Length-adjustable connecting rod with hydraulic control device

A technology of control device and hydraulic control valve, applied in the direction of connecting rod, engine control, shaft and bearing, etc., can solve the problems of engine knocking, quiet operation, engine parts damage, etc., to reduce thermal load and improve running time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

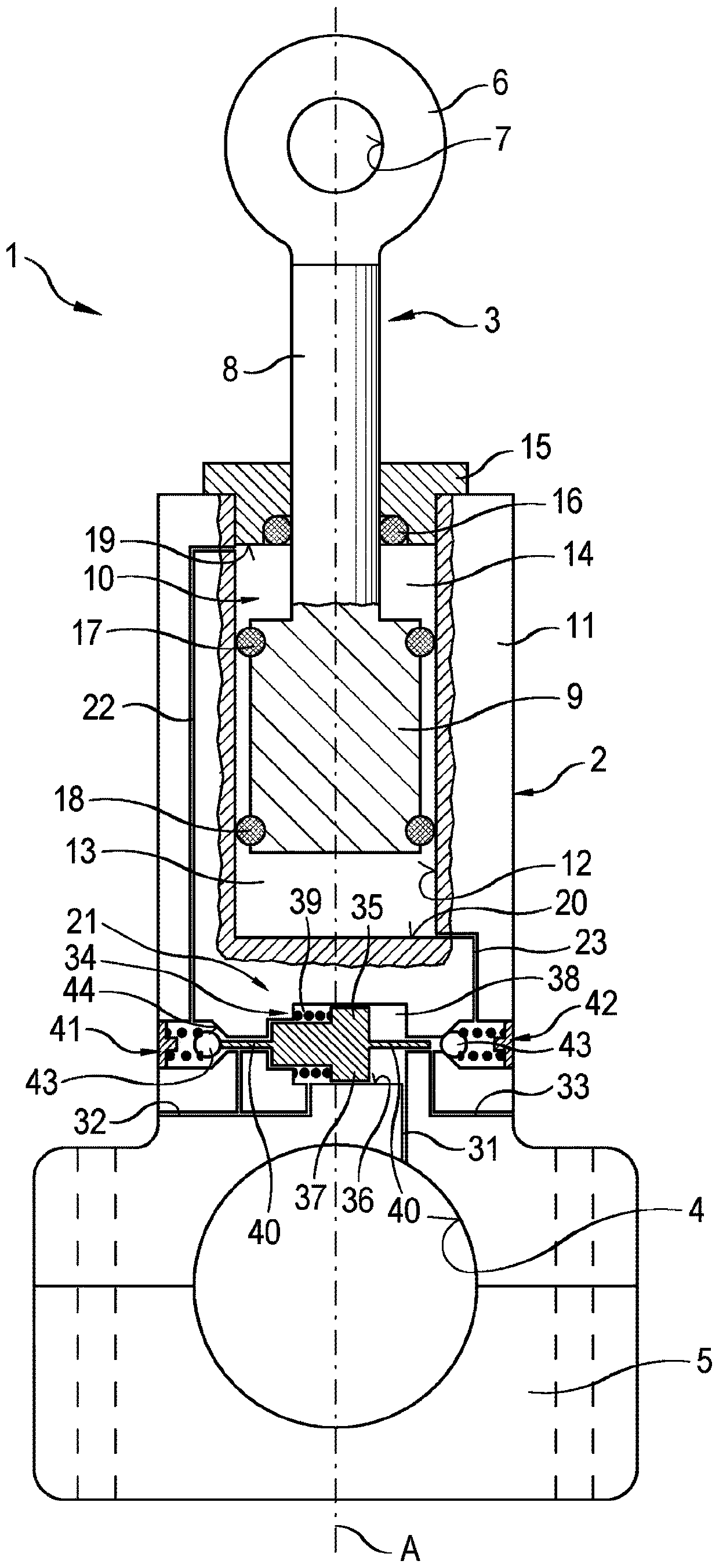

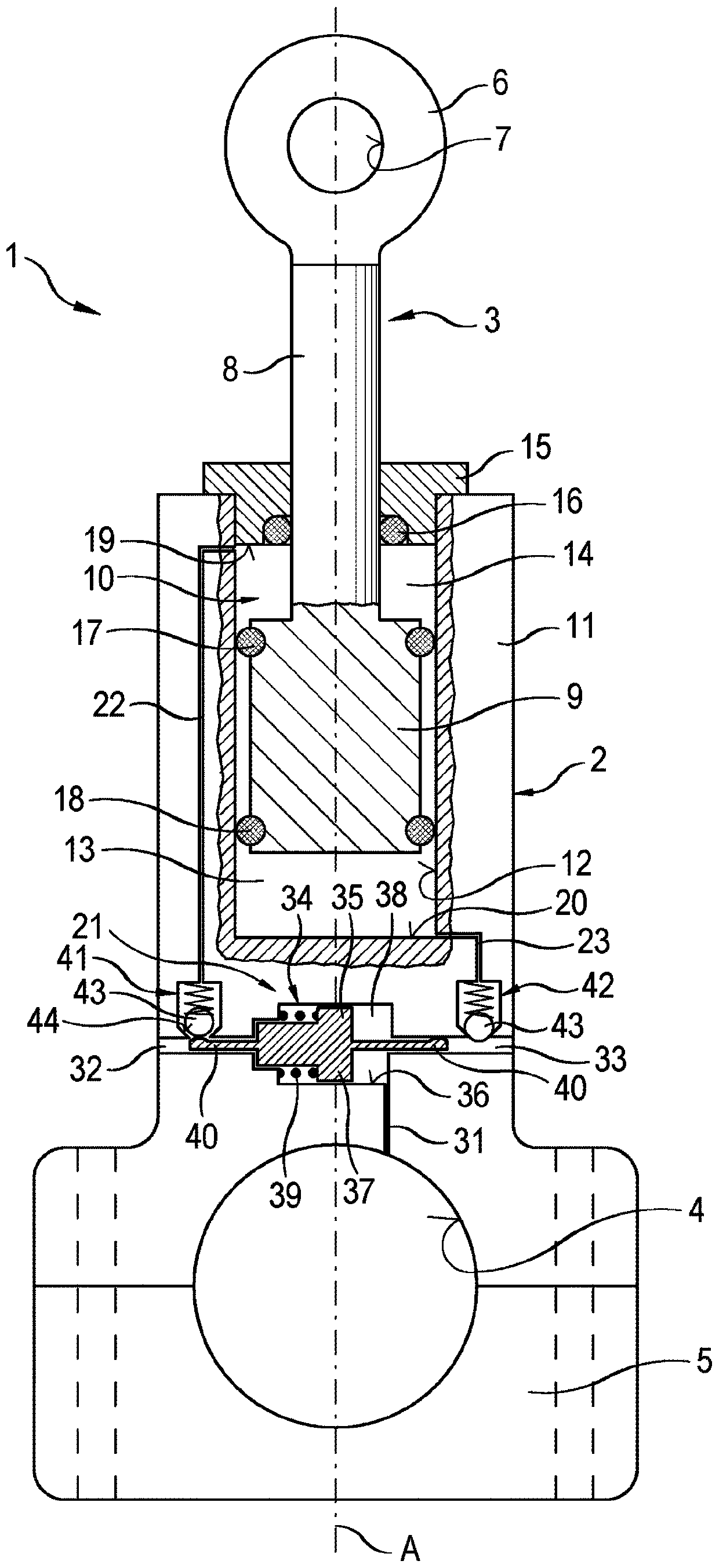

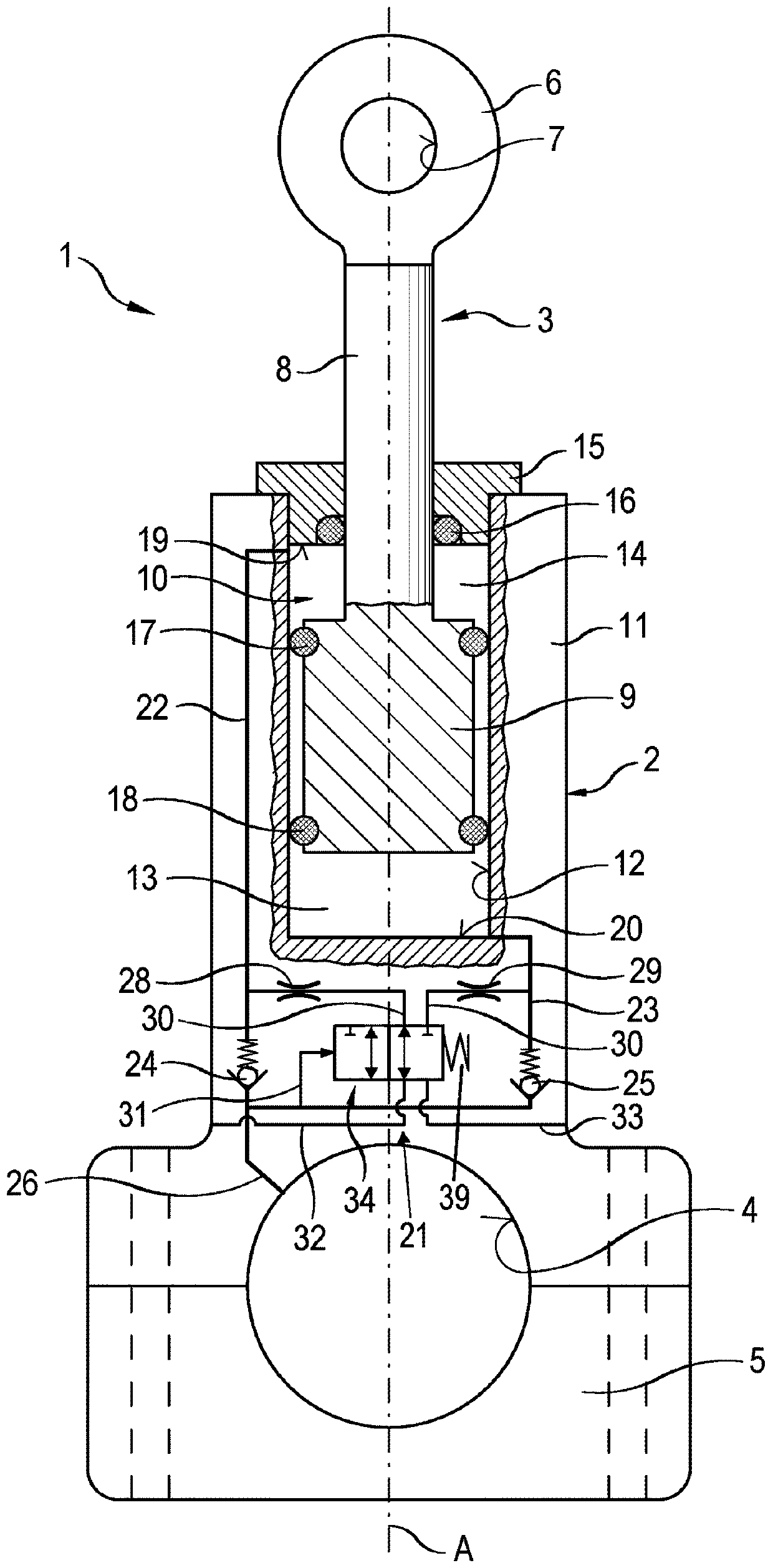

[0024] exist figure 1 The length-adjustable link 1 shown in the schematic diagram in , comprises two link parts 2 , 3 that are telescopically movable relative to each other. exist figure 1 The lower connecting rod part 2 arranged below in the diagram of the length-adjustable connecting rod 1 has a large connecting rod eye 4 with which the length-adjustable connecting rod 1 is supported on the piston engine crankshaft (not shown). For this purpose, a bearing shell 5 is also arranged on the lower connecting rod part 2 , which forms a large connecting rod eye with the lower region of the lower connecting rod part 2 , which is likewise designed as a bearing shell. 4.

[0025] The bearing housing 5 and the lower connecting rod part 2 are connected to one another by means of connecting rod bolts (shown schematically in dashed lines). The upper connecting rod part 3 has a connecting rod head 6 with a small connecting rod eye 7 accommodating a piston pin (not shown) of a reciproca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com