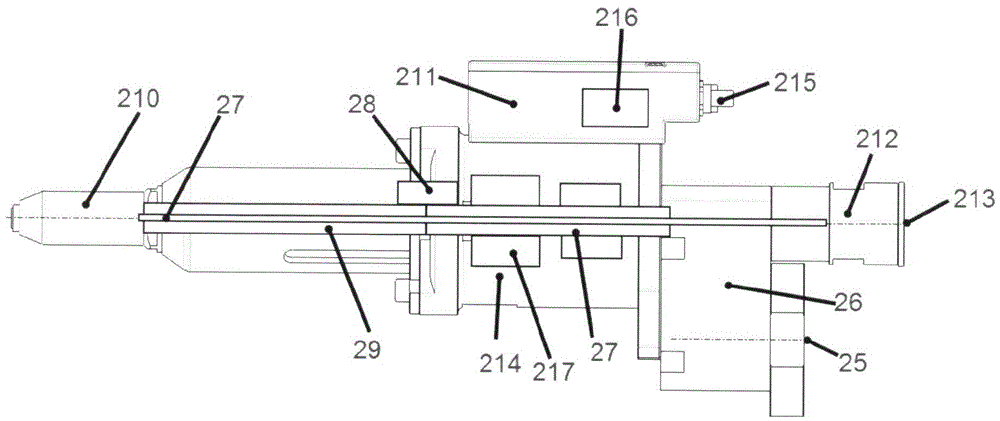

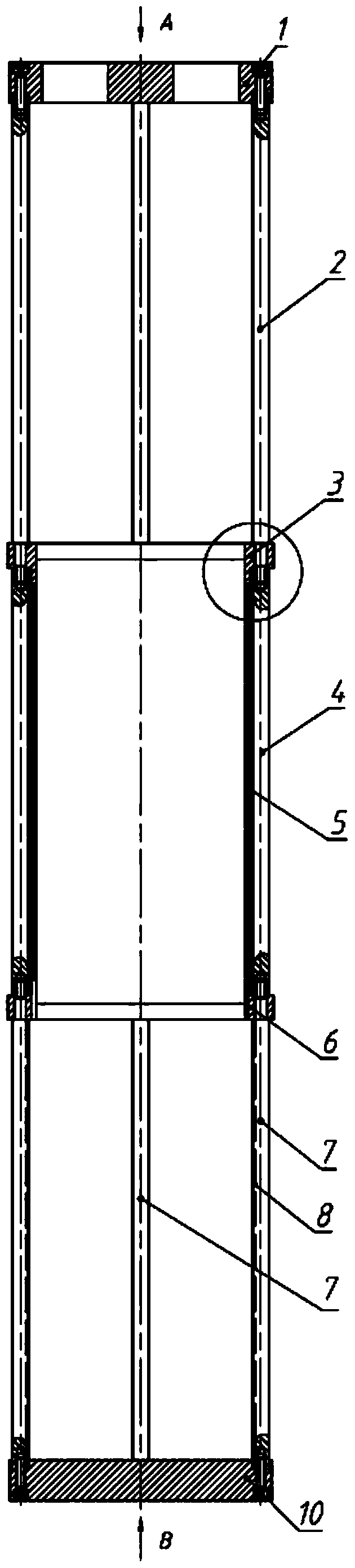

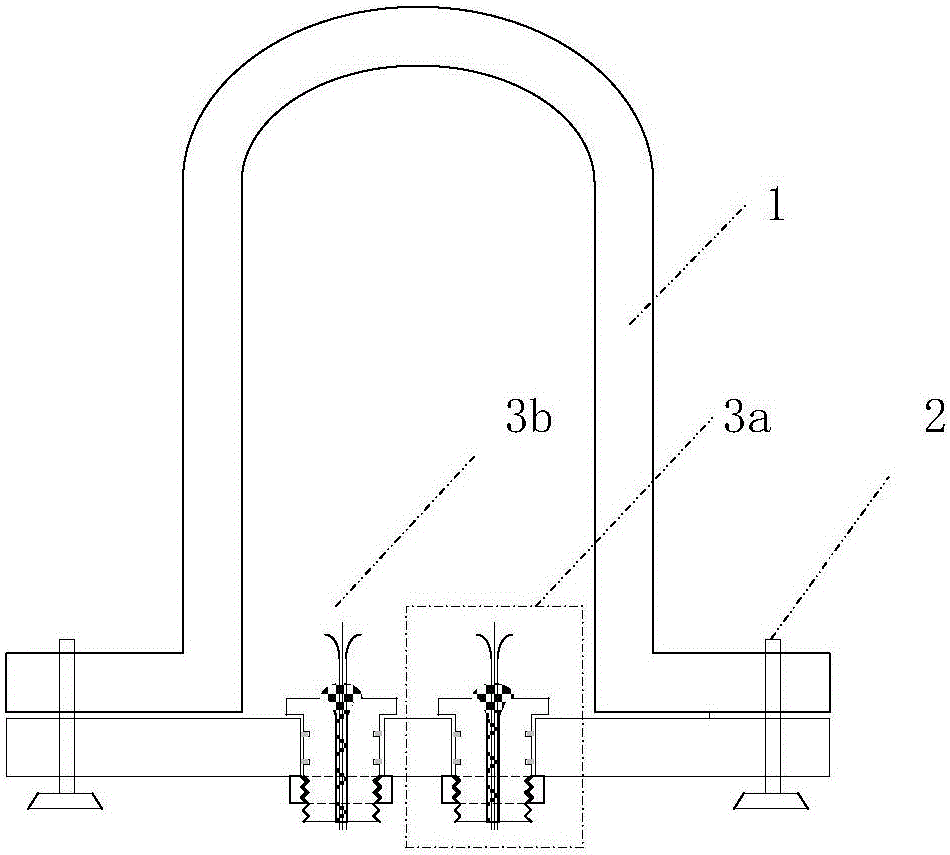

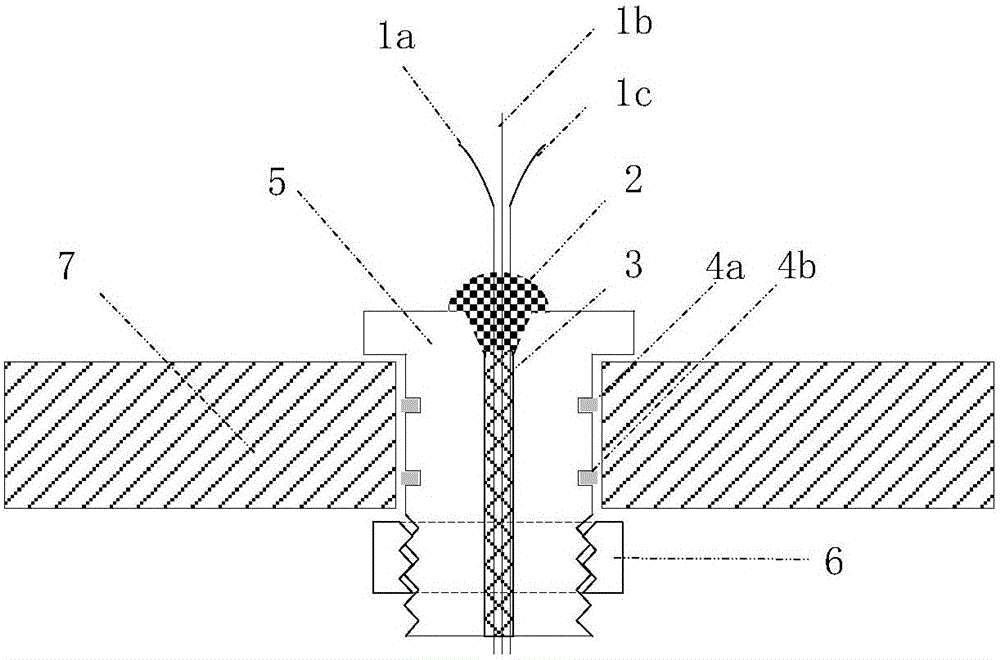

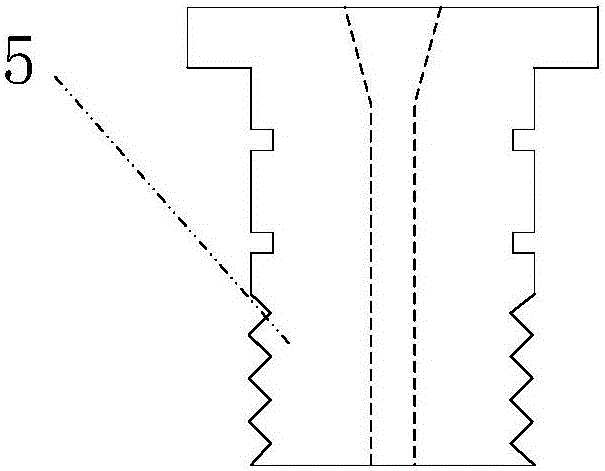

Long-stroke drive coil structure for electrodynamic vibration generator

ActiveCN105300640AAvoid damageGood guiding performanceVibration testingShock testingEngineeringCoil structure

The invention relates to the technical field of electrodynamic vibration generator for testing, and specifically discloses a long-stroke drive coil structure for an electrodynamic vibration generator. The long-stroke drive coil structure designs a structure for fixing a drive coil in the vibration generator as a form including upper and lower bracing frames which form a double bracing frame structure so that the drive coil can be rolled between the upper and lower bracing frames. The two bracing frames are fixed through a connection rod, and transmit the exciting force so that the connection strength after lengthening of the drive coil of the vibration generator and the transmission of force are not influenced; therefore the drive coil and the drive coil bracing frames do not release from the skeleton because of low bonding intensity between the drive coil and the drive coil bracing frames so as to prevent damaging of the drive coil; at the same time, the guiding mode of the drive coil is modified; guiding bars are respectively arranged on the drive coil bracing frames to realize overall guiding of the drive coil structure and to improve the guiding performance; and the lower guiding bar is also provided with a lead slot so that a wiring function is also provided and a service conductor of the drive coil can be led out reliably and the whole vibration generator can stably and safely work.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

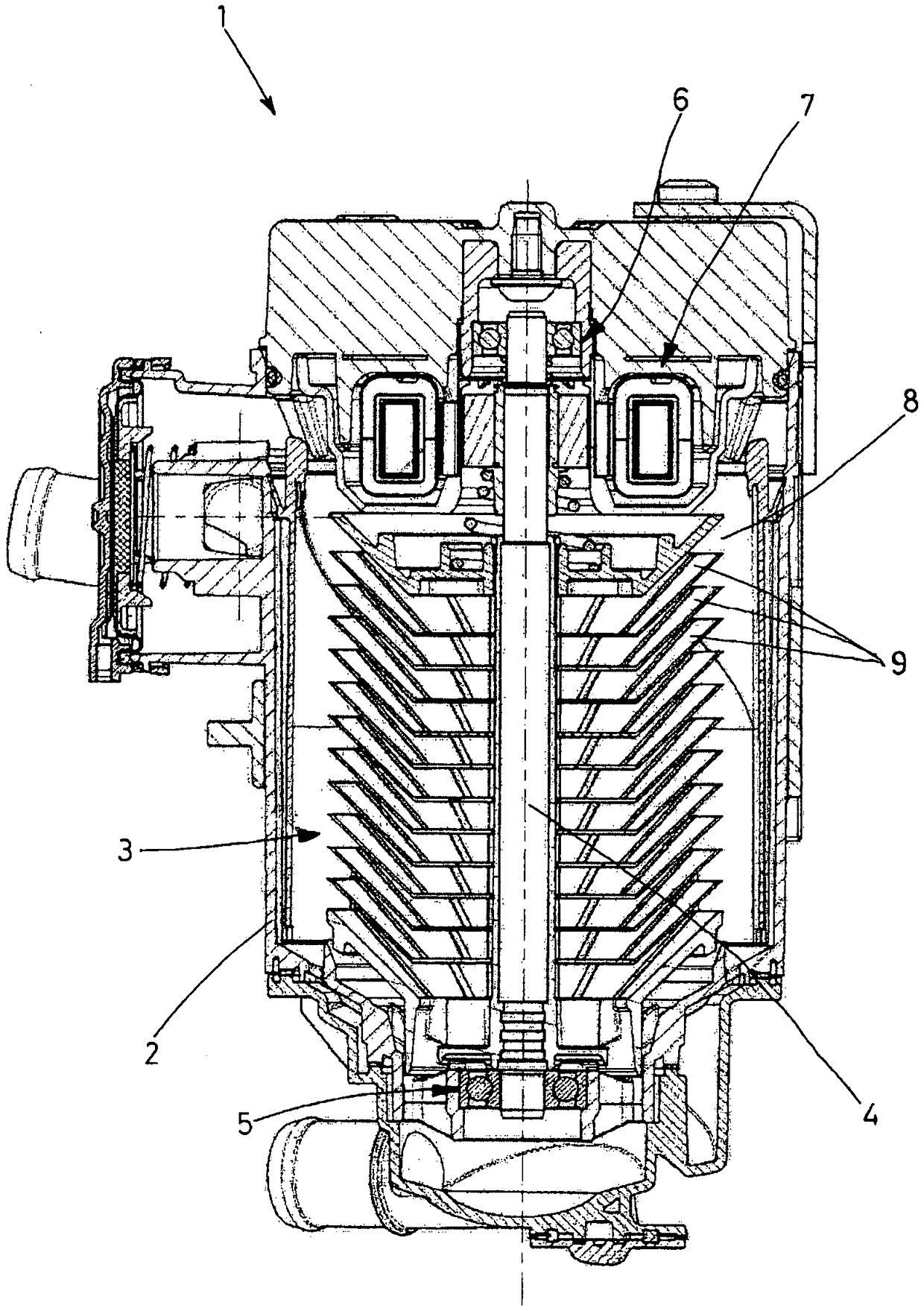

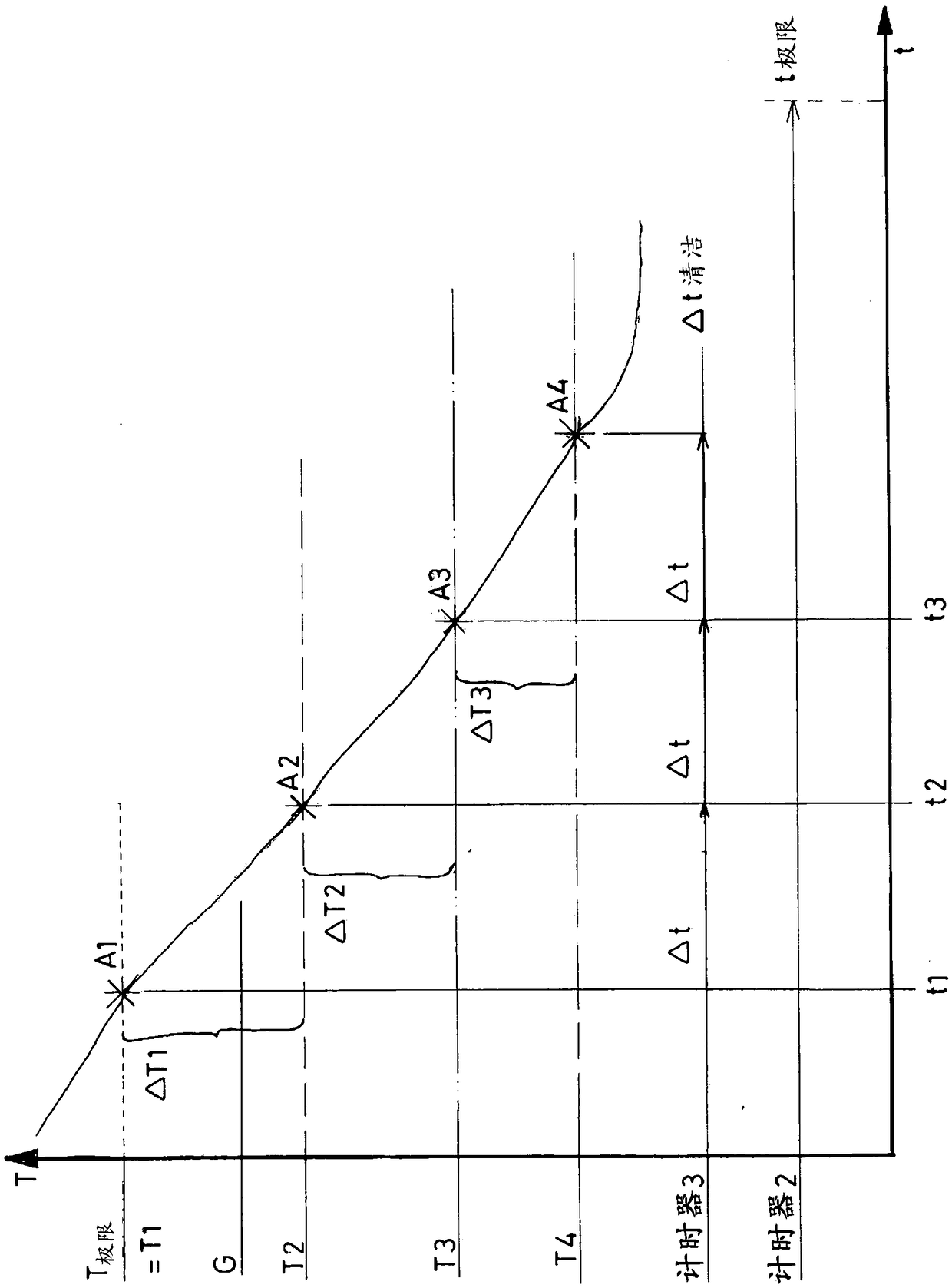

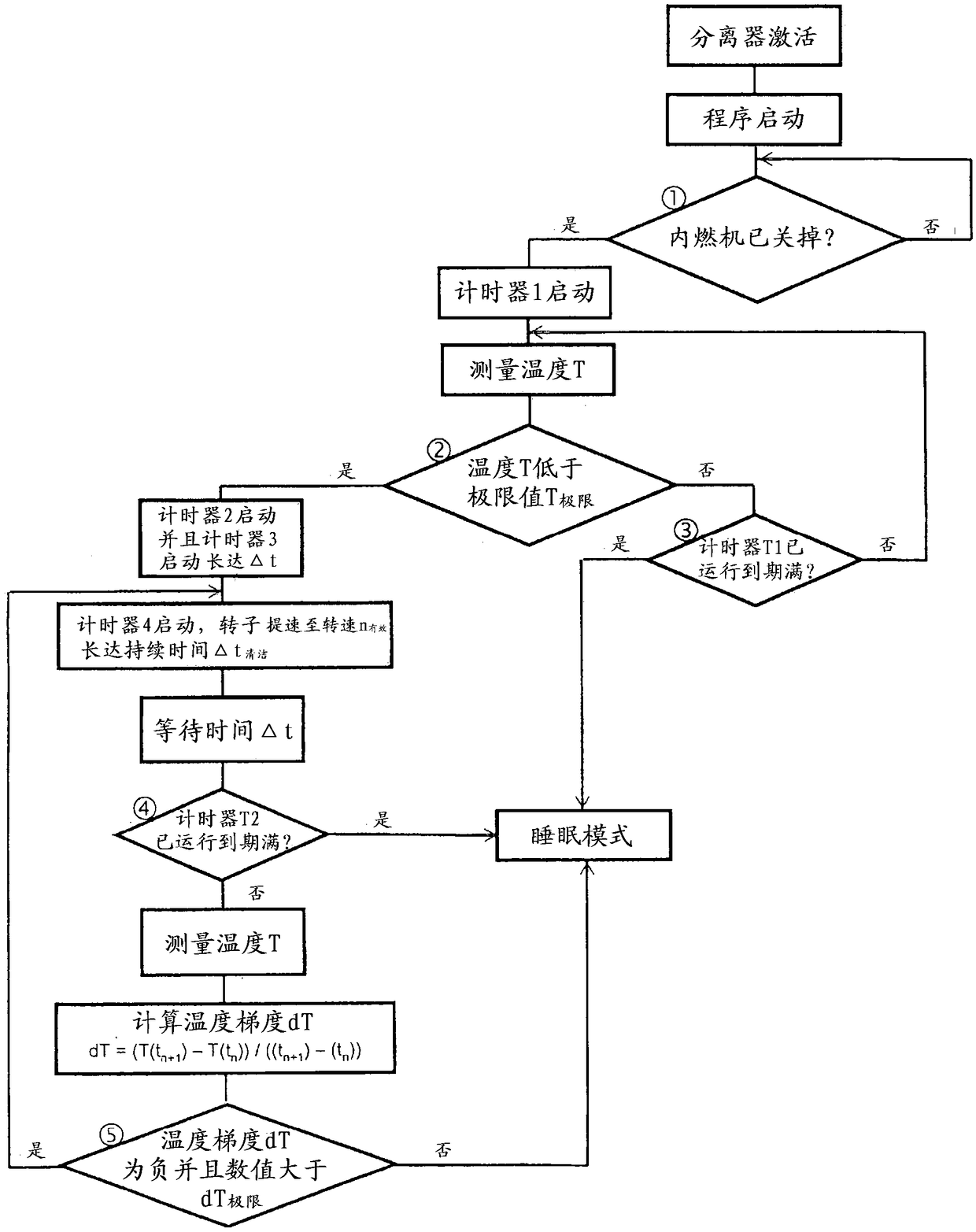

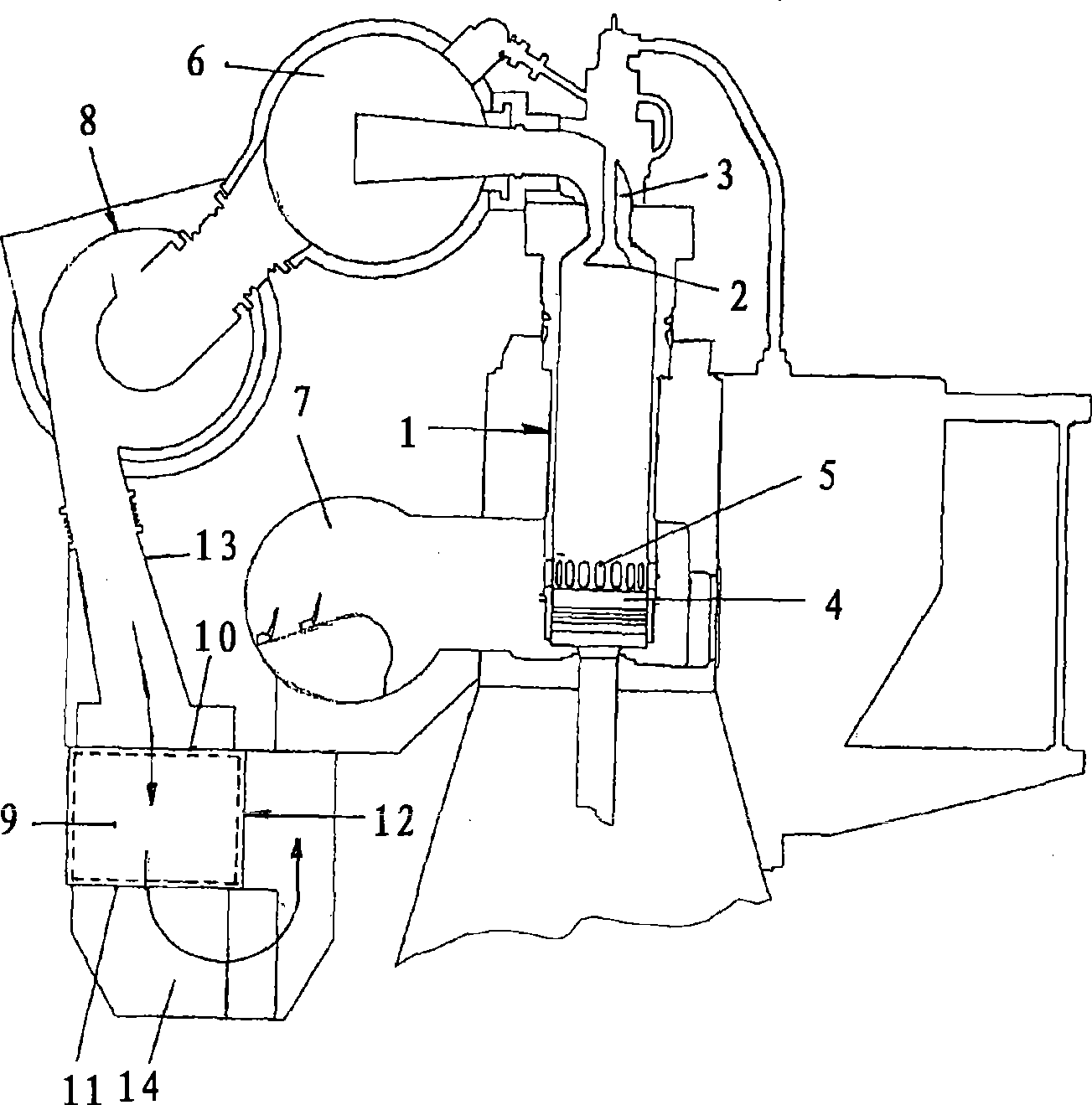

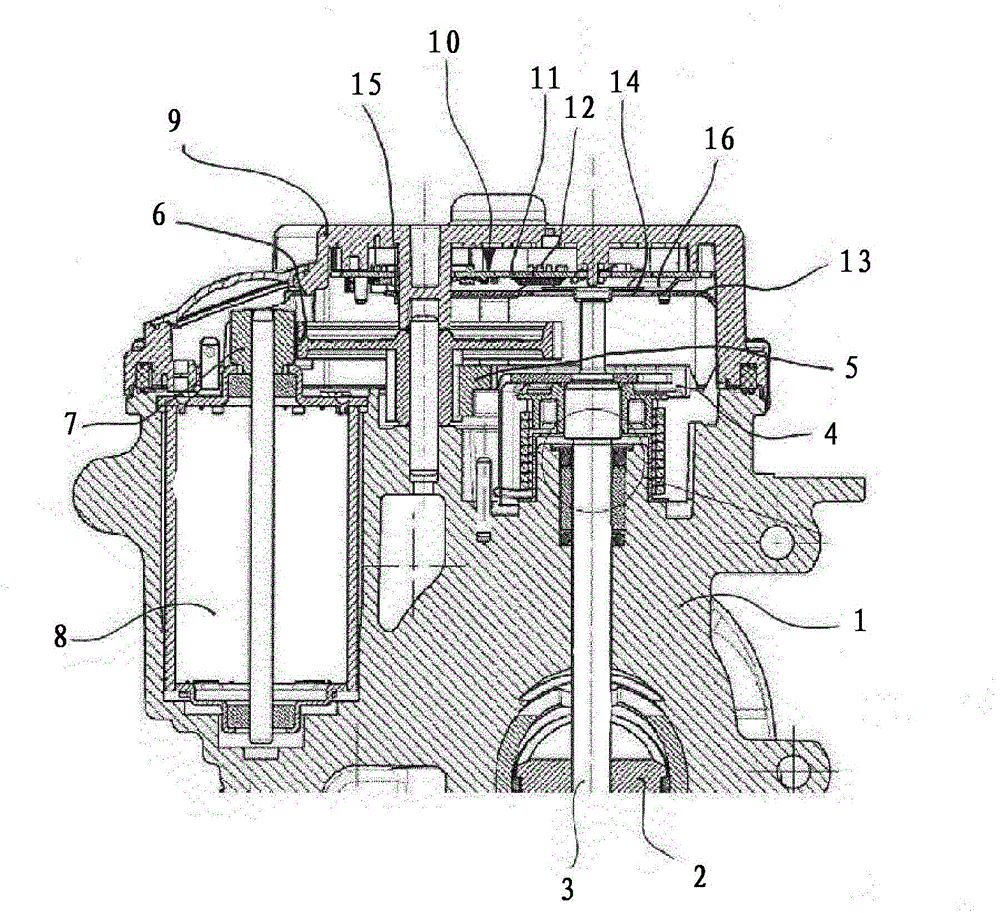

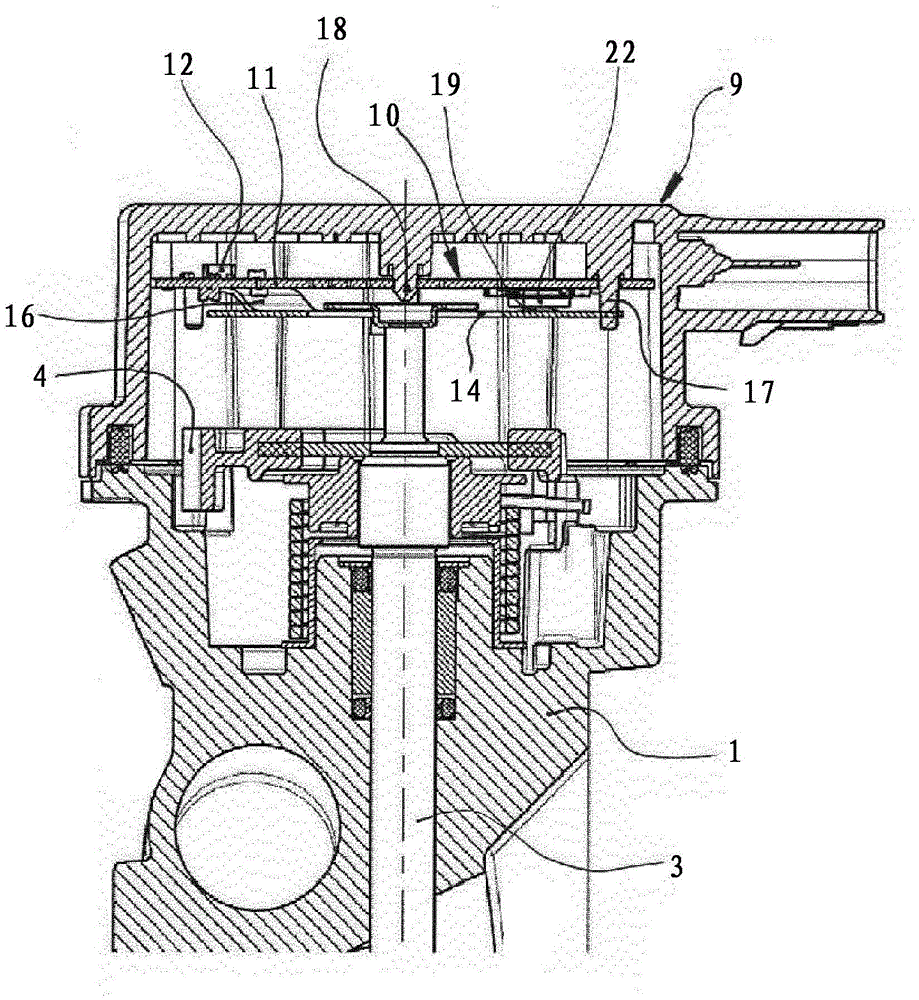

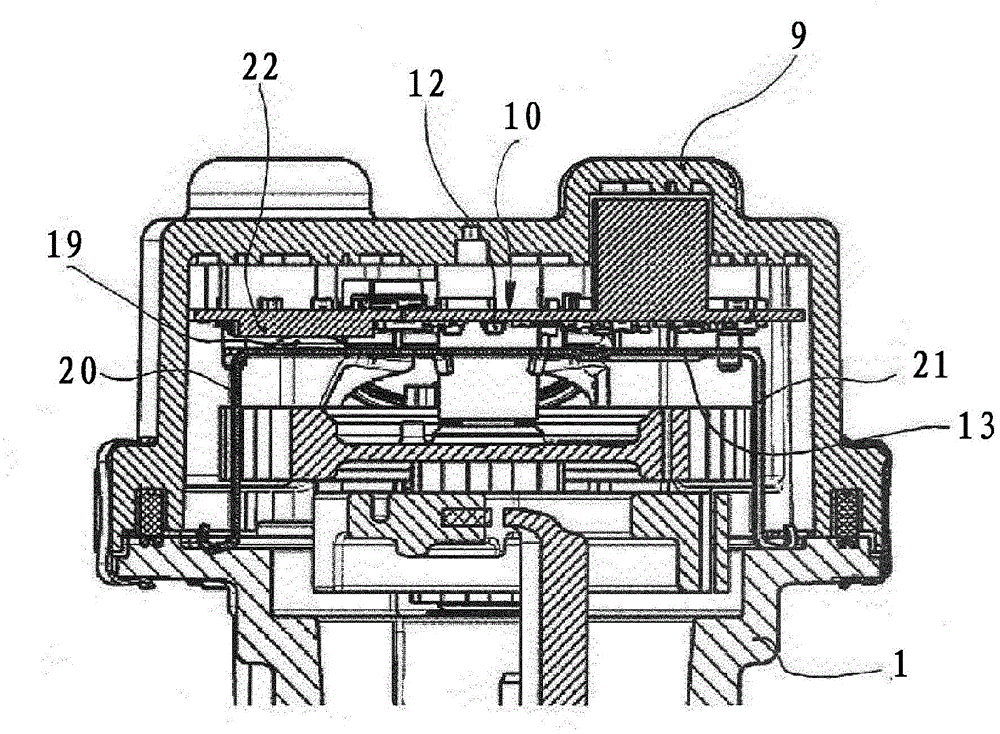

Method for protecting a rotation separator from icing, and rotation separator

ActiveCN109072739AAvoid imbalanceRaise the possibilityEngine temperatureElectrical controlCombustionExternal combustion engine

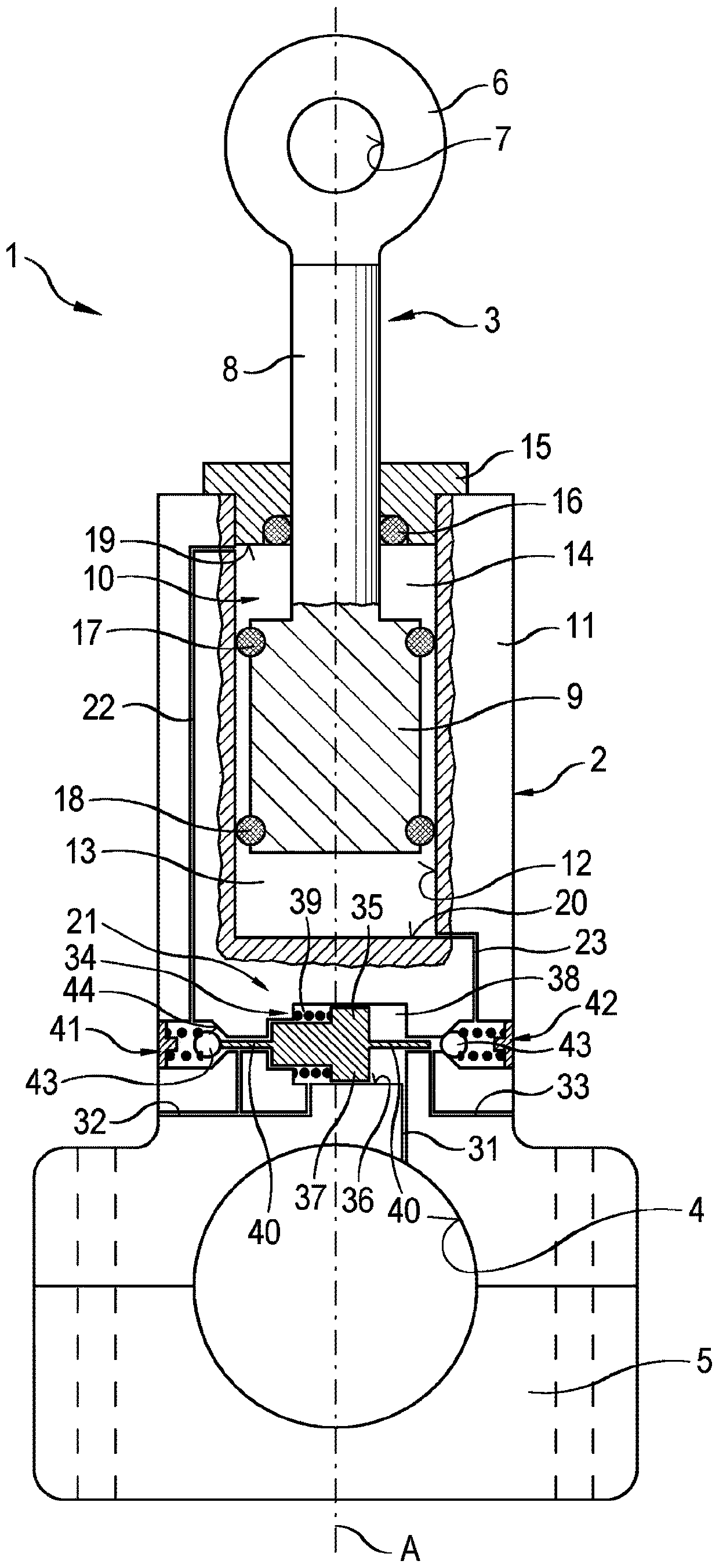

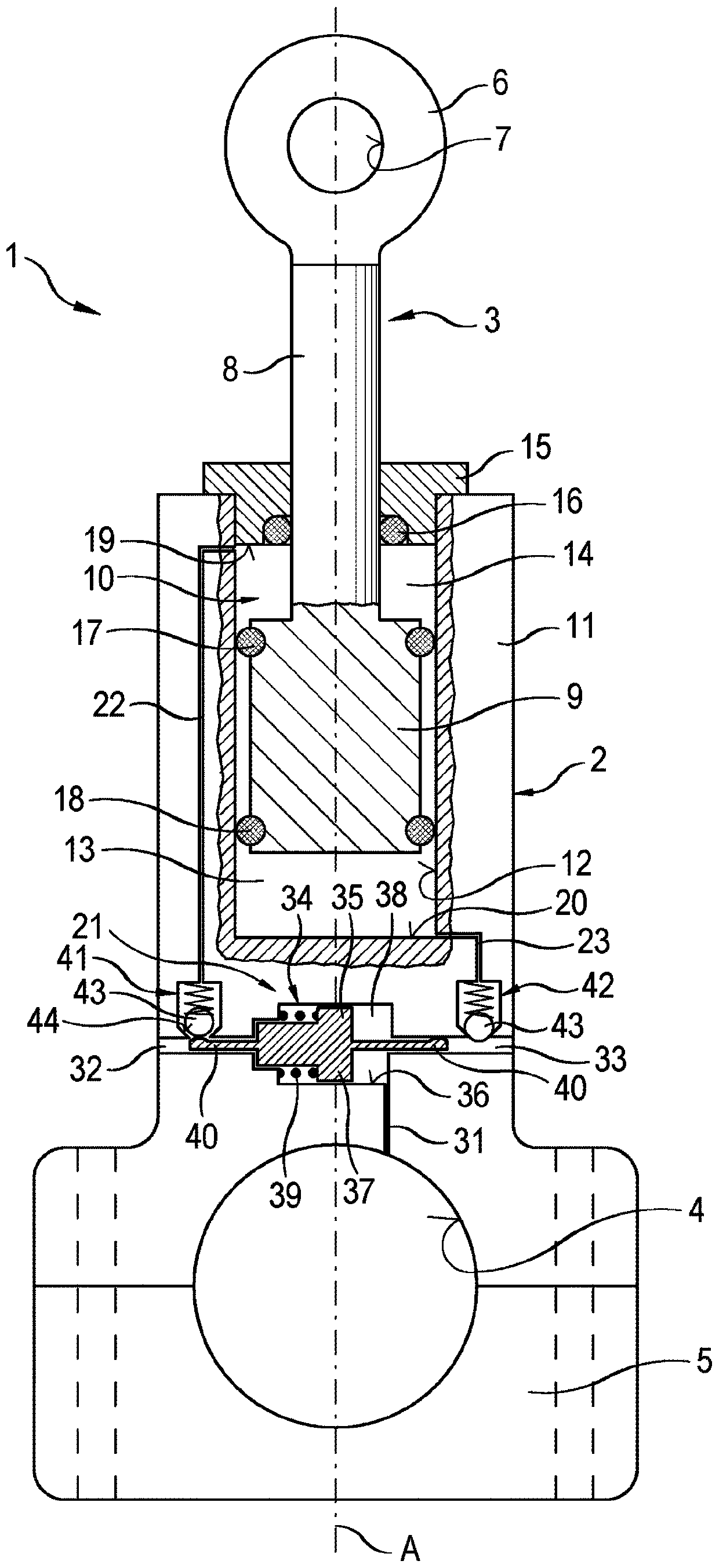

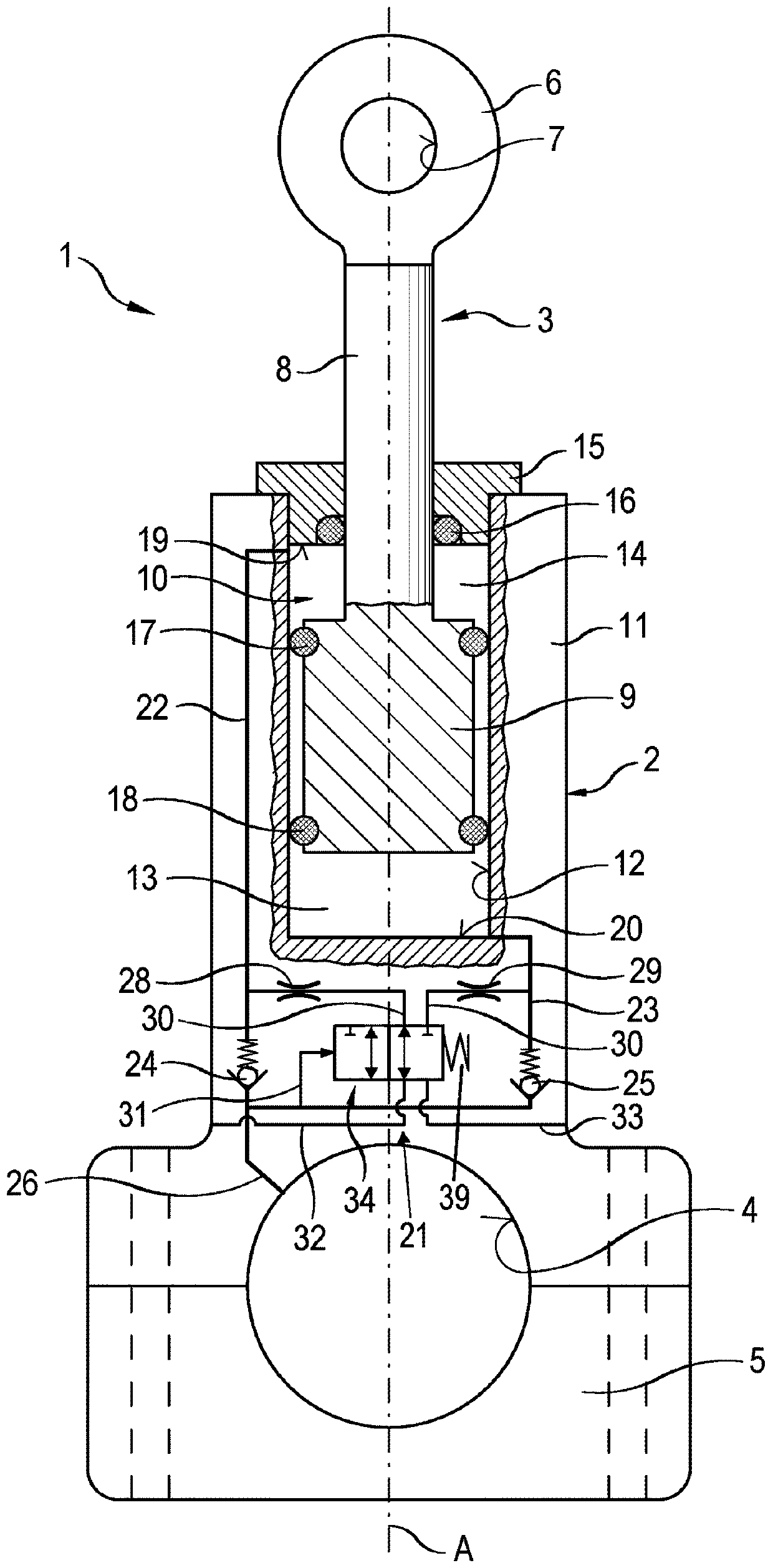

The invention relates to a method for operating a rotation separator (1), wherein a gas flow, which is laden with solid and / or liquid particles and originates from an internal combustion engine, is fed to a rotationally driven element labeled as a rotor (3), in which method particles are separated from the gas flow and deposited onto the rotor (3), wherein the rotor (3) is operated at a rotationalspeed labeled as an effective rotational speed in such a way that the particles deposited on the rotor (3) are spun off from the rotor (3) as a result of the rotational motion of the rotor (3). According to the invention, after the internal combustion engine has been shut off, the rotor (3) is set into rotation at the effective rotational speed by means of a so-called separate start (A) while theinternal combustion engine is at a standstill. The invention further relates to a rotation separator (1) that is controlled by a control system in such a way that the rotation separator is operated in accordance with said method.

Owner:HENGST WALTER

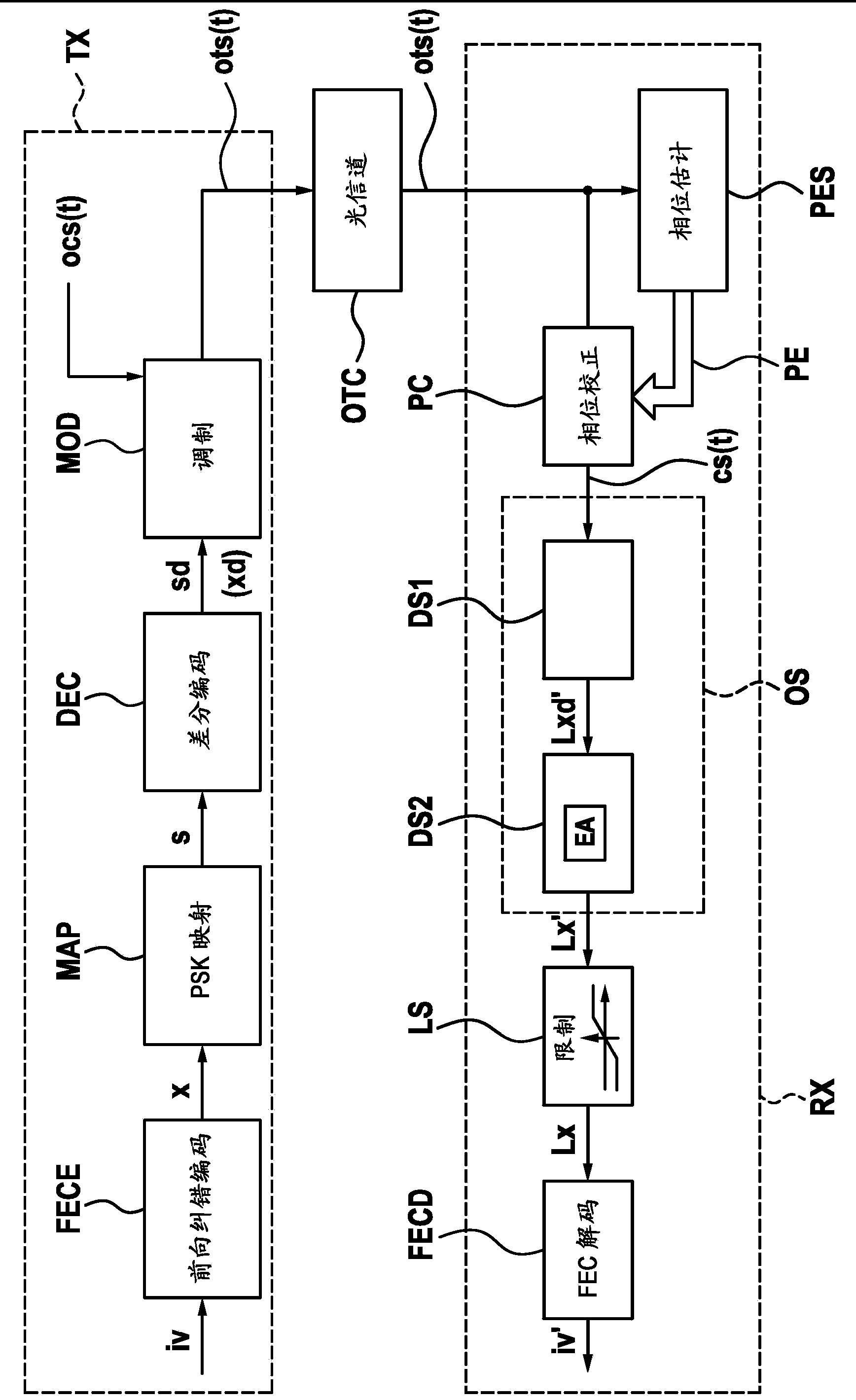

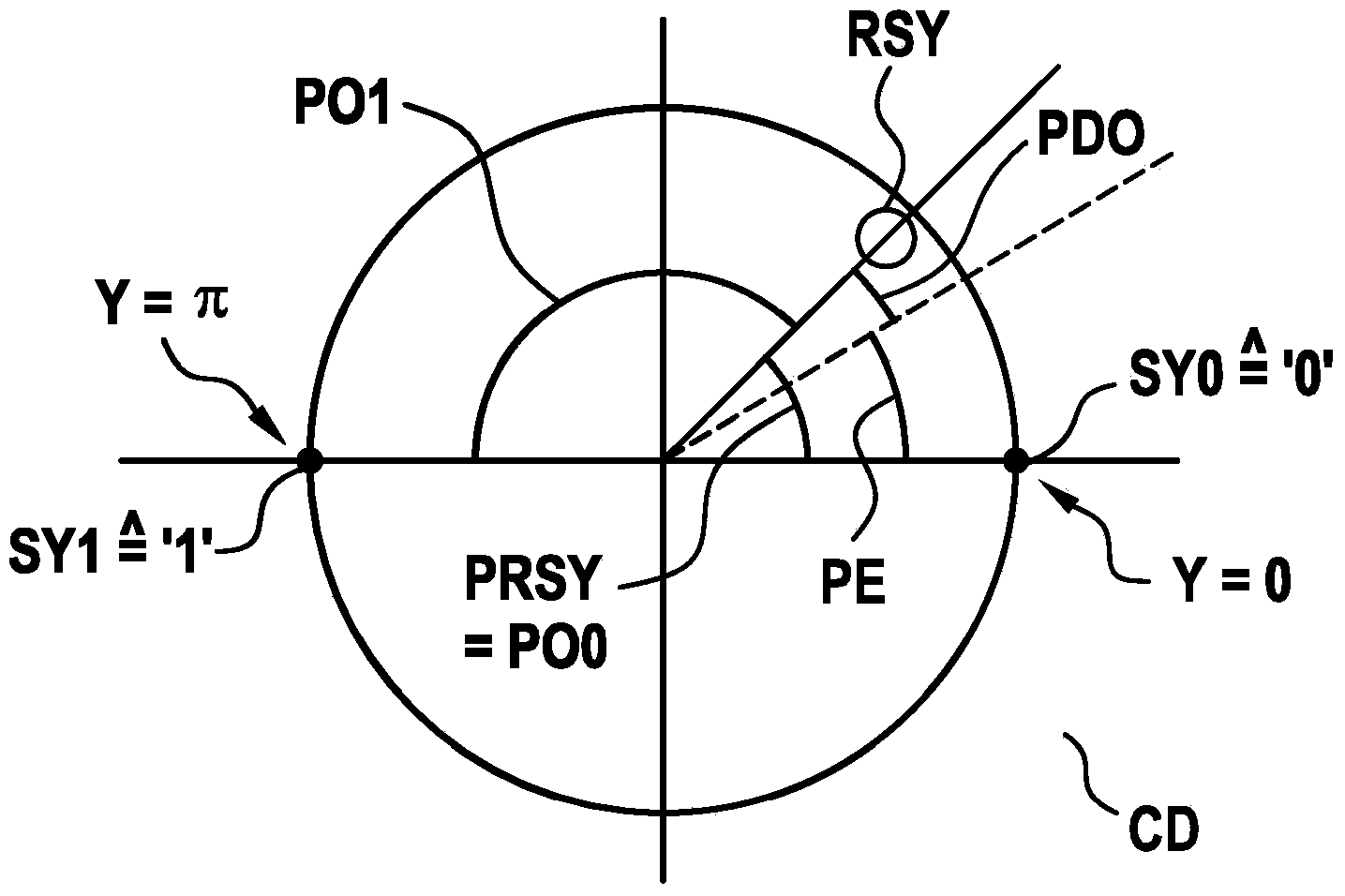

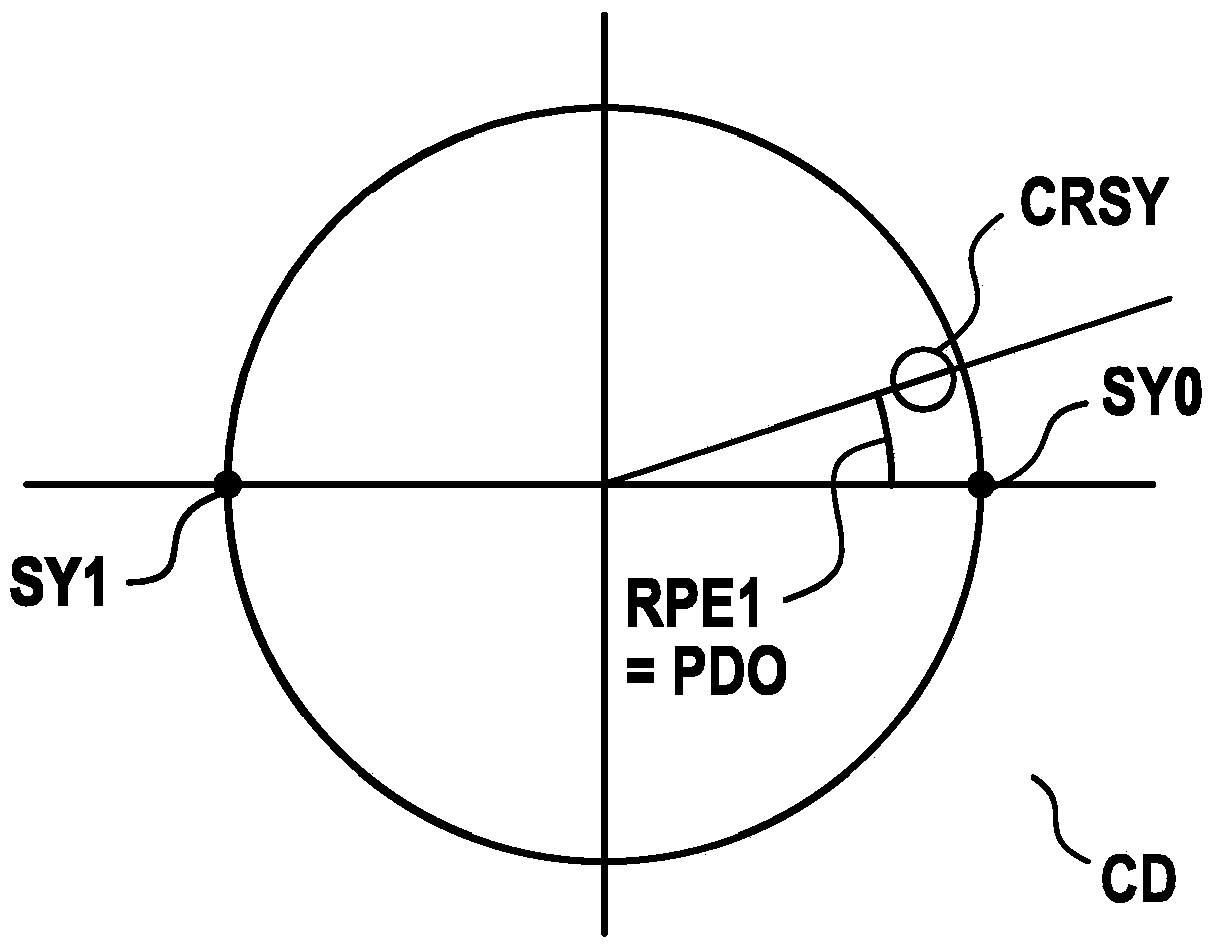

Method of decoding a differentially encoded phase modulated optical data signal

InactiveCN103620997AReliable exportElectromagnetic transmissionForward error control useData signalData value

Proposed is a method of decoding a differentially encoded PSKmodulated optical data signal carrying FEC encoded data values. The optical signal is corrected by an estimated phase offset. From the corrected signal, respective likelihood values for the FEC encoded data values are derived, using an estimation algorithm which accounts for a differential encoding rule used for differentially encoding the optical signal. The derived likelihood values are limited to a predetermined range of values. From the limited likelihood values, FEC decoded data values are derived, using an algorithm which accounts for a FEC encoding rule used for FEC encoding the FEC encoded data values.

Owner:ALCATEL LUCENT SAS

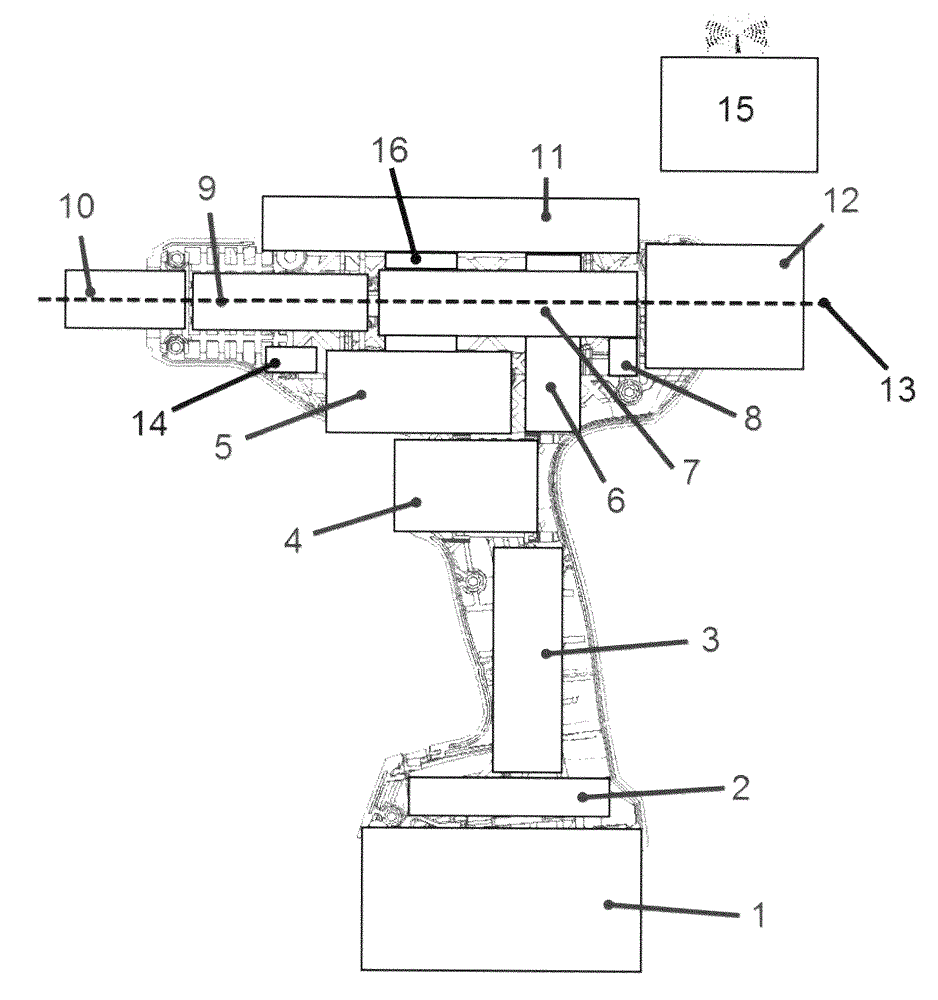

Rivet installation tool having automatic riveting core guiding out mechanism

In the prior art, the rivet core which is separated from the riveting tool is guided to the rivet core container through the appropriate movement of the rivet installation device. The invention enables the process to be automatic and gurantees the accuracy of the riveting tool and reliability of the process. As a result, the rivet installation tool having the automatic riveting core guiding out mechanism reduces the fault and reduces the circulation time of the tool.

Owner:ROBERT BOSCH GMBH

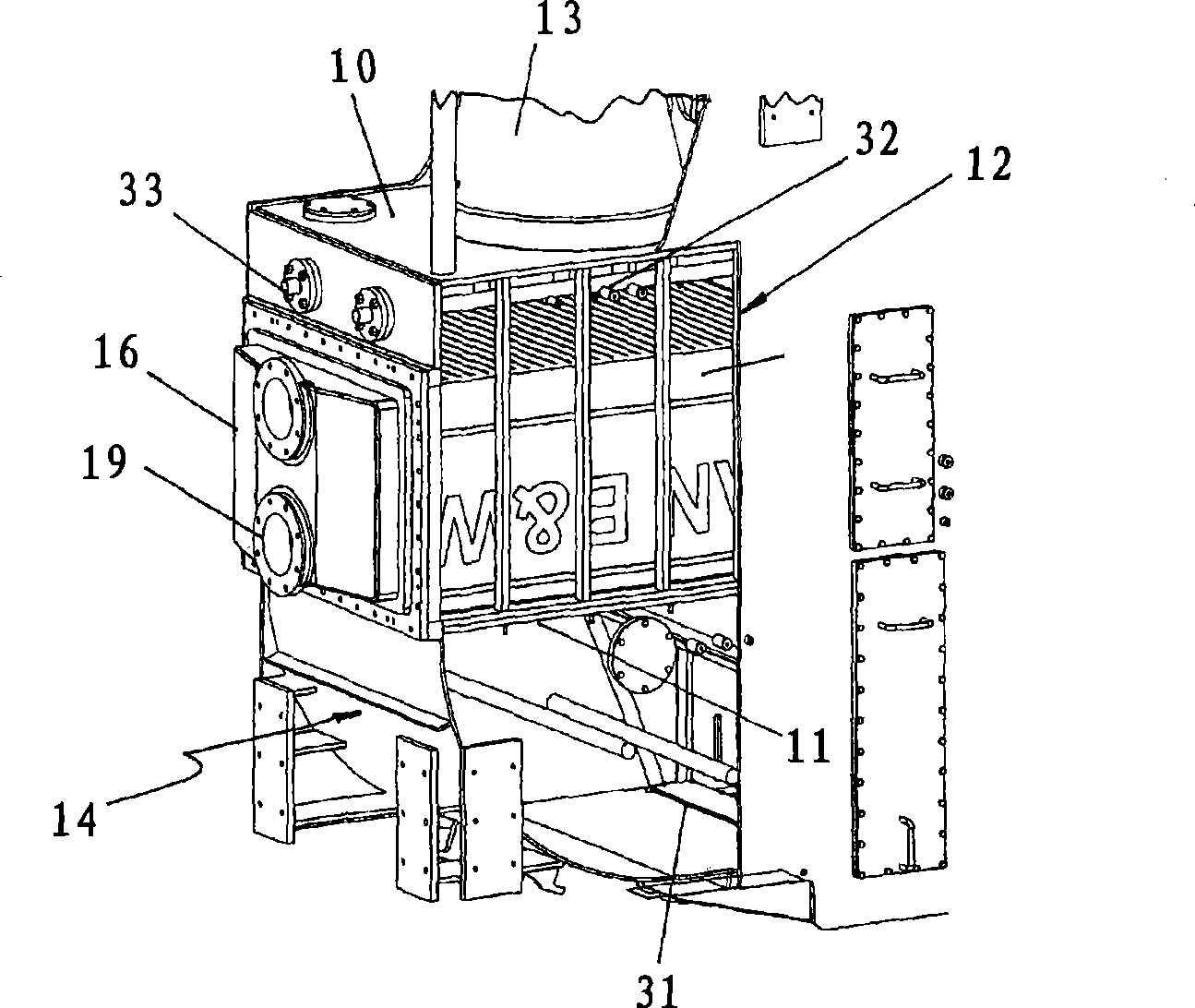

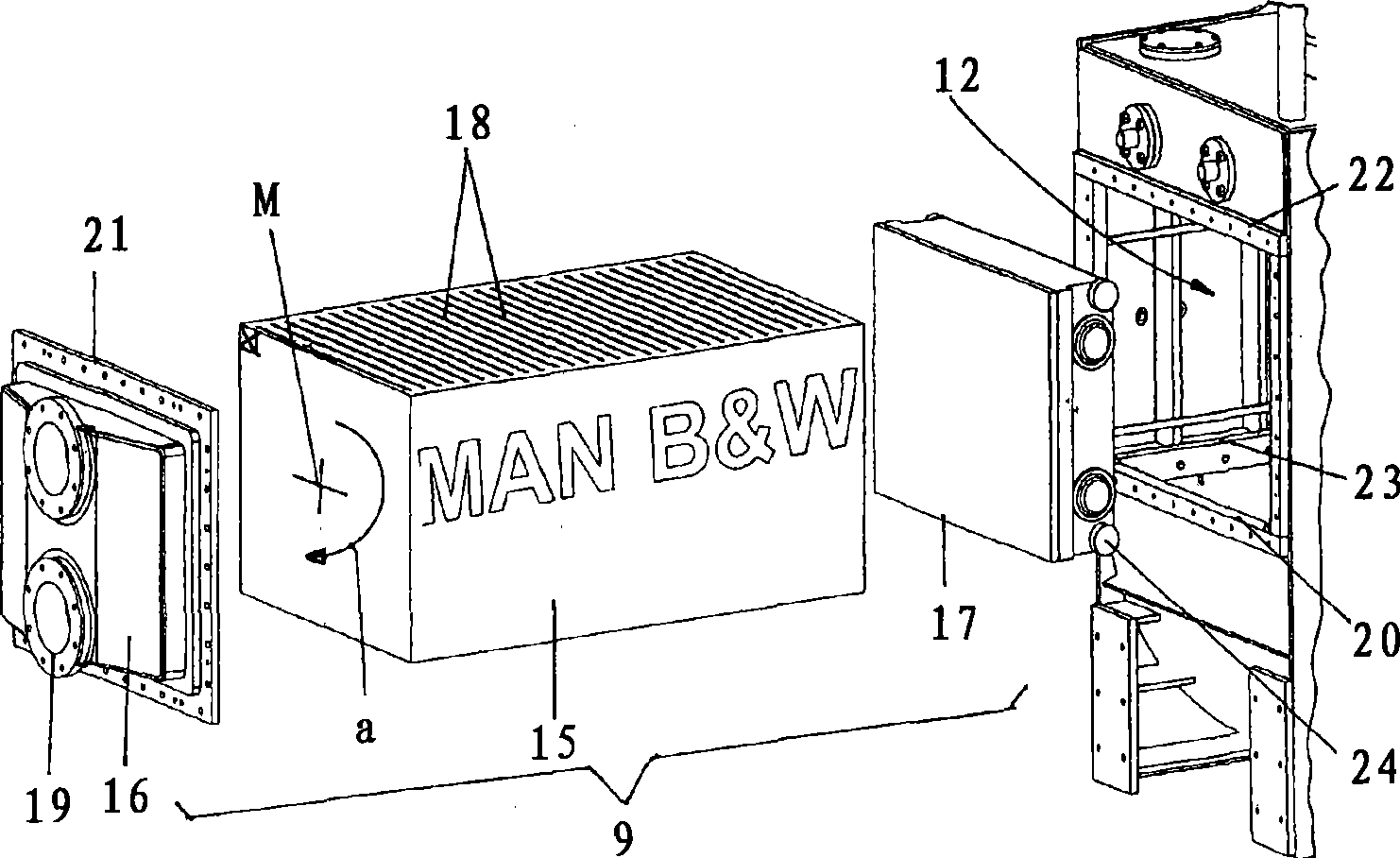

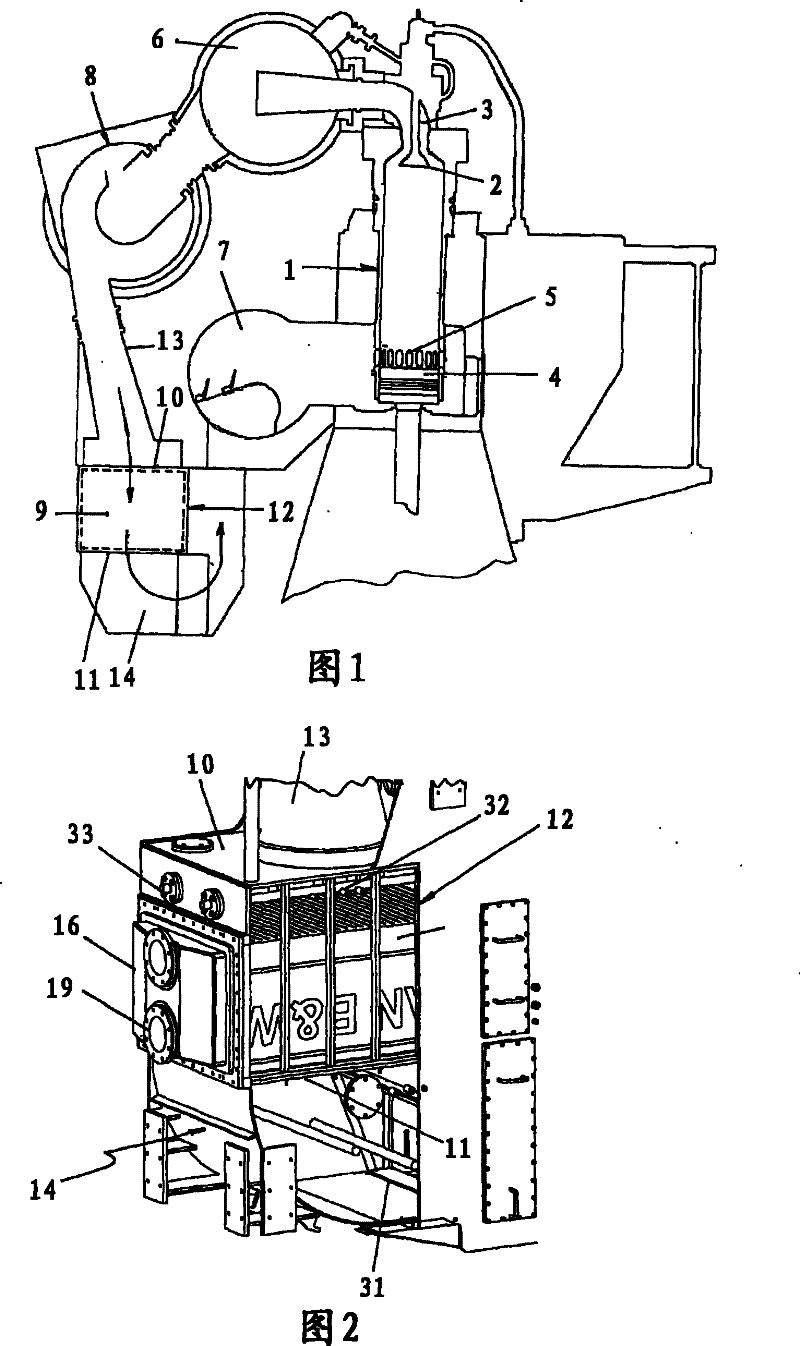

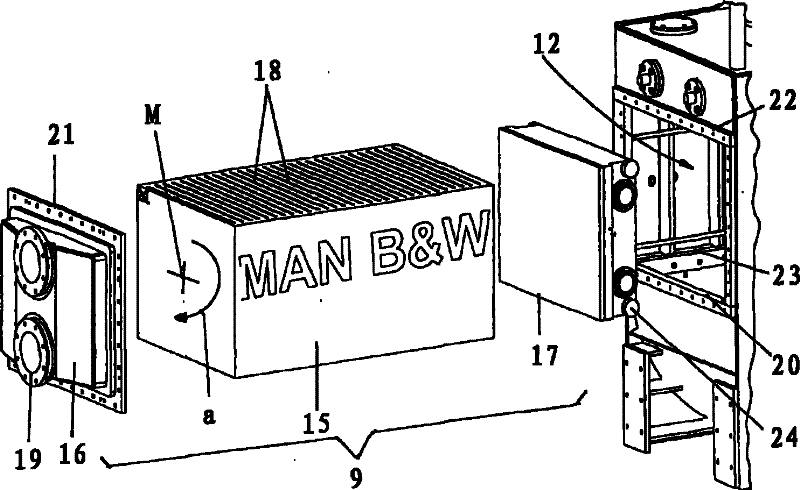

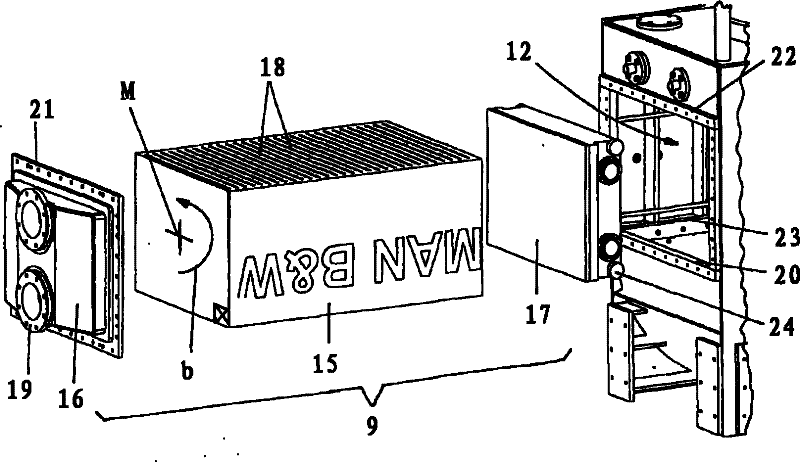

Method for cleaning air cooler as well as device for carrying out the method, and air cooler equipped for the same

InactiveCN101464110AReliable Pollution ControlReliable removalCleaning heat-transfer devicesInternal combustion piston enginesEngineeringChiller

The invention relates to an air loaded air cooler (9) such as an engine. The air cooler has an area (15) designed to a heat exchanger arranged between an air inlet and an air outlet. The area contains a plurality of vertical flow passages (18) which is crossed by an uncooling air from up to down and limited by an outer cooling surface, wherein a high reliability and a long service life can be realized by that the area (15) designed to the heat exchanger is rotated about a half rotation around an axis which traverses the uncooling air and extends along the flow direction from up to down, and the area (15) designed to the heat exchanger can be loaded by the uncooling air crossing the area from up to down at an up and down reversal position which is rotated about a half rotation.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

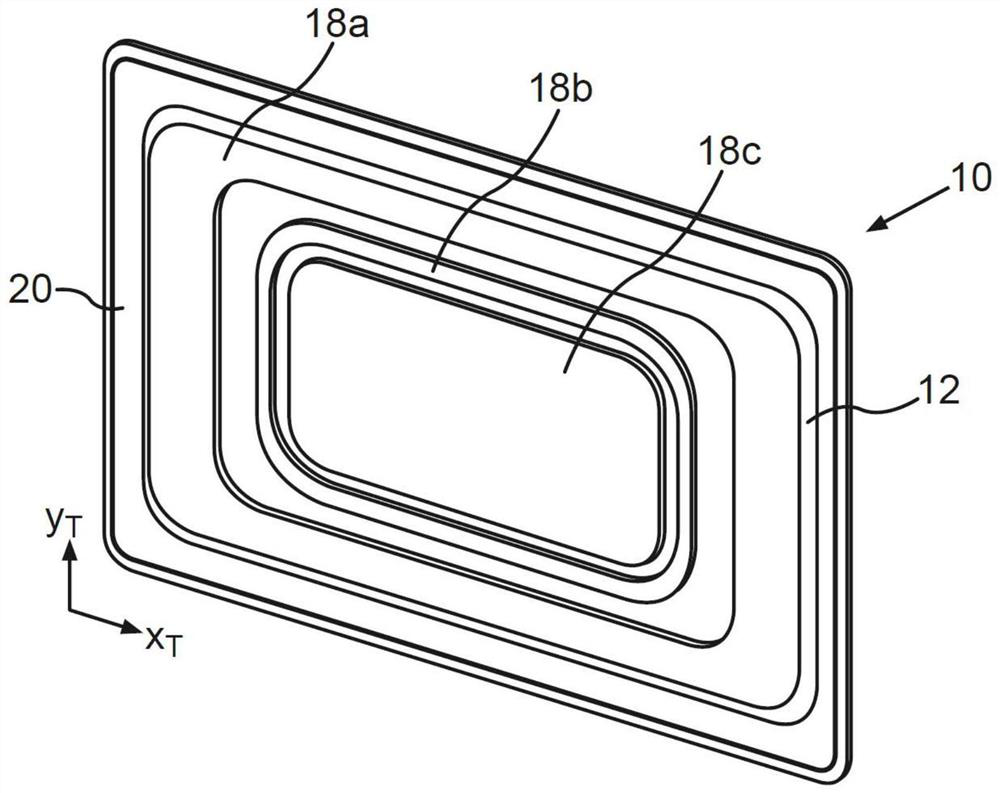

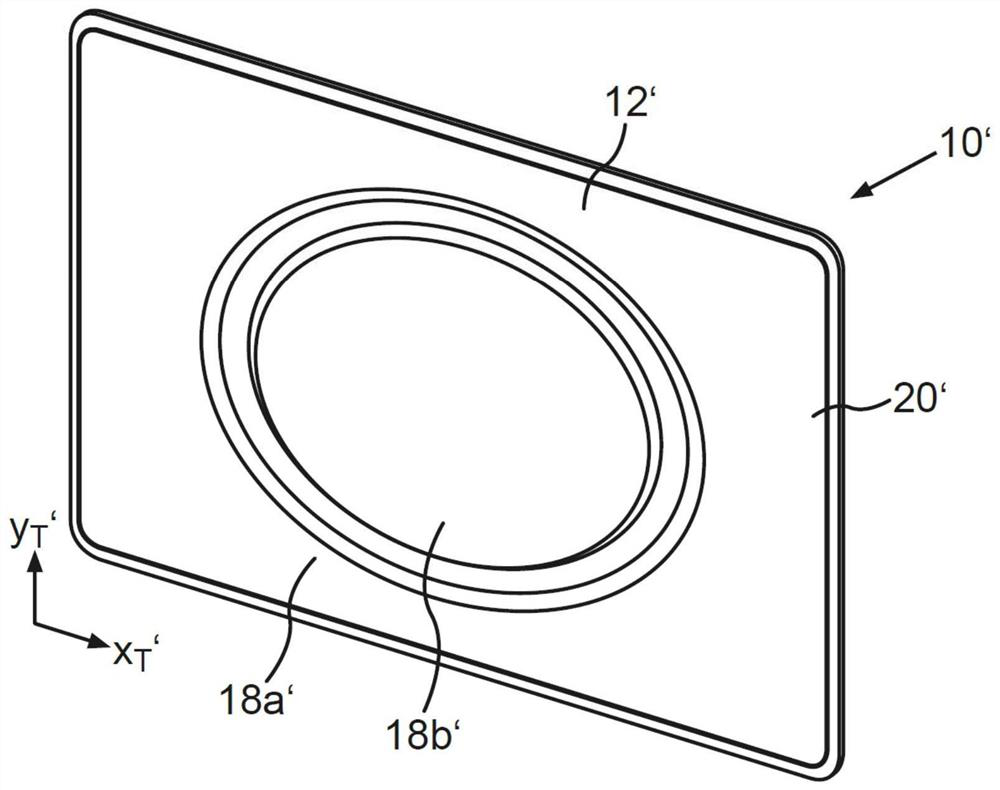

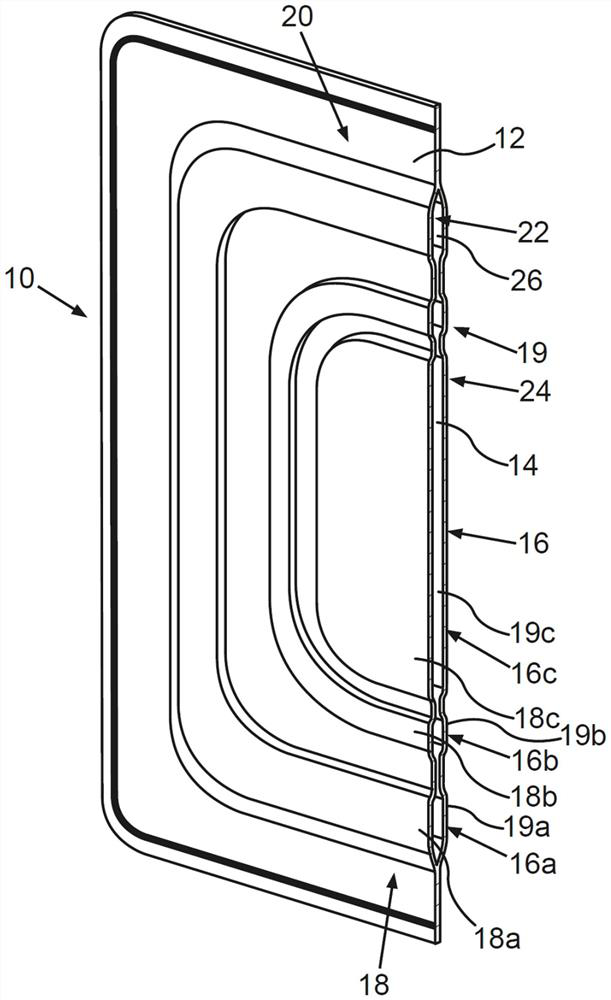

Actuator

InactiveCN104838569AReliable exportEasy to manufactureAssociation with control/drive circuitsOperating means/releasing devices for valvesElectronic systemsEngineering

The invention relates to an actuator comprising a metal housing (1) that consists of multiple housing parts (1, 9), an electric motor (8), an actuating member (2), a transmission mechanism (4-7) that adapts the movement of the electric motor (8) to the actuating member (2) and an electronic system (10) for controlling the electric motor (8). At least one housing part (9) consists of plastic, a heat sink (13) being situated in the region of the housing part (9) that consists of plastic. The heat sink (3) has thermal connecting surfaces (16, 19) for the electronic system (10) and is connected to a metal housing part (1).

Owner:CONTINENTAL AUTOMOTIVE GMBH

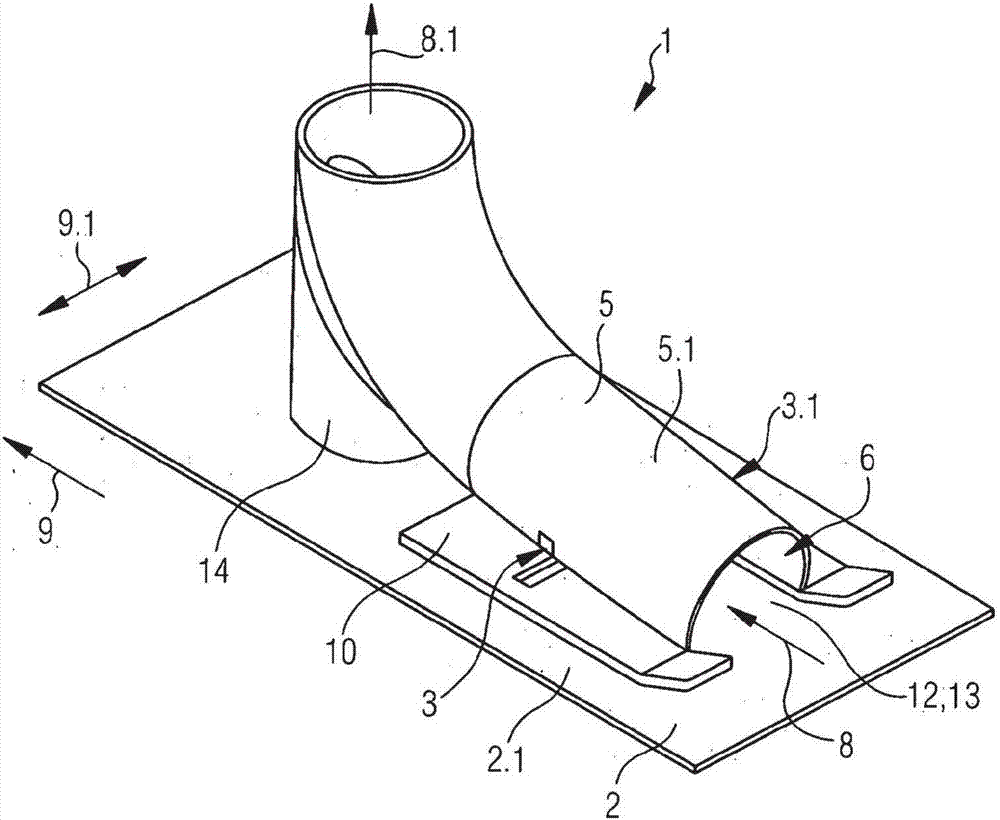

Cleaning device

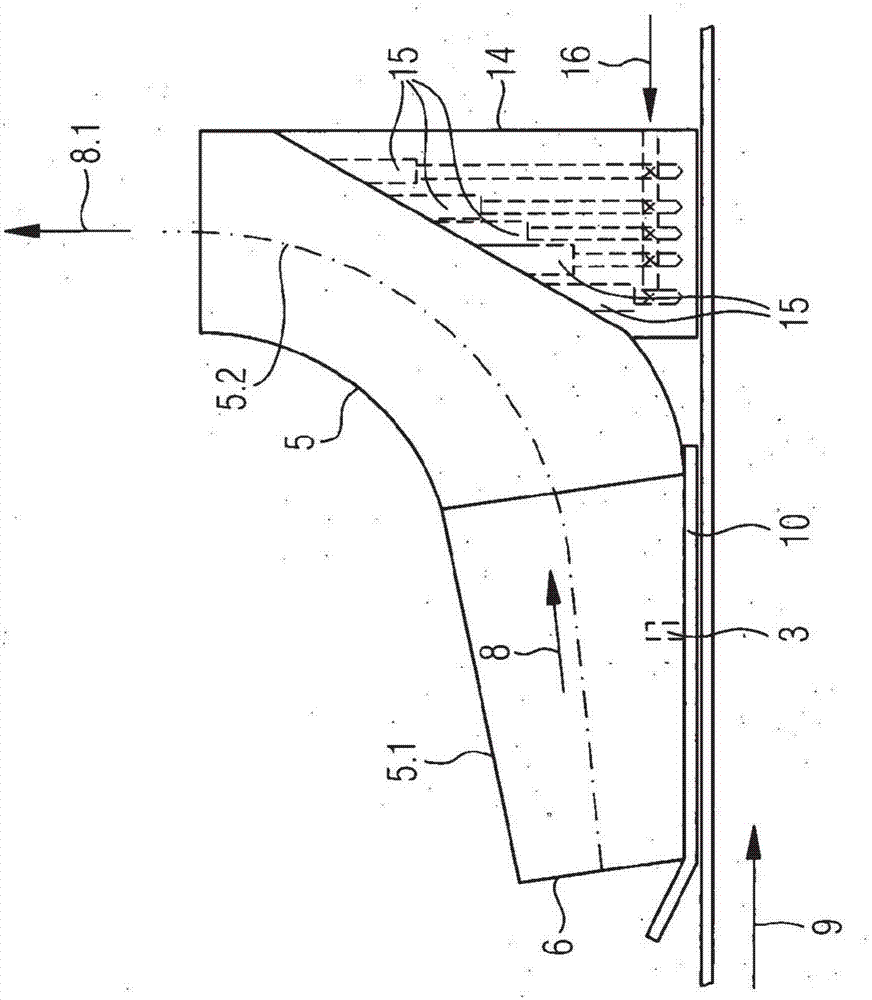

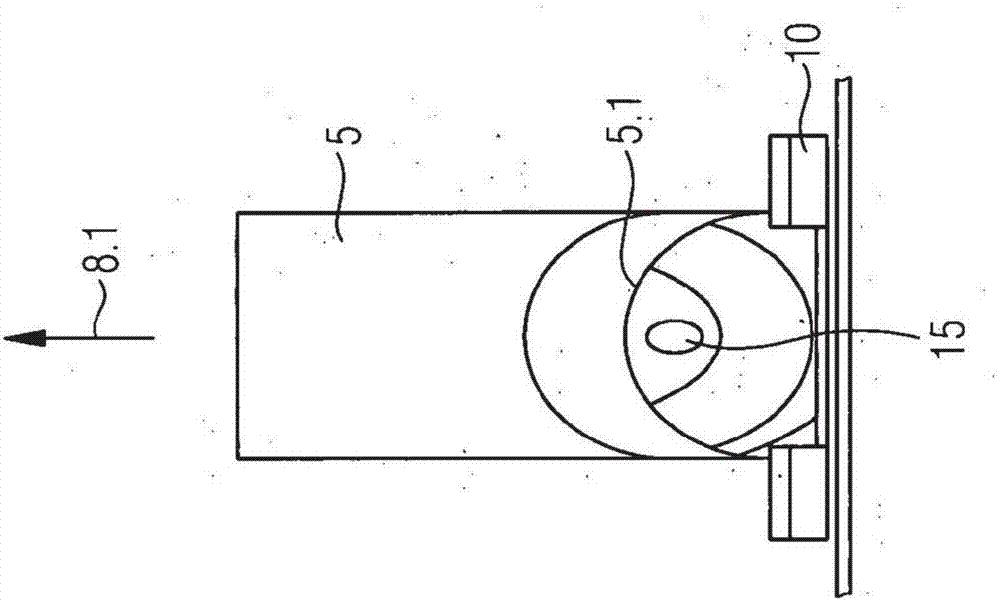

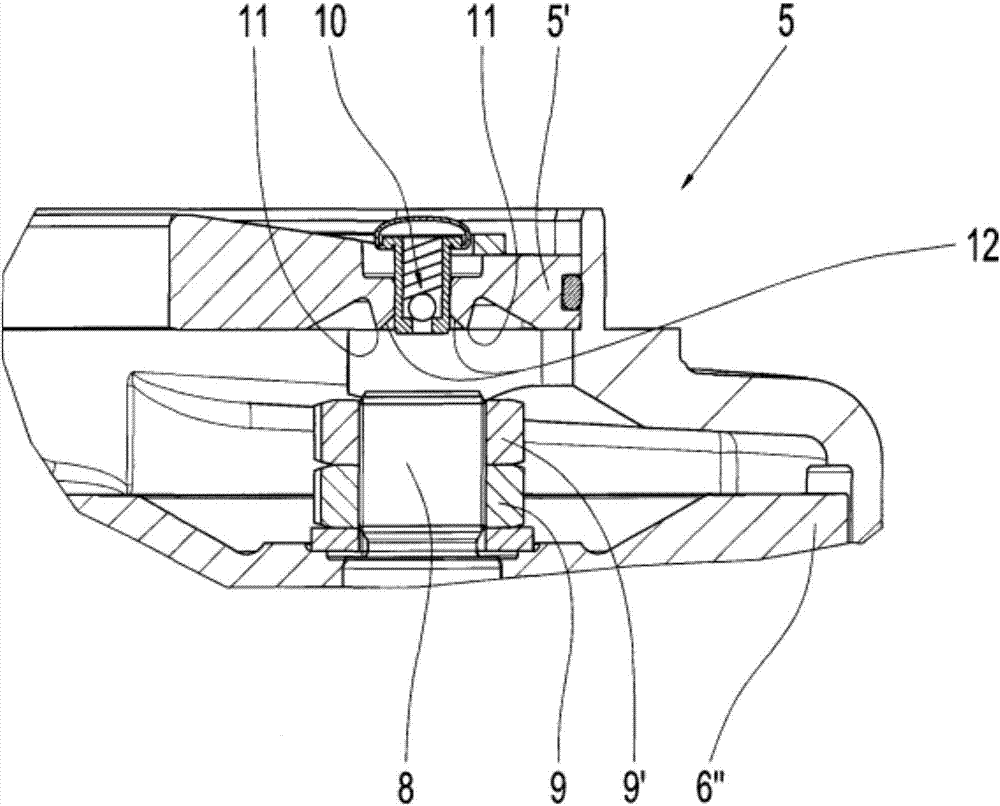

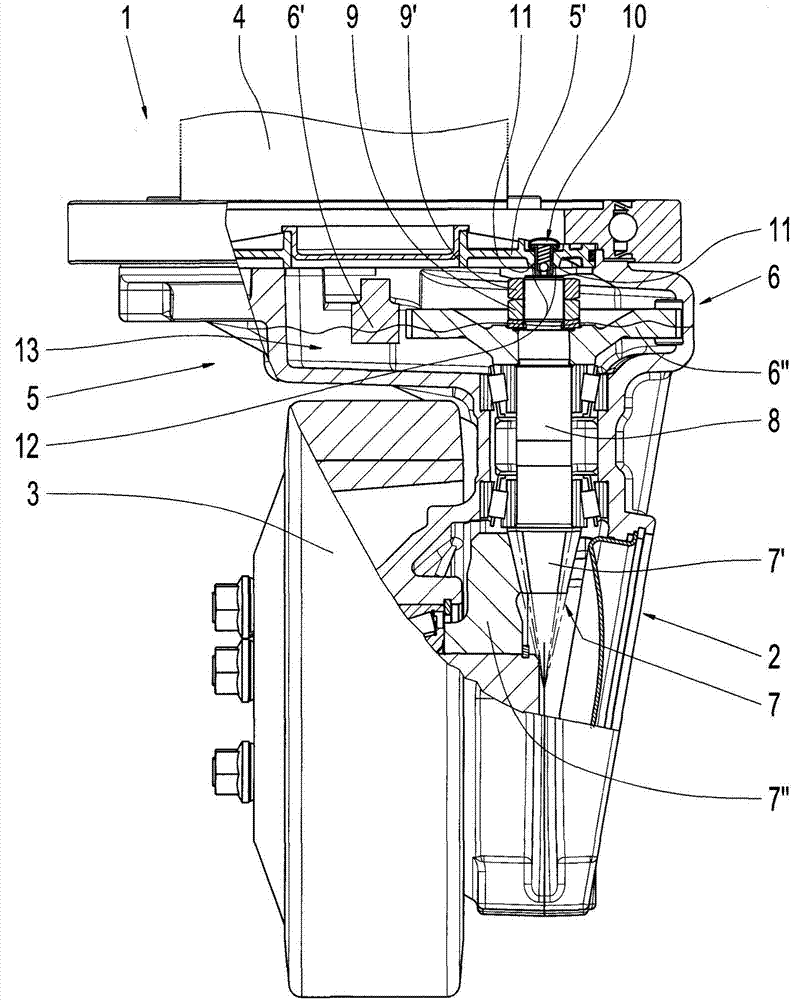

The invention relates to a device (1) for cleaning a continuously circulating fabric (2) in a paper machine for producing and / or processing a paper, cardboard, tissue or other fiber web, comprising at least one cleaning nozzle (3, 3.1), which generates at least one cleaning jet (4) from a fluid, said jet being directed towards the fabric (2), and comprising a discharge channel (5) for discharging the fluid and the dirt released from the fabric (2) by the cleaning jet (4) in a discharge direction (8). The discharge channel (5) has a first section (5.1) with a receiving opening (6) at the beginning of the discharge channel (5), said first section (5.1) of the discharge channel (5) having a cleaning opening (12) which faces the circulating fabric (2) and forms a cleaning zone (13), and the at least one cleaning nozzle (3, 3.1) is arranged such that the at least one cleaning jet (4) strikes the fabric (2) in the region of the cleaning zone (13). The device (1) according to the invention is characterized in that the receiving opening (6) is oriented opposite the running direction (9) of the circulating fabric (2) and in that the at least one cleaning nozzle (3, 3.1) is arranged such that the at least one cleaning jet (4) has a speed component in a transverse direction (9.1), thus transversely to the running direction (9) of the fabric (2), and strikes the fabric (2) in an angular range of 20 degrees < B < 80 degrees, in particular in an angular range of 30 degrees<B<70 degrees, with respect to the fabric plane (2.1) when viewed in the running direction (9) of the fabric.

Owner:VOITH PATENT GMBH

Transmission shell, transmission unit, driving unit, and ground transportation tool

InactiveCN107023649ASmall structural space requirementsFast and reliable exportGear lubrication/coolingEngineeringGround transportation

Owner:ZF FRIEDRICHSHAFEN AG

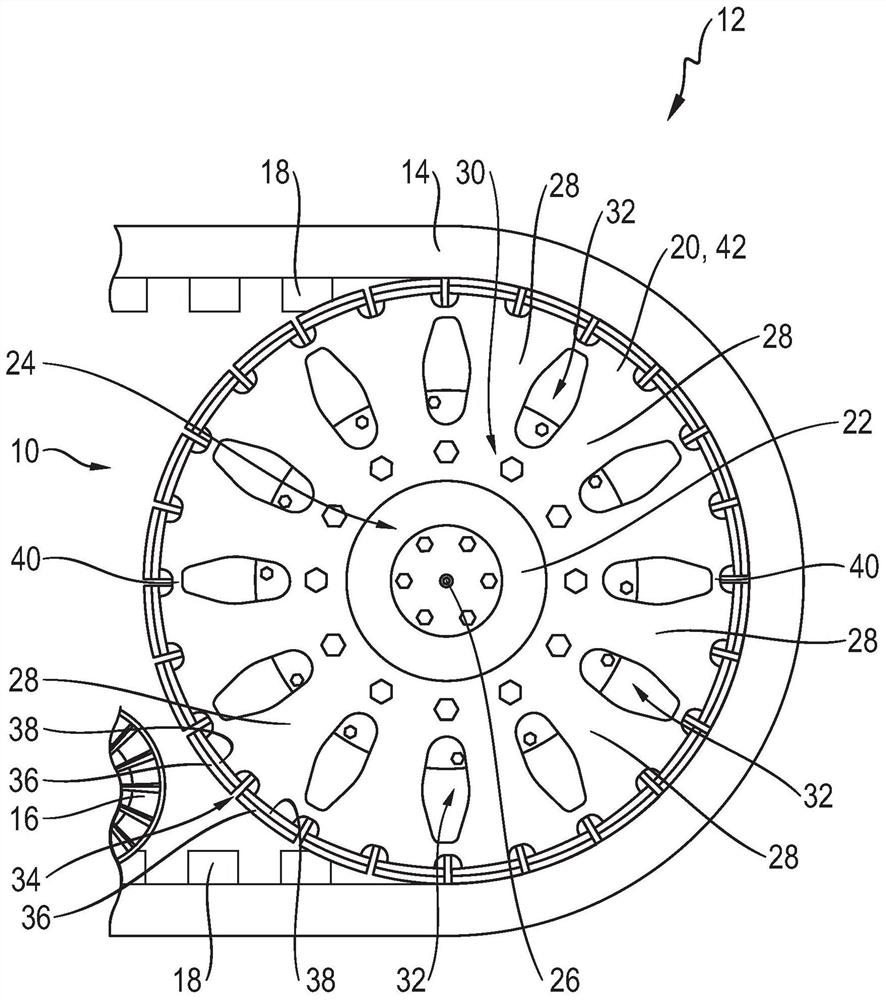

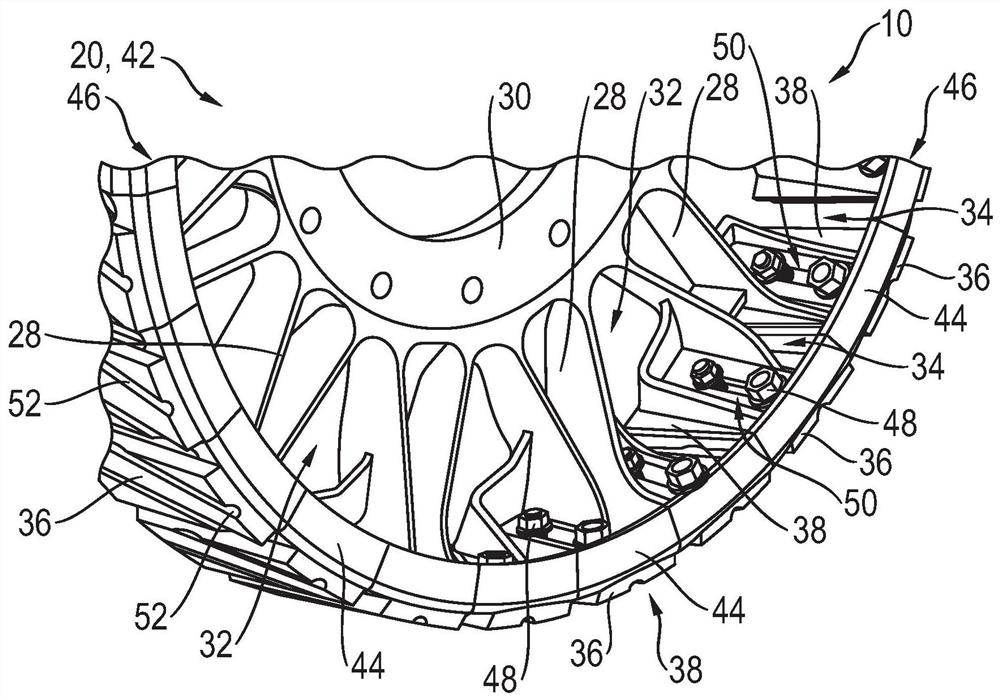

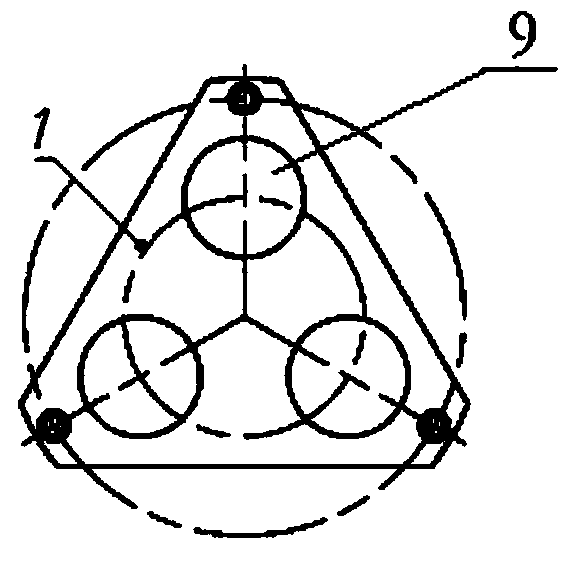

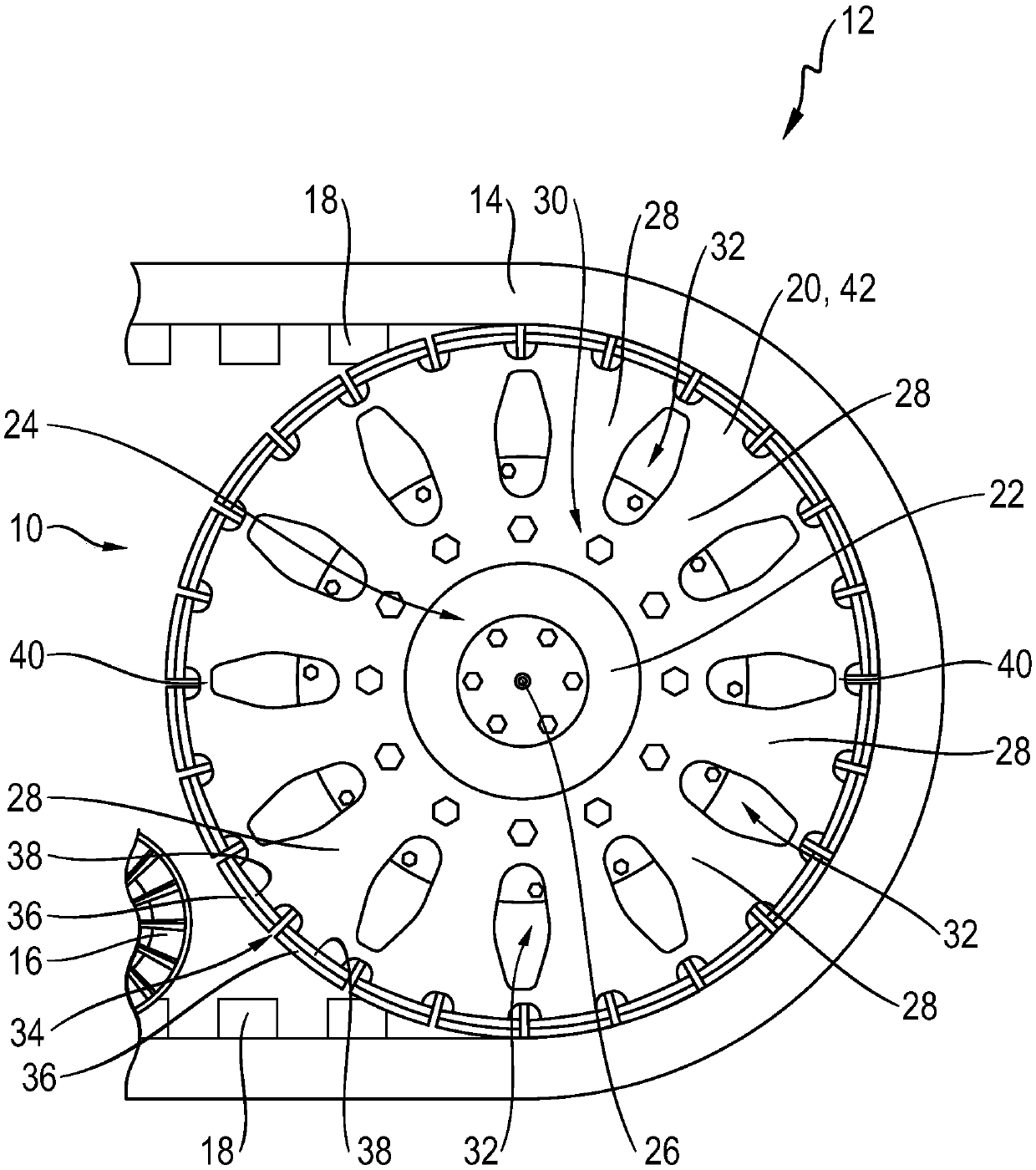

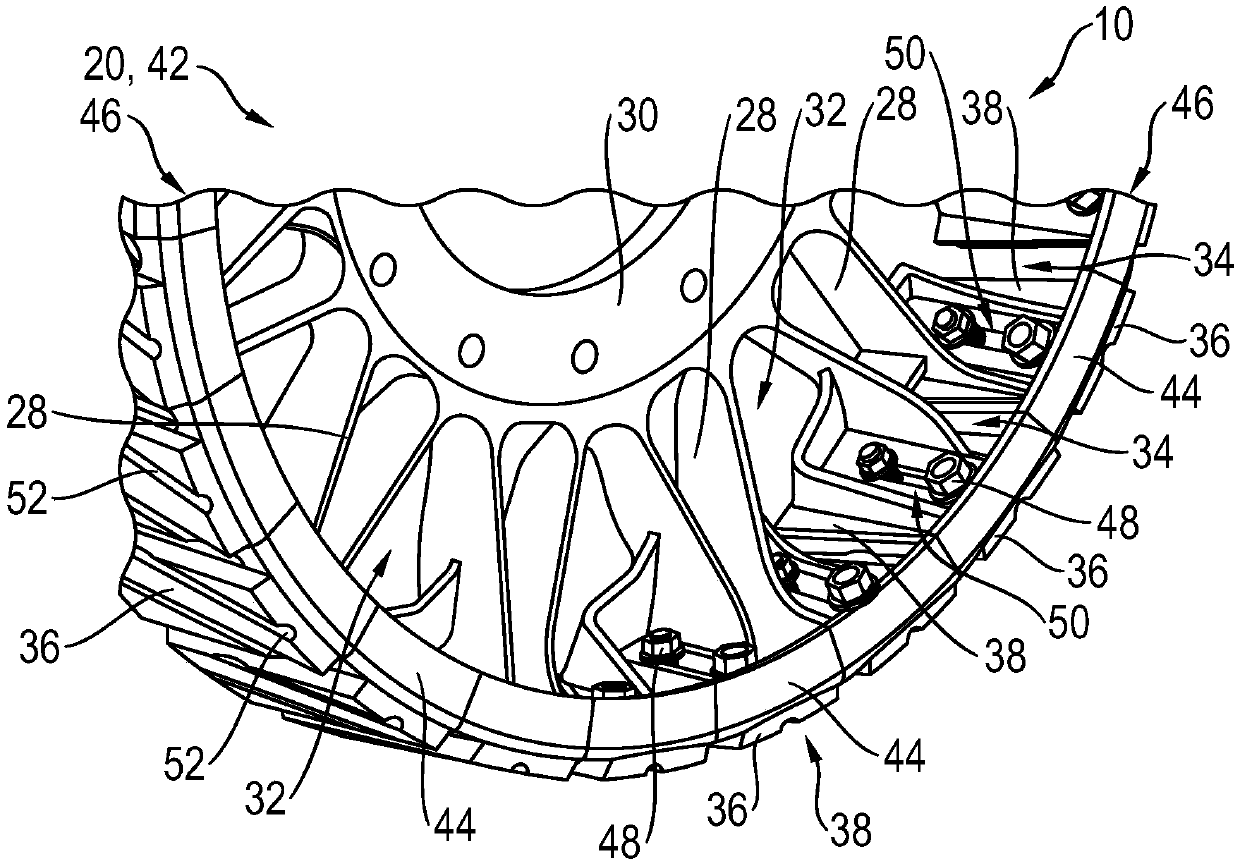

Drive wheel for crawler running gear

A driving wheel (10) for a crawler running gear (12) of an agricultural working machine, comprising at least one drive wheel (20, 42) for driving the elastic crawler belt ( 14). According to the invention, the at least one drive wheel (20, 42) has a carrying arm (28) which extends radially in the form of a spoke from the axis of rotation (26) of the drive wheel (20, 42), and At least one gap (34) is formed between two adjacent carrying arms (28) on the radially outer side, and at least one friction element (36) is respectively arranged on the carrying arms (28) on the radially outer side, with The arrangement is in particular releasable for cooperating force-lockingly with the track (14).

Owner:CLAAS INDTECHN

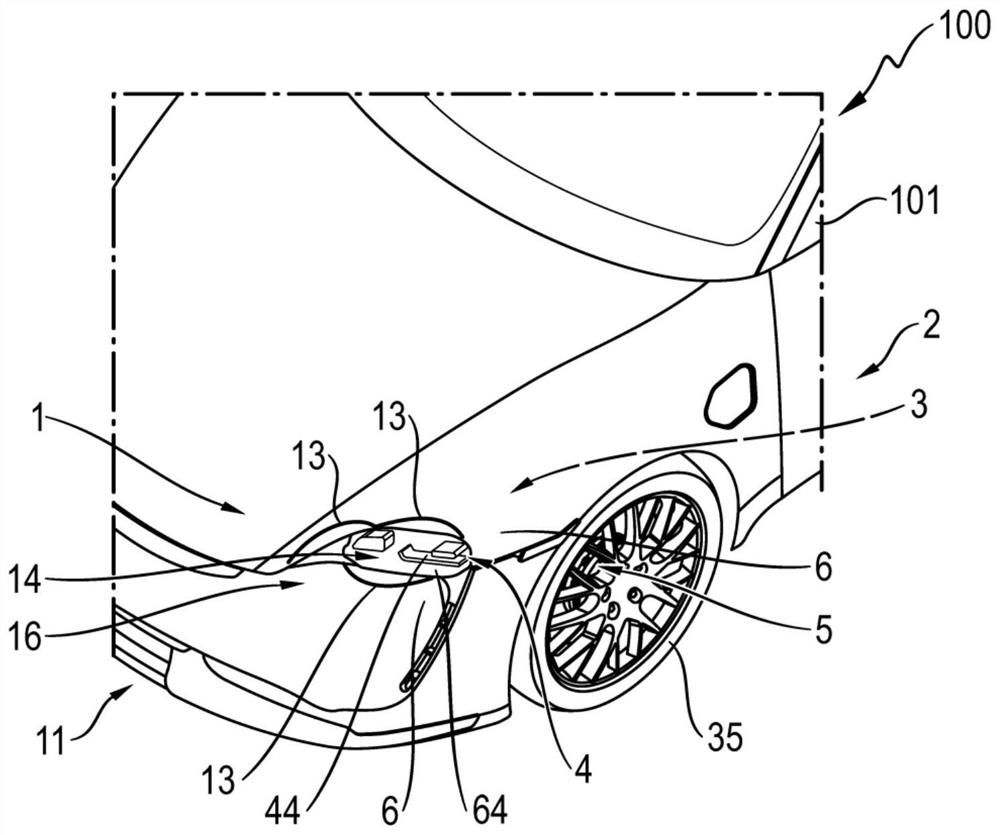

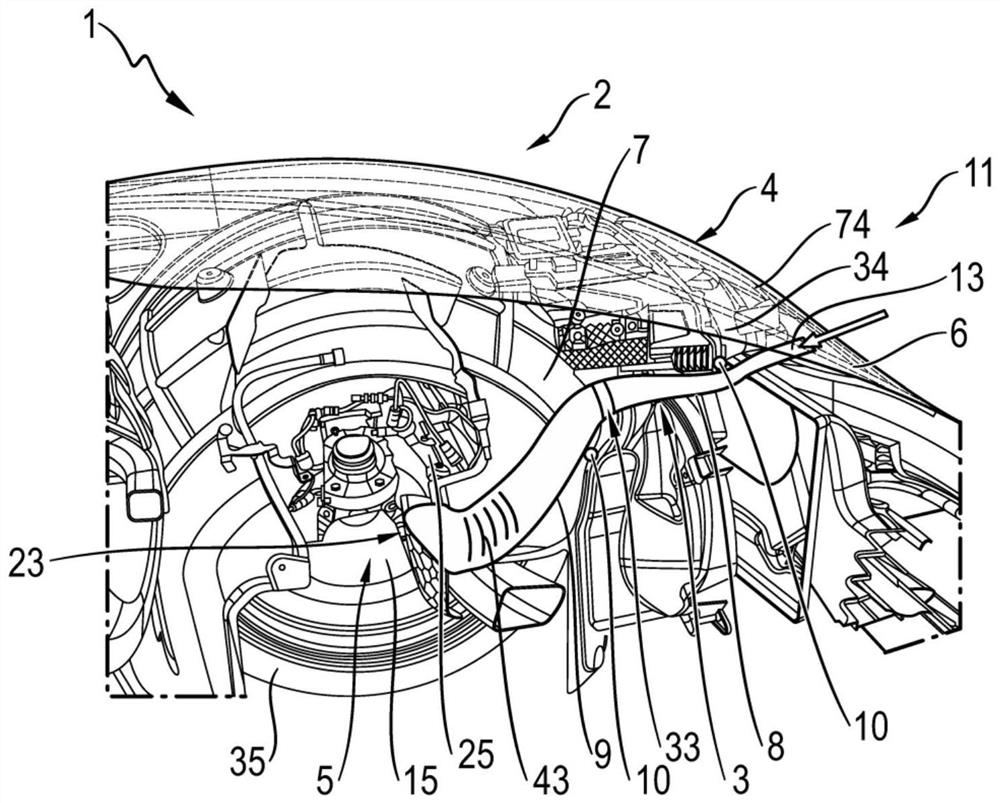

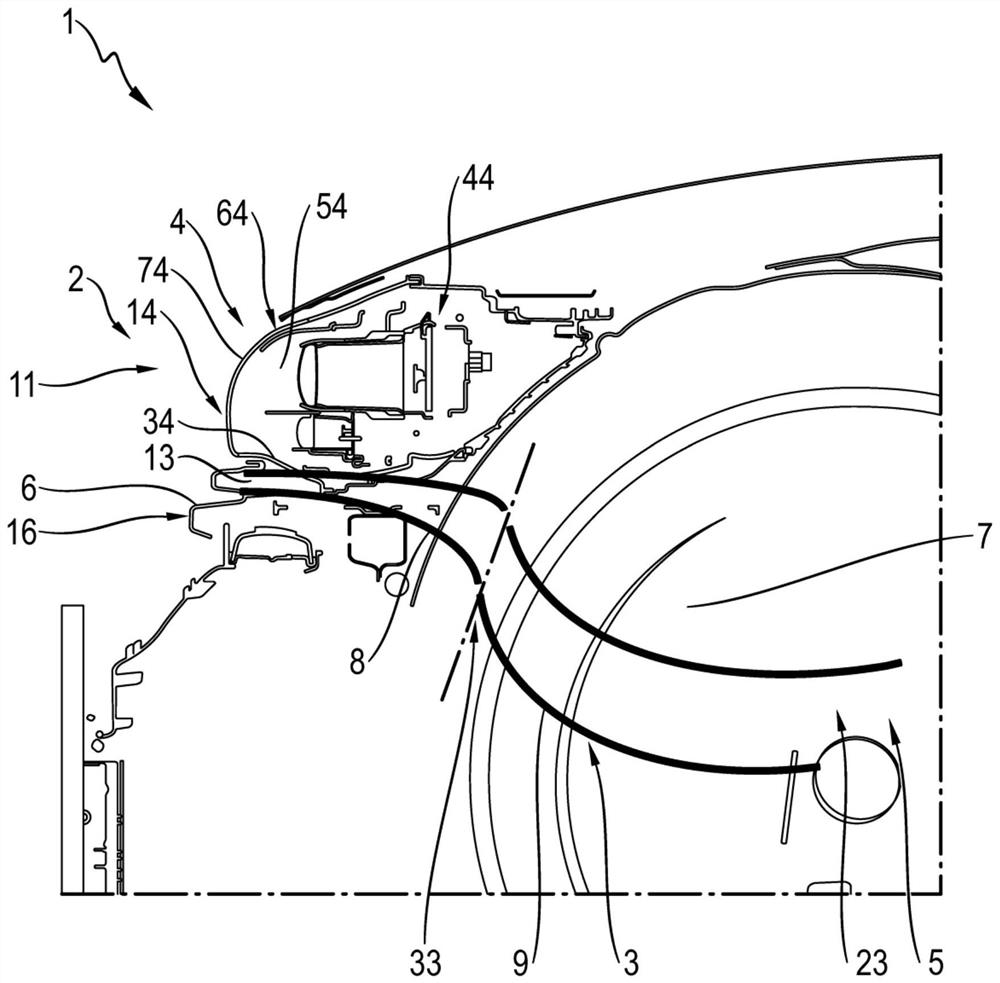

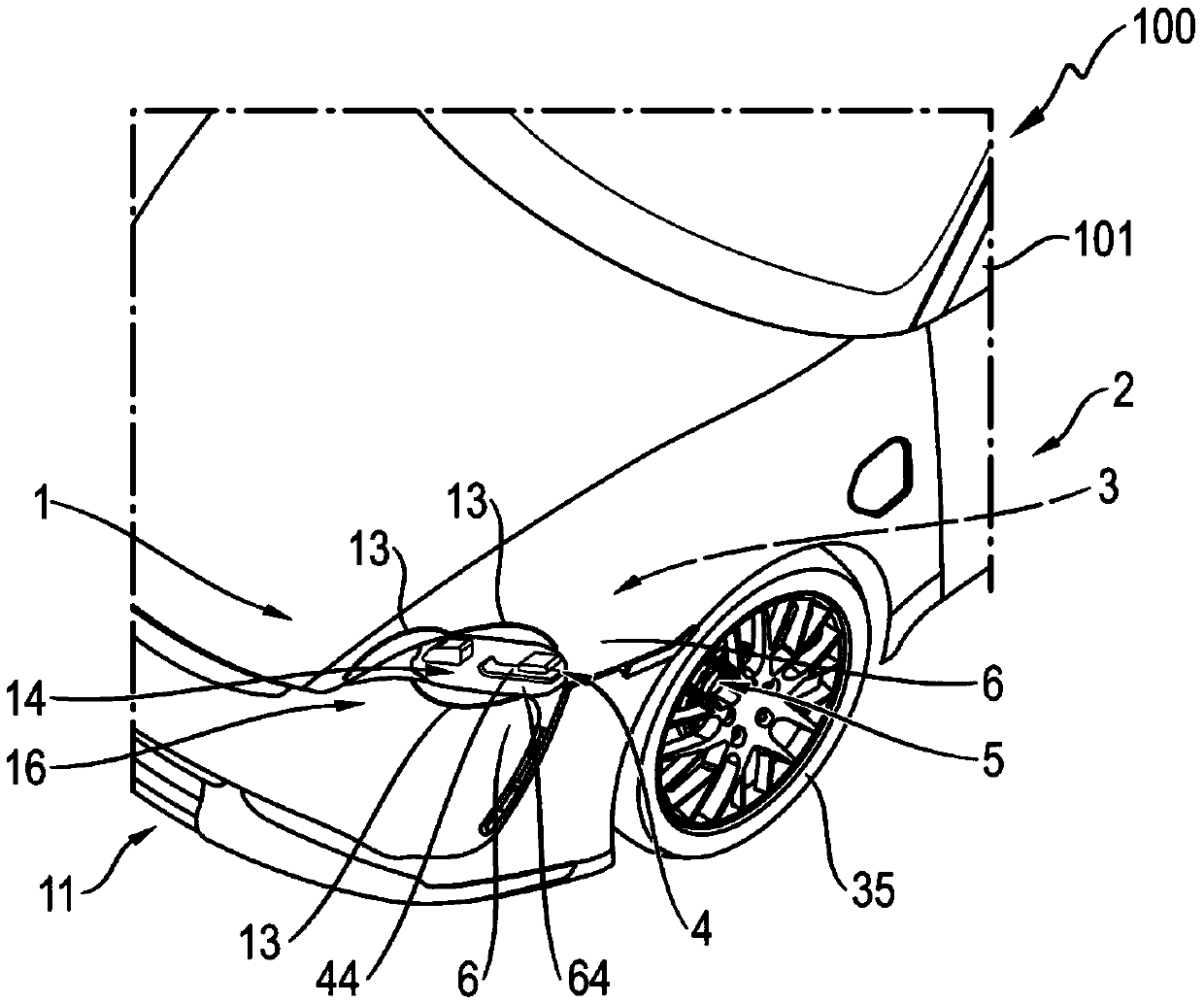

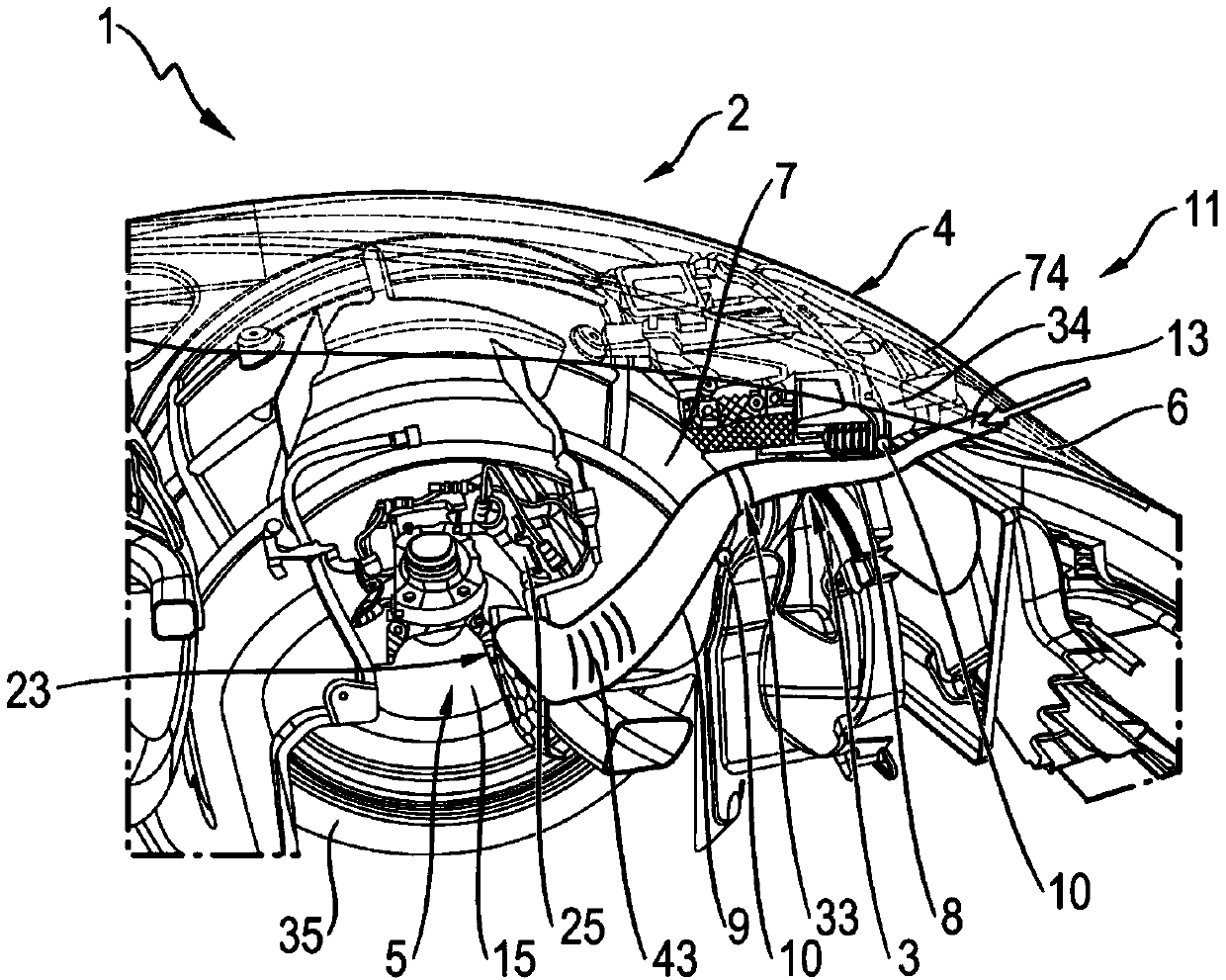

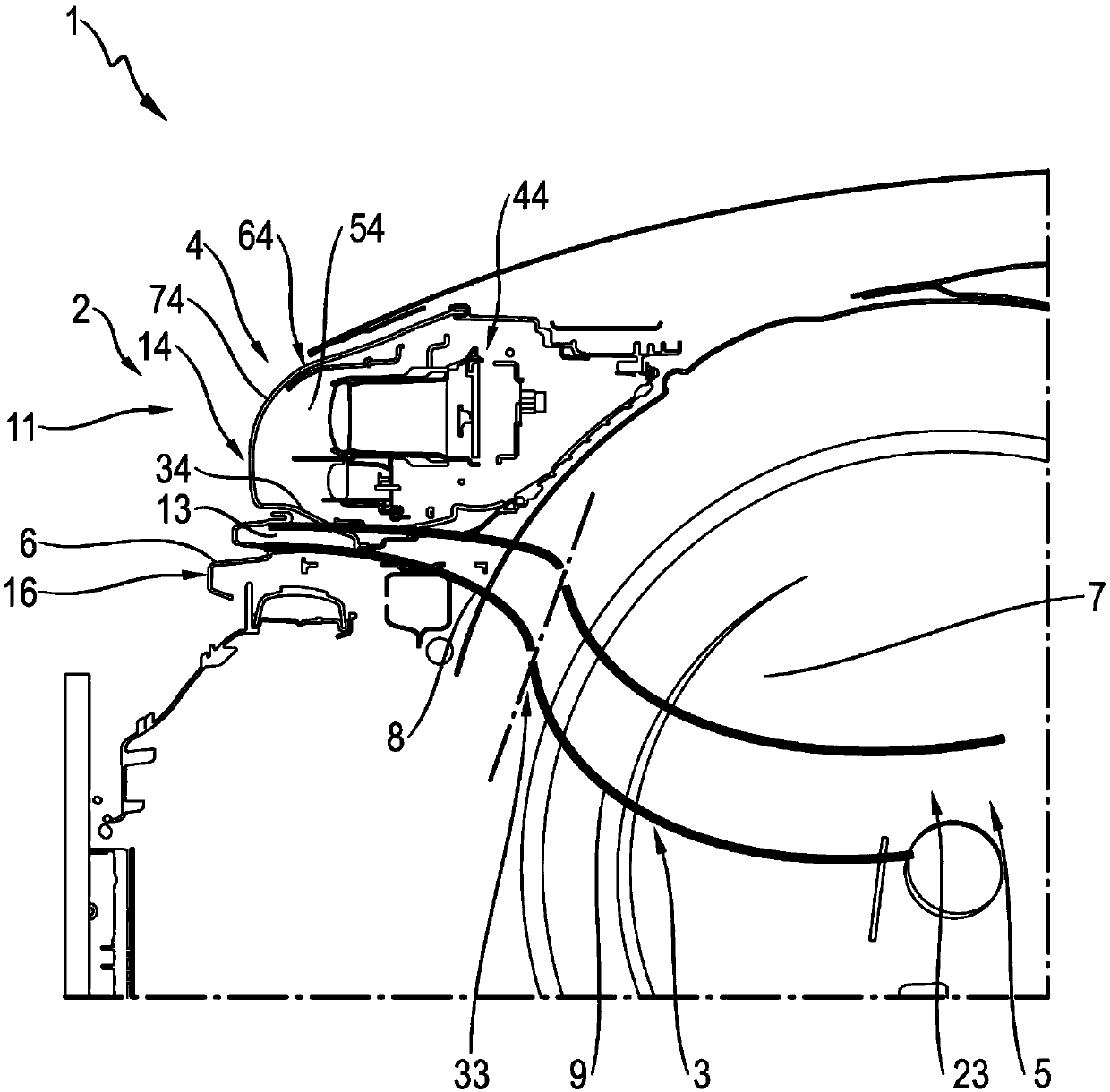

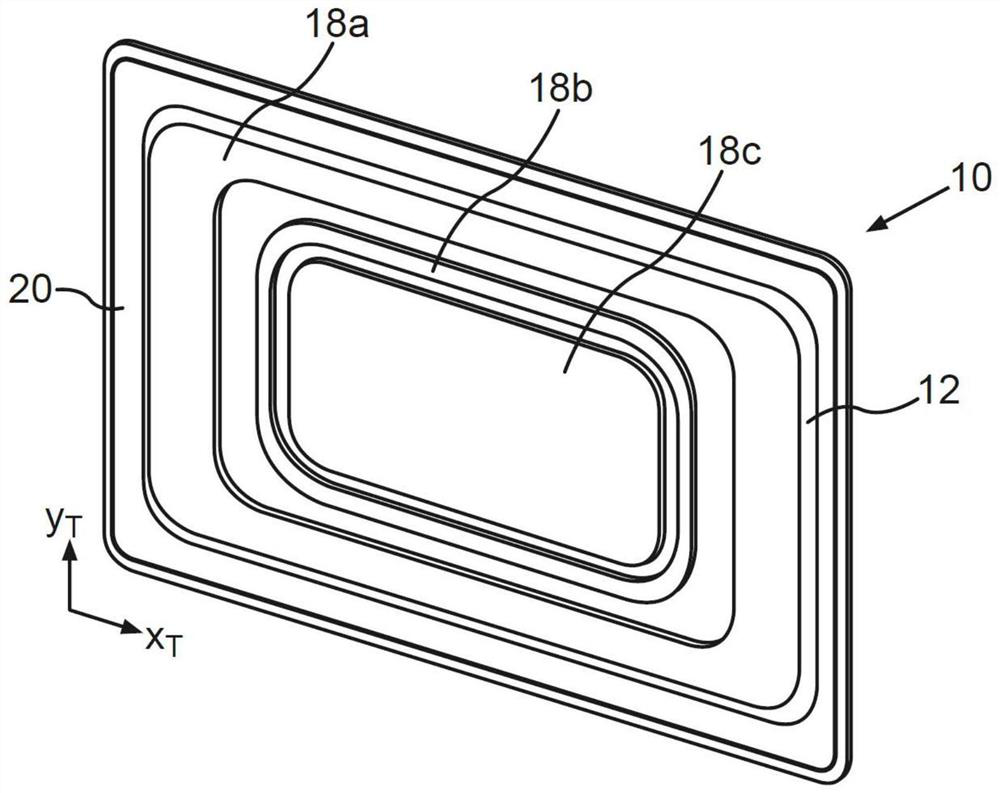

Vehicle component structures and motor vehicles

ActiveCN109677370BPrevent foggingReliable exportLighting heating/cooling arrangementsPassengers carsThermodynamicsMotorized vehicle

Owner:DR ING H C F PORSCHE AG

A vehicle component structure and a motor vehicle

ActiveCN109677370APrevent foggingReliable exportLighting heating/cooling arrangementsPassengers carsEngineeringMotorized vehicle

The invention relates to a vehicle component structure (1) including a cooling device (2). The cooling device is provided with an air passage system (3) for guiding a cooling air stream. The air passage system has an inlet opening (13). The cooling air stream can be conveyed through the air passage system (3) to at least one lighting lamp device (4) and at least one brake device (5), and therefore, waste heat of the lighting lamp device and the brake device can be discharged by the cooling air stream.

Owner:DR ING H C F PORSCHE AG

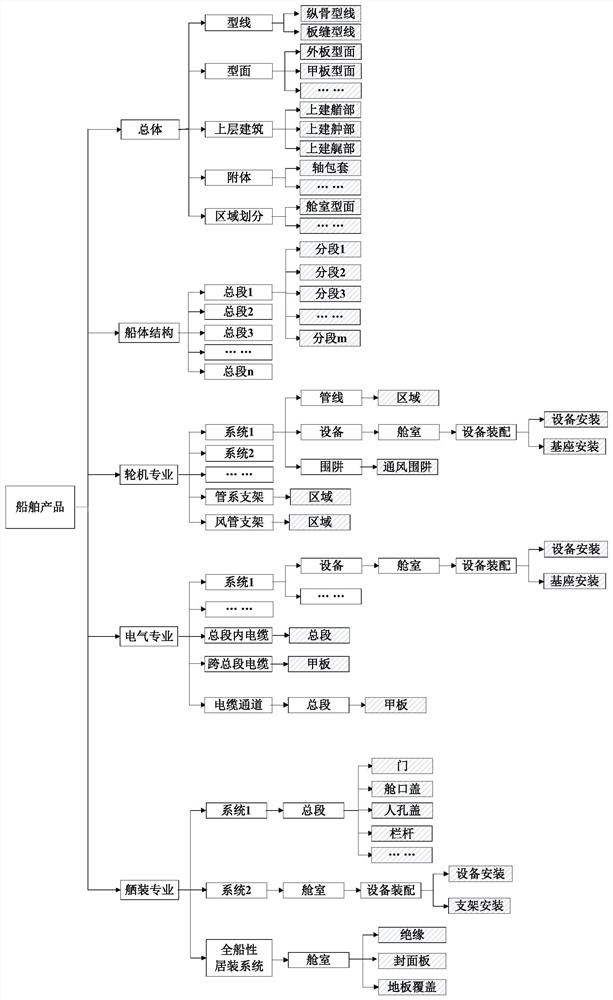

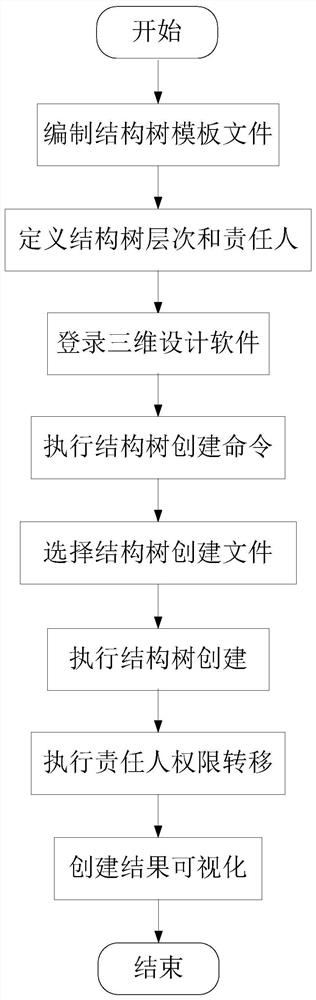

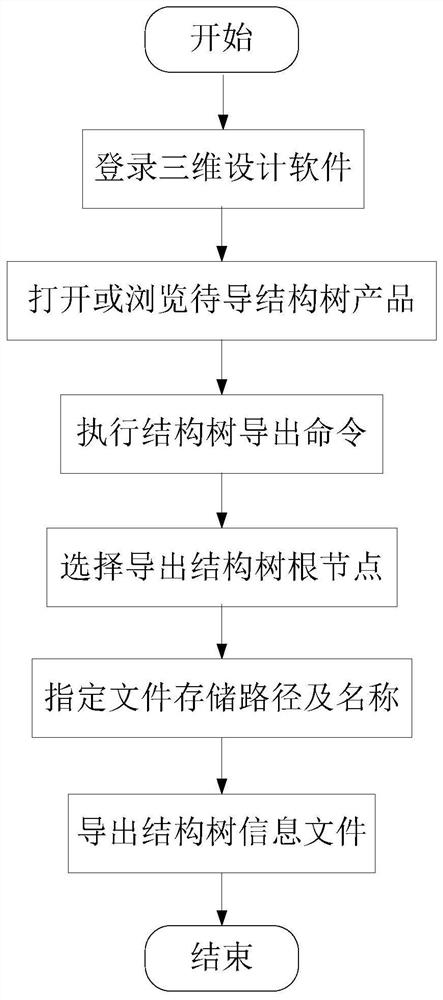

Method for quickly creating and exporting large ship product structure tree and electronic equipment

PendingCN113591209AReasonable organizational formOrganization Form SpecificationGeometric CADSpecial data processing applicationsData miningDatabase

The invention relates to the technical field of ship three-dimensional design, in particular to a method for quickly creating and exporting a large ship product structure tree and electronic equipment. On the basis of the minimum delivery unit result, ship product structure levels are reasonably planned, and the overall, hull structure, turbine specialty, electrical specialty and fitting-out specialty are covered, so that the creation and export of a subsequent structure tree are more efficient, stable and reliable; a structure tree rapid creation method is adopted to structurally define product structure levels and structure tree node responsible persons based on a pre-compiled template file, a product structure tree is rapidly generated through a program, responsible person node permission transfer is achieved, thousands of nodes can be created at a time, creation results are output in a tabular mode, and the creation of the product structure tree is quicker and more visual; according to the structure tree rapid export method, structure tree information can be automatically exported in a file form by one key for a product structure tree formed in the design process, and rapid and convenient export of the structure tree information can be realized.

Owner:CHINA SHIP DEV & DESIGN CENT

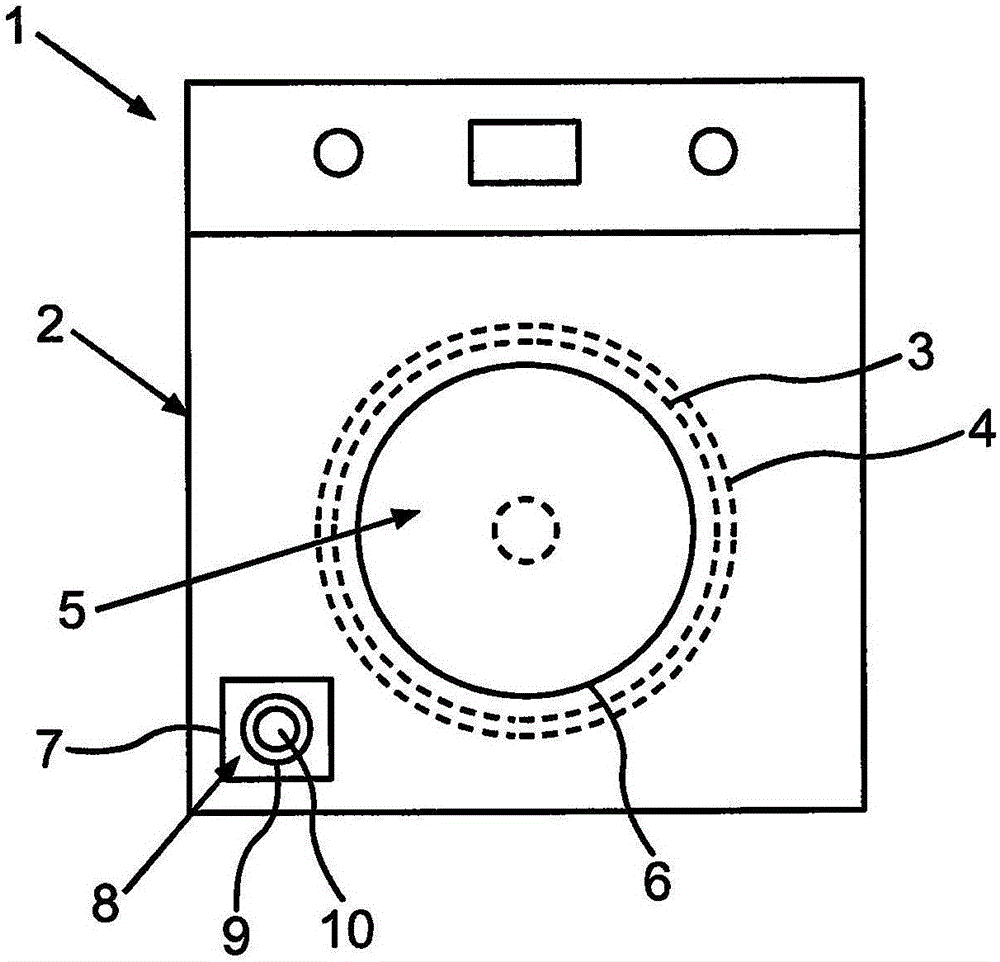

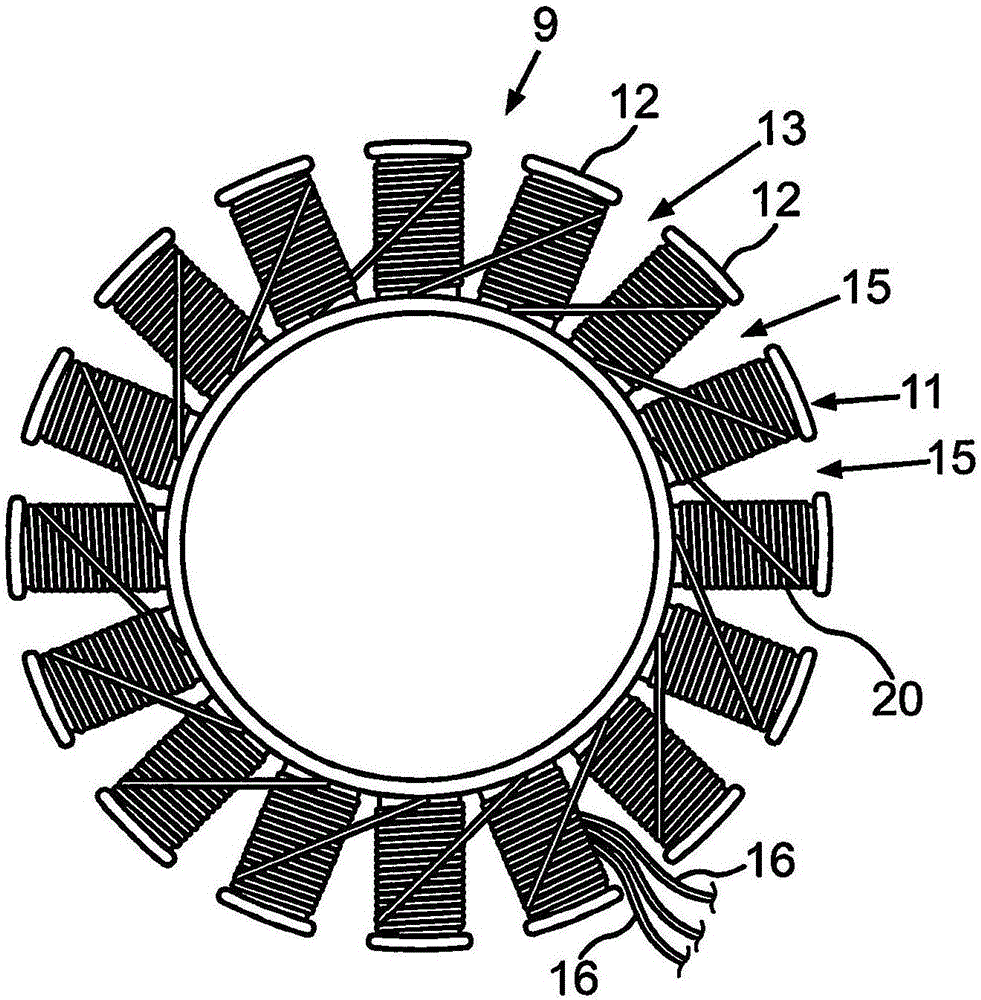

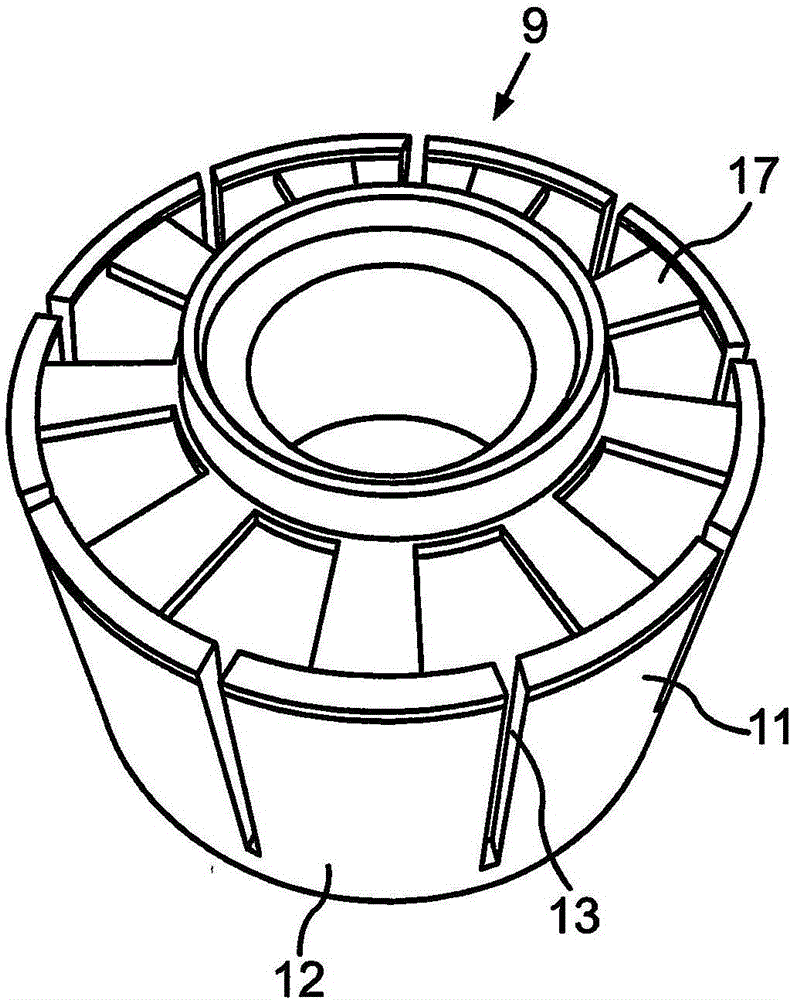

Motor FOR HOUSEHOLD APPLIANCE, PUMP, HOUSEHOLD APPLIANCE AND METHOD FOR MANUFACTURING MOTOR

InactiveCN107528440AEasy dischargeReduce current loadWindings insulation shape/form/constructionMagnetic circuit characterised by insulating materialsSynchronous motorElectric machine

The invention relates to a motor (8) for a household appliance (1), wherein the motor (8) is designed as a synchronous motor, with a stator (9) having a stator body (11) and a winding (14), and a rotor (10). The stator (9) is encapsulated at least in regions with protective material (17); the rotor is rotatable relative to the stator (9) and has at least one permanent magnet; and the winding (14) of the stator (9) is formed multi-phase.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Separating device for a battery module, battery module, and motor vehicle

ActiveCN112864506AReliable exportCell temperature controlCell component detailsEngineeringMechanical engineering

Owner:AUDI AG

Long-stroke moving coil structure for electrodynamic shaker

ActiveCN105300640BAvoid damageTransfer is not affectedVibration testingShock testingEngineeringUltimate tensile strength

The invention relates to the technical field of electrodynamic vibration generator for testing, and specifically discloses a long-stroke drive coil structure for an electrodynamic vibration generator. The long-stroke drive coil structure designs a structure for fixing a drive coil in the vibration generator as a form including upper and lower bracing frames which form a double bracing frame structure so that the drive coil can be rolled between the upper and lower bracing frames. The two bracing frames are fixed through a connection rod, and transmit the exciting force so that the connection strength after lengthening of the drive coil of the vibration generator and the transmission of force are not influenced; therefore the drive coil and the drive coil bracing frames do not release from the skeleton because of low bonding intensity between the drive coil and the drive coil bracing frames so as to prevent damaging of the drive coil; at the same time, the guiding mode of the drive coil is modified; guiding bars are respectively arranged on the drive coil bracing frames to realize overall guiding of the drive coil structure and to improve the guiding performance; and the lower guiding bar is also provided with a lead slot so that a wiring function is also provided and a service conductor of the drive coil can be led out reliably and the whole vibration generator can stably and safely work.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

Rivet setting device with automatic rivet mandrel export mechanism

Currently, the rivet cores separated from the riveting tool have to be guided into the rivet core container by the operator of said riveting tool by means of a suitable movement of the rivet setting device. The invention automates this process and thereby ensures precise and process-reliable operation of the riveting tool. This reduces breakdowns and reduces cycle times when using the appliance.

Owner:ROBERT BOSCH GMBH

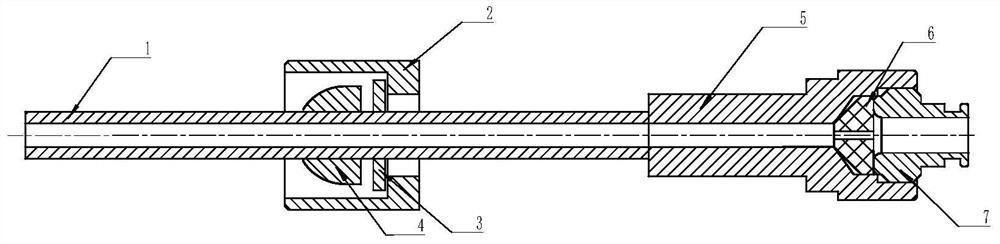

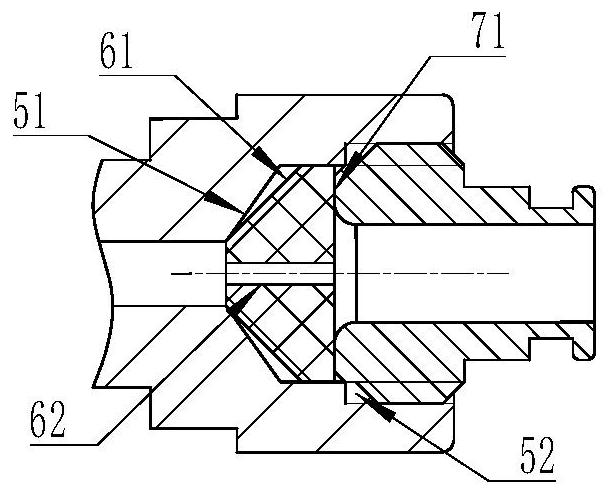

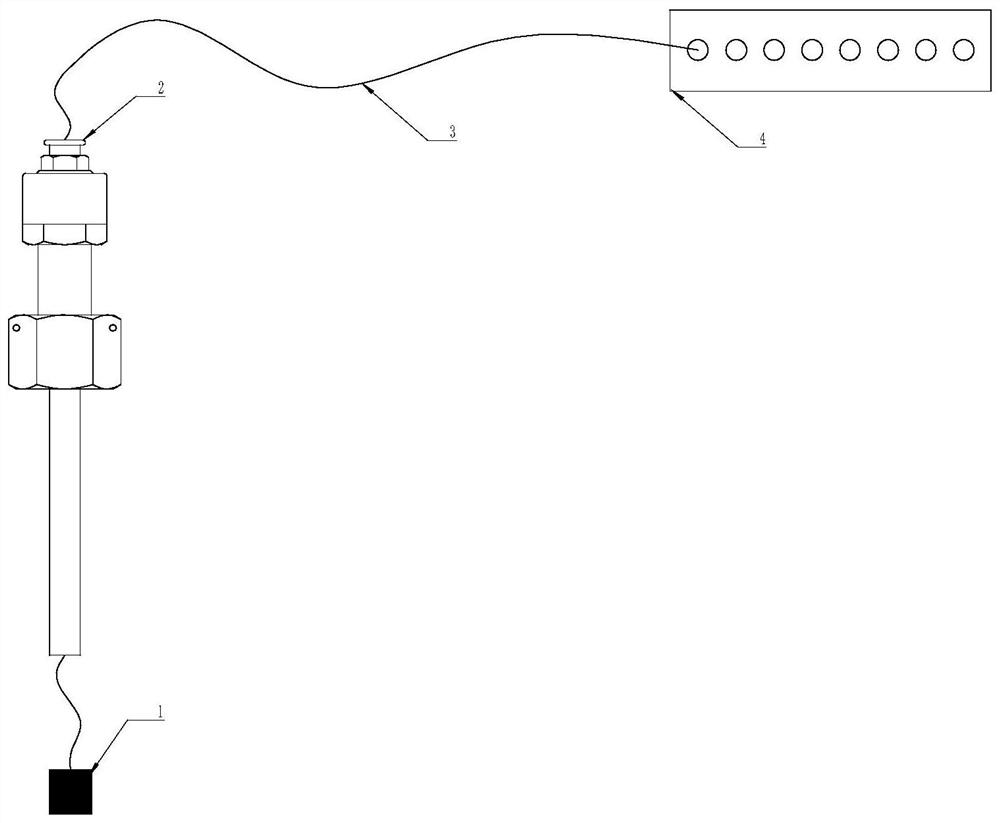

Device for leading out sensor cable in ultralow-temperature high-pressure environment and installation method thereof

PendingCN113640138AEasy to installGuaranteed tightnessMaterial strength using tensile/compressive forcesRocket engine plantsElectric cables

Owner:BEIJING AEROSPACE PROPULSION INST

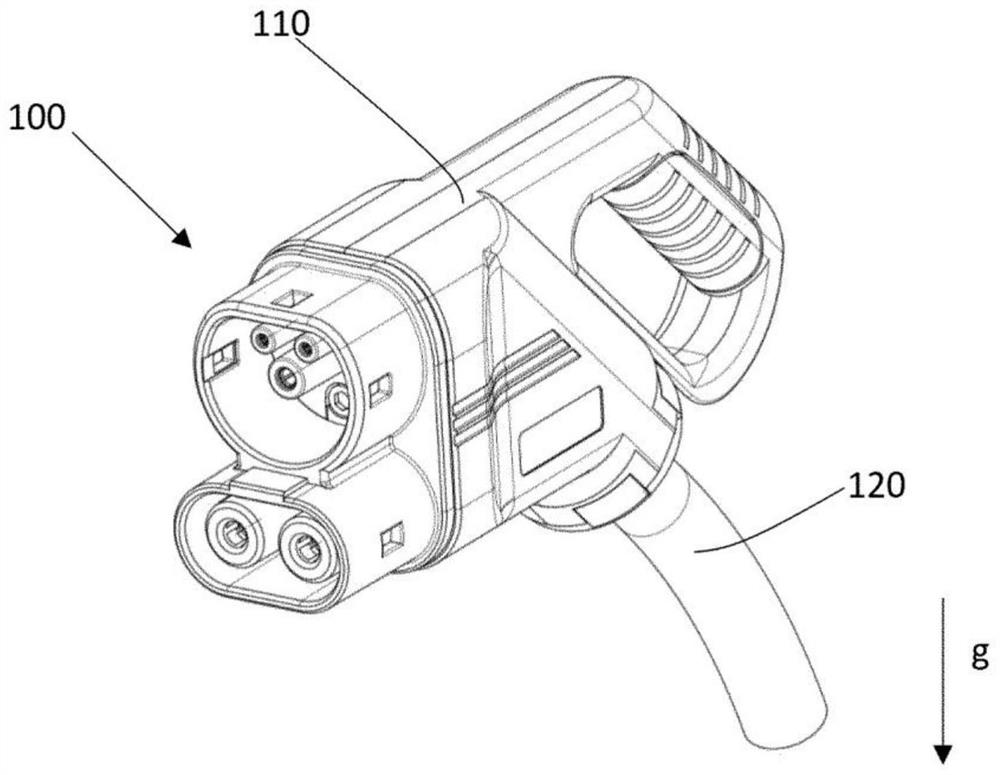

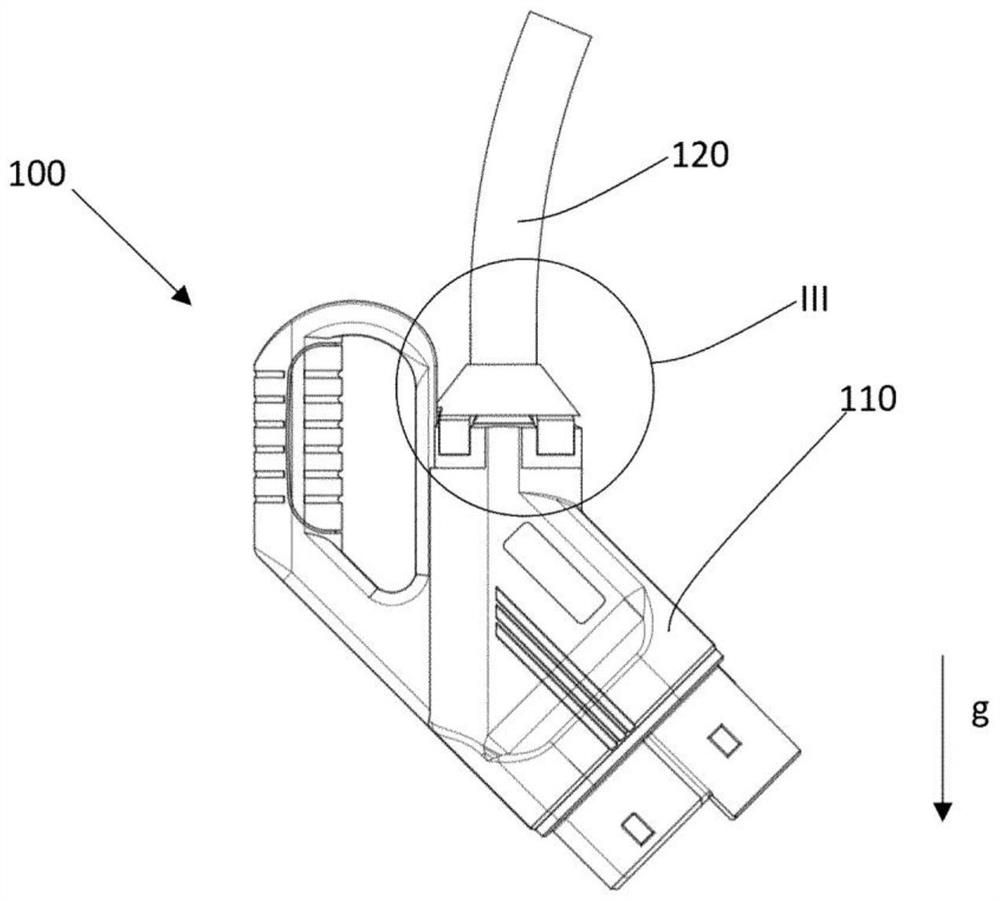

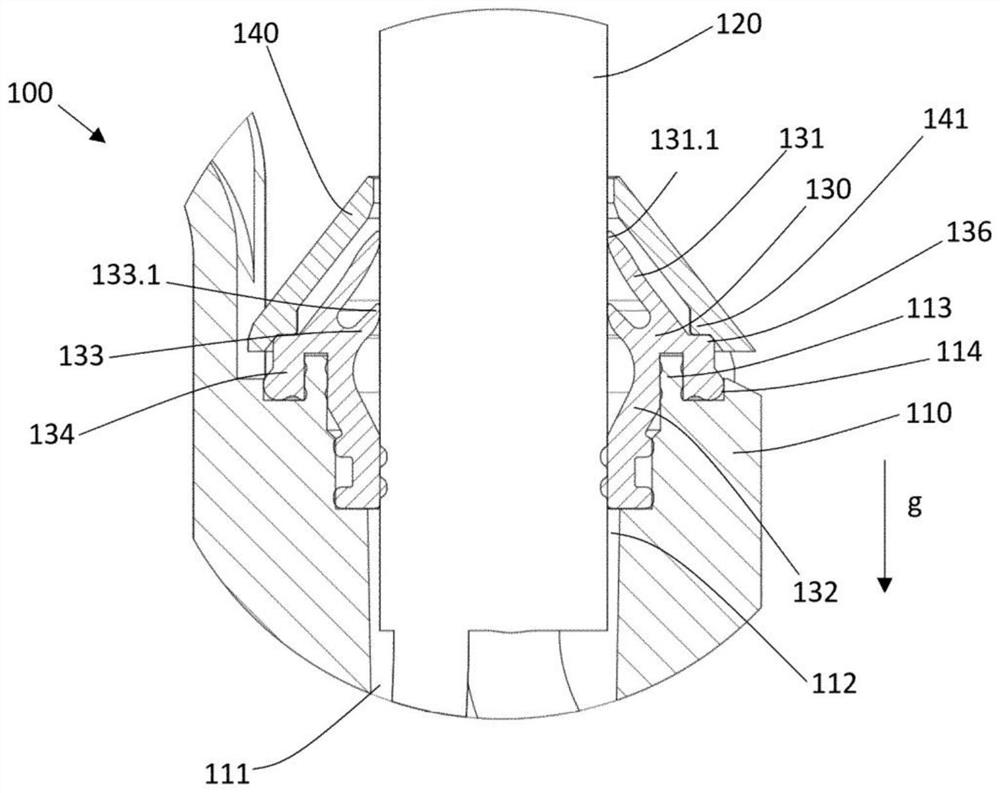

Plug connector

PendingCN114342188AAvoid enteringReliable exportVehicle connectorsCharging stationsStructural engineeringElectric cars

The invention relates to a plug connector for charging an electric vehicle, comprising: a housing (110), which defines a housing interior (111); a cable (120) guided through an opening (112) of the housing (110) into the housing inner cavity (111); the invention relates to a cable assembly (100) comprising a housing (110) having a housing inner cavity (111), a cable (120) arranged in the housing (110), a seal (130) arranged between the cable (120) and the housing (110) to seal the housing inner cavity (111), the seal (130) having a sealing lip (131) surrounding the cable (120) and resting on the cable (120), and the seal (130) having a sealing tab (132) surrounding the cable (120) and resting on the housing (110).

Owner:PHOENIX CONTACT E MOBILITY

Regulating device and method for drying and temperature regulation of ballast bed

Conditioning device (24) and method for drying and / or controlling the temperature of a ballast bed (12) of a railway track system (10), wherein the railway track system (10) has sleepers (14) resting on the ballast bed (12) and rails (16) resting on the sleepers, wherein the conditioning device has a bogie (30) for moving the conditioning device (24). An outlet nozzle (36) for blowing temperature-controlled air into the ballast bed (12) via at least one blowing-in region (26) positioned between two adjacent sleepers (14) is connected to the bogie (30), as is at least one cover plate (42) for essentially air-tight coverage of an upper side, pointing essentially in the direction counter to the direction of gravity, of a side strip (20), provided next to the sleepers (14) in the direction of travel, of the ballast bed (12). In a method for drying and controlling the temperature of a ballast bed (12) of a railway track system (10), an upper side of the ballast bed (12) and / or at least one sleeper (14) and at least one rail (16) are sealed in an essentially air-tight fashion outside a blowing-in region (26) before temperature-controlled air is blown into the ballast bed (12) via the blowing-in region (26).

Owner:COVESTRO DEUTSCHLAND AG

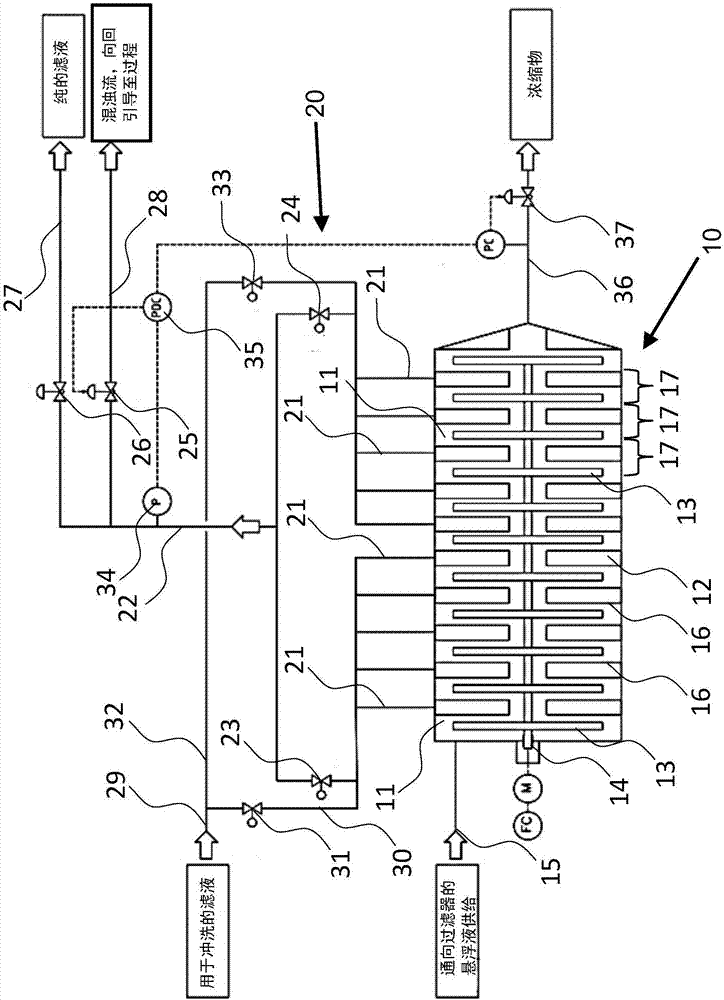

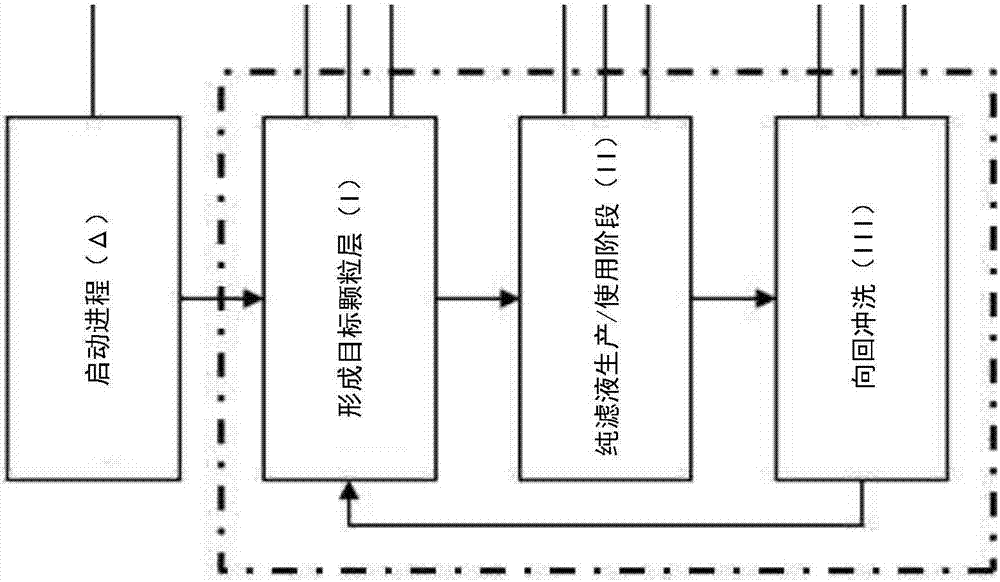

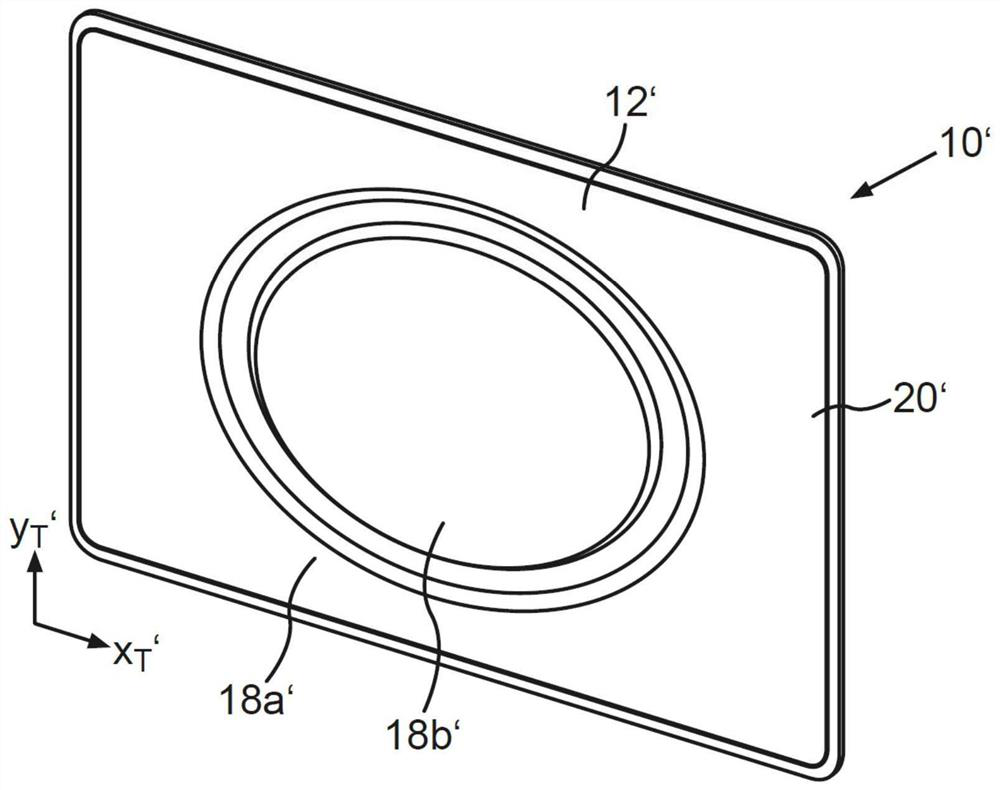

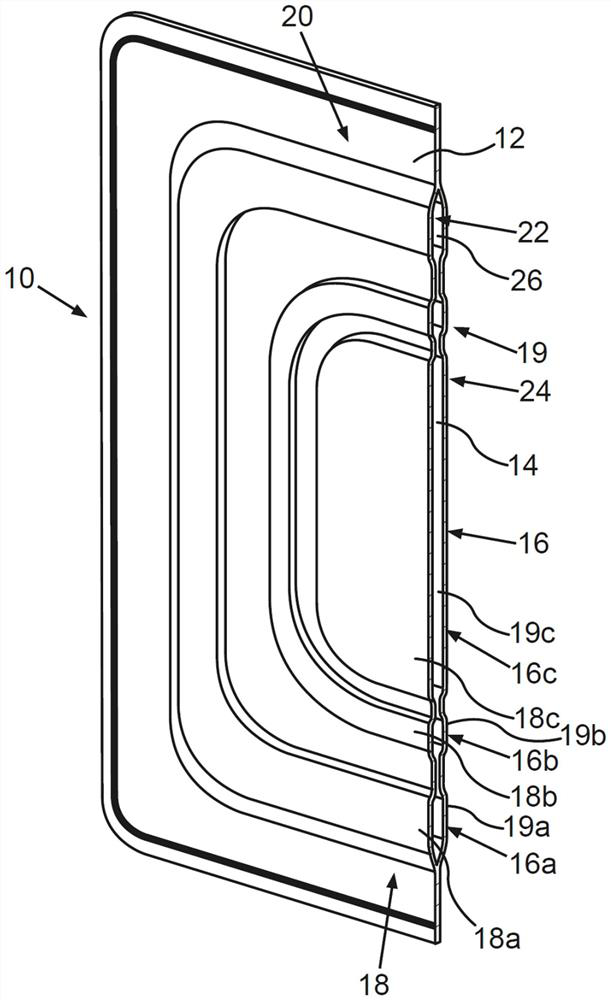

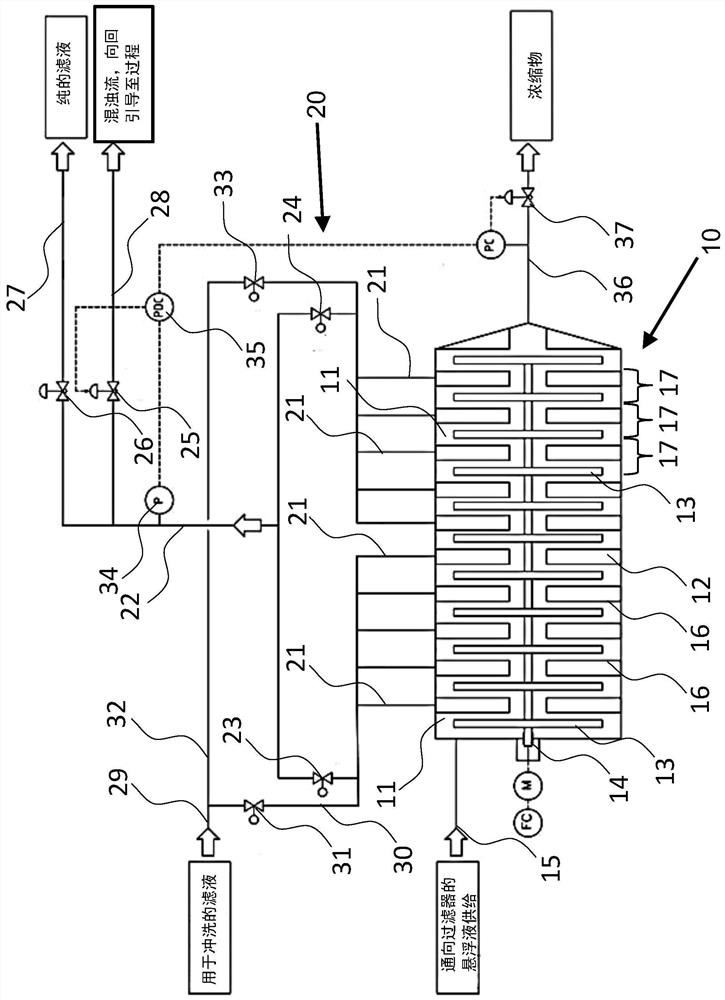

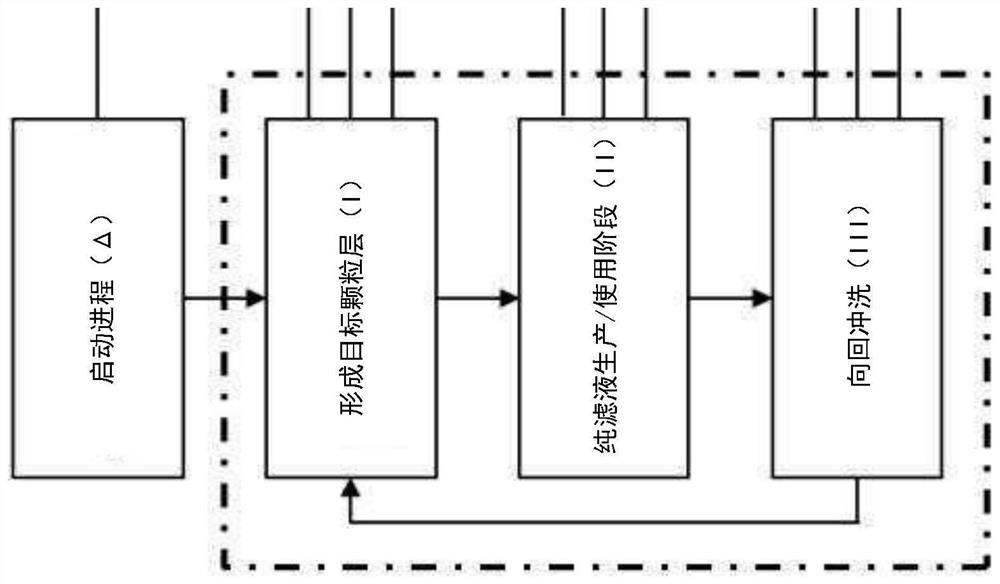

Method and device for separation of a suspension by means of a cross-flow filtration into a concentrate and a filtrate

ActiveCN107335276AImproved filtrate mobilityPrevent excessive solids concentrationFiltration circuitsStationary filtering element filtersCross-flow filtrationEngineering

The invention relates to a method and device for separation of a suspension by means of a cross-flow filtration into a concentrate and a filtrate. The suspension is introduced into a suspension chamber with a plurality of chamber-like modules arranged in series, in each of which an annular separating element with a separating surface is provided, in each module, at least one stirring member with radially arranged stirring elements in the suspension chamber moves a small distance over the separating surface relative thereto, so that a directed flow transverse to the separating surface is produced in a gap between the stirring member and the separating surface. A differential pressure is set between the suspension chamber and a filtrate chamber for filtering, the filtrate, which penetrates the separating element due to the differential pressure, is derived via a filtrate pipeline while the remaining suspension in the suspension chamber is concentrated to be a concentrate which is derived from the suspension chamber via a drain. A screen is used as a separating element, which has a mean pore size greater than the average particle size of the solid in the suspension, on which a permeable target particle layer is targetedly filtered, which is designed for separation of particles or for producing a pure filtrate.

Owner:BOKELA INGGES FUR MECHANISCHE VERFAHRENSTECHN

Length-adjustable connecting rod with hydraulic control device

InactiveCN111005805AReduce heat loadExtended run timeConnecting rodsEngine controllersPhysicsGudgeon pin

The invention relates to a length-adjustable connecting rod with a hydraulic control device, wherein the connecting rod has a first connecting rod hole for accommodating a piston pin and a second connecting rod hole for accommodating a crankshaft journal, wherein the distnace between the piston pin and the crankshaft journal can be adjusted in the longitudinal direction of the connecting rod by means of the hydraulic control device with a hydraulic control valve. The hydraulic control device has a control cylinder, a control slide block which is movably guided in the control cylinder and can be applied with a pressure, and at least one exhaust valve which can be controlled by the control slide block. The exhaust valve is connected with an exhaust channel without over-pressure so as to output the exhausted hydraulic medium to an environment. The invention further relates to application of the length-adjustable connecting rod with the hydraulic control device, and a corresponding pistontype engine.

Owner:IWIS MOTORSYSTEME GMBH & CO KG +1

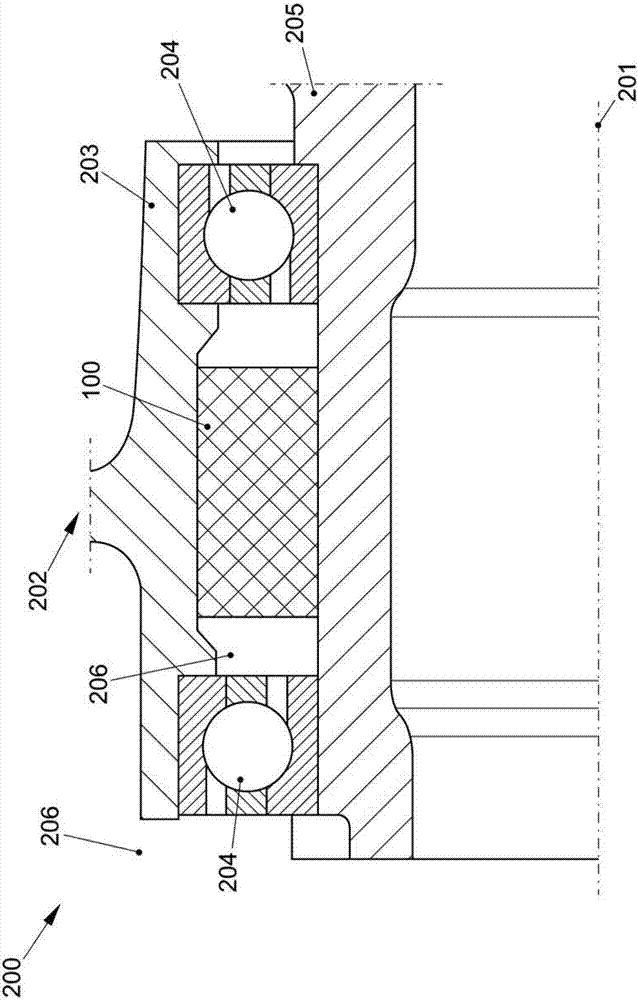

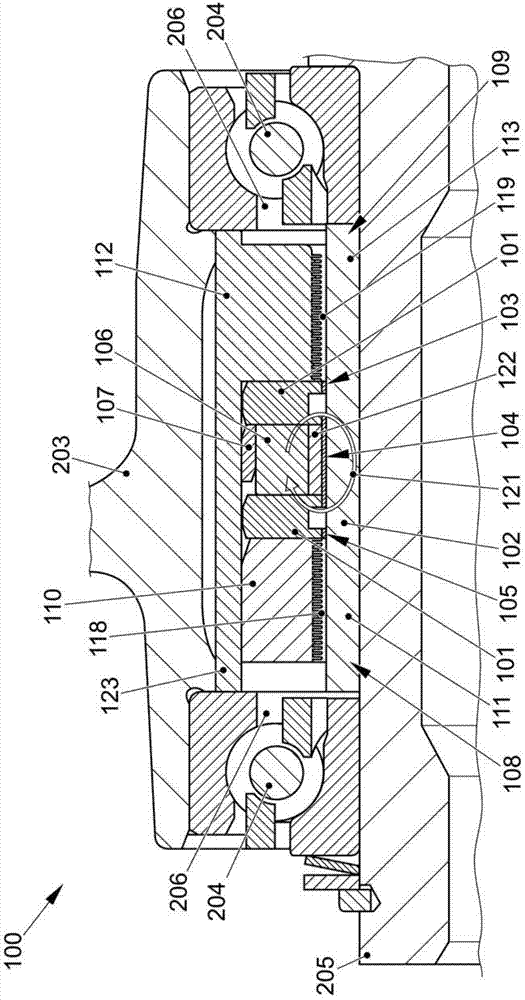

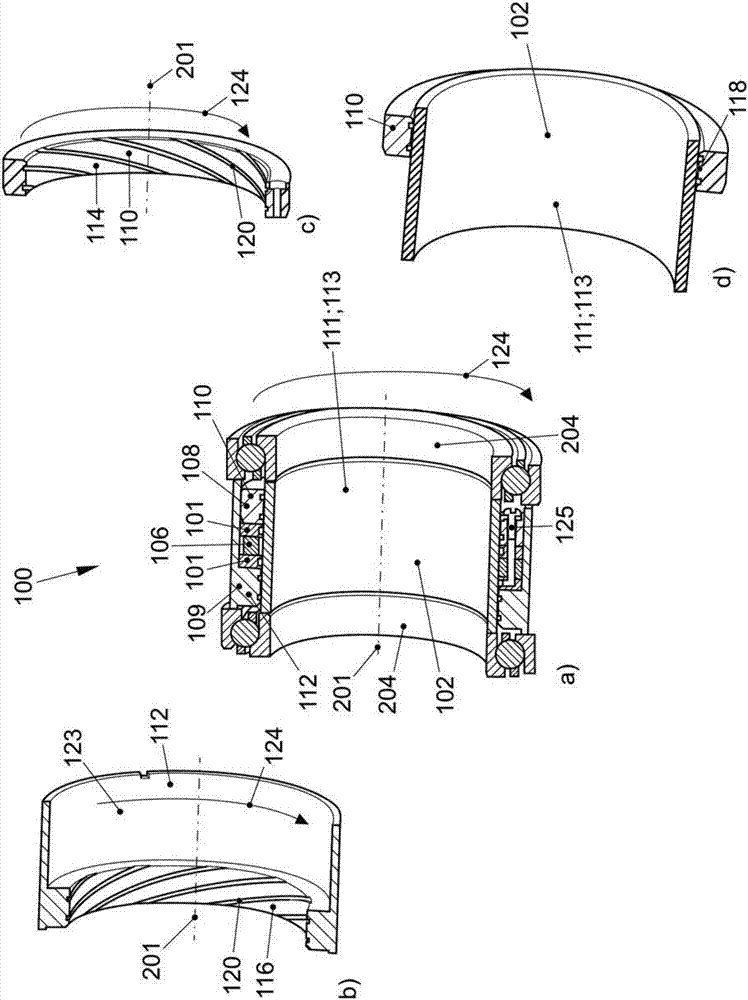

Contact arrangement for electric machine as well as related motor and traffic tool

ActiveCN107453521AAffect functionalityGuaranteed functionalityRotary current collectorAssociation with grounding devicesElectricityElectric machine

The invention relates to an electrical contact arrangement (100) for an electrical machine (200). The arrangement comprises: a first element (202) of the machine formed with electrically conductive material is movable, in particular rotatable about an axis of rotation (201), relative to at least one second element formed with electrically conductive material (205) of the machine. The contact arrangement is provided for the movable, in particular rotatable about the axis of rotation for electrical connection of the electrically conductive material of the first element of the machine with the electrically conductive material of the at least one second element of the machine. In order to achieve a reliable separation of the contact arrangement from a lubricant space (206) of the machine, in which no lubricant can get into the contact arrangement, and mechanical losses, in particular by friction, is preferably at least almost completely avoided; the contact arrangement is completed with respect to the lubricant space by at least one lubricant discharge device (108, 109), wherein at least one lubricant discharge device is adapted to promote lubricant from the lubricant space against the contact to be back into the lubricant space.

Owner:VOLKSWAGEN AG

Driving wheel for crawler-type walking mechanism

The invention discloses a driving wheel (10) for a crawler-type walking mechanism (12) of an agricultural working machine. The driving wheel includes at least one driving wheel (20, 42) for driving elastic crawlers (14) of the crawler-type walking mechanism (12). According to the driving wheel, the at least one driving wheel (20, 42) is provided with bearing arms (28), the bearing arm extends in aradial direction from a rotation axis (26) of the driving wheel (20, 42) in a spoke manner, gaps (34) are formed outside the radial direction and at least between the two adjacent bearing arms (28),and at least one friction element (36) is arranged on the bearing arm (28) and outside the radial direction correspondingly for combined acting with the crawlers (14) in a force closure manner. The arrangement is carried out in particular in a manner of capable of be loosened.

Owner:CLAAS INDTECHN

Method for cleaning air cooler as well as device for carrying out the method, and air cooler equipped for the same

InactiveCN101464110BReliable Pollution ControlReliable removalCleaning heat-transfer devicesInternal combustion piston enginesEngineeringChiller

The invention relates to an air loaded air cooler (9) such as an engine. The air cooler has an area (15) designed to a heat exchanger arranged between an air inlet and an air outlet. The area contains a plurality of vertical flow passages (18) which is crossed by an uncooling air from up to down and limited by an outer cooling surface, wherein a high reliability and a long service life can be realized by that the area (15) designed to the heat exchanger is rotated about a half rotation around an axis which traverses the uncooling air and extends along the flow direction from up to down, and the area (15) designed to the heat exchanger can be loaded by the uncooling air crossing the area from up to down at an up and down reversal position which is rotated about a half rotation.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

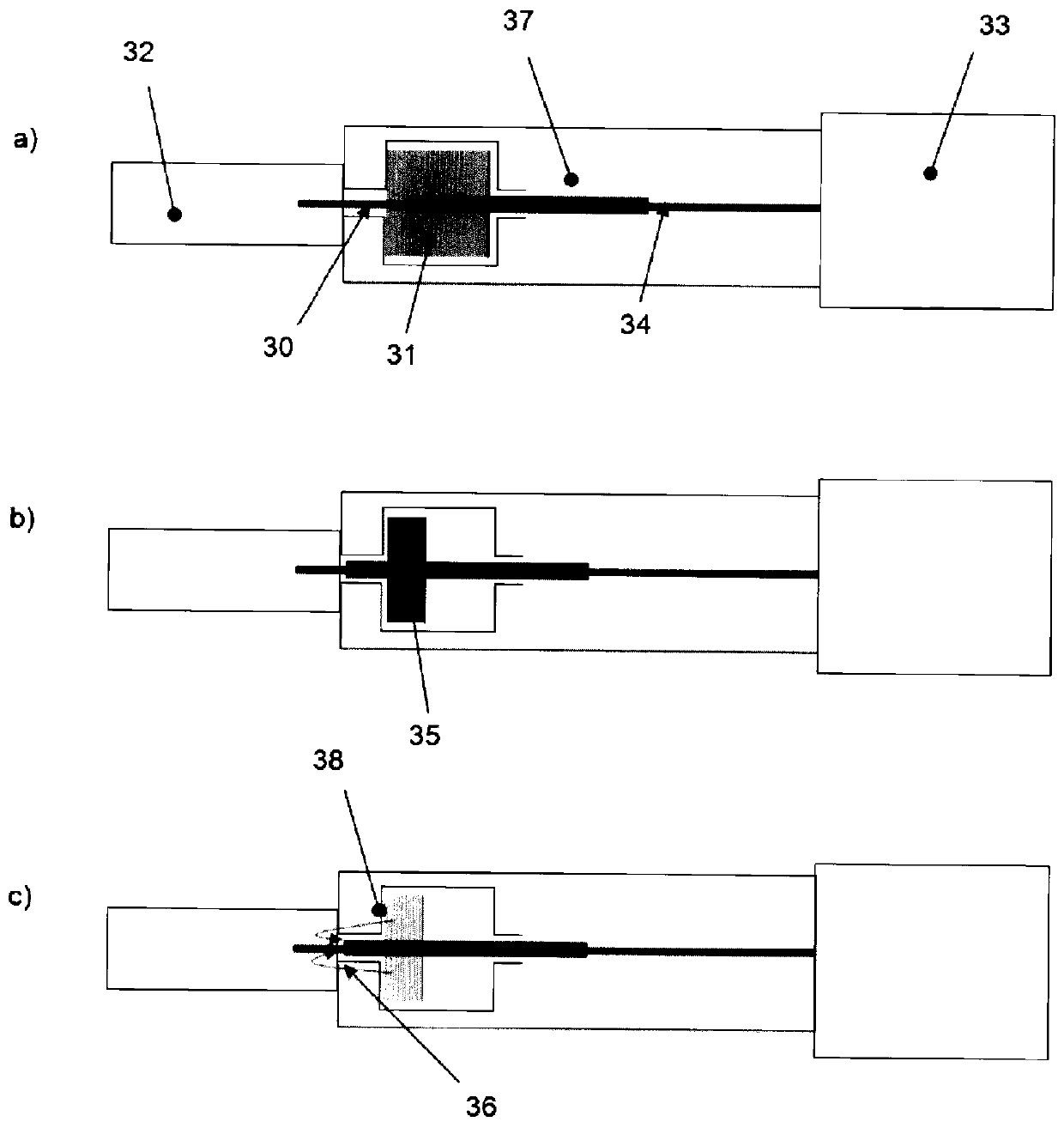

A multi-line lead-out device for a high-pressure vessel

The invention discloses a multi-wire lead-out device of a high-pressure container. A first lead, a second lead and a third lead are inserted into a hole in the middle of a T-shaped wire-leading bolt. Gaps between the first lead and the hole, between the second lead and the hole and between the third lead and the hole are filled by pouring flexible sealing resin and rigid sealant in a layered mode. The T-shaped wire-leading bolt is inserted into a metal shell of the high-pressure container. The bottom of the T-shaped wire-leading bolt is provided with a nut for connection. A first O-shaped ring and a second O-shaped ring are arranged between the T-shaped wire-leading bolt and the metal shell of the high-pressure container, and therefore gaps between the T-shaped wire-leading bolt and the metal shell of the high-pressure container are sealed. The leads are inserted into the hole in the middle of the T-shaped wire-leading bolt and the flexible sealing resin and the rigidity sealant are used for sealing. The device is novel in structure, convenient to machine, low in cost and high in applicability and has certain business popularization value.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Separating device for a battery module, battery module, and motor vehicle

PendingCN112864505AAvoid spreadingReliable exportCell temperature controlVent arrangementsAutomotive engineeringElectrical and Electronics engineering

A separating device 10 for a battery module 27. The separating device 10 includes a first separating element 12 and a second separating element 14, which are arranged congruently with respect to one another and adjacent one another. Furthermore, the first separating element 12 and the second separating element 14 enclose a chamber 16 between them, and the chamber 16 is filled with a flame-retarding and / or insulating fluid.

Owner:AUDI AG

Method and apparatus for separating a suspension into a concentrate and a filtrate by means of cross-flow filtration

ActiveCN107335276BContribute to the loadImprove structural integrityFiltration circuitsStationary filtering element filtersFiltrationPhysical chemistry

The present invention relates to a method and an apparatus for separating a suspension into a concentrate and a filtrate by means of cross-flow filtration. The suspension is introduced into a suspension chamber with a plurality of chamber-shaped modules arranged in series, in each of which an annular separating element with a separating surface is provided, in each module at least one stirring mechanism with radially arranged stirring elements In the suspension chamber, a movement is made above the separating surface at a small distance relative to the separating surface, so that in the gap between the stirring mechanism and the separating surface a directional flow is generated transversely to the separating surface. A pressure difference is set between the suspension chamber and the filtrate chamber for filtration, and the filtrate is led out through the filtrate line, and the filtrate passes through the separation element due to the pressure difference, and the suspension remaining in the suspension chamber is concentrated into a concentrate, which is discharged from the suspension chamber through the outlet elicited in. Using a sieve as the separation element, the average pore size of the sieve is larger than the average particle size of the solids in the suspension, on which the permeable target particle layer is filtered in a targeted manner, allowing it to be used for separating particles or producing a pure filtrate.

Owner:BOKELA INGGES FUR MECHANISCHE VERFAHRENSTECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com